Serial excitation electromotor control device and its rotation speed control method

A speed control, series excitation motor technology, applied in the direction of AC motor control, control system, electrical components, etc., can solve problems such as safety hazards, save electrical components, simplify the motor control circuit, and facilitate the installation of the whole machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

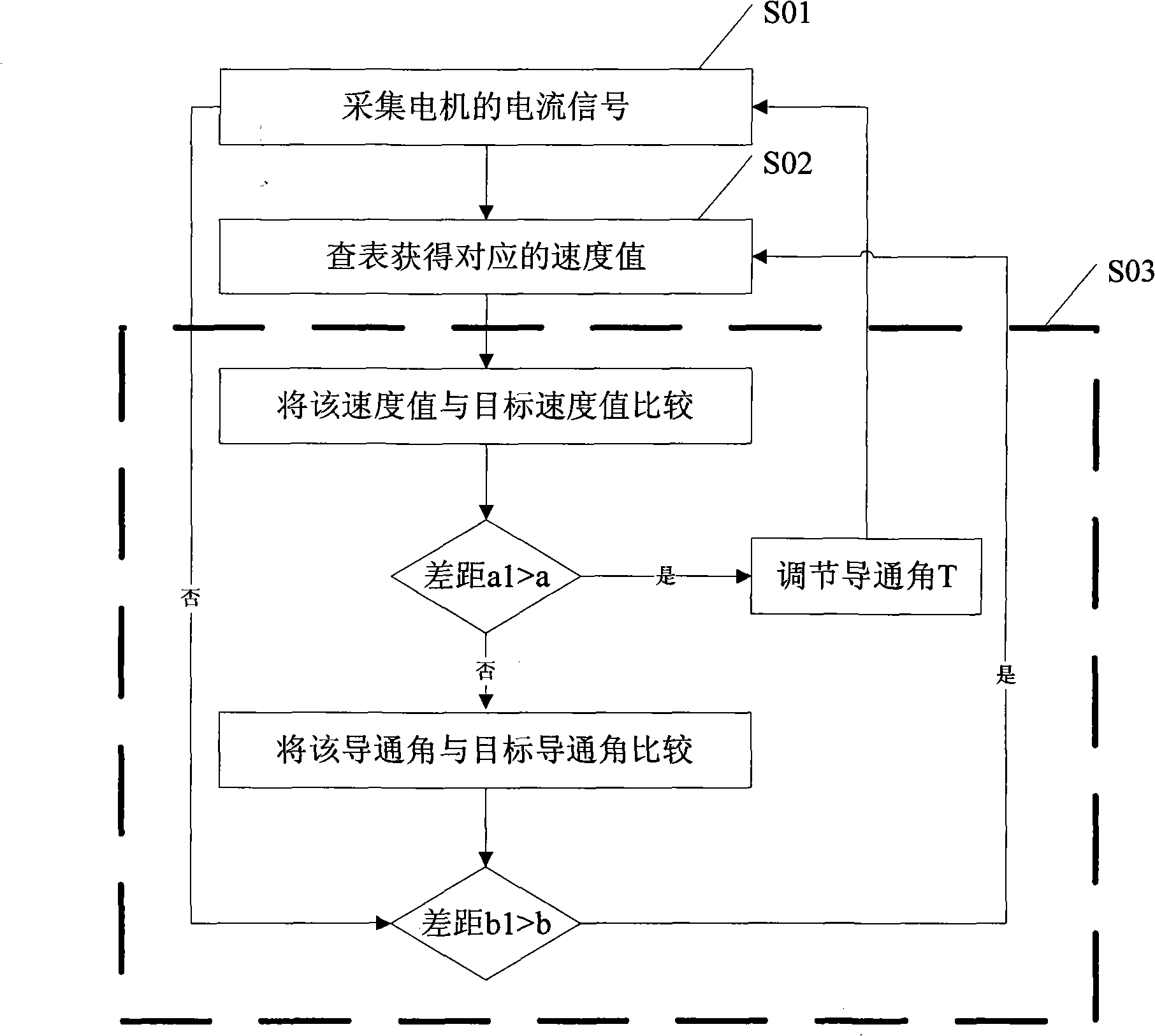

[0020] refer to figure 1 , which is a flowchart of an embodiment of the method for controlling the speed of a series-excited motor provided by the present invention; as shown in the figure, the specific flow of the speed control of a series-excited motor in this embodiment is as follows:

[0021] Step S01, a signal collection step, collects the voltage signal of the motor.

[0022] Step S02, the first signal conversion step, searches the preset first voltage-speed relationship mapping table to obtain the speed value corresponding to the current voltage value.

[0023] Step S03, the speed control step, controls the motor to reach a preset target speed according to the speed value.

[0024] During specific implementation, step S03 may specifically include:

[0025] The comparison step is to compare the speed value with the preset target speed value, if the difference a1 exceeds the preset first critical value a, after adjusting the control parameter value, execute the signal c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com