Military guard non-lethal fragmentation bomb-shell type small specific kinetic energy bomb

A non-lethal, projectile technology, applied in the direction of warheads, ammunition, weapon accessories, etc., can solve the problems of energy loss, affecting accuracy, kinetic energy, specific kinetic energy gap, etc., and achieve the effect of good projectile shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] specific implementation

[0069] 1. Preparation

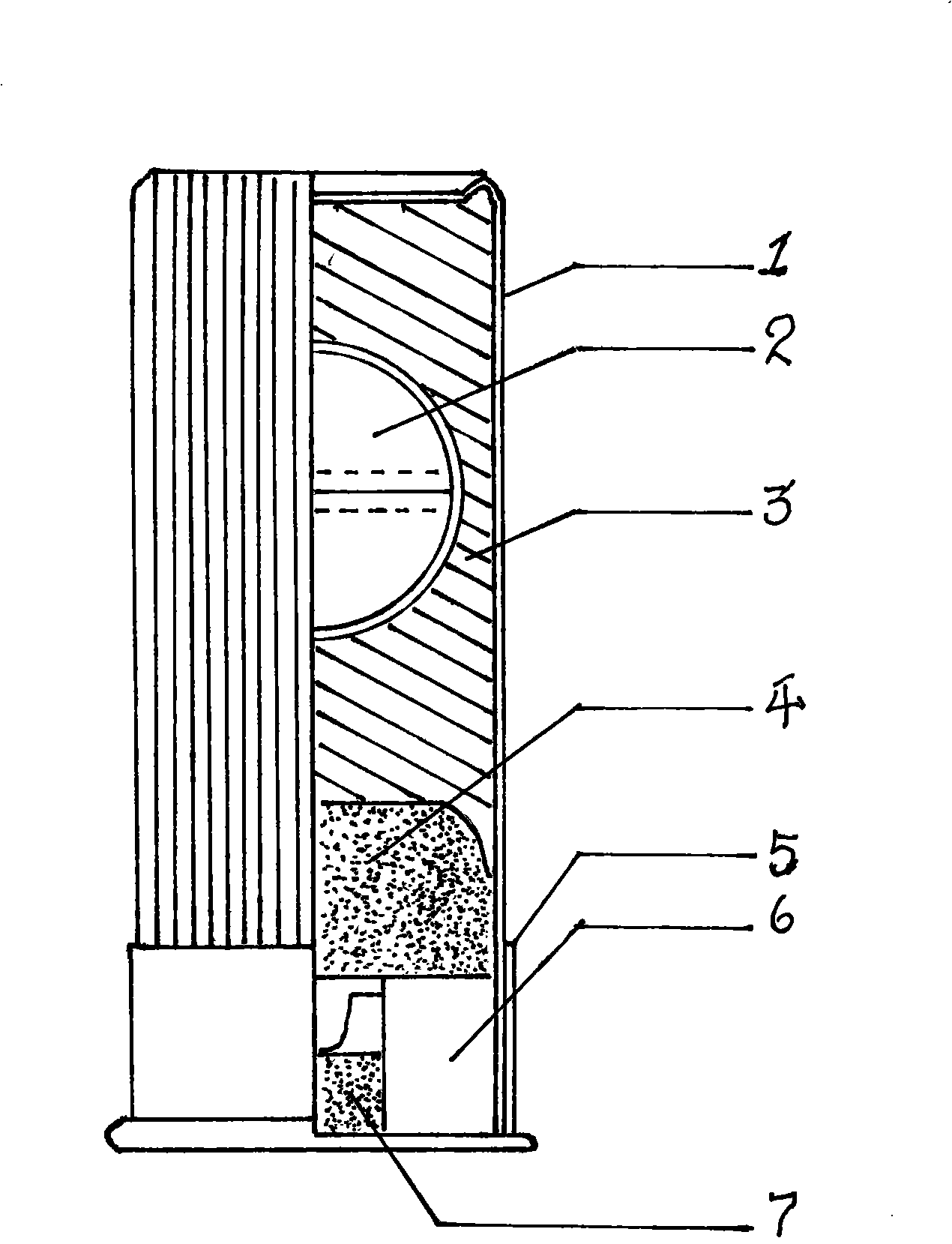

[0070] 1. Projectile shell, requirements: hard, fragile, and easy-to-process materials. Hard plastic (such as gas lighter body material) glass, cement, etc.

