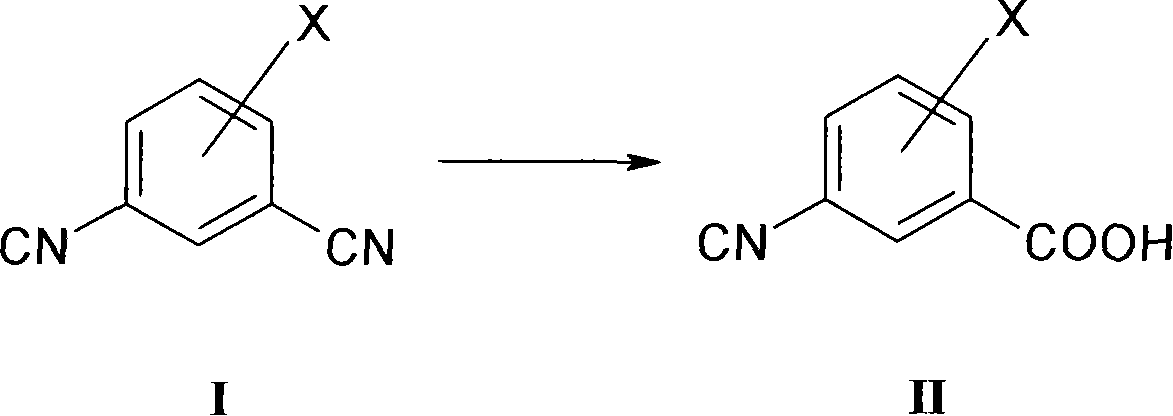

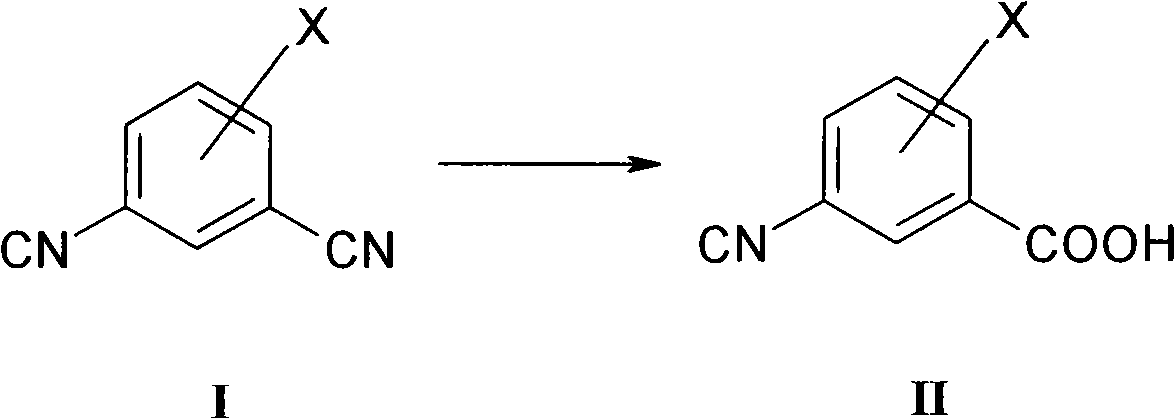

New process for converting aromatic halo-substituted dinitriles into halo-substituted cyanocarboxylic acids

A technology of carboxylic acid and amino acid, applied in fermentation, hydrolase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] 1. Preparation of Cell-Free Extract (CFE) Biocatalyst

[0047] 1 liter of Terrific Broth (TB) medium supplemented with carbenicillin (100 mg / l) was inoculated with a glycerol stock of E. coli DH 10B (pMS470-3-14-1-4 from Rhodococcus rhodochrous nitrilase). After 68 hours of growth, this culture was used to inoculate 9 liters of TB medium supplemented with carbenicillin (100 mg / l) and IPTG was used as inducer. After 41 hours of growth in laboratory-grade fermenters, fully grown fermentation broth (OD 600 = 16.7) Harvest the cells, resuspend the cell wet weight biomass into 20 mM HEPES / NaOH buffer (pH 7.0, 13 μg benzonase enzyme per gram wet weight cells) at the ratio of 1 kg cells + 3 kg buffer, and transfer Cells were disrupted at 1600 bar in a (nanojet) (two runs). 1.04 liters of CFE were obtained with a yield of 86% (328 g wet biomass + 880 ml buffer).

[0048] 2. Enzyme conversion

[0049] 1.5 mol of 5-fluoro-1,3-dicyanobenzene was suspended in 81 0.1M sodium pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com