Vapor recovery warehouse

A recovery chamber and steam technology, applied in the fields of environmental protection, water and steam discharge, safe production, power generation equipment, equipment protection, consumption reduction, energy saving, emission reduction, and recovery, and can solve heat loss, high-purity loss, waste, etc. problems, to achieve the effect of reducing power generation costs, keeping coal consumption unchanged, and saving high-quality water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

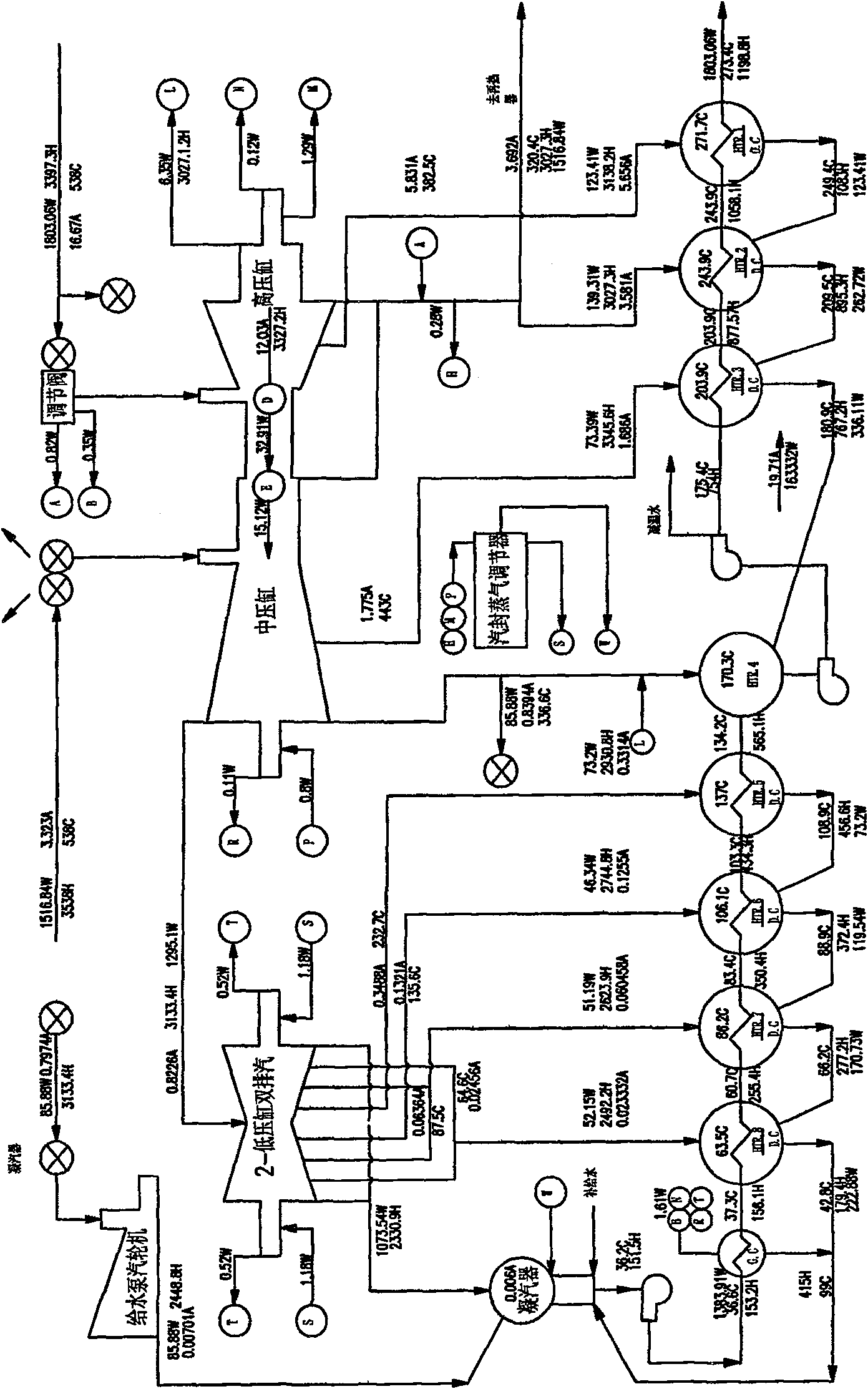

