Patents

Literature

36results about "Water accumulator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

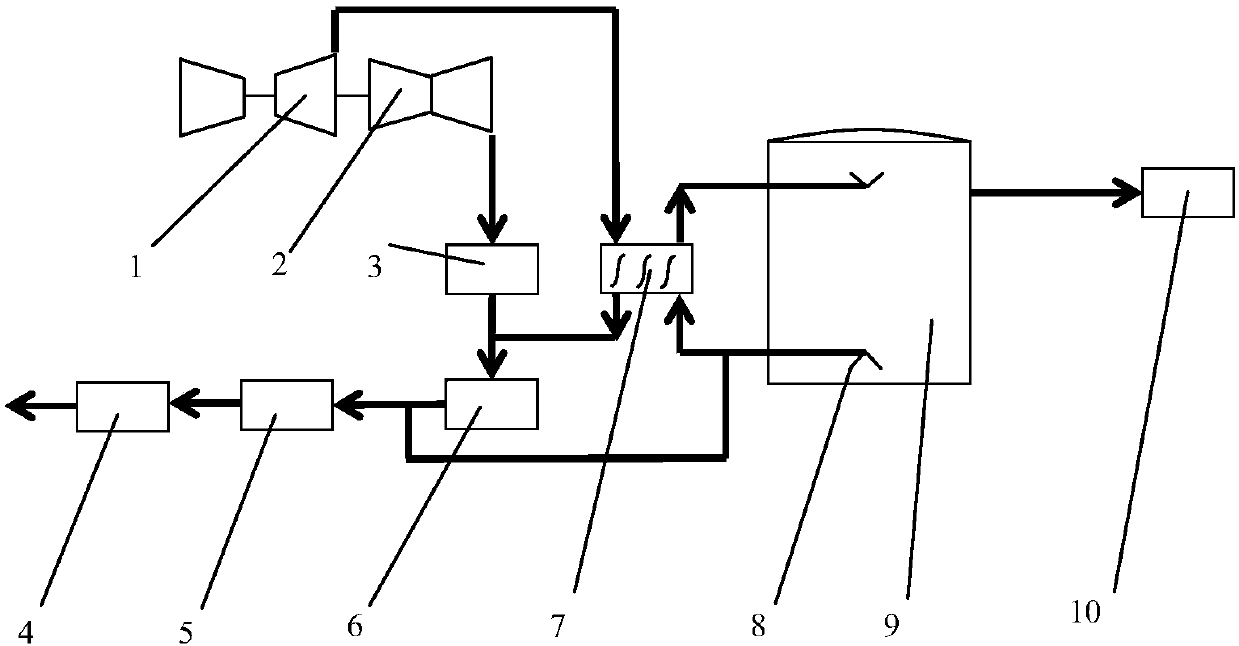

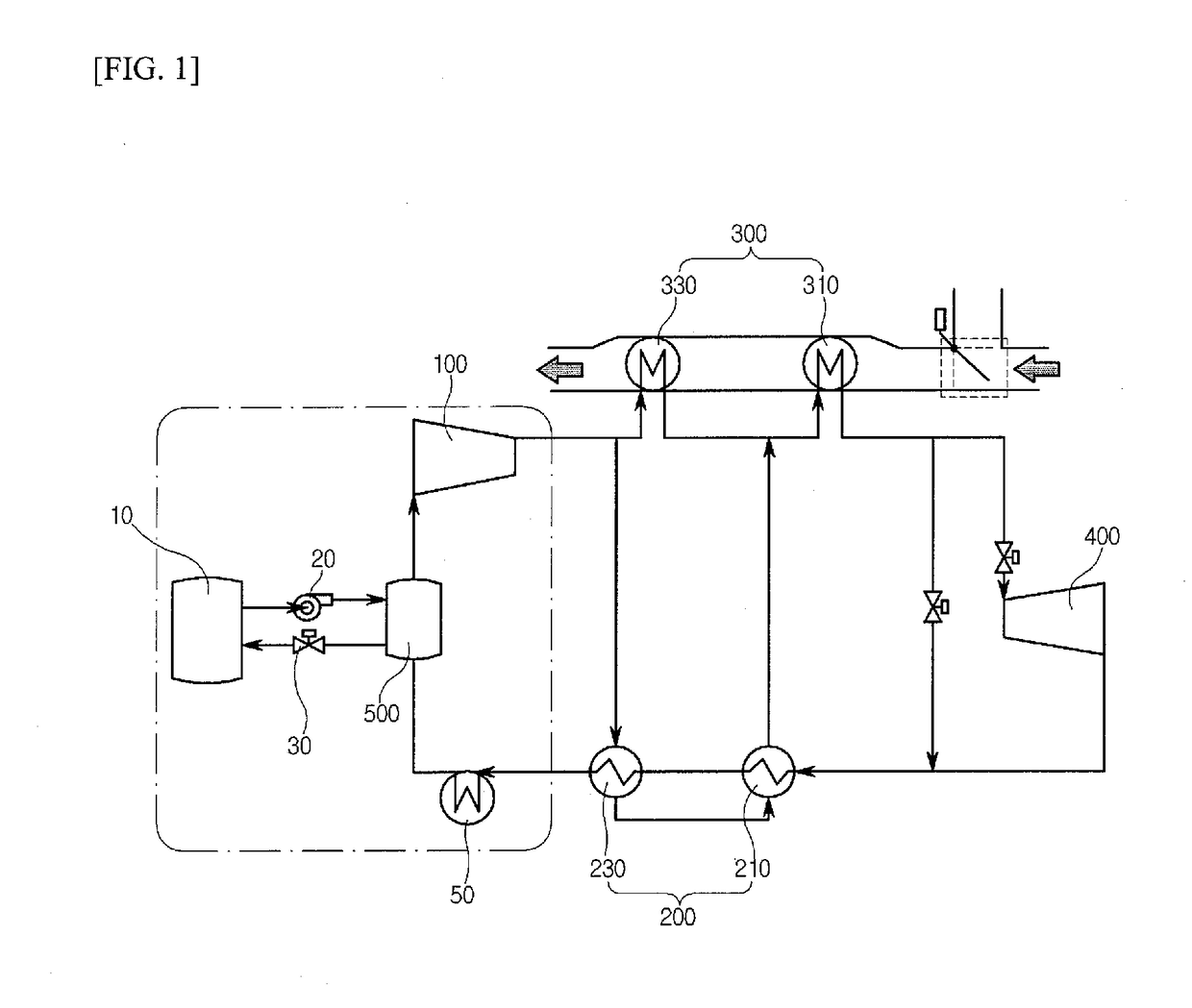

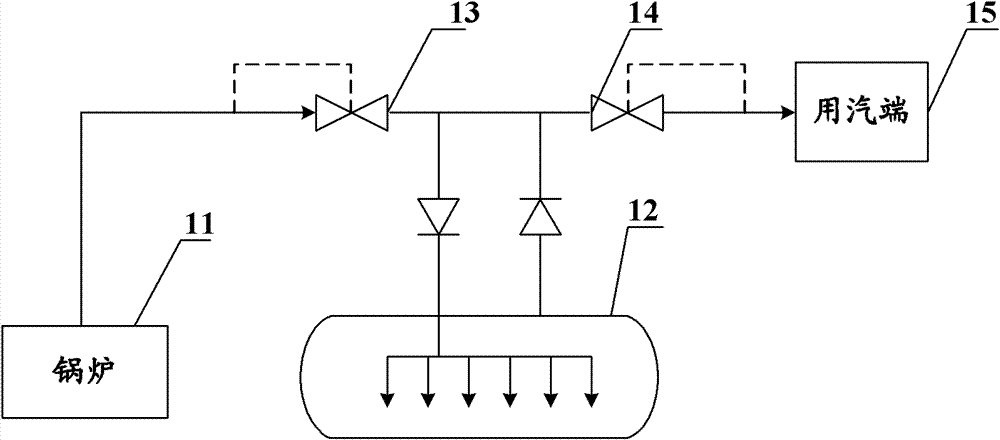

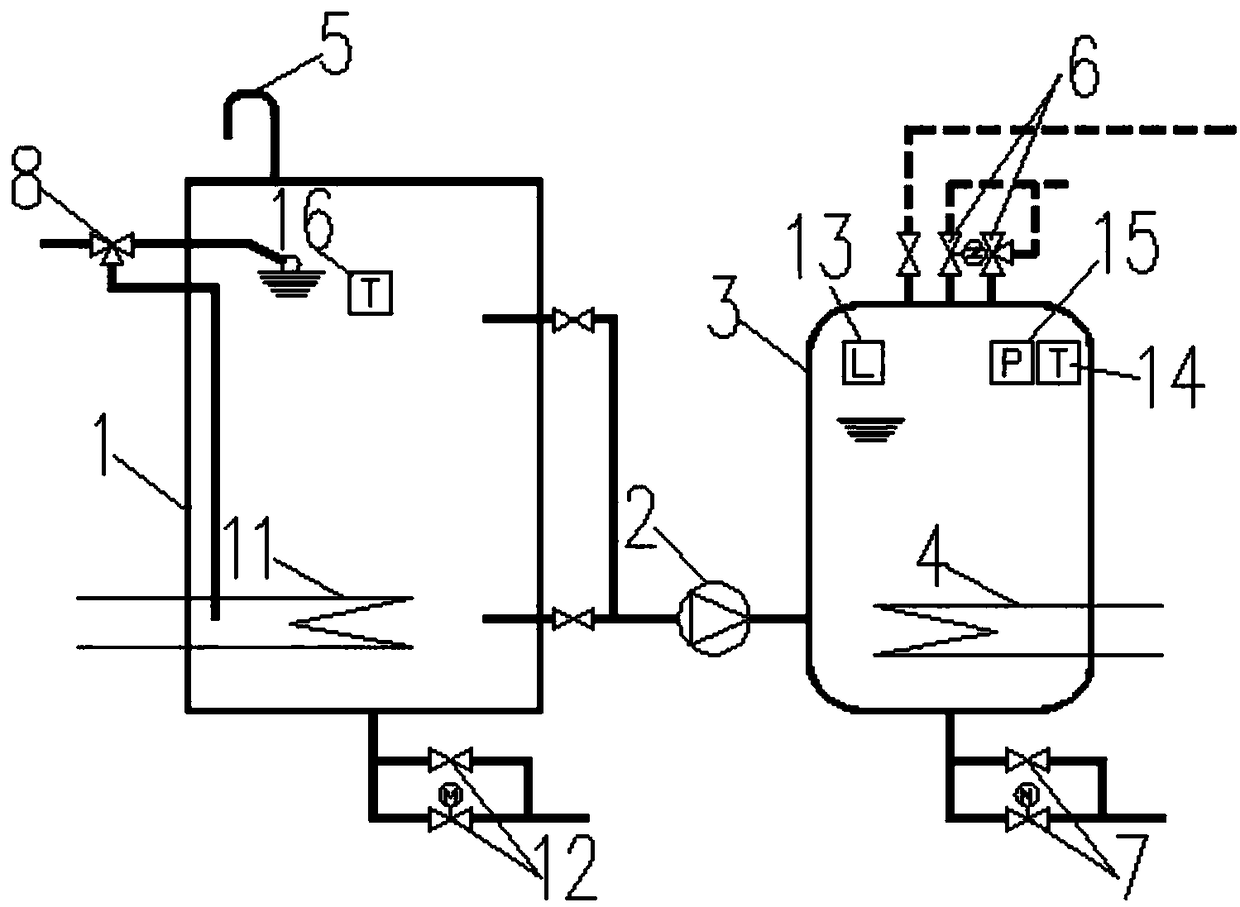

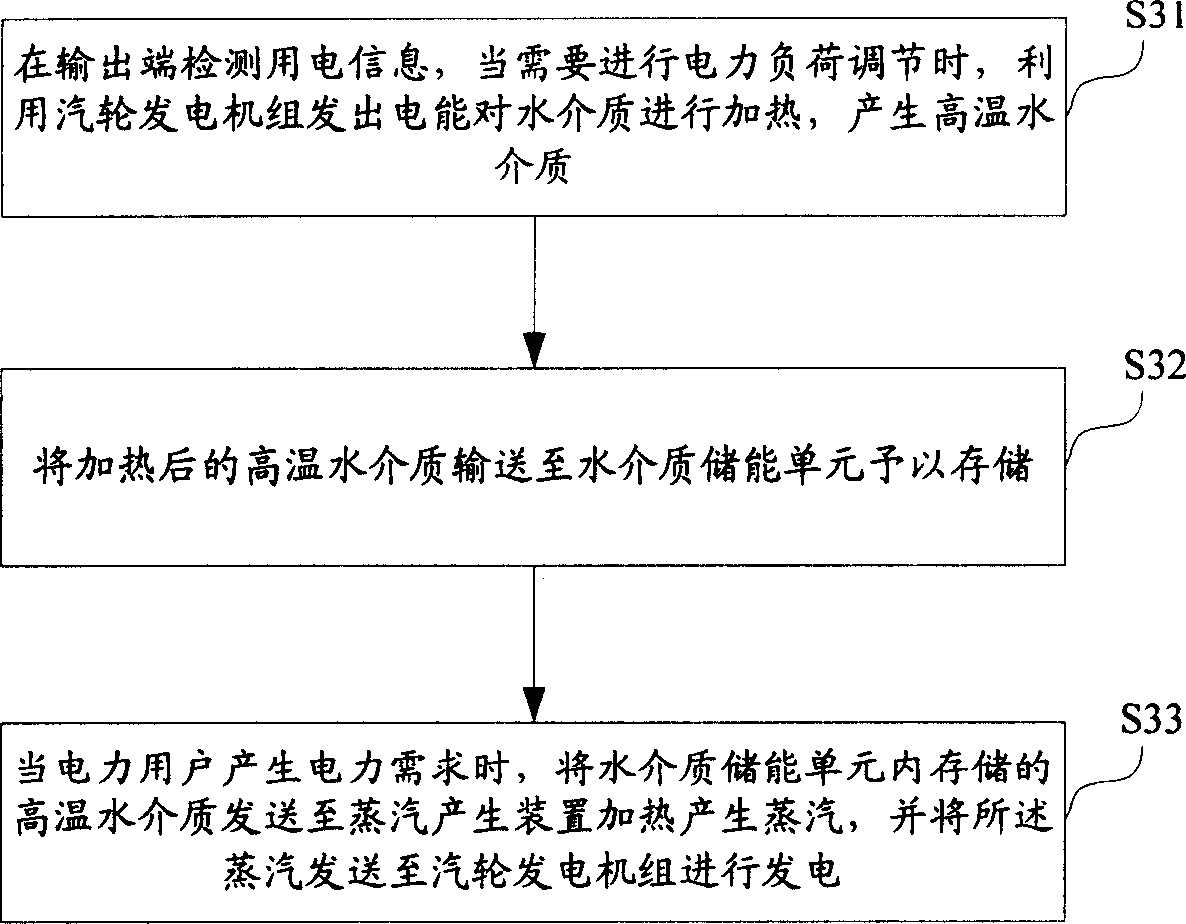

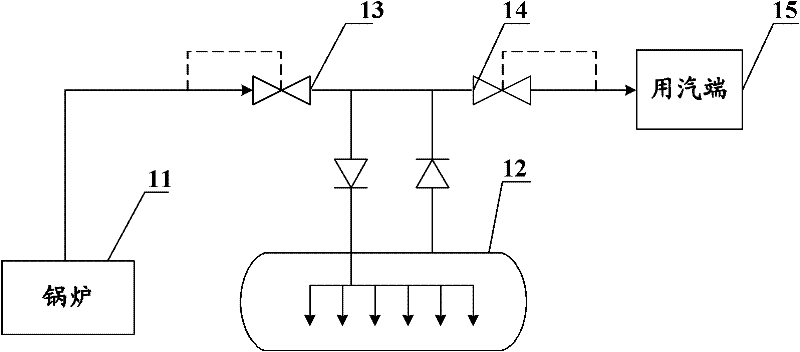

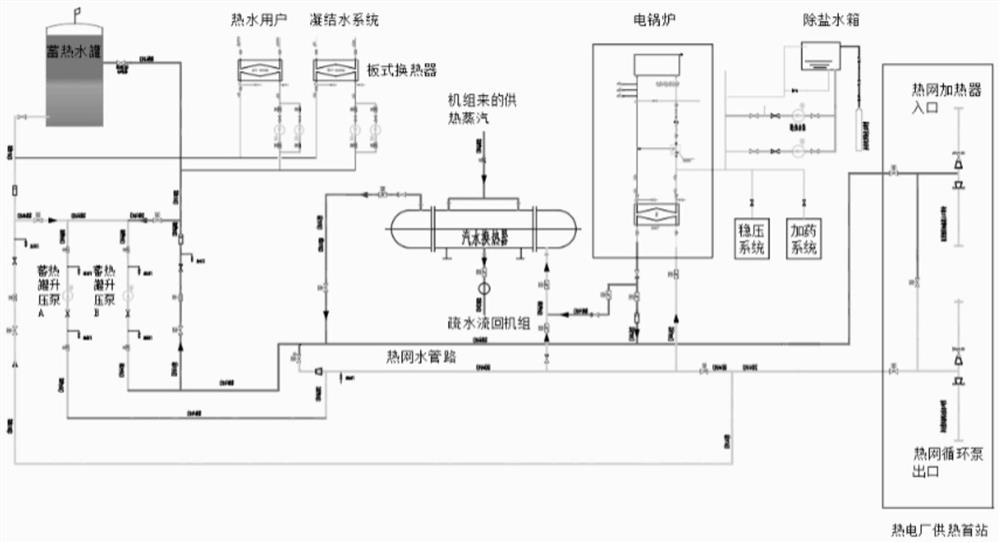

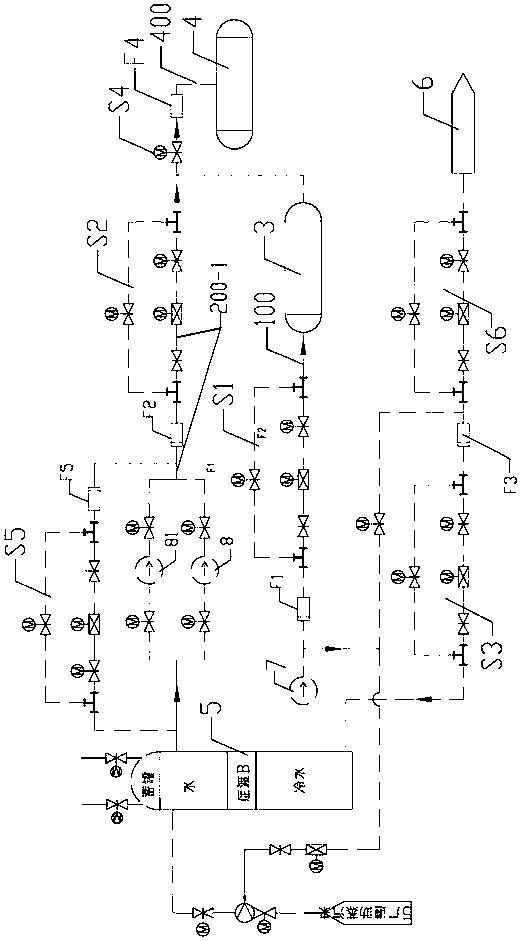

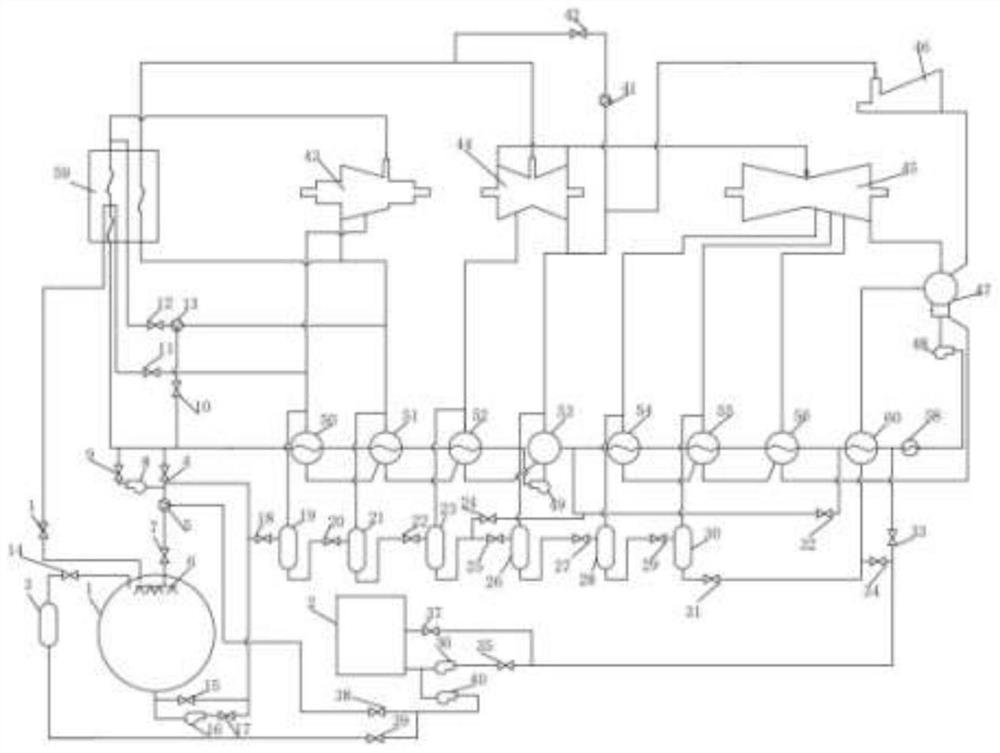

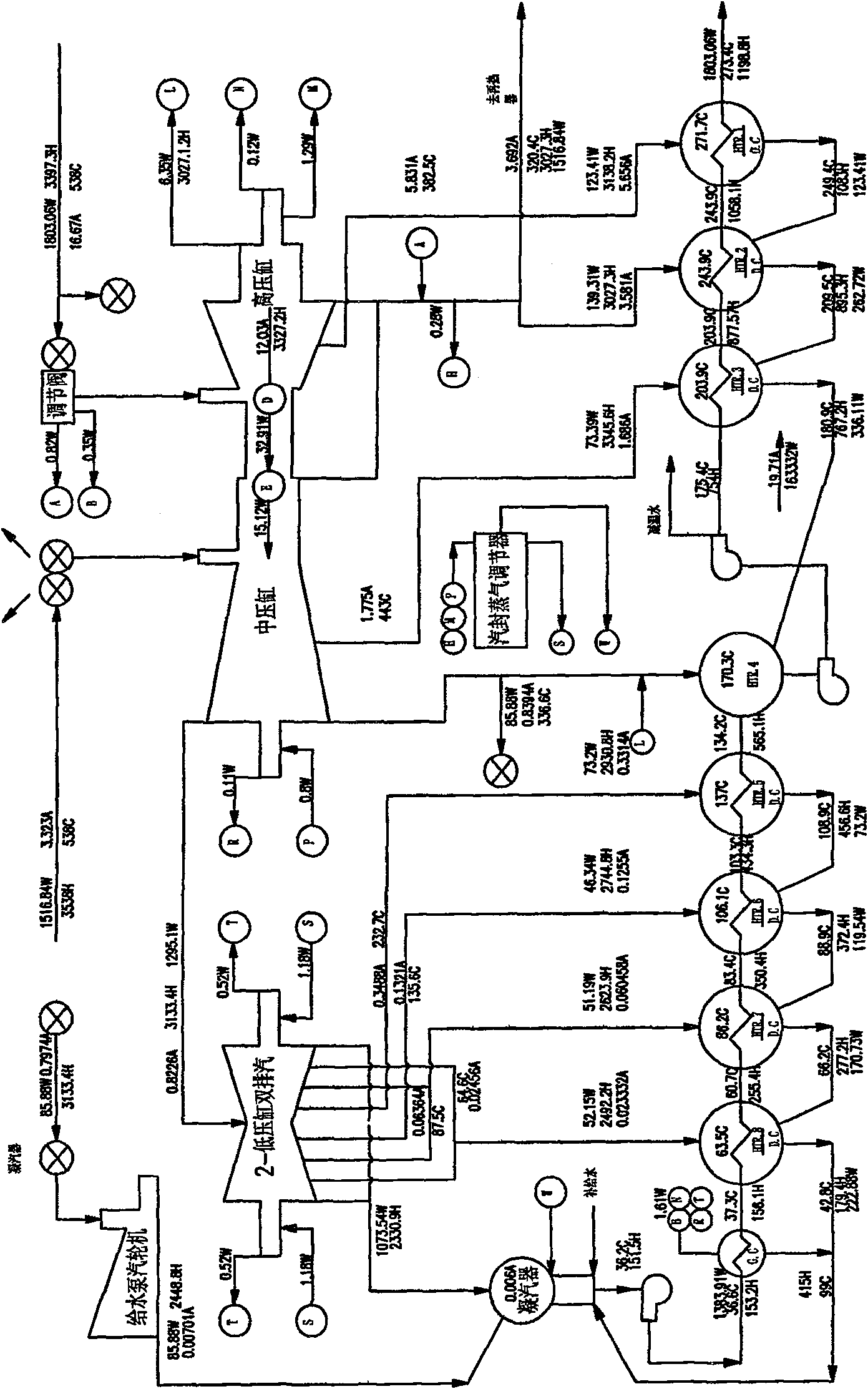

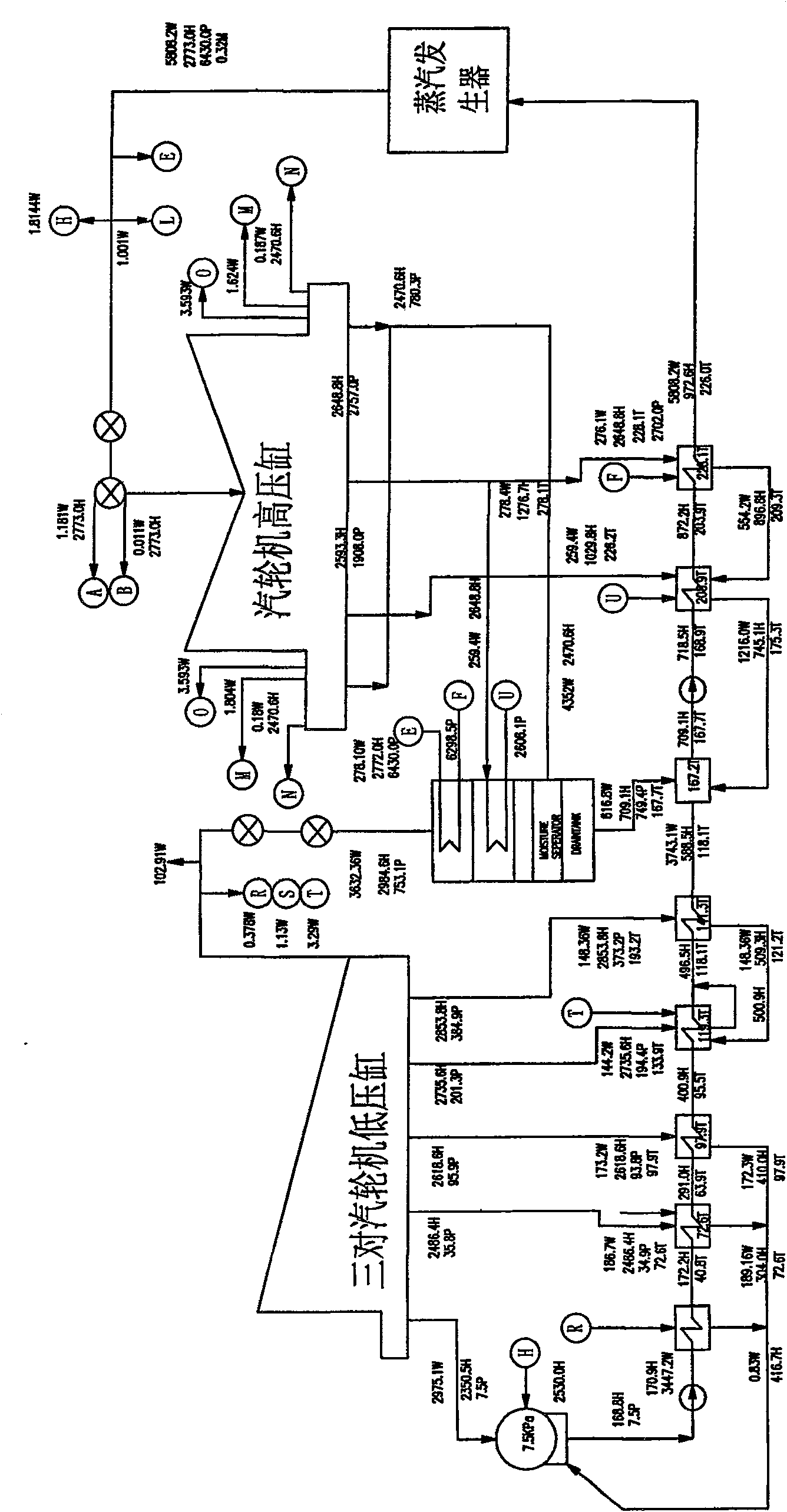

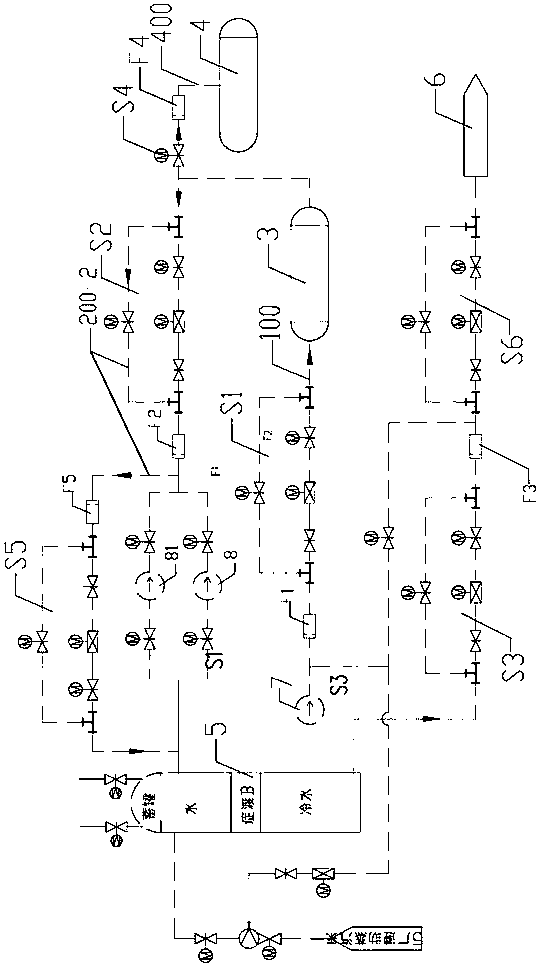

Thermal power generating unit deep peak regulation and backheating energy saving method

InactiveCN107631288AGuarantee continuous and stable operationImprove the ability of online peak shavingLiquid degasificationWater accumulatorCondensed waterCoal

The invention provides a thermal power generating unit deep peak regulation and backheating energy saving method. Through a manner that a hot water heat storing system is arranged in a thermal power generating unit system, at the period when deep peak regulation needs to be participated in, exhaust steam in a pressure cylinder in the unit is extracted, cold water is heated through a heat exchanger, heated water is stored in a heat storage water tank, and deep peak regulation is achieved; meanwhile, the power generation load is reduced, and continuous and stable running of the unit is guaranteed; and at the period when deep peak regulation does not need to be participated in, hot water in the heat storage water tank is supplied to a condensed water pipe in front of a deaerator through a water pump, and therefore heat stored at the deep peak regulation period is sufficiently used, the heating steam amount of a low-pressure heater system at present is greatly reduced, and the aims of increasing the power generation load, recycling the heat stored in the heat storage water tank and reducing the coal consumption are achieved. In the overall peak regulation process, the hot water heat storage technology is applied, the on-grid peak regulation capacity of the unit is improved, the running energy consumption of the unit is saved, and the dilemma of clean energy consumption is effectively released.

