Flat-plate split joint latching device for flat-plate continuous sulfuration machine

A technology of locking mechanism and vulcanizing machine, applied in the field of locking mechanism, can solve the problems of unavailability of automation and continuous work, insufficient locking strength and rigidity, interference of automation and continuous operation, etc. Simple and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

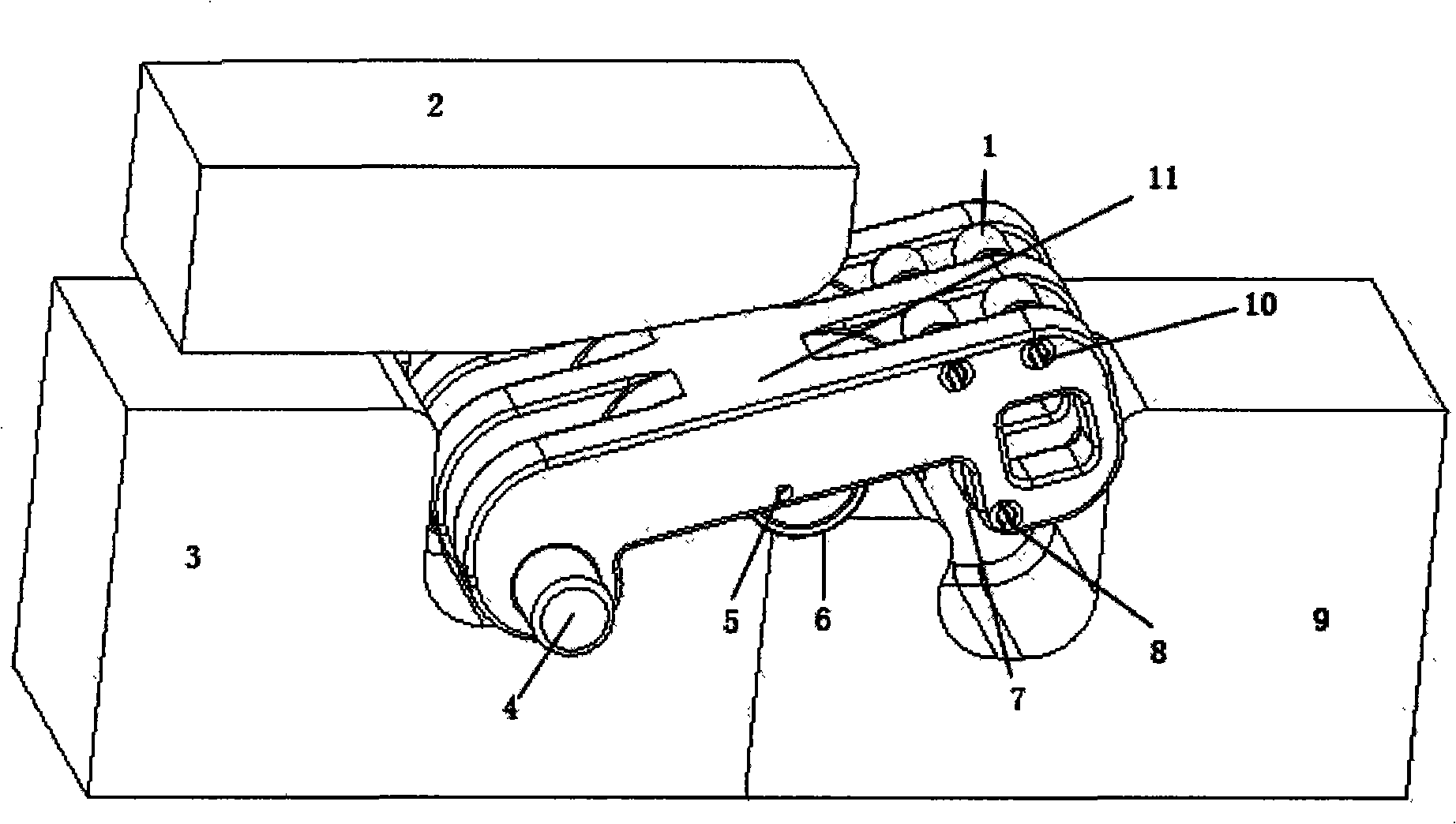

[0012] The present invention will be described in detail below with reference to the accompanying drawings.

[0013] The present invention includes a friction reducing wheel 1, a fixed block 2, a splicing flat plate 3, a locking member rotating shaft 4, a restoring elastic element fixing rod 5, restoring elastic elements 6, a friction reducing wheel 7, a friction reducing wheel rotating shaft 8, and another Splicing flat plate 9, anti-friction wheel rotating shaft 10 and locking link 11. The locking link 11 has a "冂"-shaped structure, which determines the force of the locked state. The friction reducing wheel 1 is fixed on the link 11 through the rotating shaft 10, and the friction reducing wheel 7 is installed on the locking link through the rotating shaft 8. Entering the hook portion in the locking groove, the compressed elastic element 6 is connected to the locking link 11 through the restoring elastic element fixing rod 5 , and the locking link 11 is connected to the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com