Device for the ultrasound testing of hot rolling material

A technology of ultrasonic and material rolling, which is applied in the direction of material analysis, measuring device, and length measuring device using sound wave/ultrasonic wave/infrasonic wave, which can solve the problems of inspection size limitation and achieve the effect of large ultrasonic inspection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

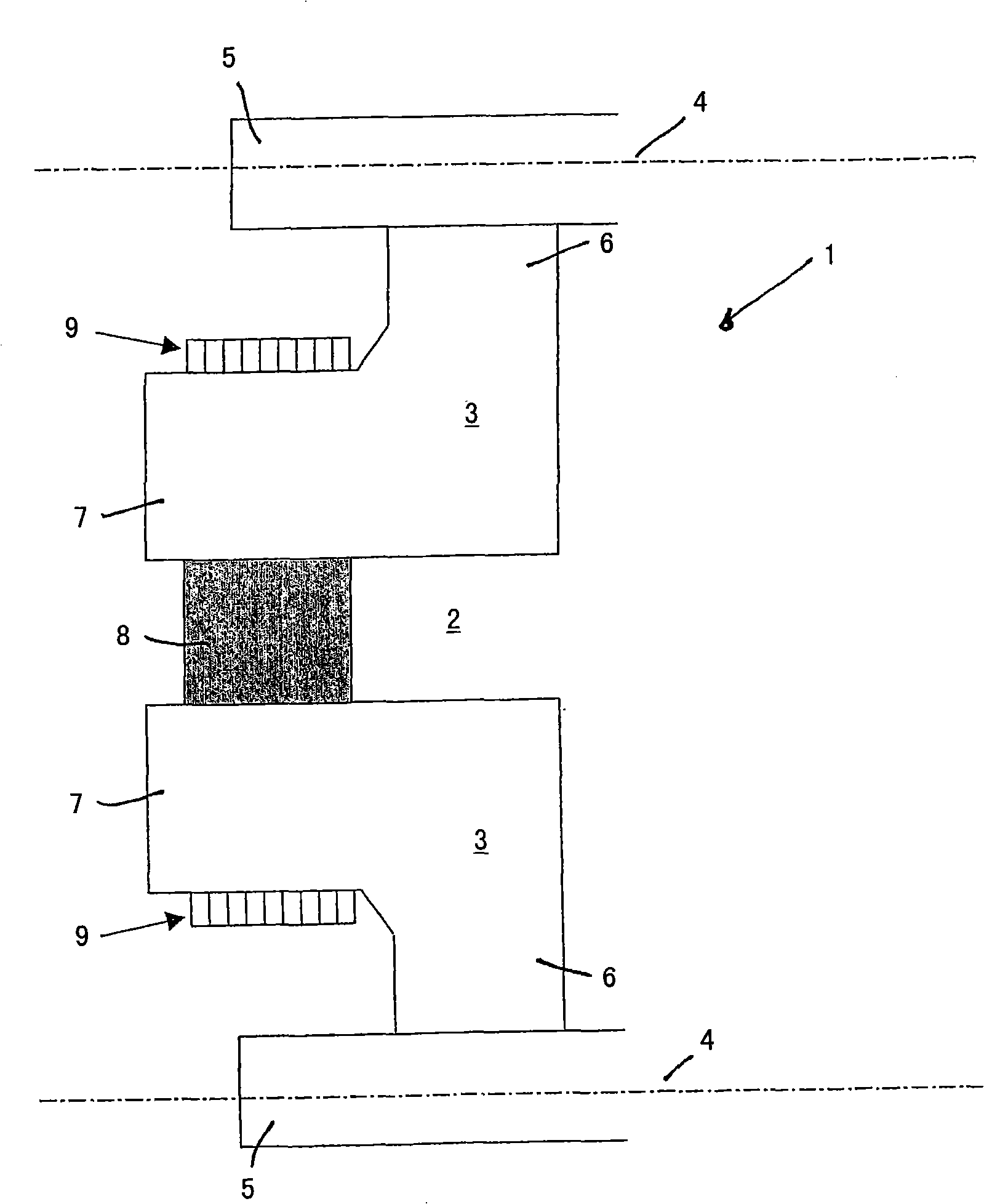

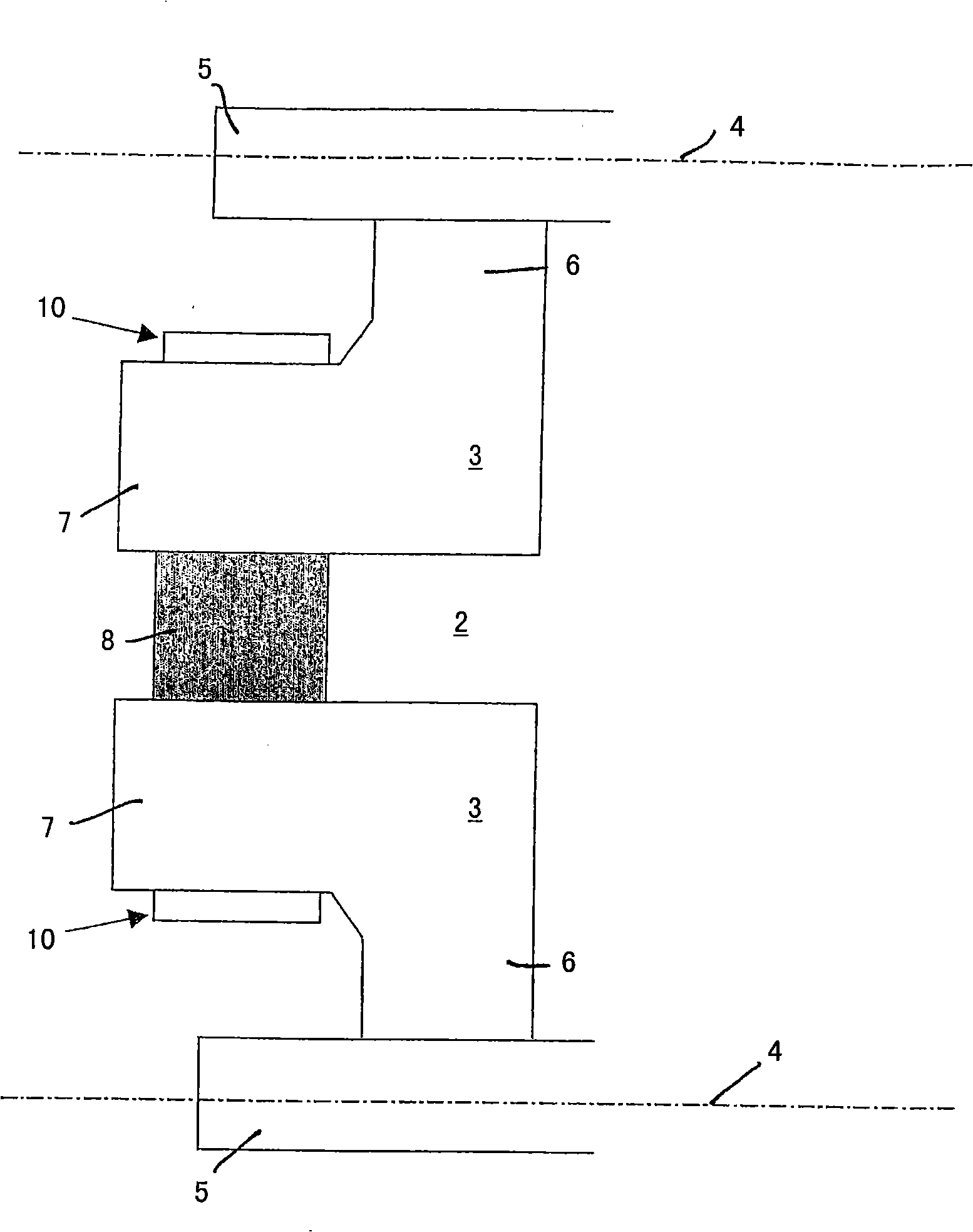