[0071]2. Bullet core materials, heavy lead sand, lead powder, iron sand, etc.

[0072] 3. Adhesive materials and auxiliary materials: cement, asphalt rosin butter (lubricating grease), chemical viscose, aluminum foil paper, gauze, 10mm long short cotton fiber, narrow viscose paper tape.

[0073] Two, production

[0074] 1. Projectile shell

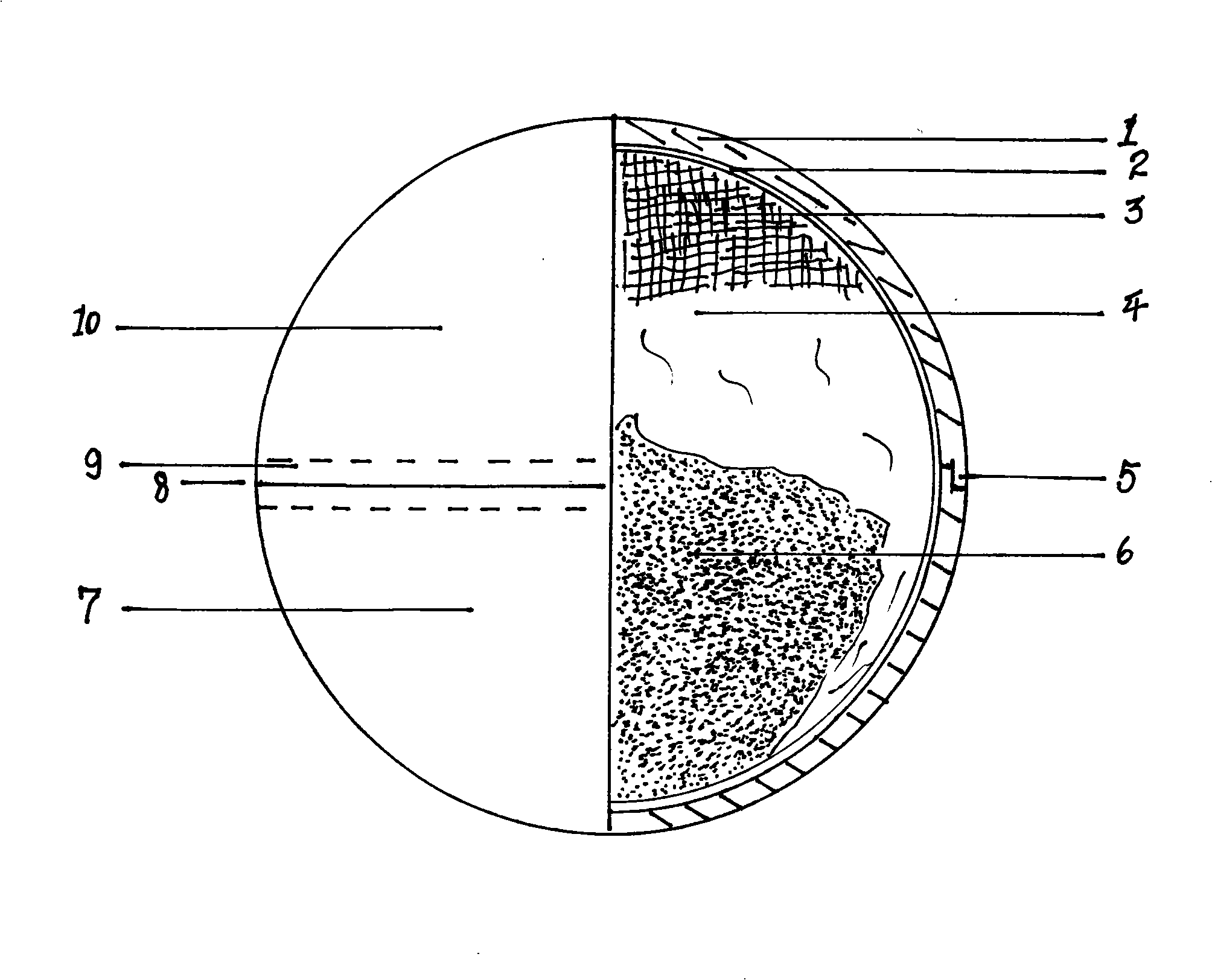

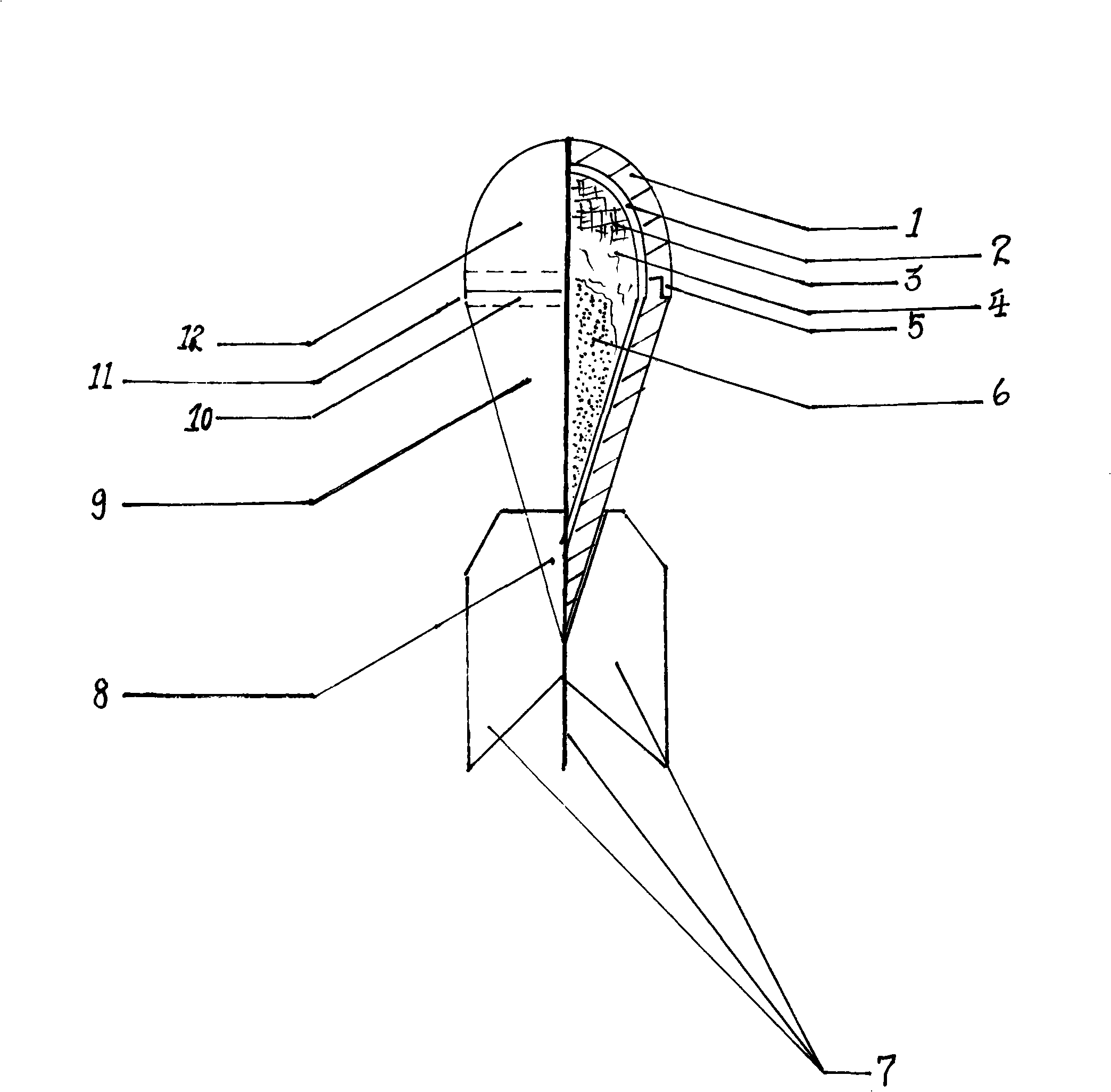

[0075] Make two hemispherical projectile shells out of hard, brittle plastic (see figure 1 ) The opening of the projectile shell adopts a threaded or stepped shape so that two semi-spherical projectile shells can be butted to form a complete spherical projectile shell.

[0076] Sand the inner walls of the two hemispherical projectile shells with tools, coat them with rubber water, and then adhere the gauze to the rubber w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com