Multifunctional high pressure vapour storage warehouse

A high-pressure steam, multi-functional technology, used in steam engine installations, machines/engines, mechanical equipment, etc., can solve problems such as environmental pollution, waste, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

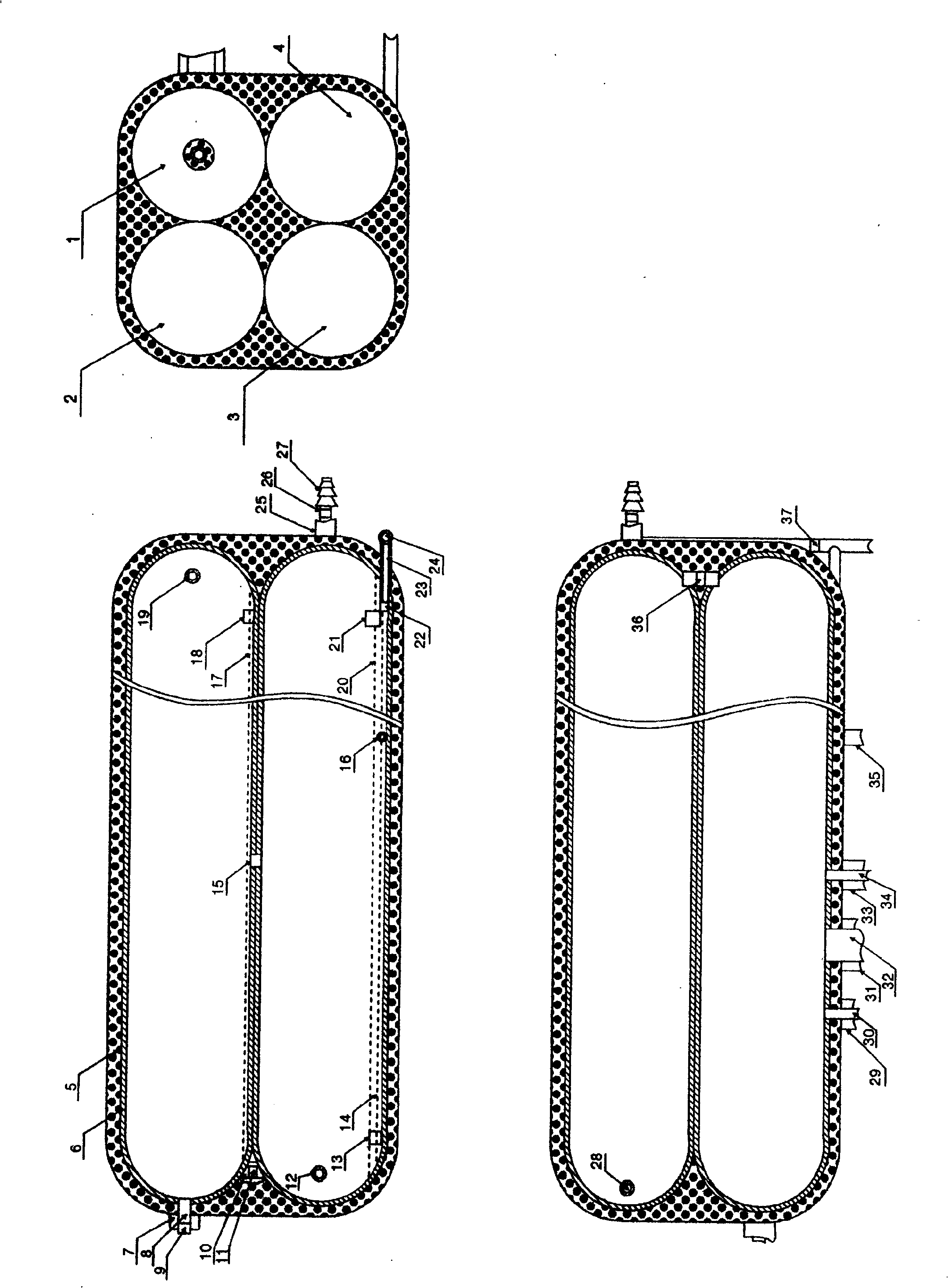

[0030] As shown in the figure, the multi-functional high-pressure steam storage tank is characterized in that it is connected with a multi-functional subcritical steam cylinder, a multi-functional high-pressure steam tank, a multi-functional medium-pressure steam tank and a multi-functional vacuum circulating water tank respectively.

[0031] The low-temperature and low-pressure water vapor after steam turbine work is discharged to the multi-function vacuum circulation water tank by the air extractor, the water vapor that does not become water, and other parts of the steam sent to the multi-function vacuum circulation water tank, plus the multi-function circulation The steam generated in the water tank is forcibly sent to the multi-functional steam recovery tank by the air extractor with an extraction capacity five times greater than that of the steam turbine extractor; the waste steam with a higher steam pressure than the multi-functional steam recovery tank is also sent to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com