Method and mechanism for cleaning beach sand

A beach and sand technology, applied in applications, cleaning equipment, household appliances, etc., can solve the problem of high energy consumption and achieve high productivity and good cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

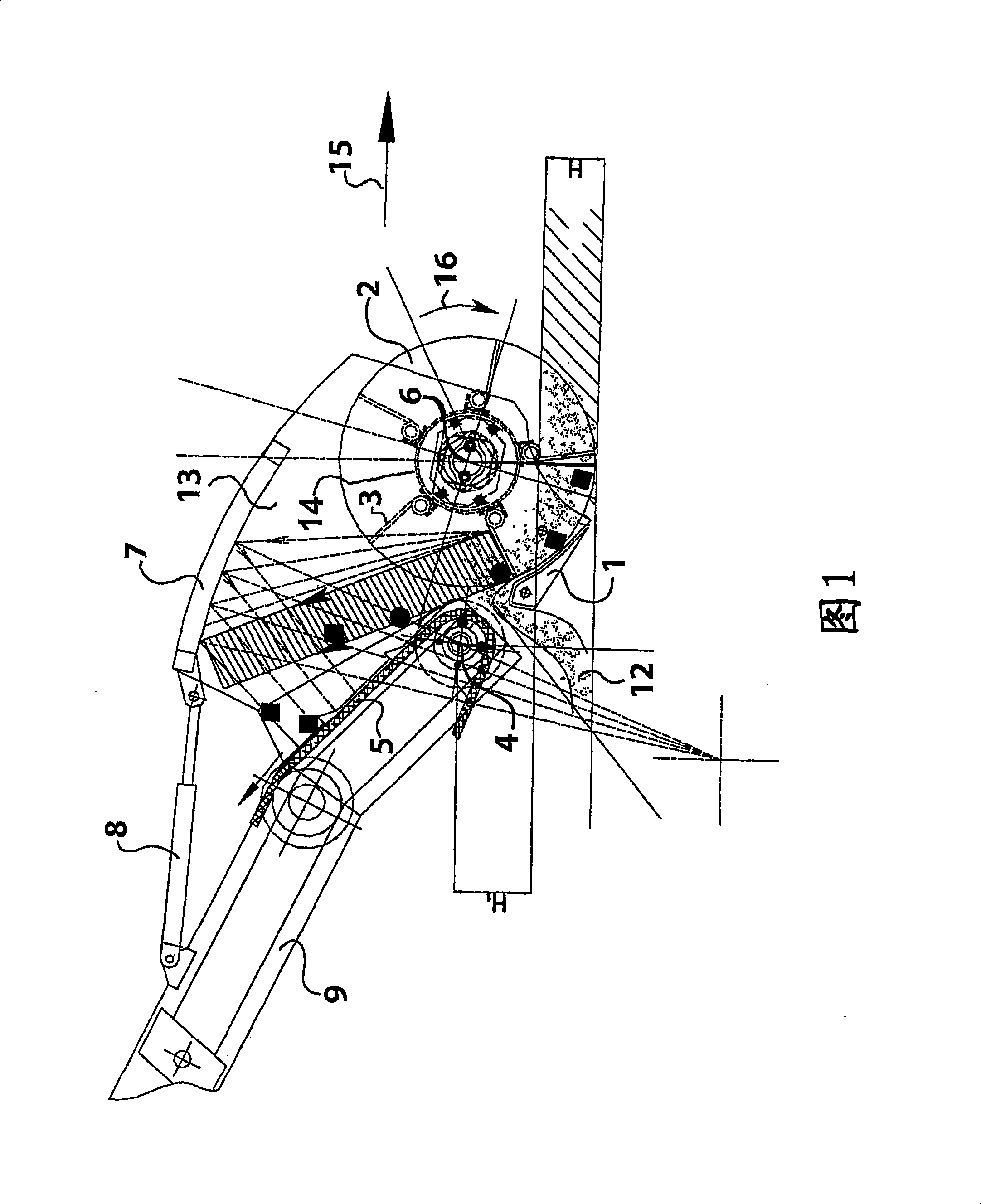

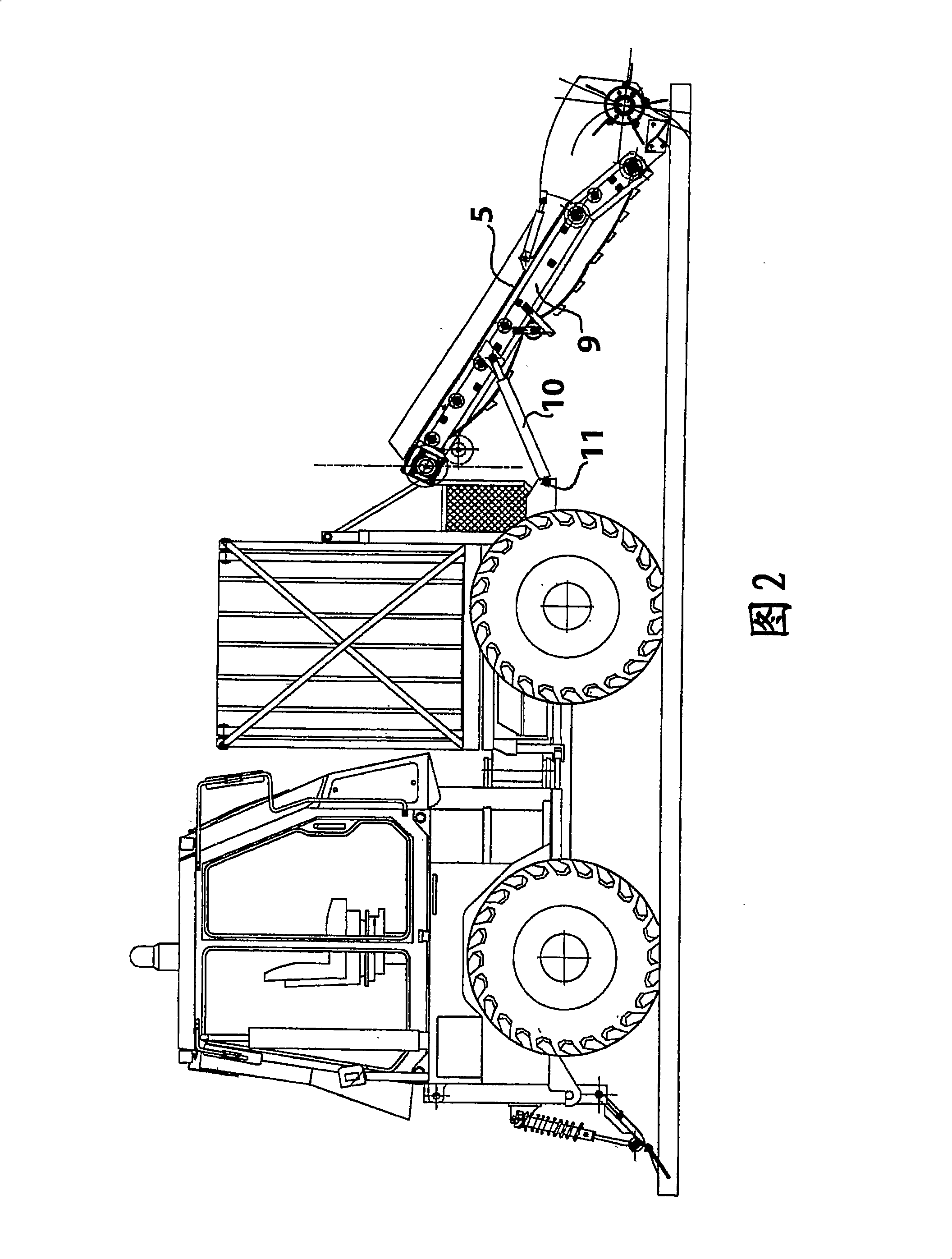

[0013] The important elements of this special mechanism are:

[0014] a) The rotor (2) formed by a metal cylinder (14) equipped with metal spikes (3) whose edges terminate in a cylindrical surface of suitable diameter so as to meet the requirements of the working depth (H) need. The spikes are fixed equidistantly along a line parallel to the axis of the cylinder, or on a helix. Figure 1 shows the rotor (2) of the mechanism for churning sand according to the invention, preferably with 5 sets of spikes. The length of the spike should preferably be about 60% of the radius of the cylindrical surface. During the rotation of each spike, the edge of each spike turns over the cylindrical surface, the axis of which is equal to the rotor width. The number of spikes, the distance between each set of spikes, and the positioning of each set of spikes were set such that there was about 1 mm of clearance between the tracks the spikes left on the ground across the working width. This stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com