Plaster sprayer for road

A spreader, lime technology, applied in the direction of roads, roads, road repairs, etc., can solve the problems of uneven soil subgrade surface, health impact of constructors, increase of road construction costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific structure and principle of the road lime sprinkler provided by the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

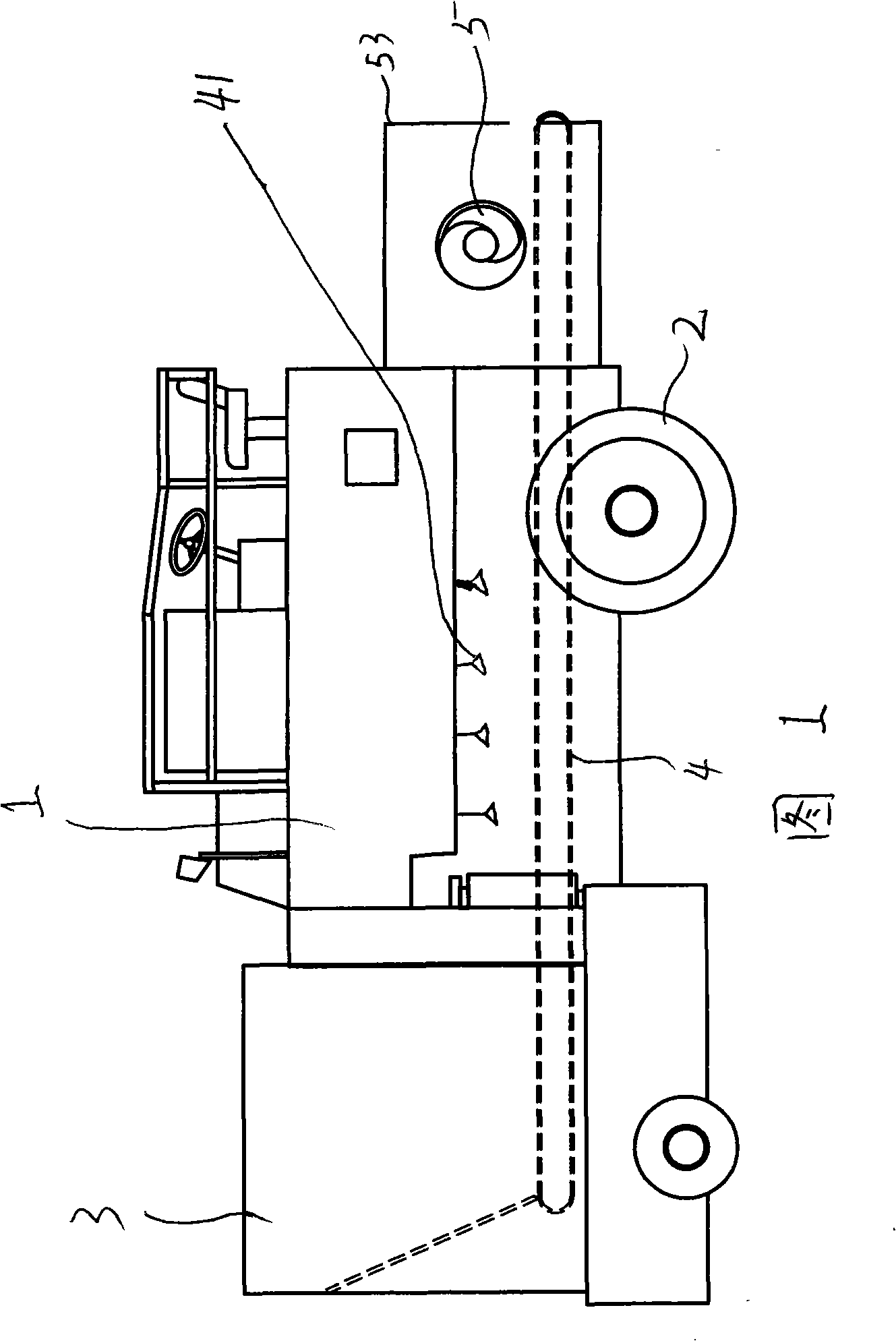