Owner:北京姚魏环保技术有限公司

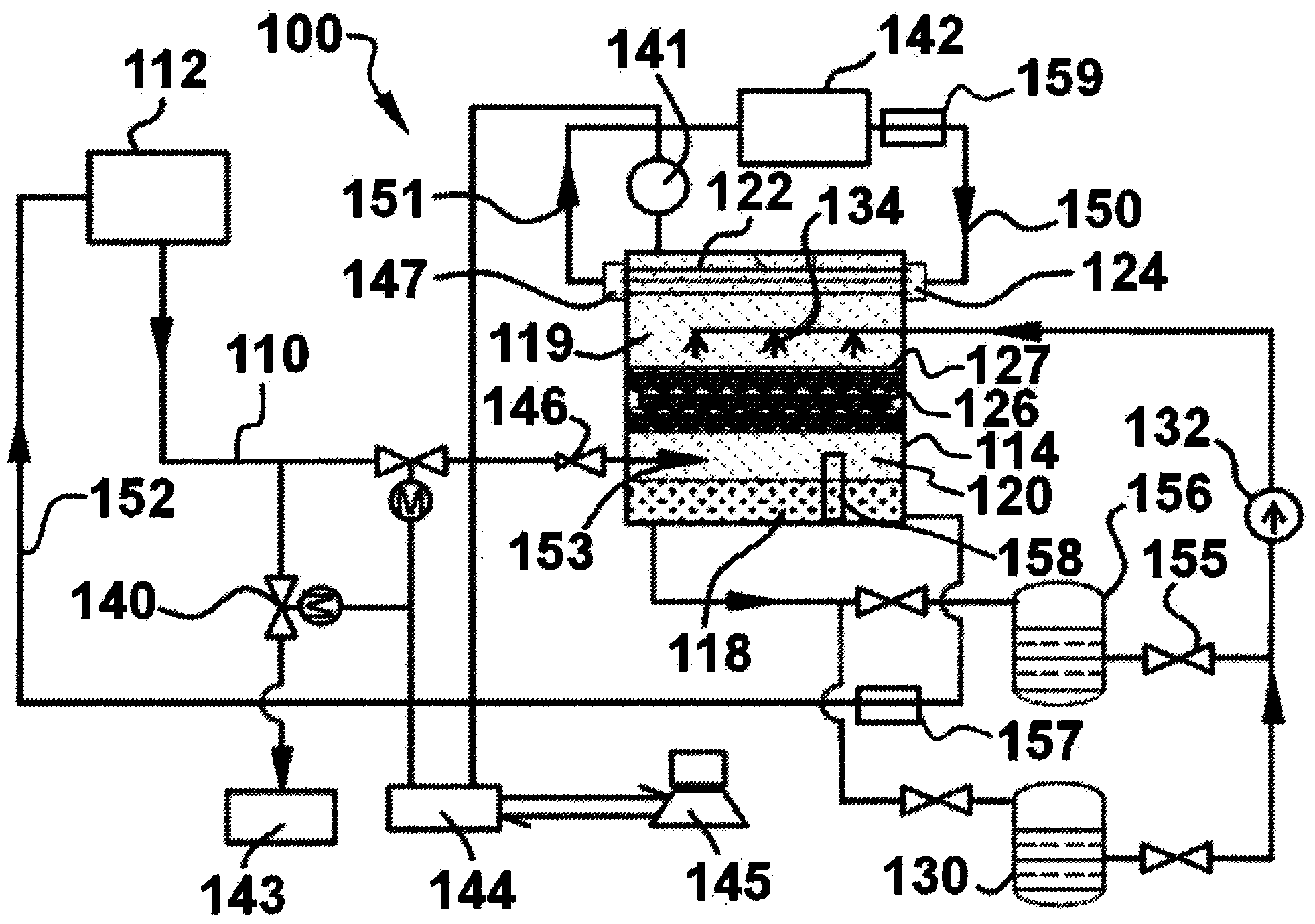

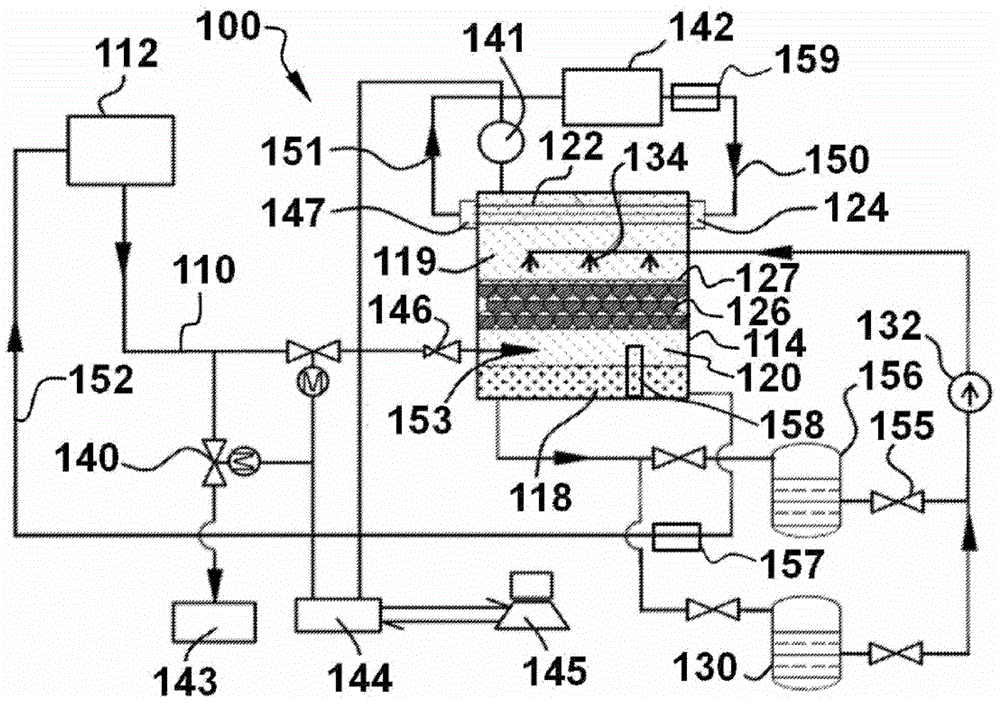

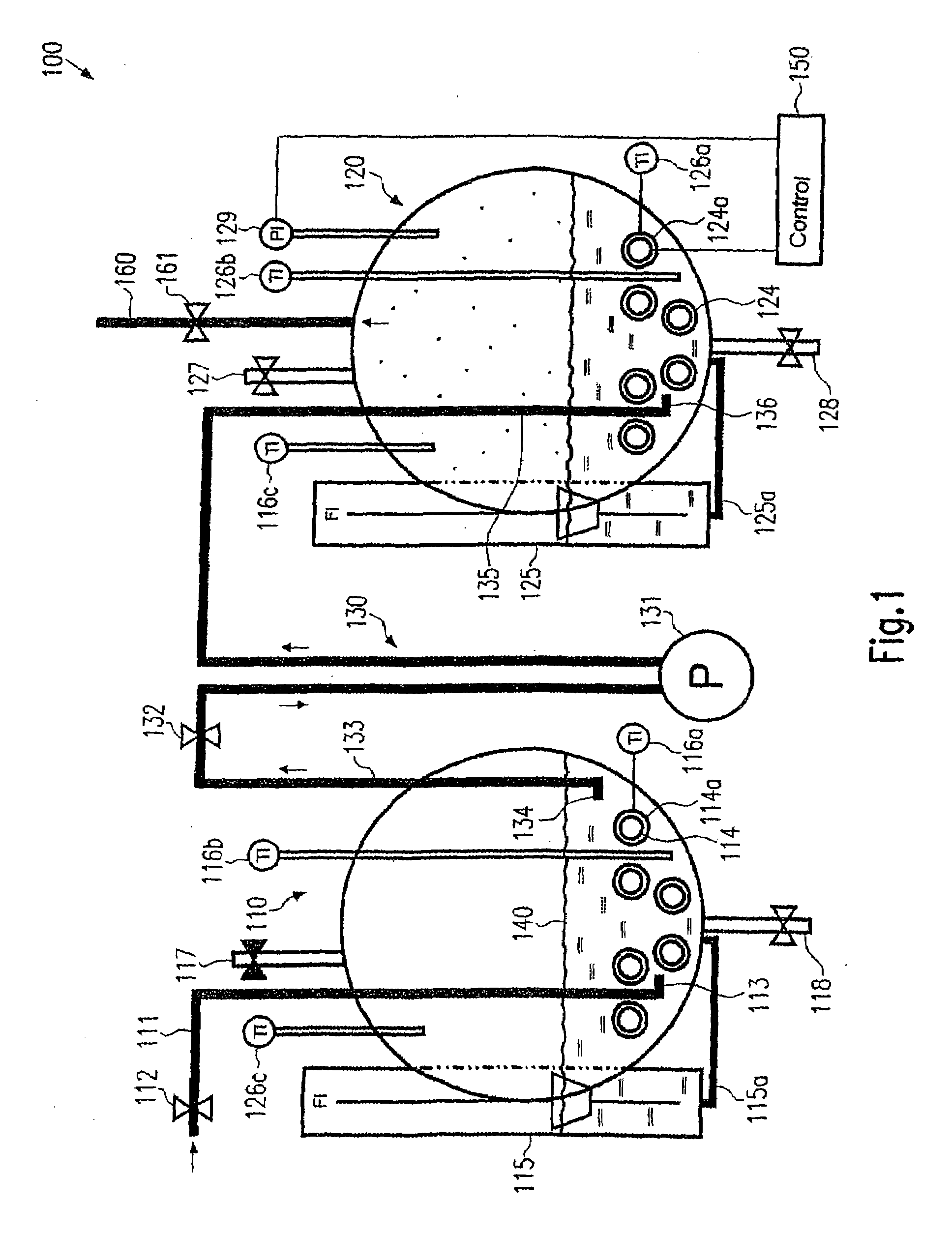

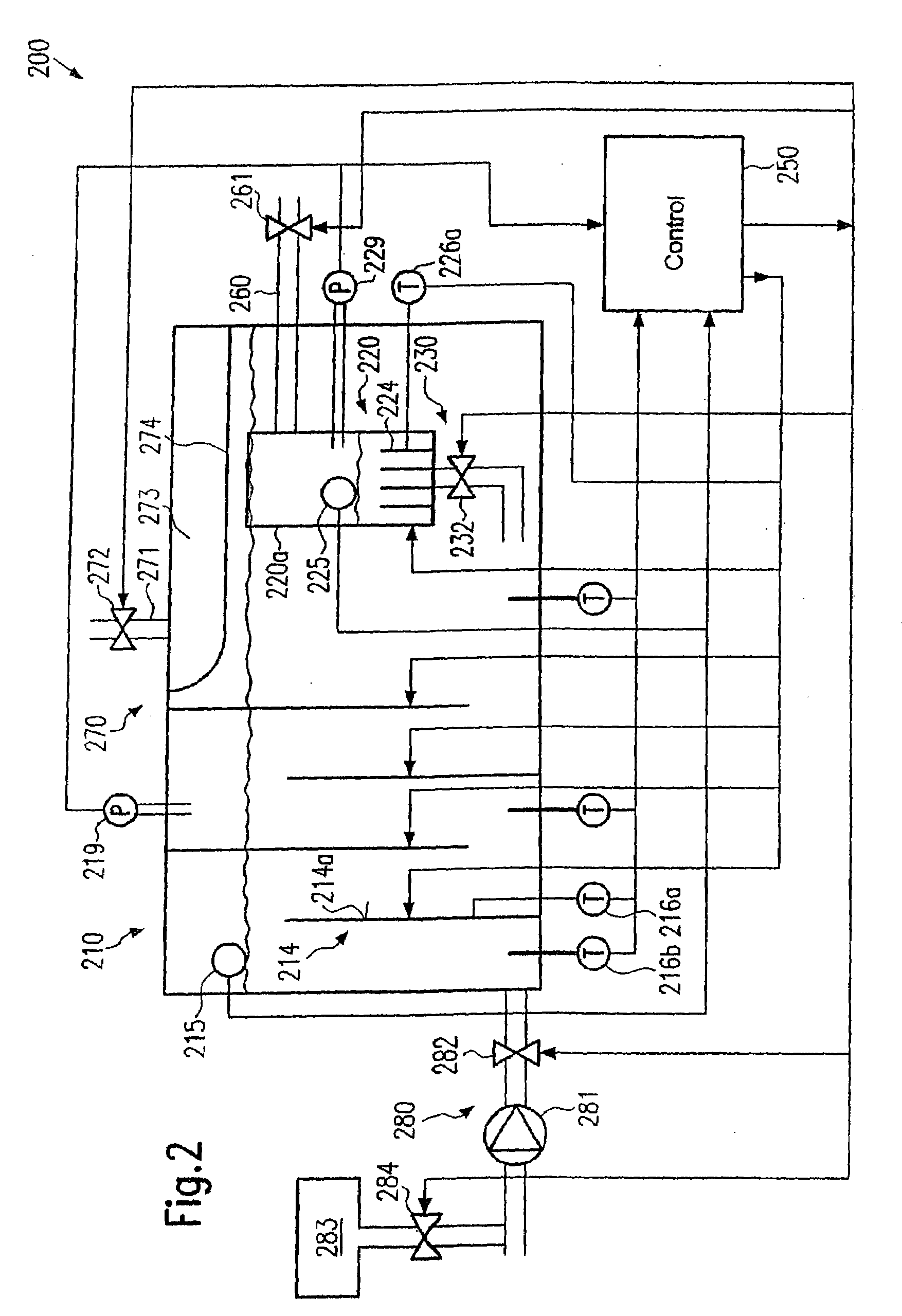

Methods and apparatus for latent heat (phase change) thermal storage and associated heat transfer and exchange

ActiveCN103890322ASteam generation heating methodsFrom solar energyThermal energy storageEngineering

In various embodiments, phase change and heat exchange methods between heat collection, heat transfer, heat exchange, heat storage, and heat utility systems are described. In certain embodiments, the heat transfer fluids / heat exchange fluids, heat storage media, and working media in the system are all phase change materials with transition temperatures close to each other and in decreasing order and perform their respective function through phase changes within a relatively narrow temperature range. Methods to control heat transfer rate, heat exchange and / or heat charging / discharging rate between heat collection, thermal energy storage and heat utility apparatus at will are provided. Methods of controlling such systems are also provided.

