Hot air engine

A hot air engine and cylinder technology, which is applied to hot air variable capacity engine devices, mechanical equipment, machines/engines, etc., can solve the problems of increased friction between the valve piston and the cylinder wall, wear, and difficulty in sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

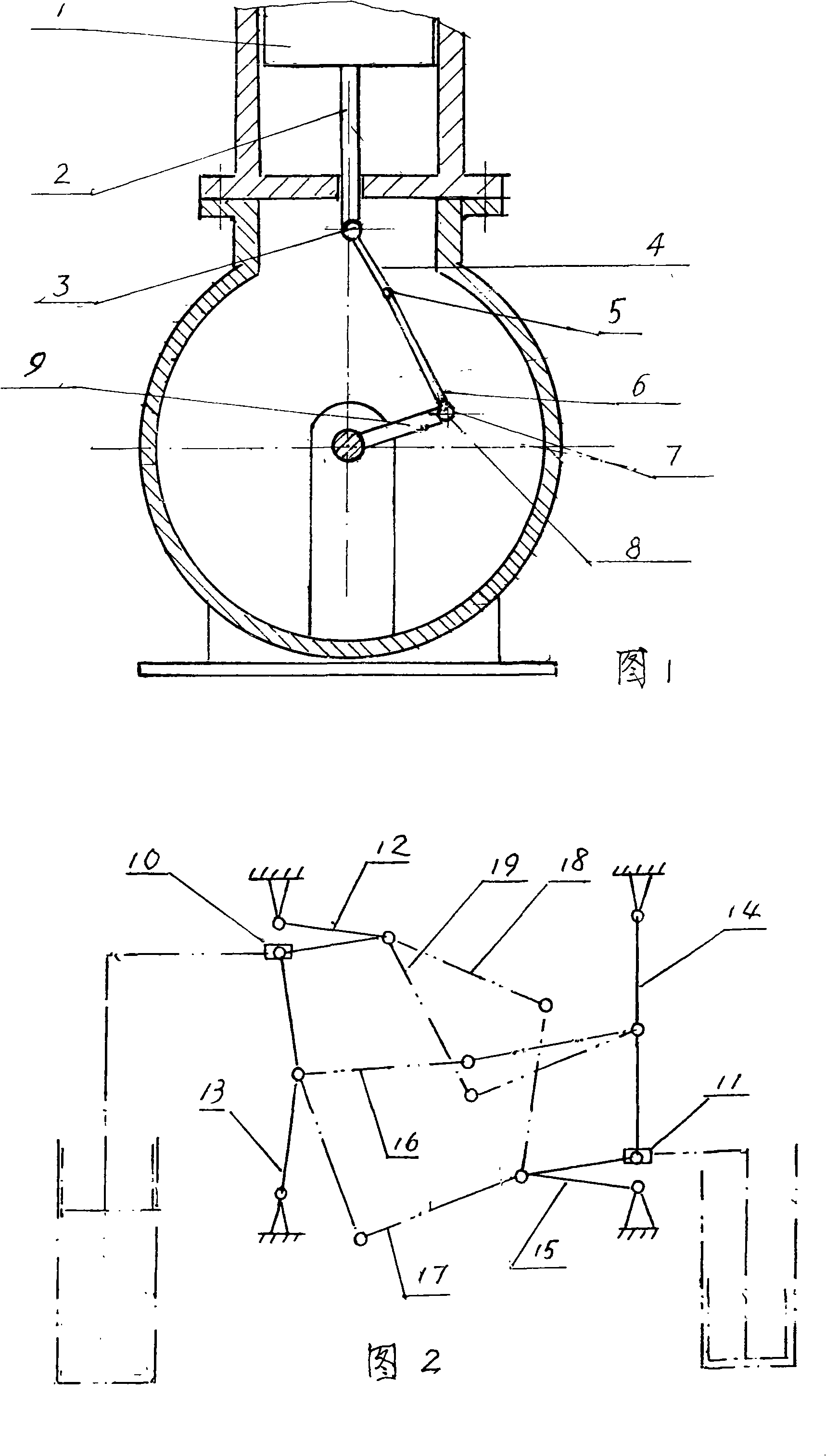

[0018] Further description will be made below in conjunction with the embodiments. Fig. 1 is a schematic diagram of the connection of the piston, the two connecting rods and the crankshaft. The piston of the double-acting heat engine and the power piston of the gas distribution type heat engine are all connected by this connection. The guide rod 2 of the piston 1 is connected with the connecting rod 4 through the hinge 3, and the latter is hinged with the connecting rod 6 through the hinge 5. The connecting rod 6 is connected with the connecting rod journal 8 of the crankshaft through the bearing 7. The length of the crank 9 of the crankshaft is the radius of rotation of the journal 8. The principle for determining the length of each rod is: when the piston is at the highest point, that is, when the journal 8 is at the highest point, its The axis is used as the starting point of 0 degrees. When the journal 8 is at the 180-degree position and the second connecting rod is straigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com