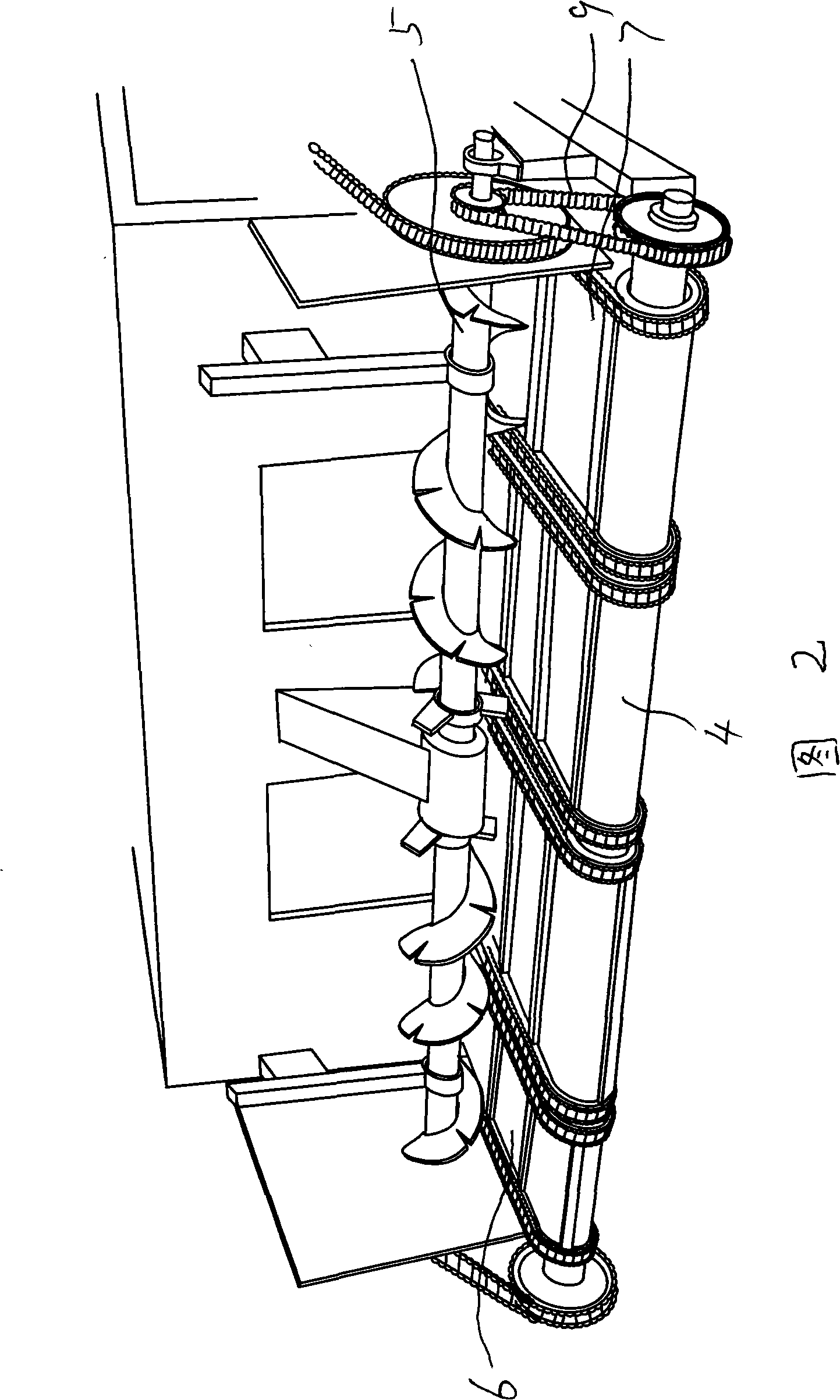

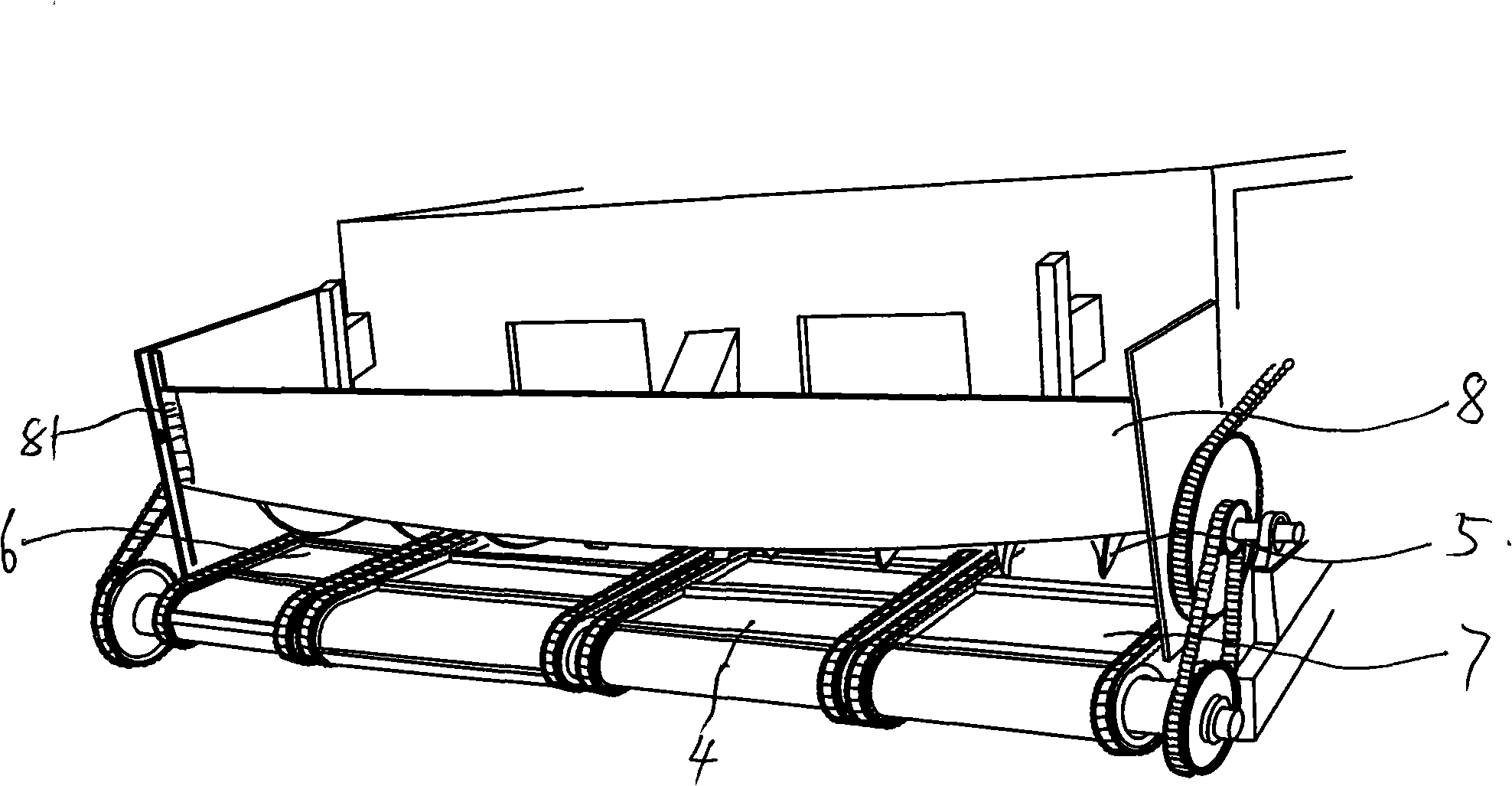

[0022] As shown in Fig. 1 and Fig. 2, the road lime sprinkler provided by the present invention comprises vehicle body 1, and vehicle body 1 has traveling mechanism 2, and the front portion of vehicle body 1 is provided with storage bin 3, and the storage bin 3 The bottom is provided with a material conveying mechanism 4 extending backward at the bottom of the vehicle body 1, and the material conveying mechanism 4 may be a conveyor belt. The material conveying mechanism 4 can also be other known material conveying mechanisms. The rear of the vehicle body 1 is located on both sides of the material conveying mechanism 4 and is respectively provided with a first material rear row mechanism 6 and a second material rear row mechanism 7 . Mechanism 5, the externally dialed f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com