Rock loading machine for mine

A rock loader and mining technology, applied in the field of mining machinery, can solve the problems of worker injury, low work efficiency, and many round trips, and achieve the effects of high safety performance, high mechanical efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

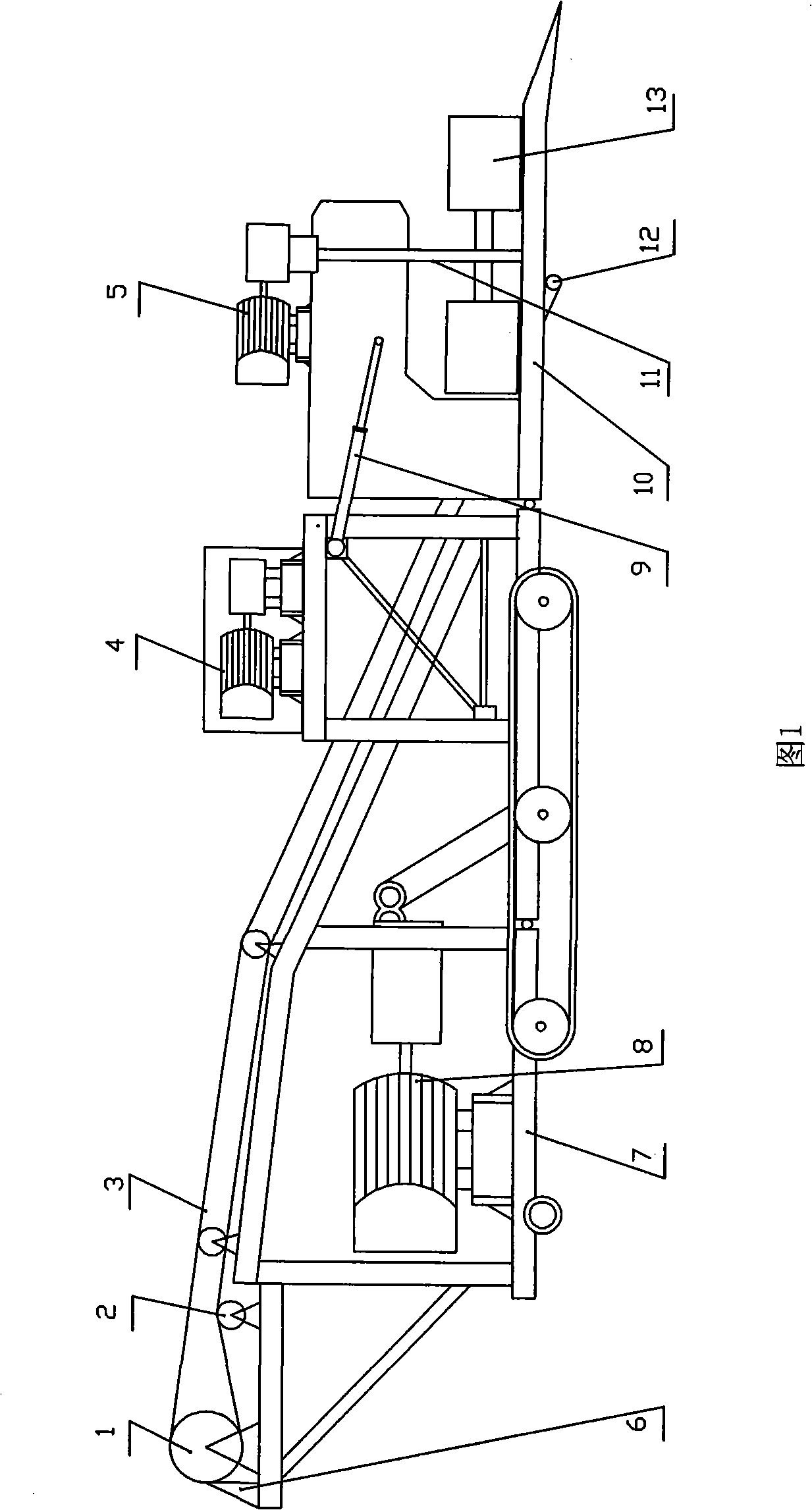

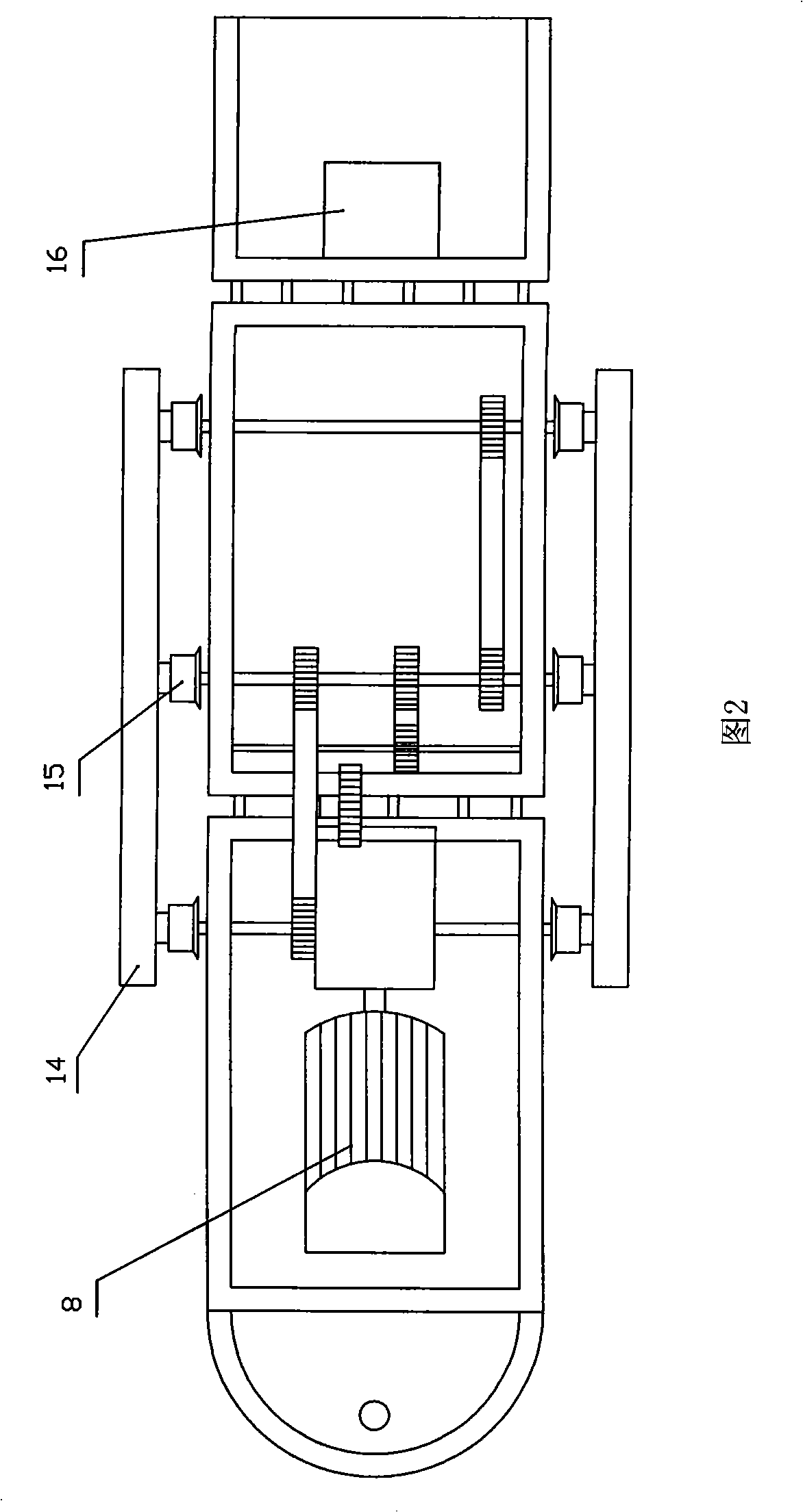

[0015] A kind of mining rock loading machine, as shown in Figure 1 and Figure 2, comprises frame 7, and hydraulic pump 4, hydraulic cylinder 9, main motor 8, transmission shaft are installed on the frame 7, and one end of hydraulic cylinder 9 is connected with Front bucket 10, the middle part of front bucket 10 is provided with feed inlet 16, and belt transmission roller 12 is installed on the frame 7 below feed inlet 16, and built-in motor drum 1 is installed on the frame 7 of rear upper part, and built-in motor The drum 1 and the belt drive roller 12 are connected by a belt 3 transmission, the main motor 8 is a transmission connection with the transmission shaft, and the two ends of the transmission shaft are respectively equipped with track wheels 15; Crawler belt 14 is installed on it; In the present embodiment, a material shifting motor 5 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com