Artificial elbow joint

An elbow joint and artificial technology, applied in the field of semi-constrained artificial elbow joint, can solve problems such as unreliable screwing, and achieve the effects of shortening operation time, improving safety and easy assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

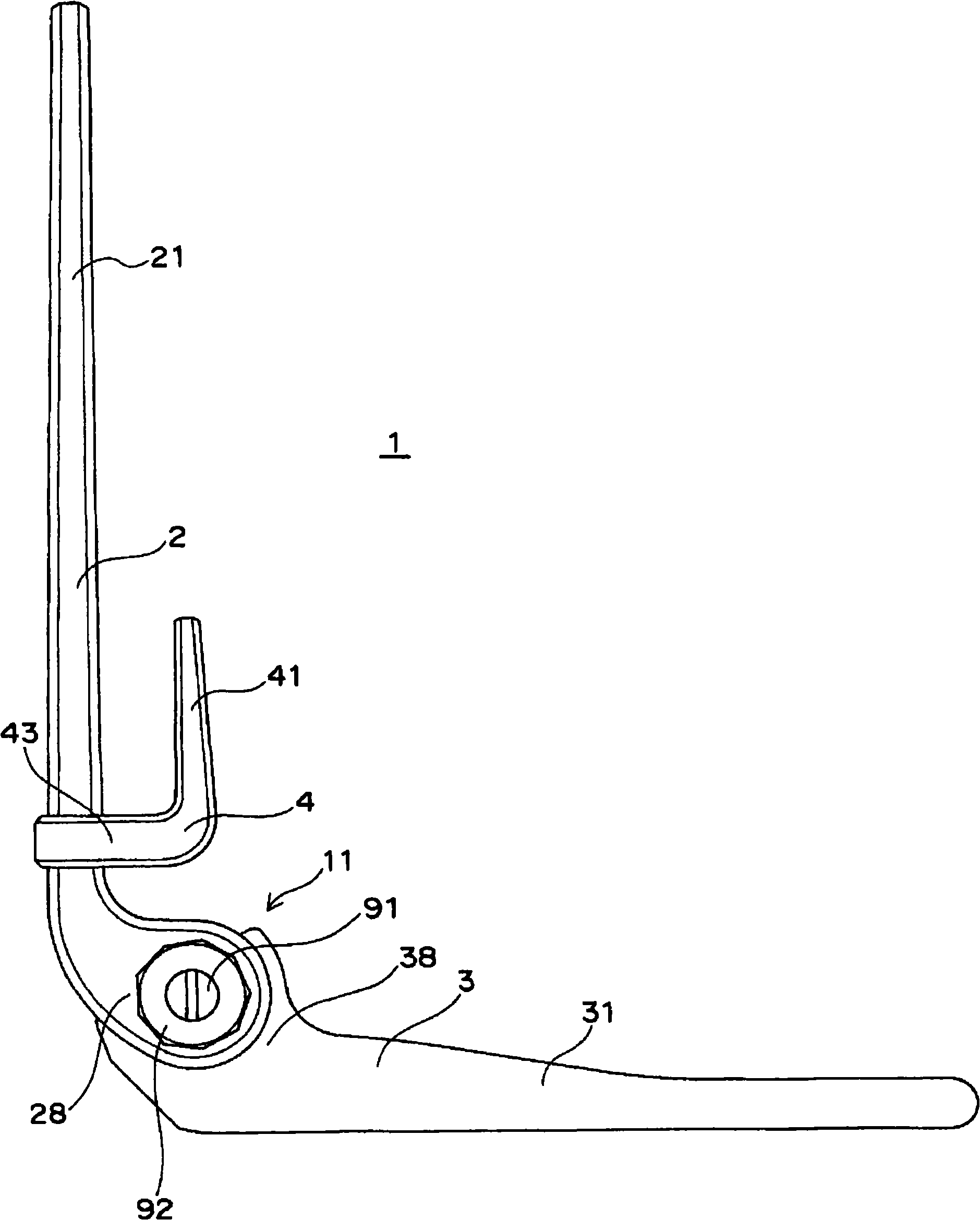

[0042] Artificial elbow joint of the present invention such as figure 1 As shown, the humeral component 2 and the ulna component 3 are connected by the joint part 11 .