Owner:BLUELAGOON TECH

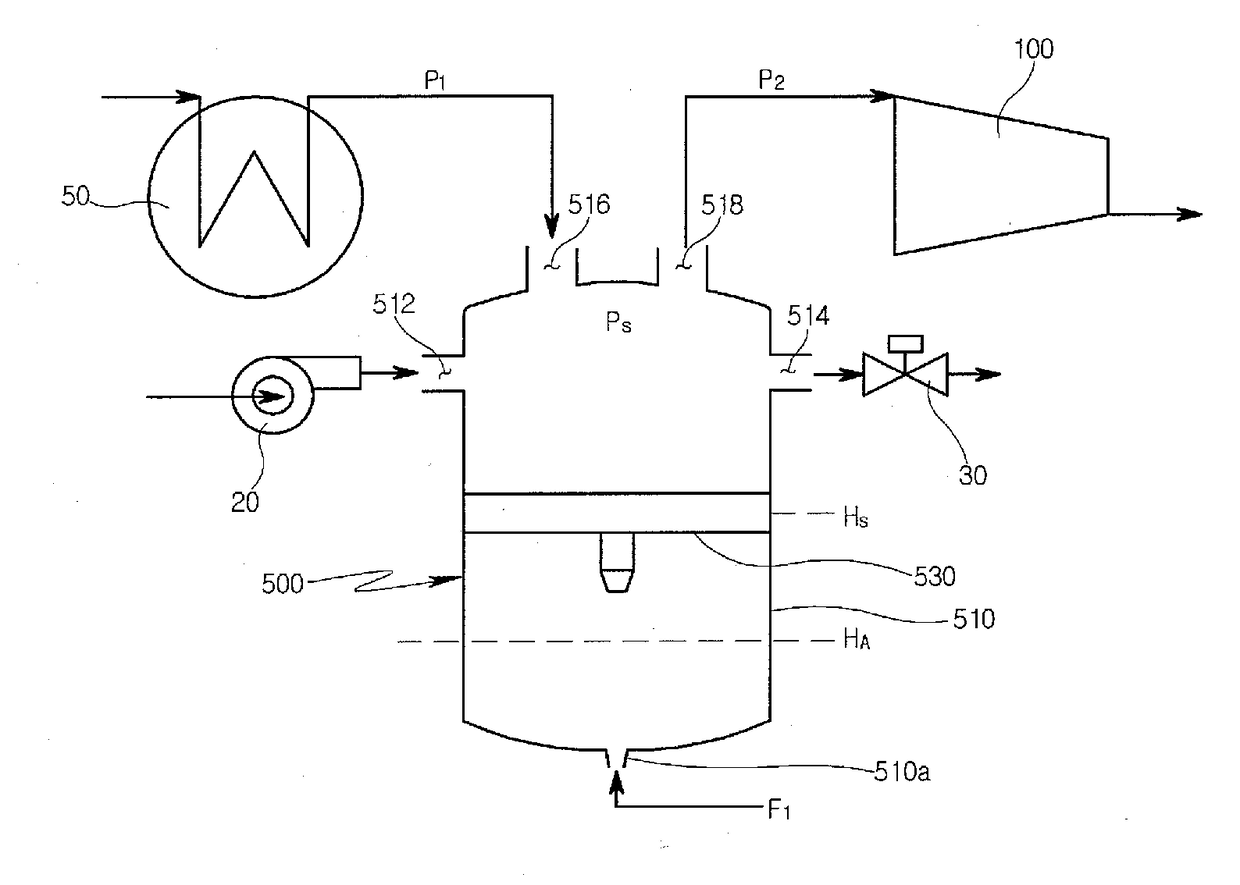

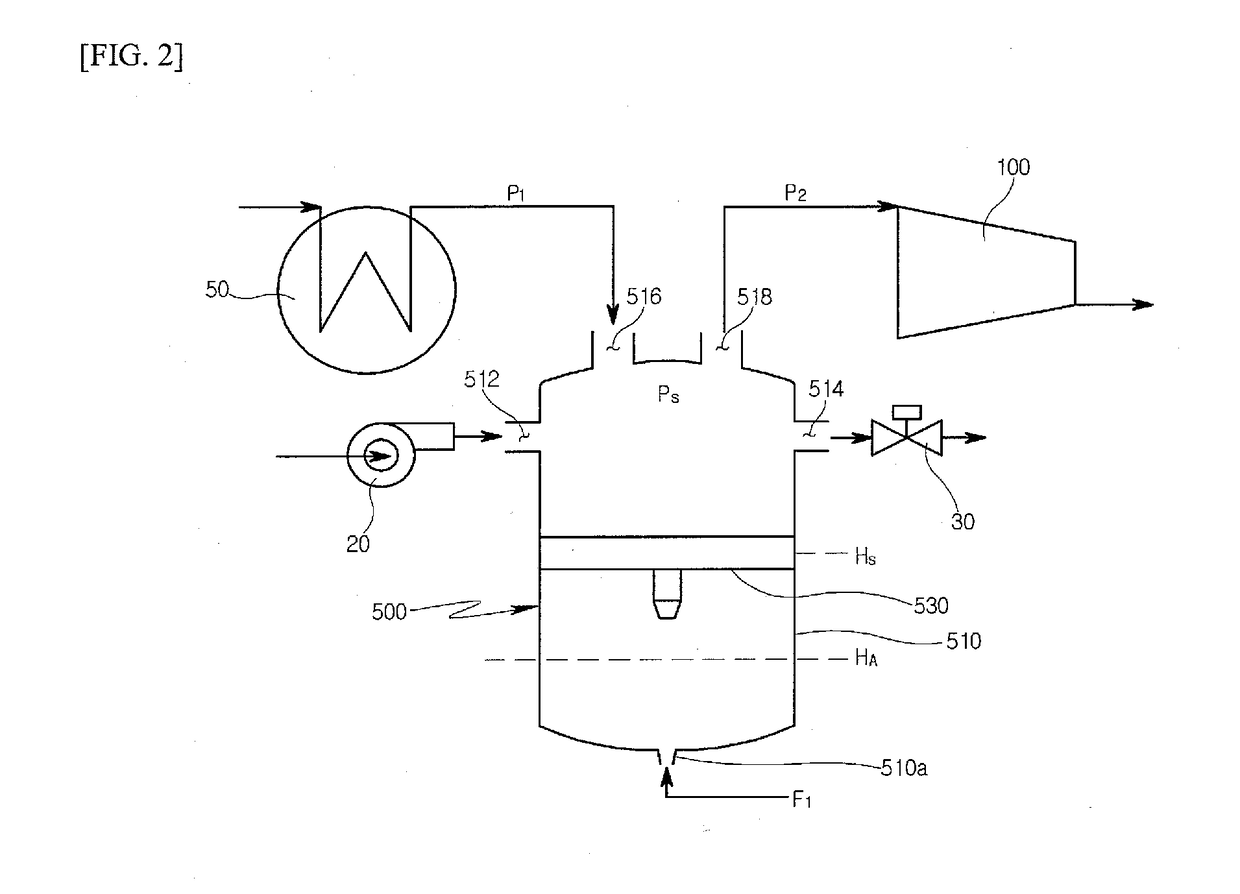

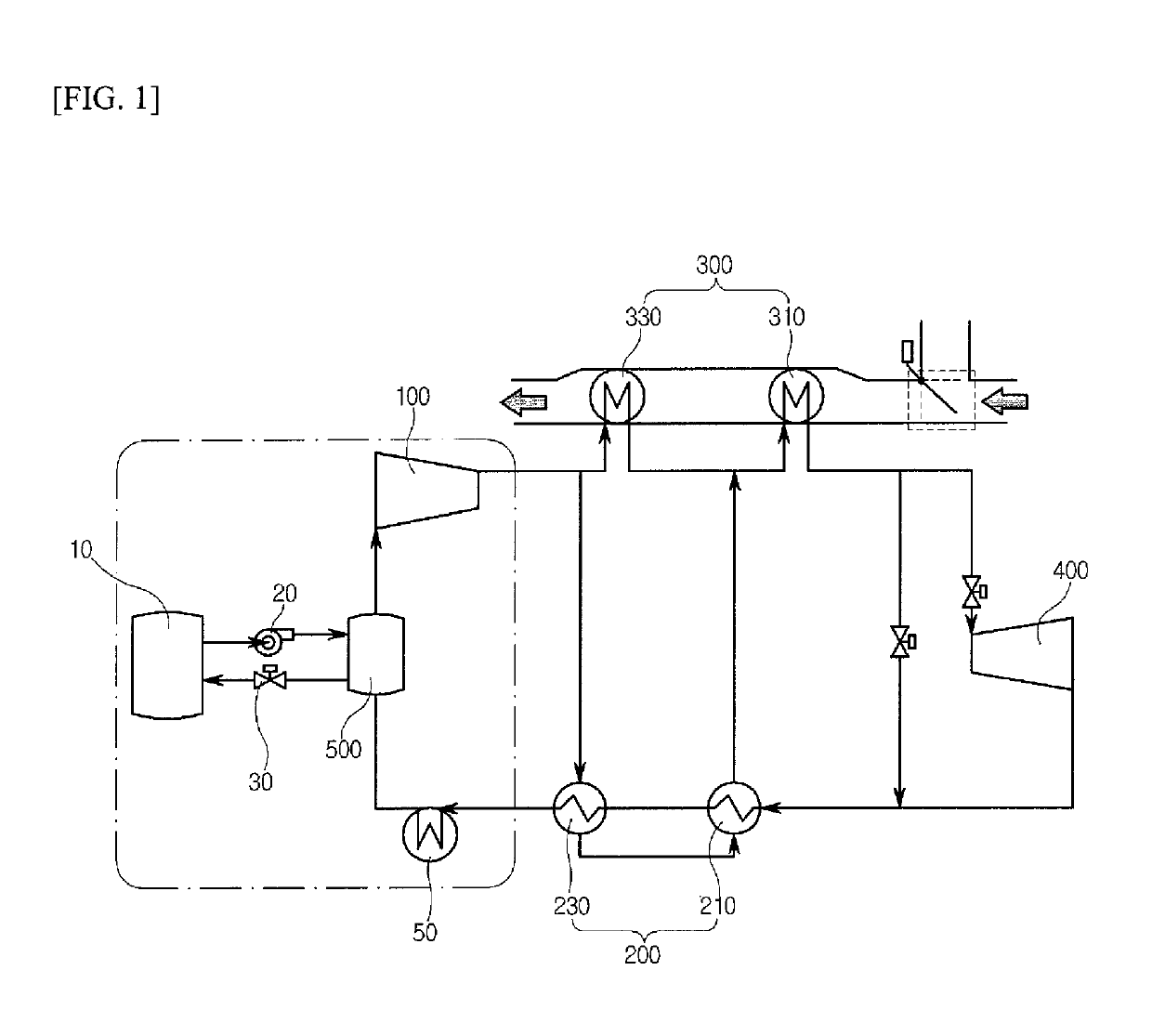

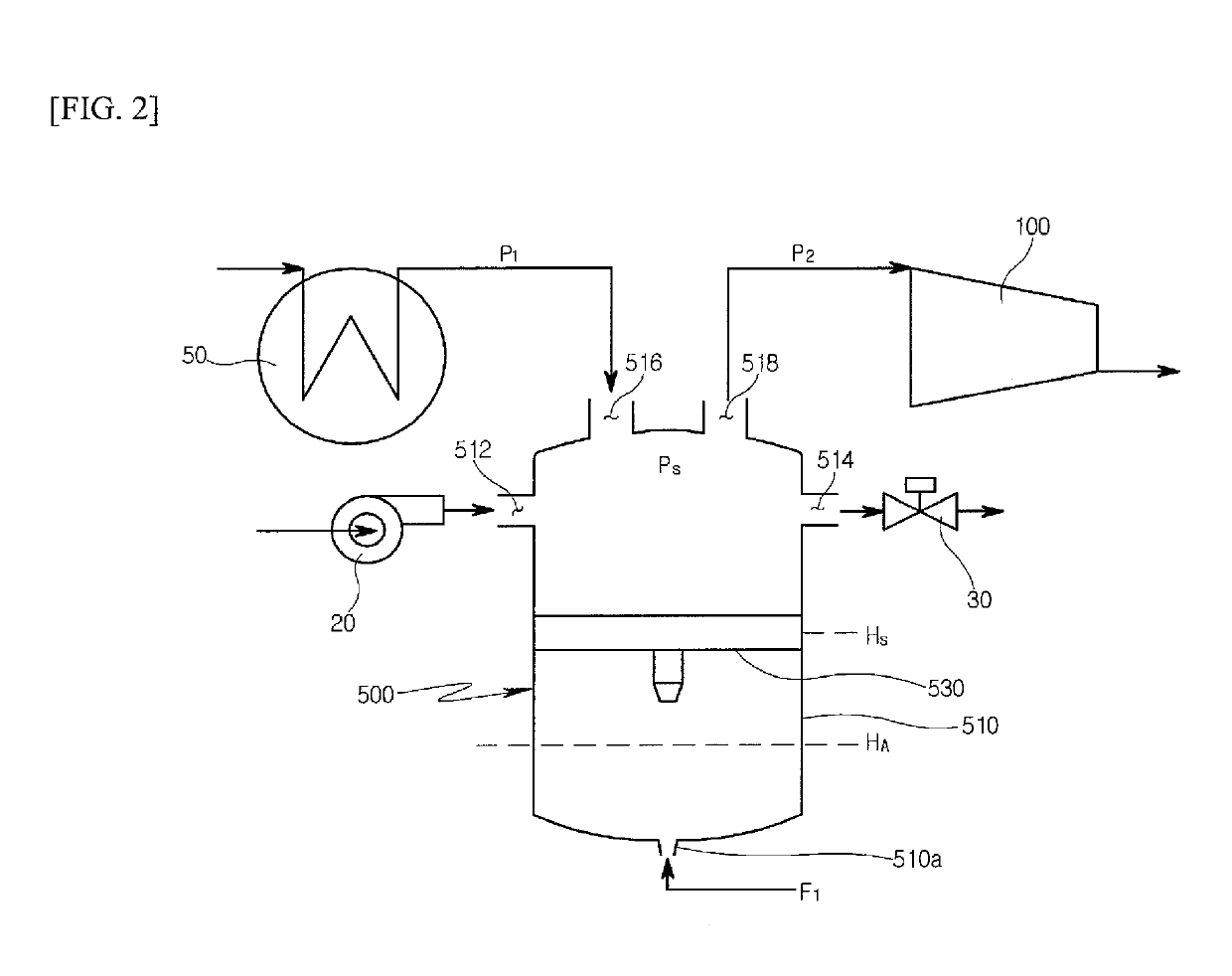

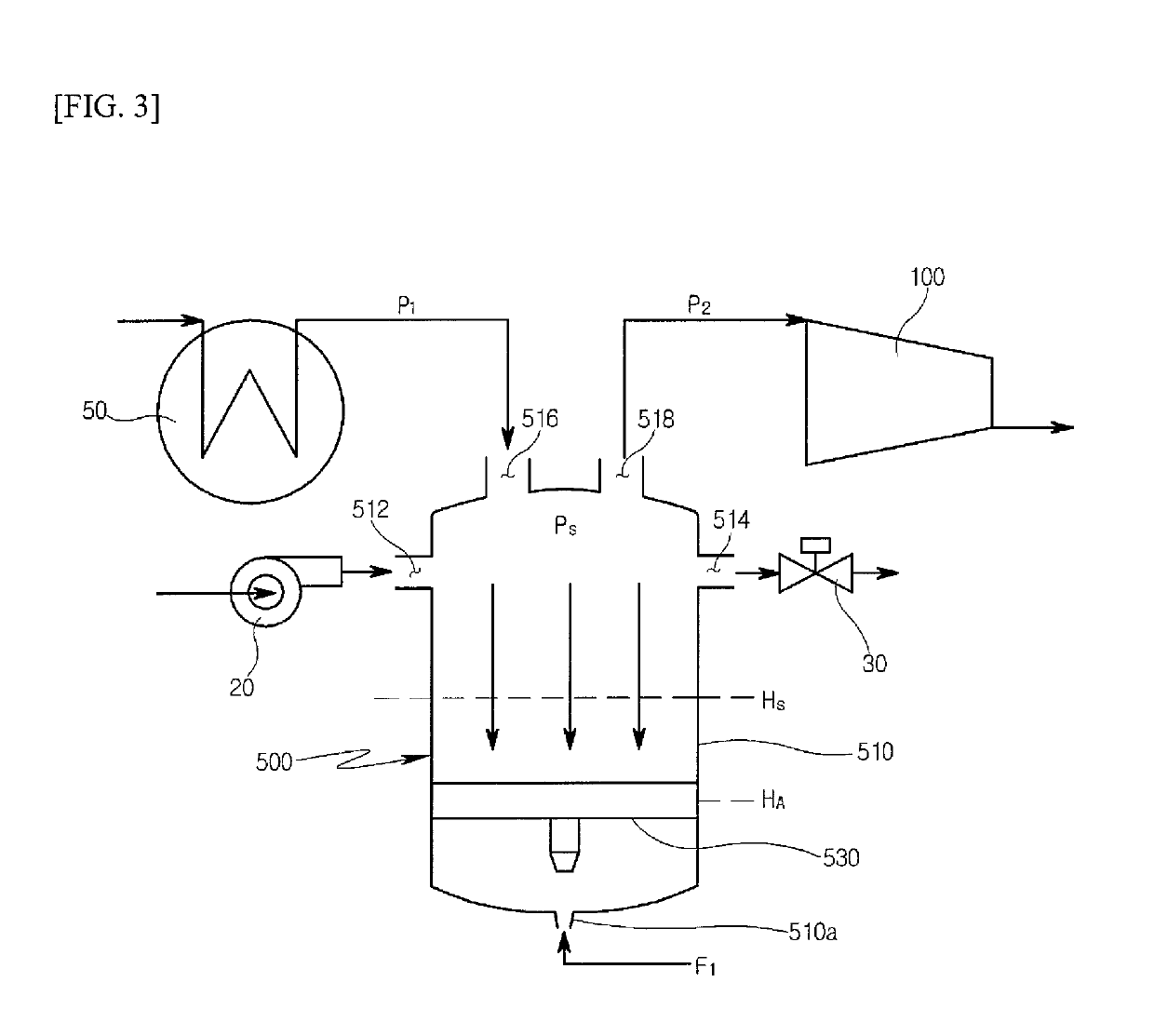

Device for controlling supply of working fluid

ActiveUS20180283222A1Efficiently and economicallySteam regenerationWater accumulatorWorking fluidProcess engineering

A device for controlling a supply of a working fluid to a power generation cycle with a compressor compressing the working fluid and a precooler cooling the working fluid supplied to the compressor comprises a storage tank storing