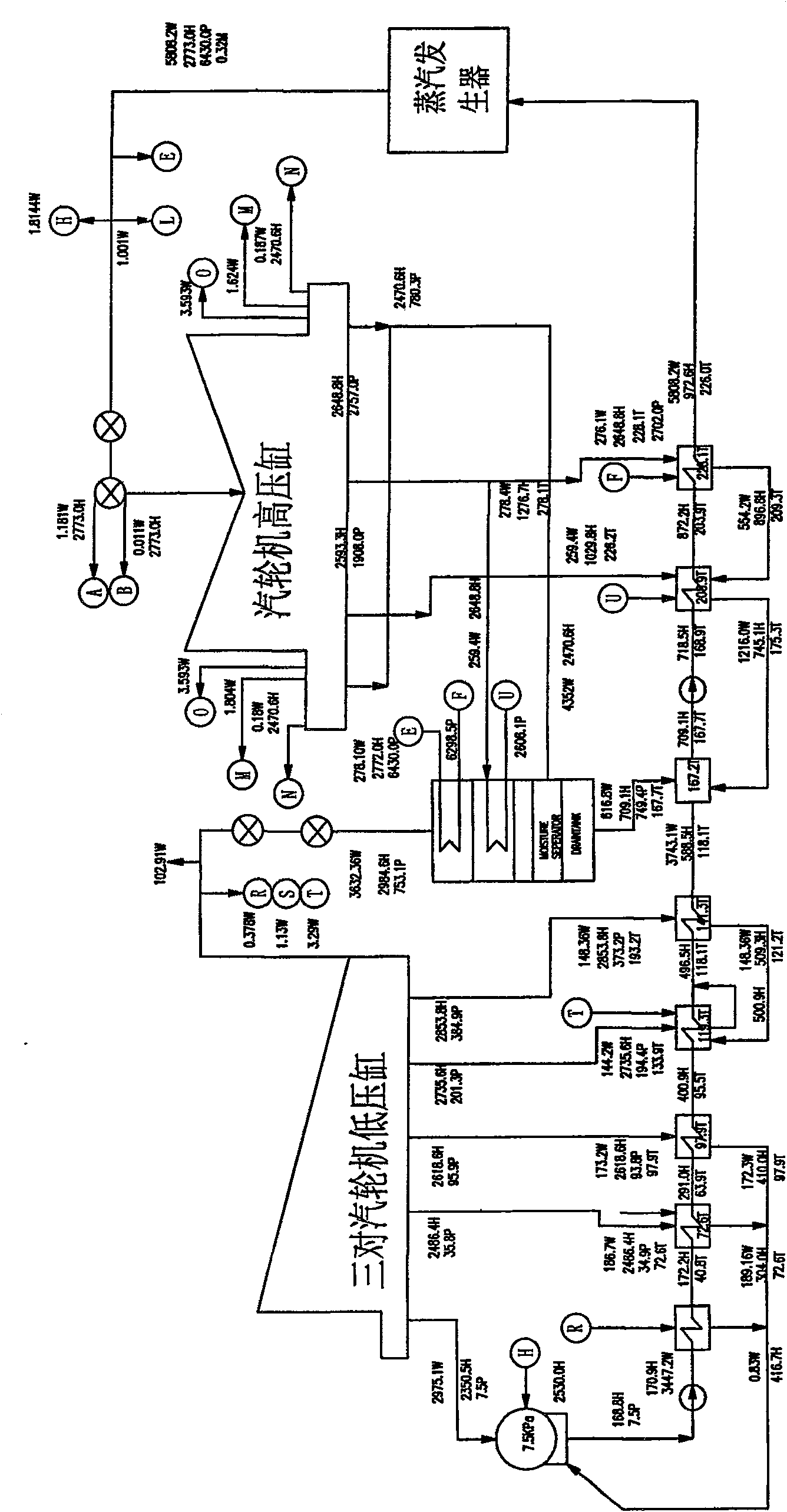

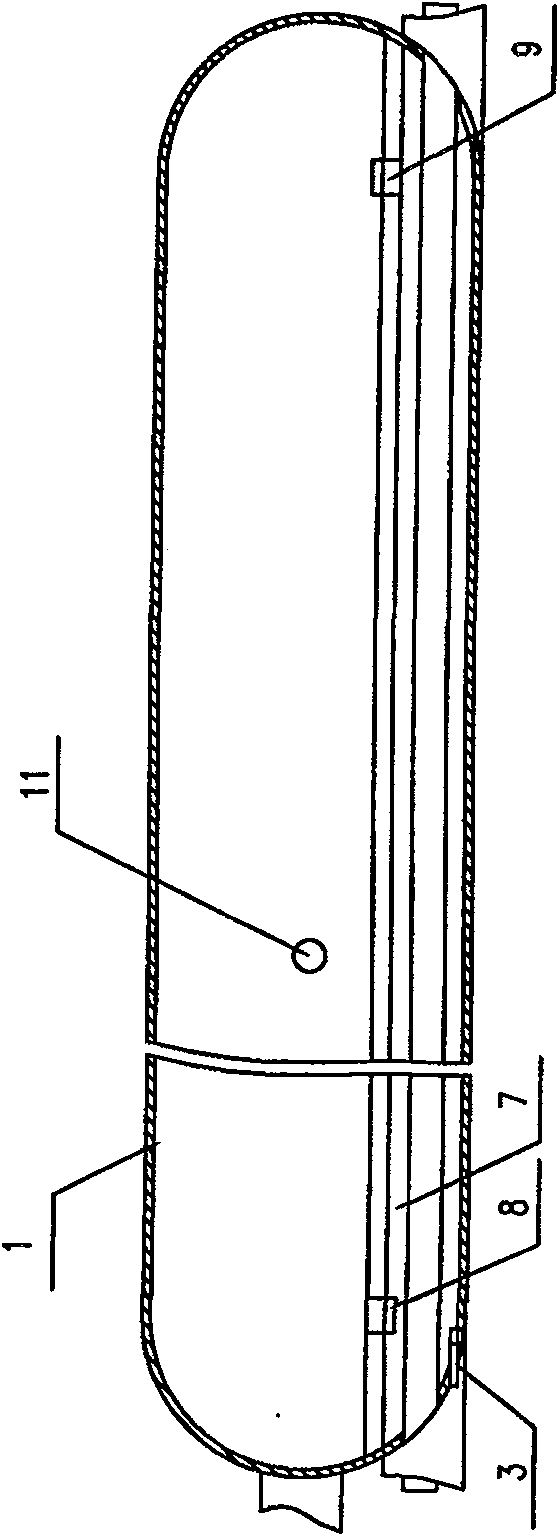

[0020] like Figure 3 ~ Figure 5 Shown, a kind of multi-functional steam recovery warehouse of the present invention, it comprises the steam recovery warehouse 1 that is connected with boiler, circulating water warehouse and low-pressure warehouse respectively, is a kind of water vapor complete steam in the large-scale solar power plant that electricity generation cost is lower than thermal power generation. Circulation thermal power generation technology is one of the main equipment in the thermal power water vapor full cycle thermal system designed in combination with the characteristics of thermal power plants. The power generation thermal efficiency of this system is the highest in the world today, and the main theoretical basis is Carnot's theorem (all heat engines working between the same-temperature heat source and the same-temperature cold source have the highest efficiency with reversible machines). The condenser and its auxiliary systems, one of the main equipment in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com