Fuel press-fitting mold for cylinder thin-wall structure projectile body and using method of fuel press-fitting mold

A technology of thin-walled structure and press-fitting molds, which is applied in the direction of ammunition, weapon accessories, offensive equipment, etc., can solve the problems of the design difficulty of press-fitting fuel molds, reduce the risk of personnel burns, reduce manufacturing costs, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

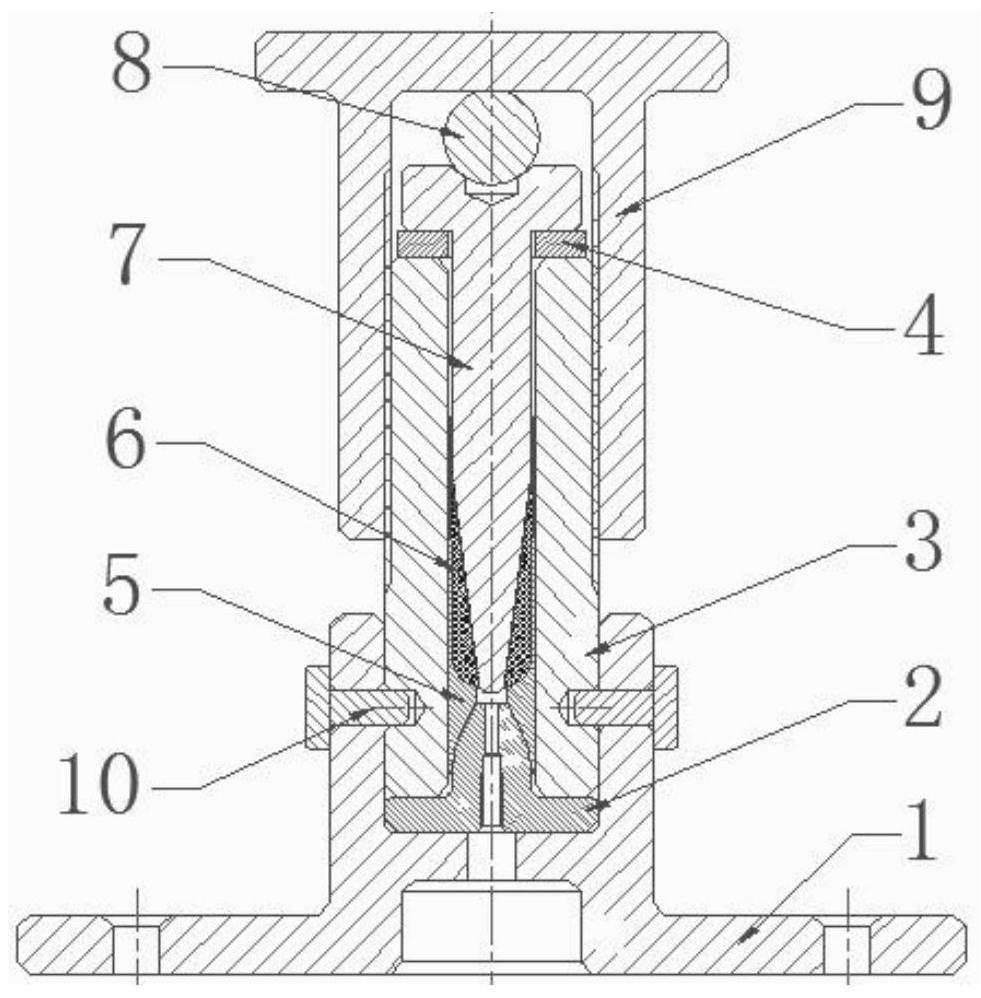

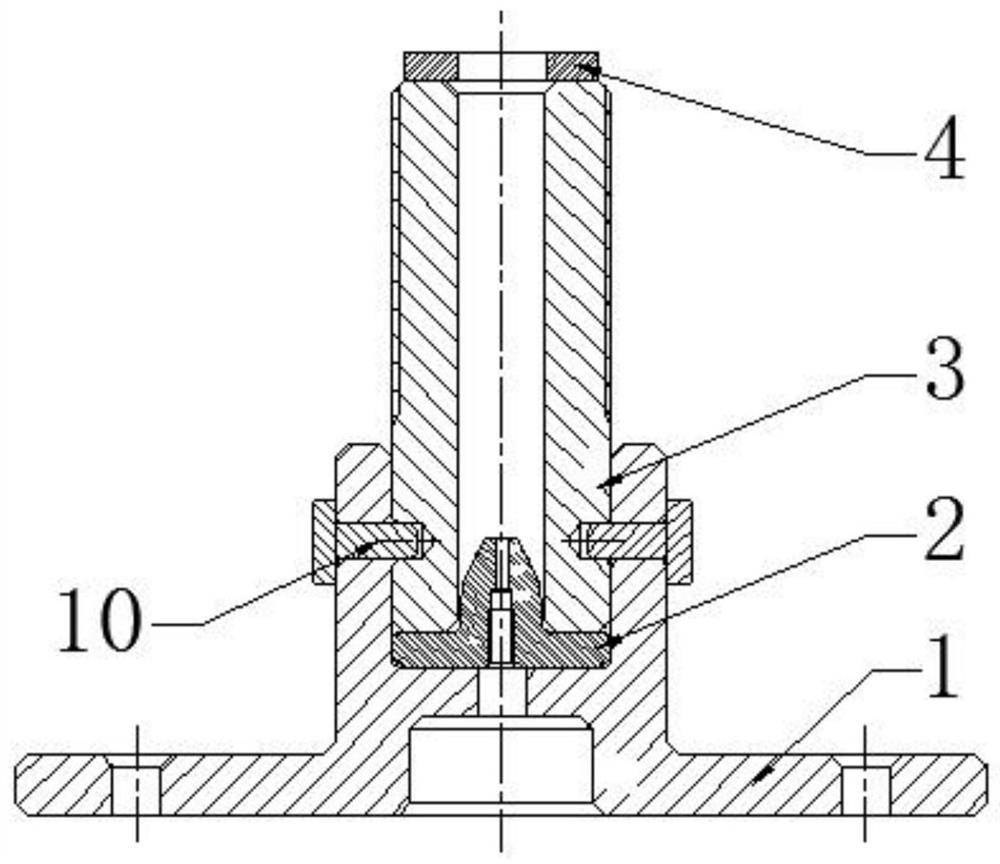

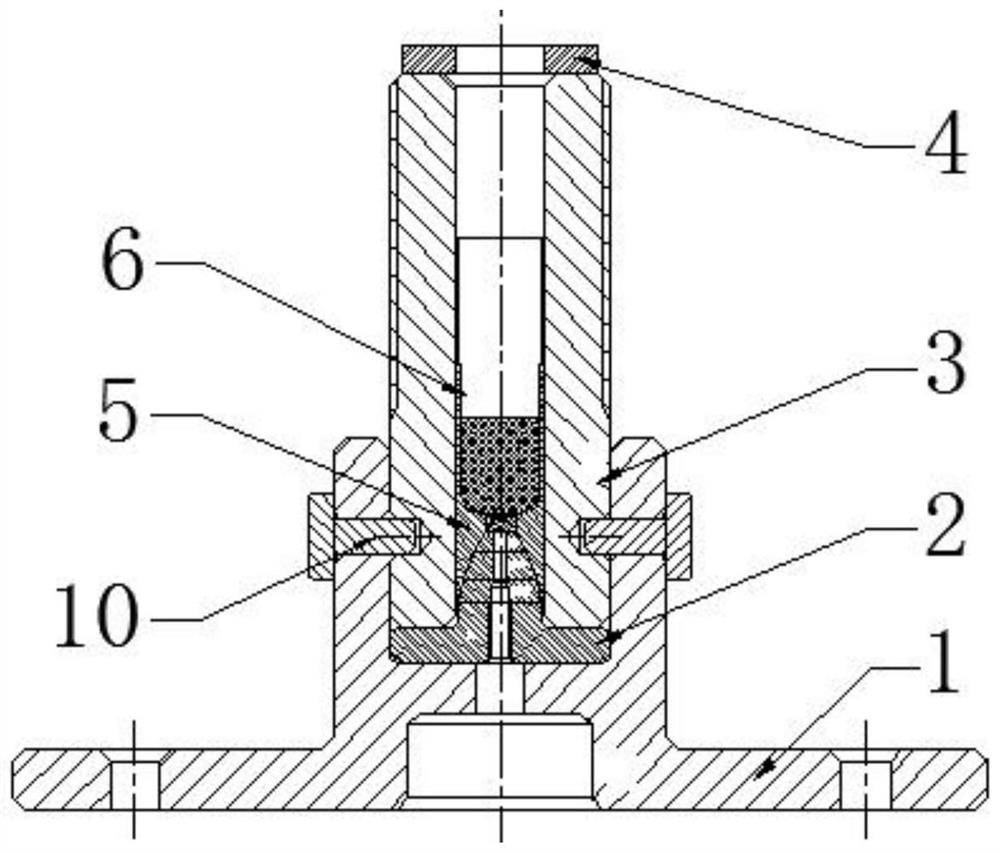

[0046] A fuel press mold for cylindrical thin-walled projectiles, such as figure 1 As shown, its structure includes a base 1, a plug 2, a first sleeve 3, a tightening structure 10 and a pressure rod 7; specifically, a first groove is opened on the top surface of the base 1, and the cross section of the first groove is Circular shape; coaxial sleeve plug 2 in the first groove, and the plug 2 is used to limit the elastic body 5. A first sleeve 3 is arranged on the upper side of the plug 2, and the first sleeve 3 is coaxially sleeved in the first groove, and a pressing rod 7 is inserted into the first sleeve 3 .

[0047] Wherein, the elastic body 5 is inserted into the first sleeve 3, and the elastic body 5 and the first sleeve 3 are fitted with a small gap.

[0048] A tightening structure 10 is provided on the base 1 for fixing the relative positions of the first sleeve 3 and the first groove. Specifically, the tightening structure 10 includes at least one bolt, and the bolt ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com