the working fluid supplied to the power generation cycle and a flotation tank disposed between the precooler and the compressor to flow or temporarily store the working fluid, wherein a pressure within the flotation tank and a flow rate of the working fluid are controlled based on pressures at an inlet of the compressor and an outlet of the precooler.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

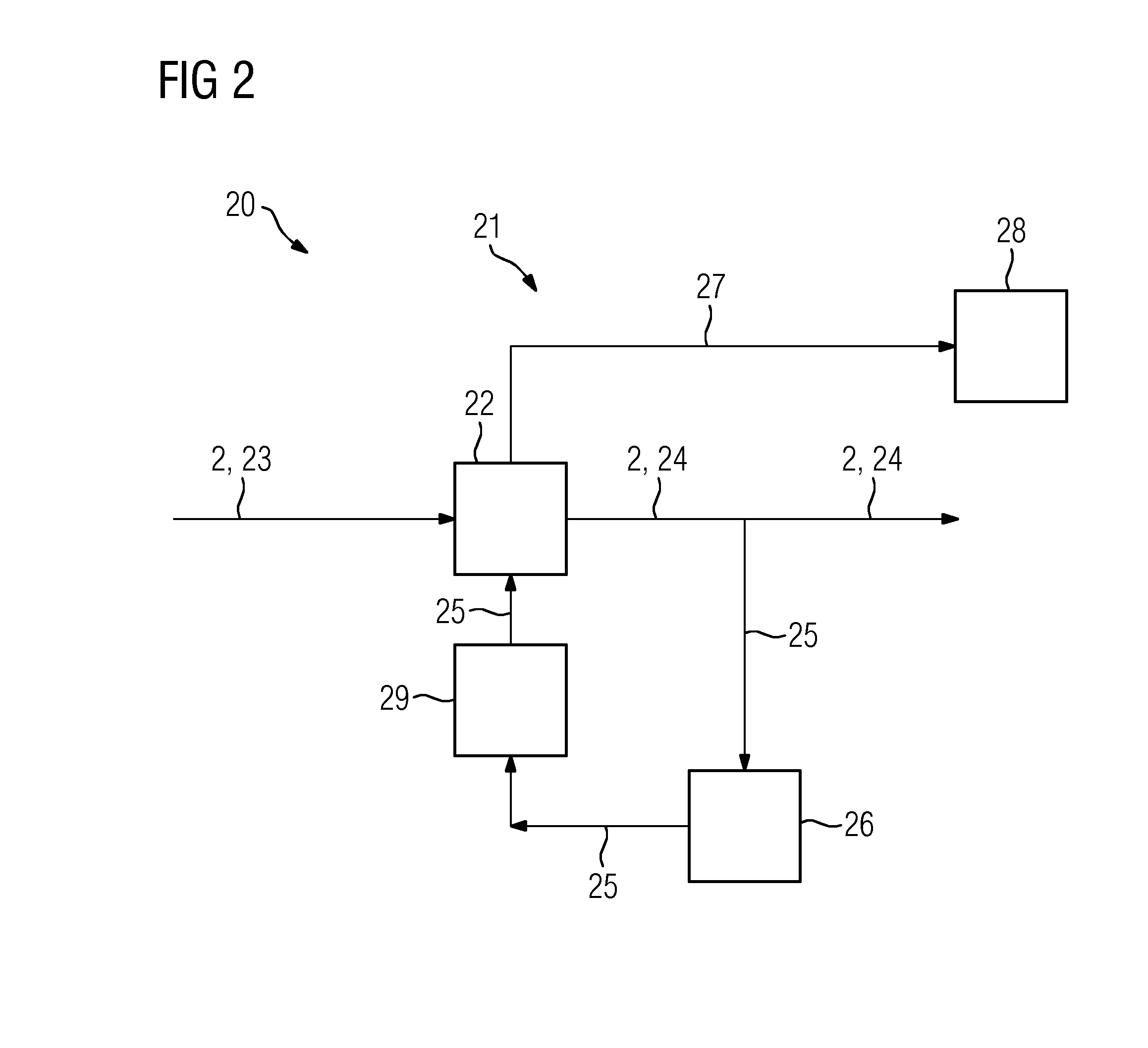

Auxiliary steam generator system for a power plant

InactiveUS20150000276A1Reduce installation costsAvoid disadvantagesAuxillary drivesFrom solar energyPower stationEngineering