[0043] figure 1 It is a diagram showing a state where the elbow joint is bent to approximately 90°, and the rod 21 of the humerus component 2 extends vertically, whereas the rod 31 of the ulna component 3 extends horizontally. The front flange 4 is mounted on the humerus rod 21 in such a manner as to be located inside the movable region of the elbow joint.

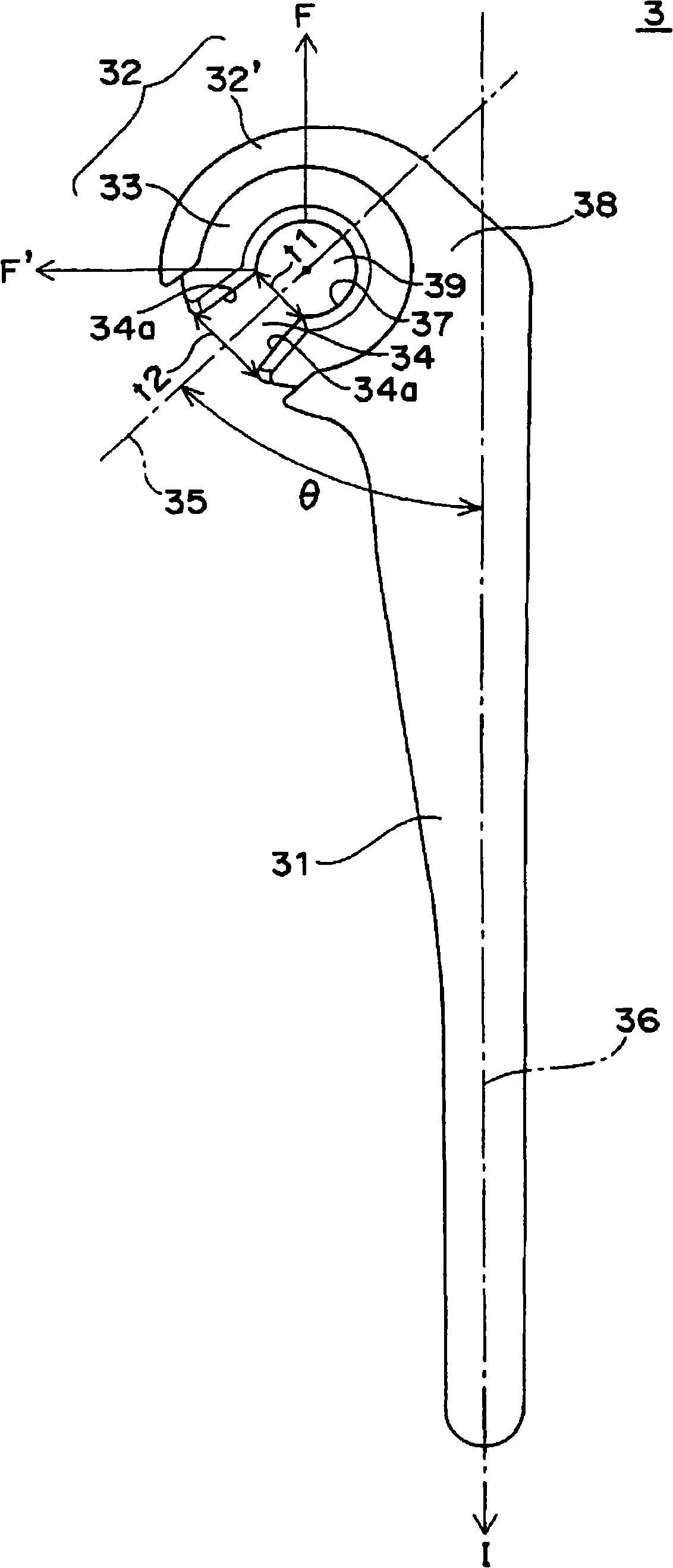

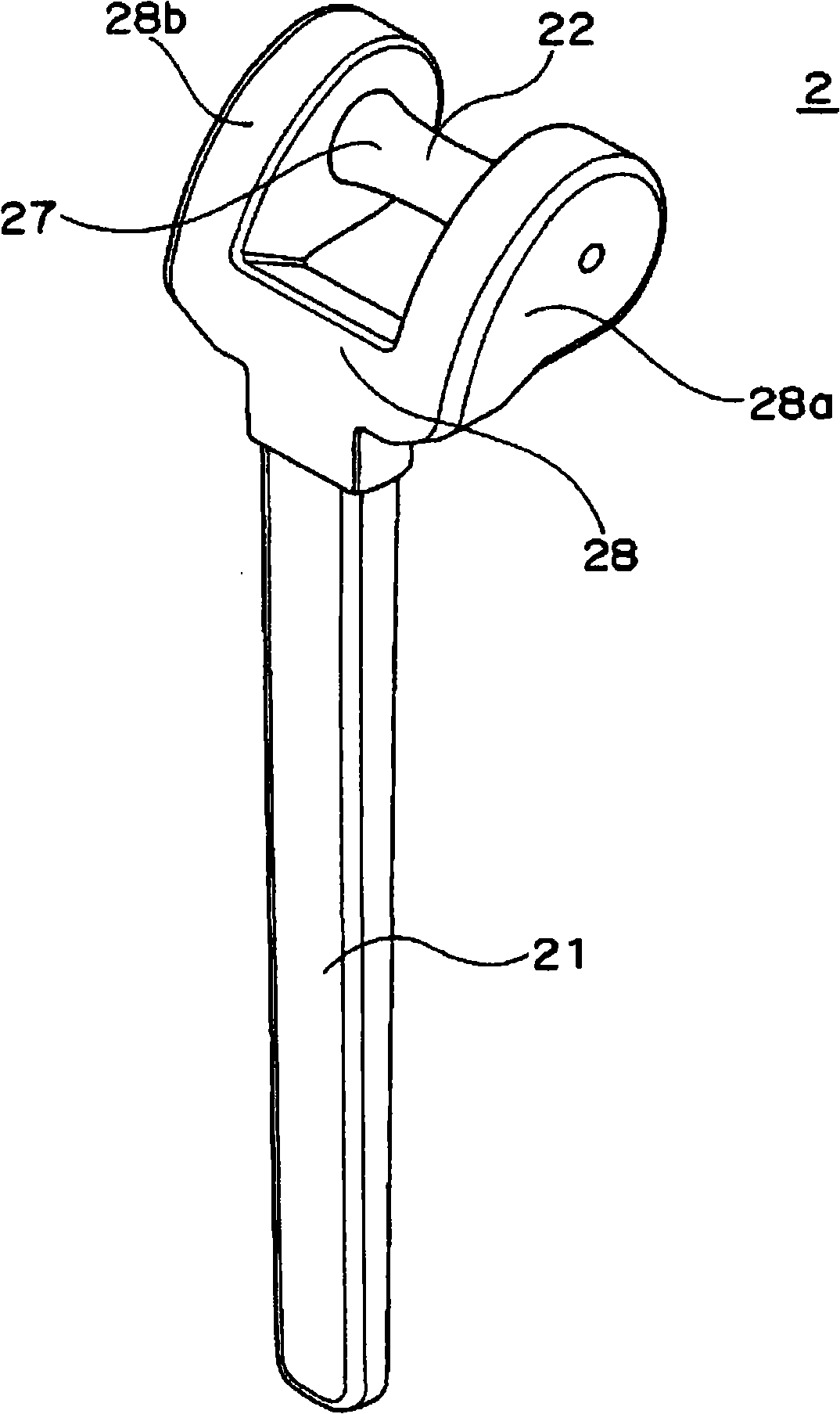

[0044] figure 2 and image 3 is a diagram showing the ulna component 3 and the humerus component 2 .

[0045] figure 2 The illustrated ulnar component 3 consists of an ulnar rod 31 for insertion into the bone marrow of the proximal part of the ulna and a sleeve portion 32 formed on the proximal side 38 of the rod 31 . The sleeve part 32 is made up of a sleeve shell part 32' made of a hard material and an embedded sleeve 33 made of a flexible part. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com