Carrying device for electronic component detection classifier

A technology of electronic components and sorting machines, which is applied in the direction of measuring devices, mechanical conveyors, sorting, etc., and can solve problems such as unfavorable machine space configuration, assembly space occupation, and large machine space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

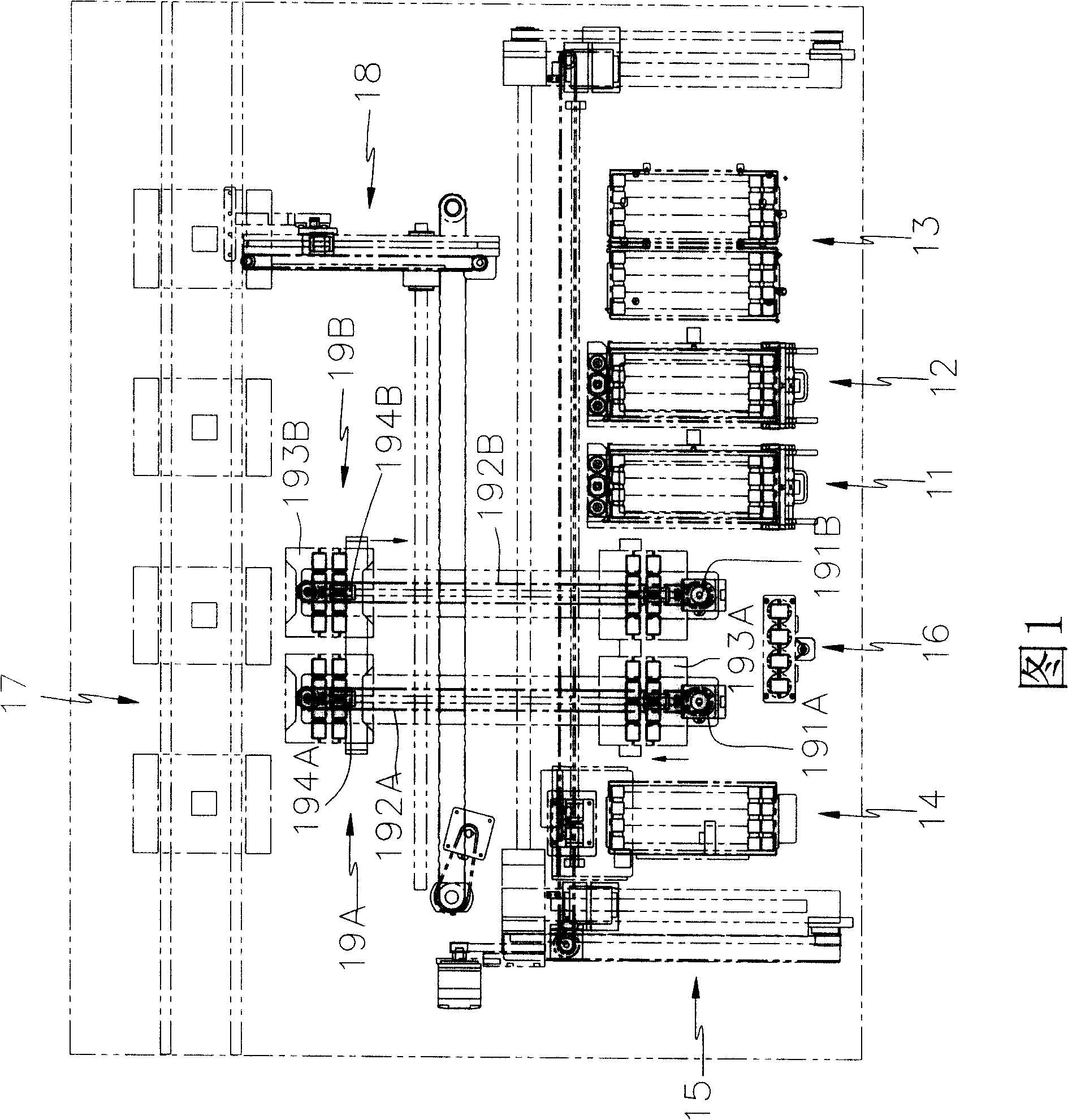

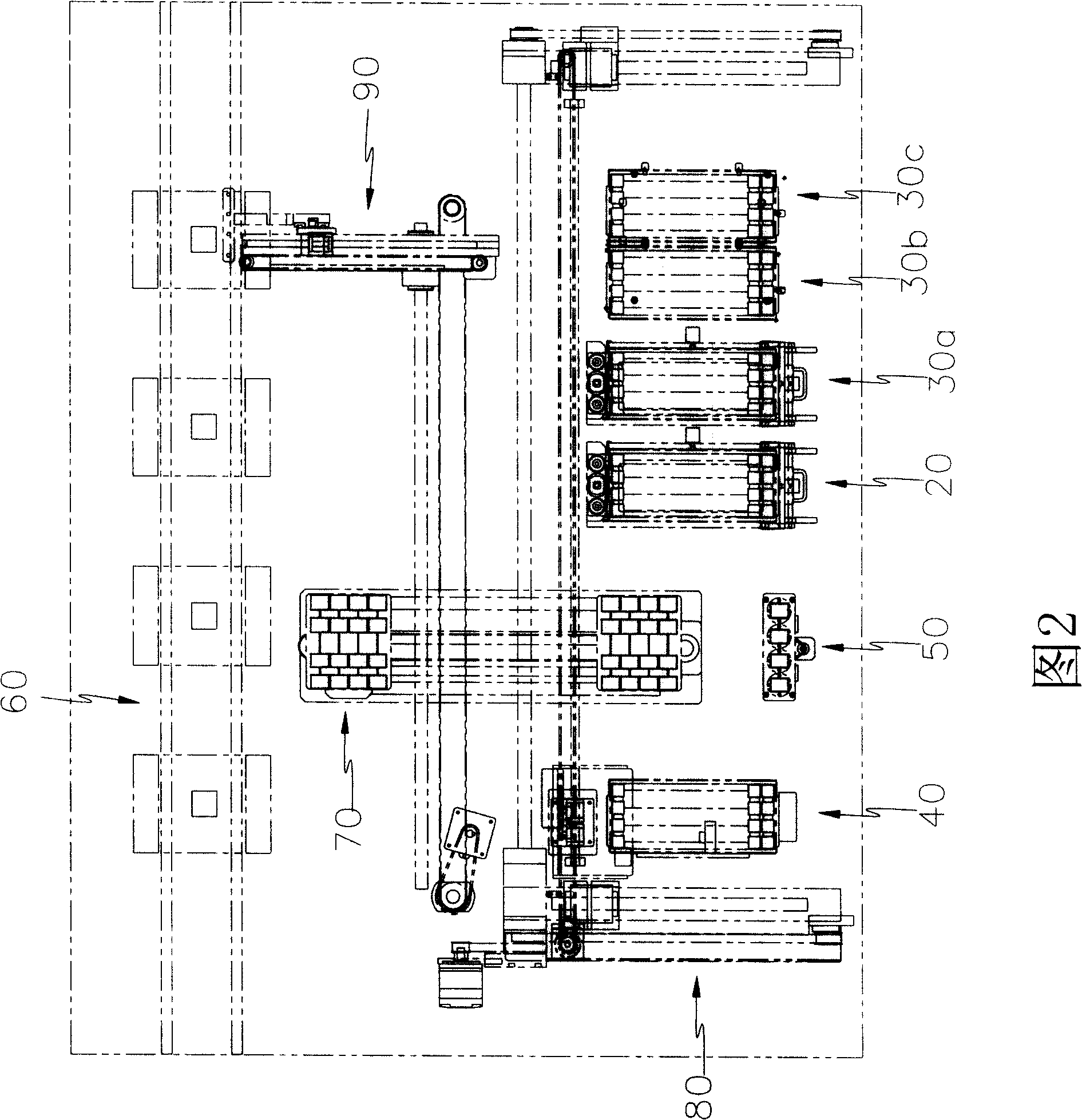

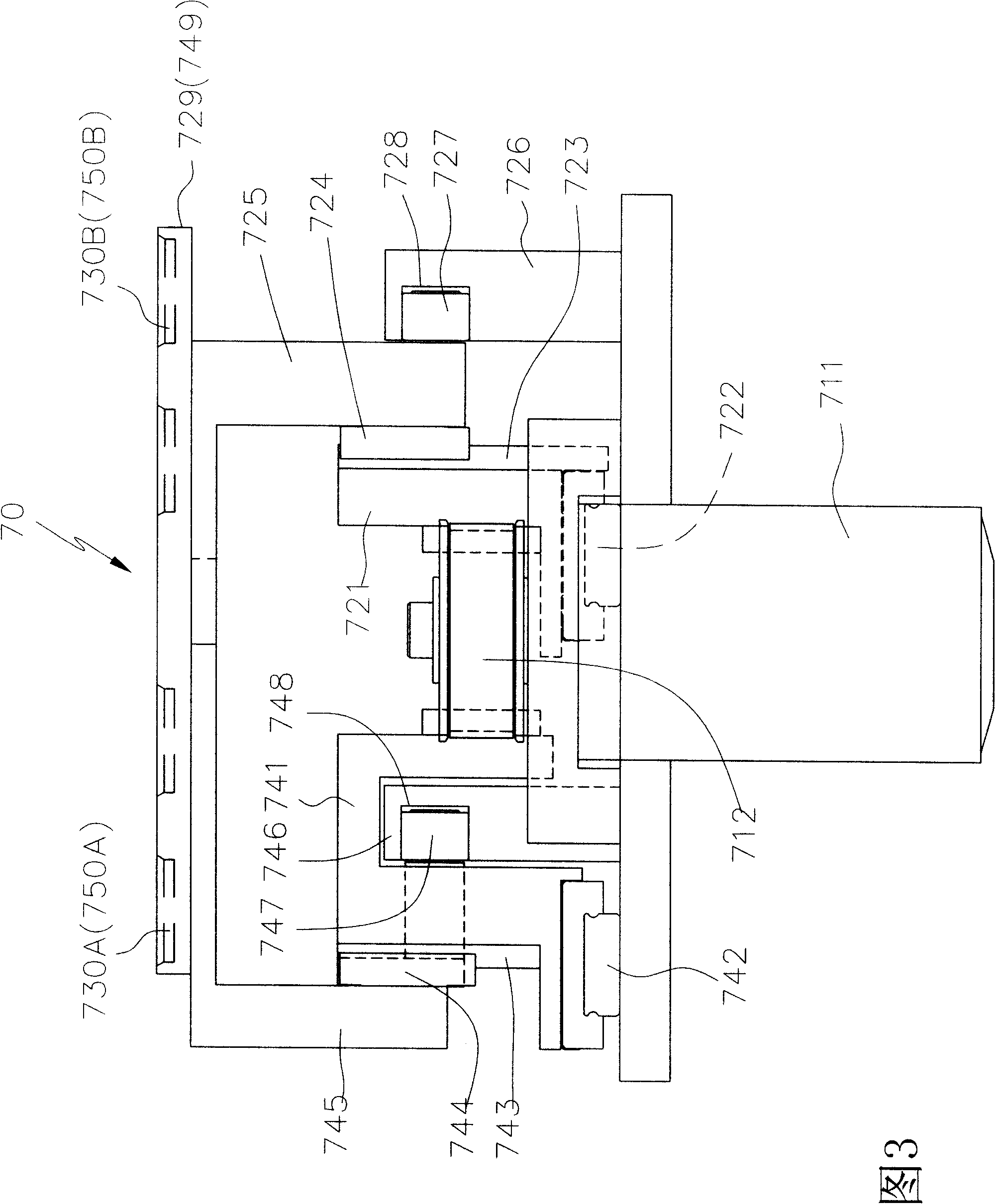

[0026] In order to further understand the present invention, now give a preferred embodiment and cooperate with the drawings, as follows in detail:

[0027] Please refer to Fig. 2, take the memory card detection and classification machine applied to the detection of memory card electronic components of the present invention as an embodiment, the memory card detection and classification machine is provided with a feeding device 20, a plurality of receiving devices at the front end of the machine table Feeding devices 30a, 30b, 30c, empty box device 40, and indexing device 50, wherein the feeding device 20 is used to accommodate at least one feeding tray containing a memory card to be tested, and several receiving devices 30a, 30b, 30c are respectively used to accommodate at least one tray containing the tested memory card, and are stored according to different test results. The empty box device 40 is used to store empty trays, and the indexing device 50 is used to rotate and adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com