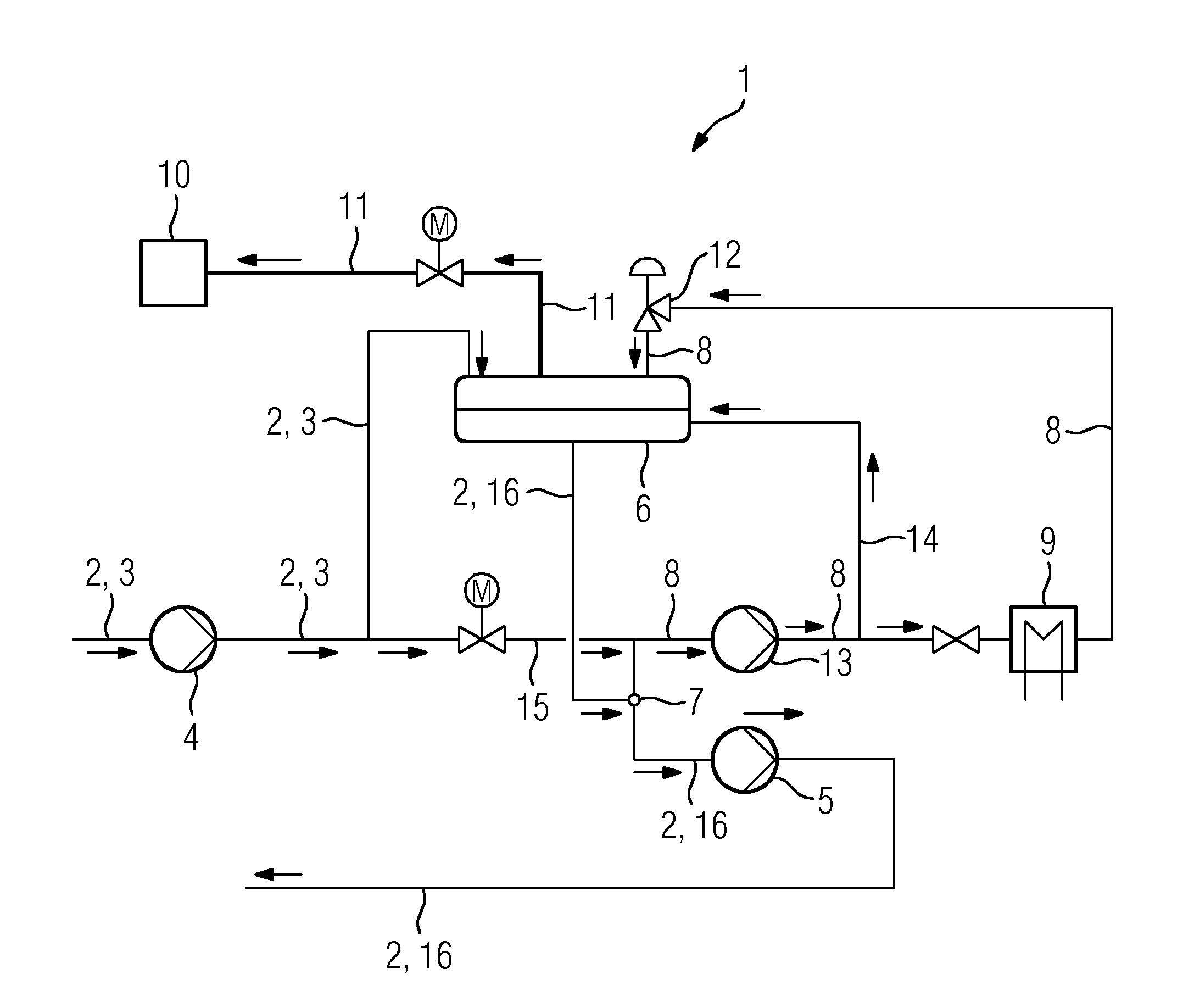

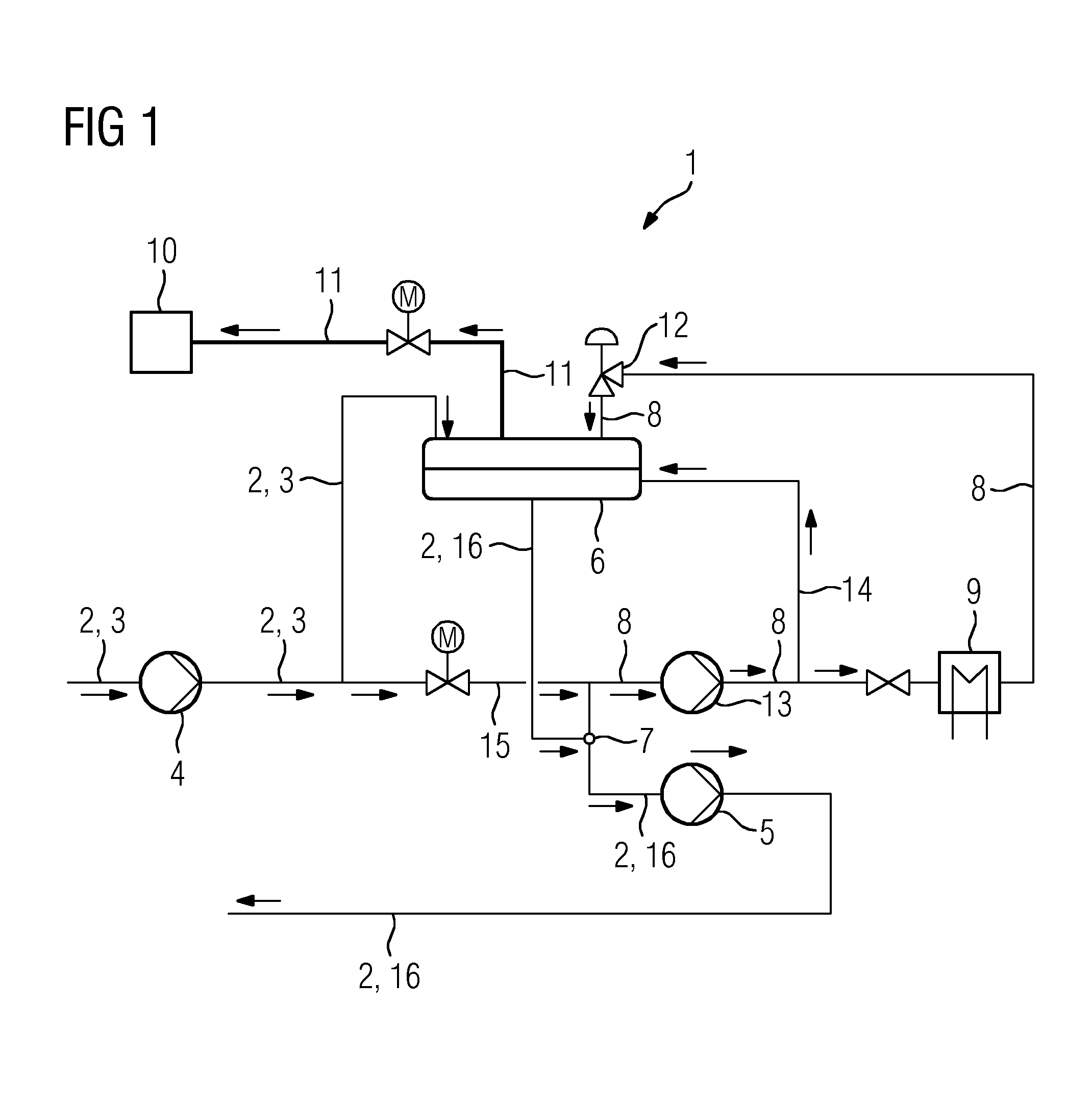

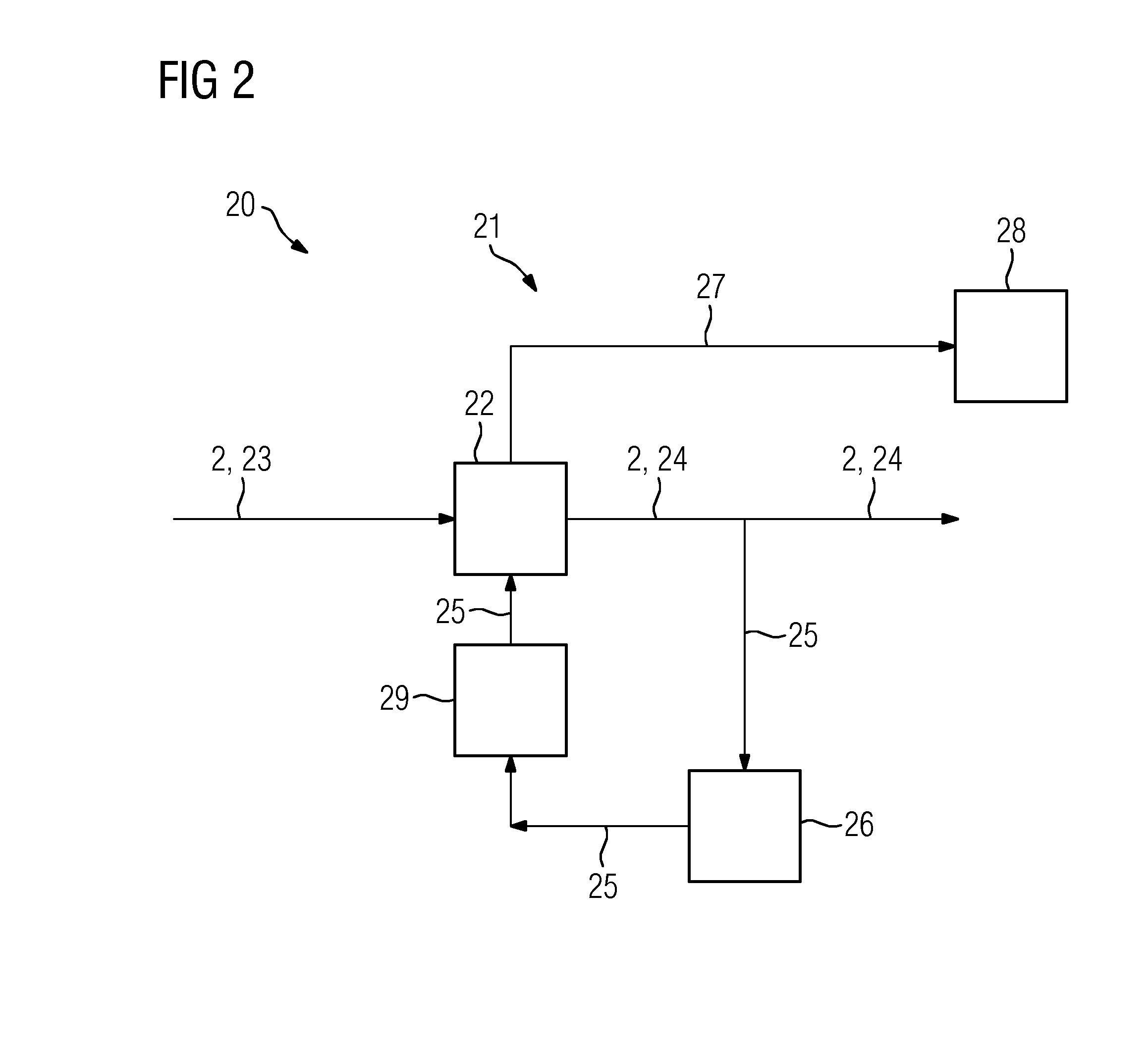

An auxiliary steam generator system for a power plant, comprising a water-steam circuit, which has a condensate line and a feed-water line, wherein a condensate pump is connected in the condensate line and a feed-water pump is connected in the feed-water line, and wherein a pressure accumulating vessel is connected between the condensate pump and the feed-water pump, and wherein a feed-water take-off line is connected to the water-steam circuit at a branch-off point after the pressure accumulating vessel is provided. The feed-water take-off line is connected to the pressure accumulating vessel and a heating device is connected in the feed-water take-off line.