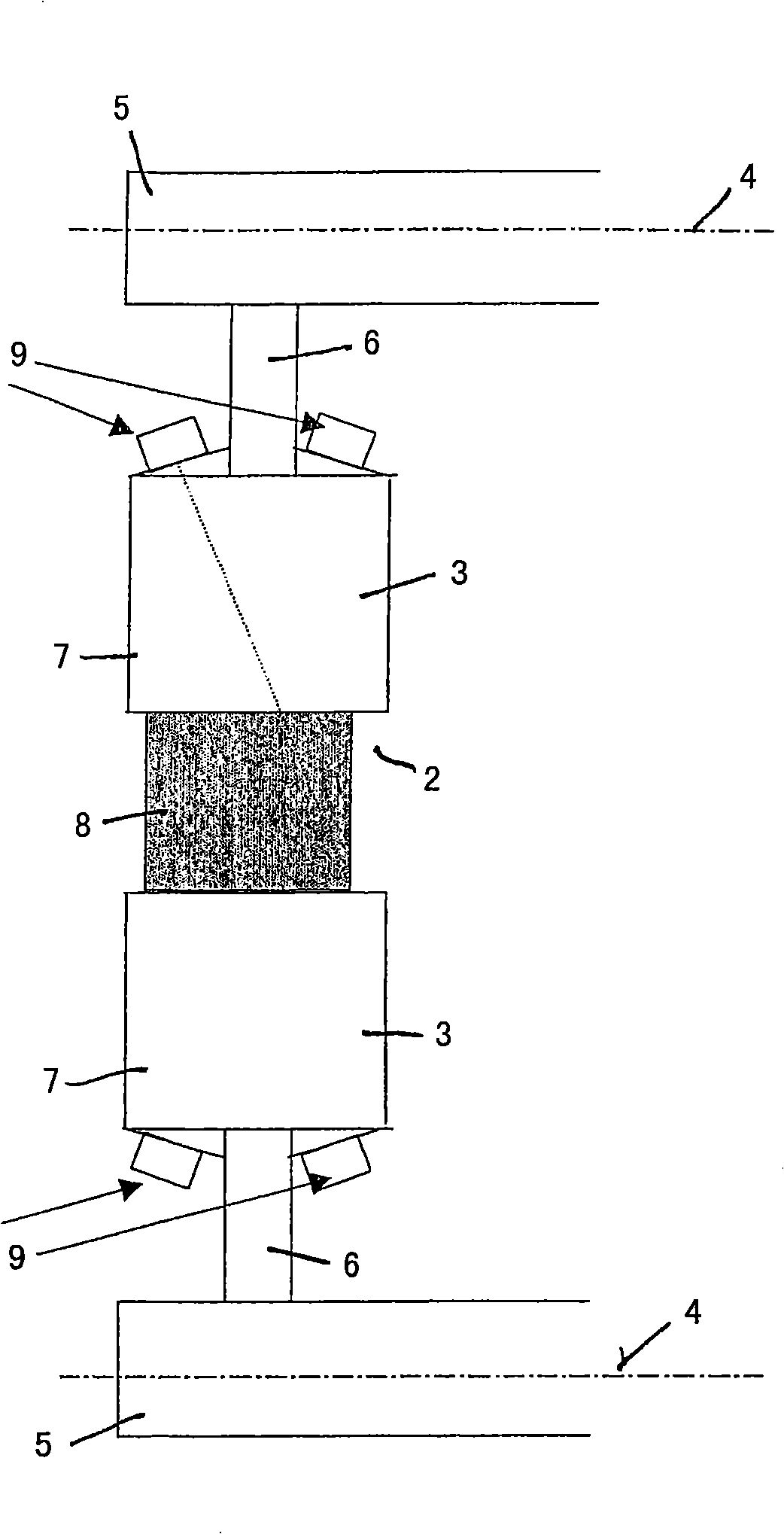

[0026] exist figure 1 and figure 2 A rolling stand is shown in a partial view and is collectively assigned the reference numeral 1 .

[0027] The rolling stand basically comprises two cantilevered rolls 3 with a roll gap 2 between them, the shaft 5 forming the axis of rotation 4 of these cantilevered rolls. The rolls 3 each have a roll disc 6 and an annular extension 7 projecting laterally outward from the roll disc. The rolling stock 8 to be tested is located between the protruding regions 7 of the rolls 3 .

[0028] The actual testing device 9 is arranged on the side of the extension 7 facing the shaft 5 , aligned with the roll gap 2 or the rolling stock 8 .

[0029] here, in figure 1 This is the case with conventional ultrasonic test heads, which are arranged in an array and wired in such a way that they can be controlled individually, with respect to the sound propagation direction and intensity.

[0030] exist figure 2 in all figure 1 Components in are provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com