Owner:SIEMENS AG

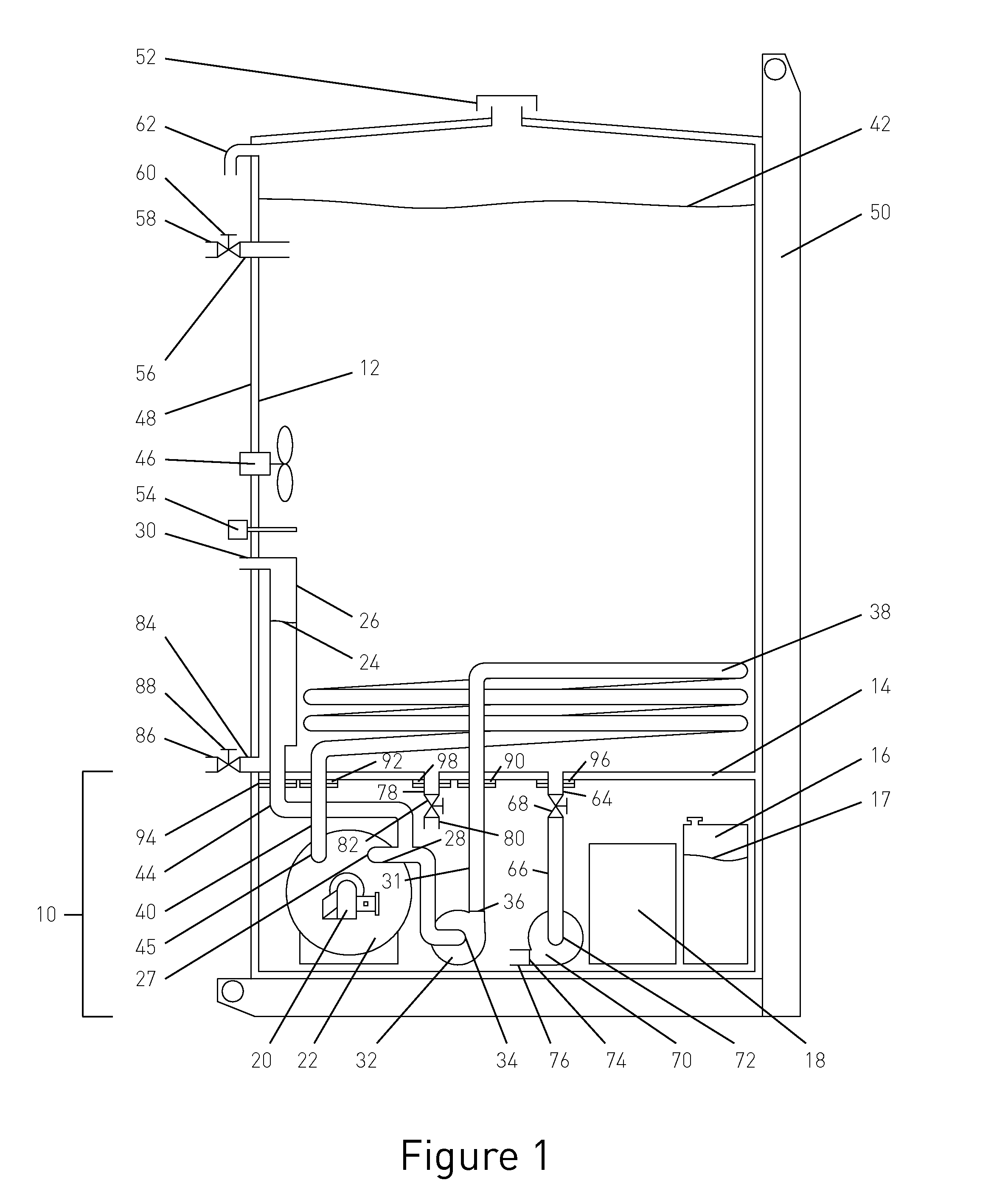

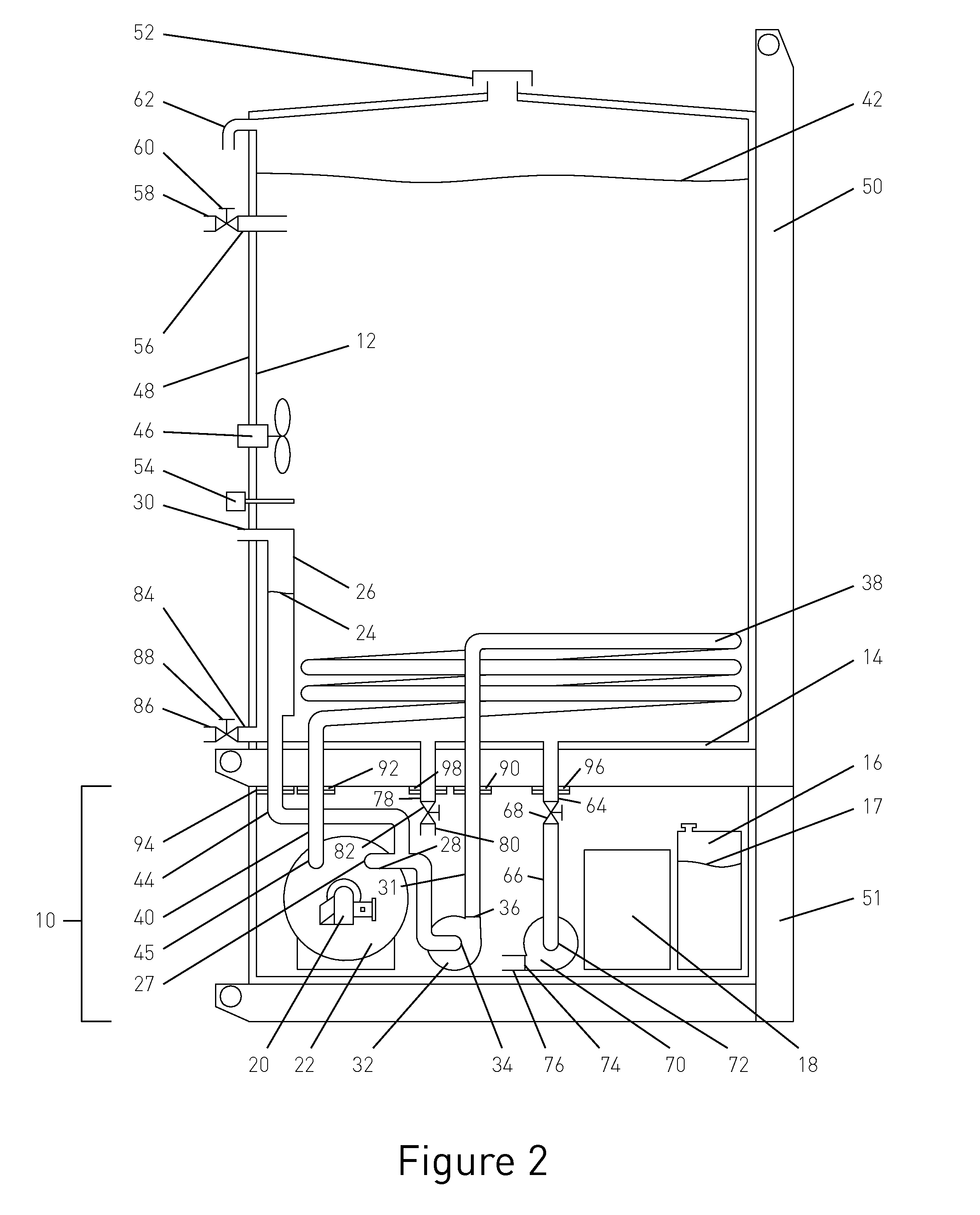

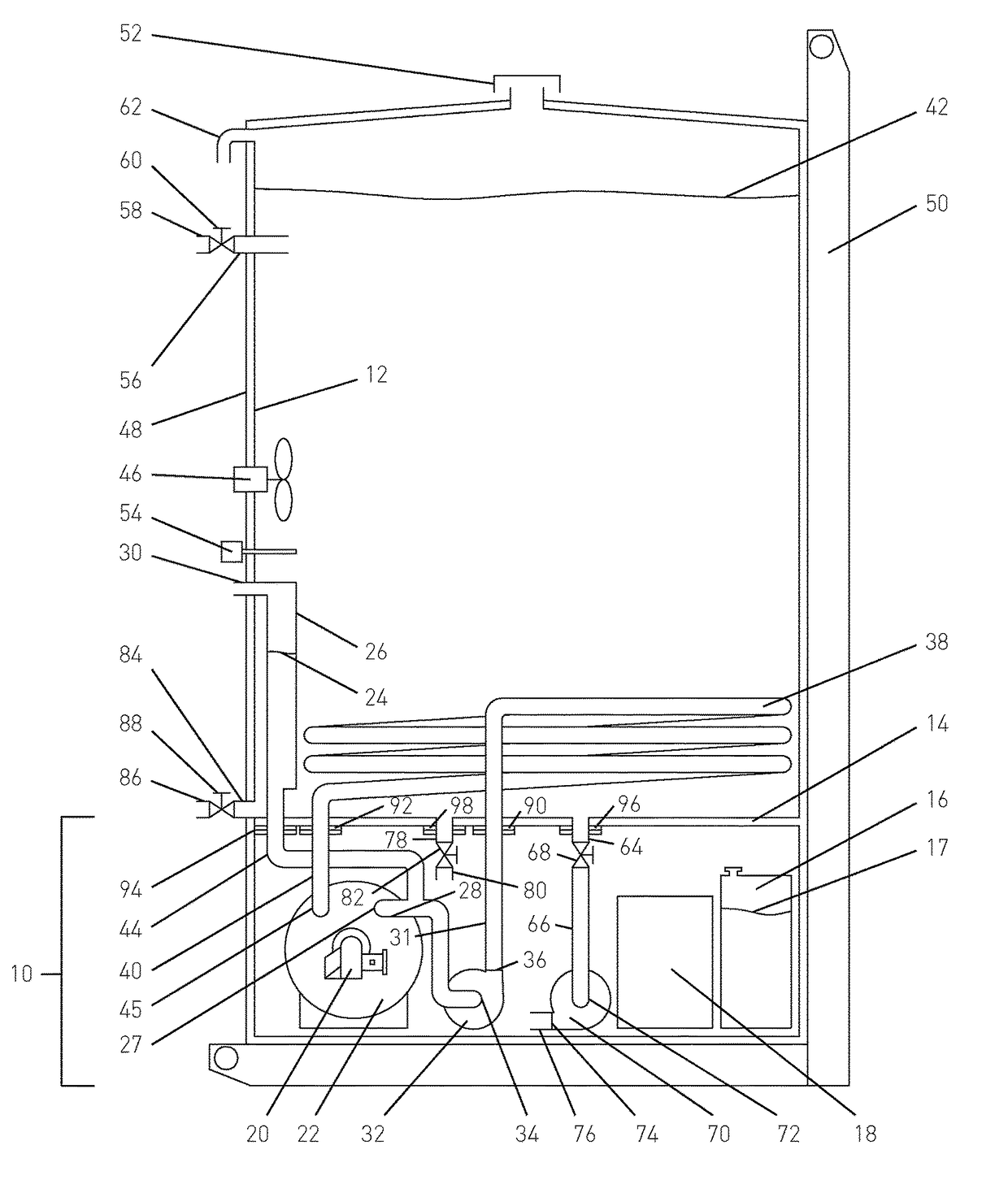

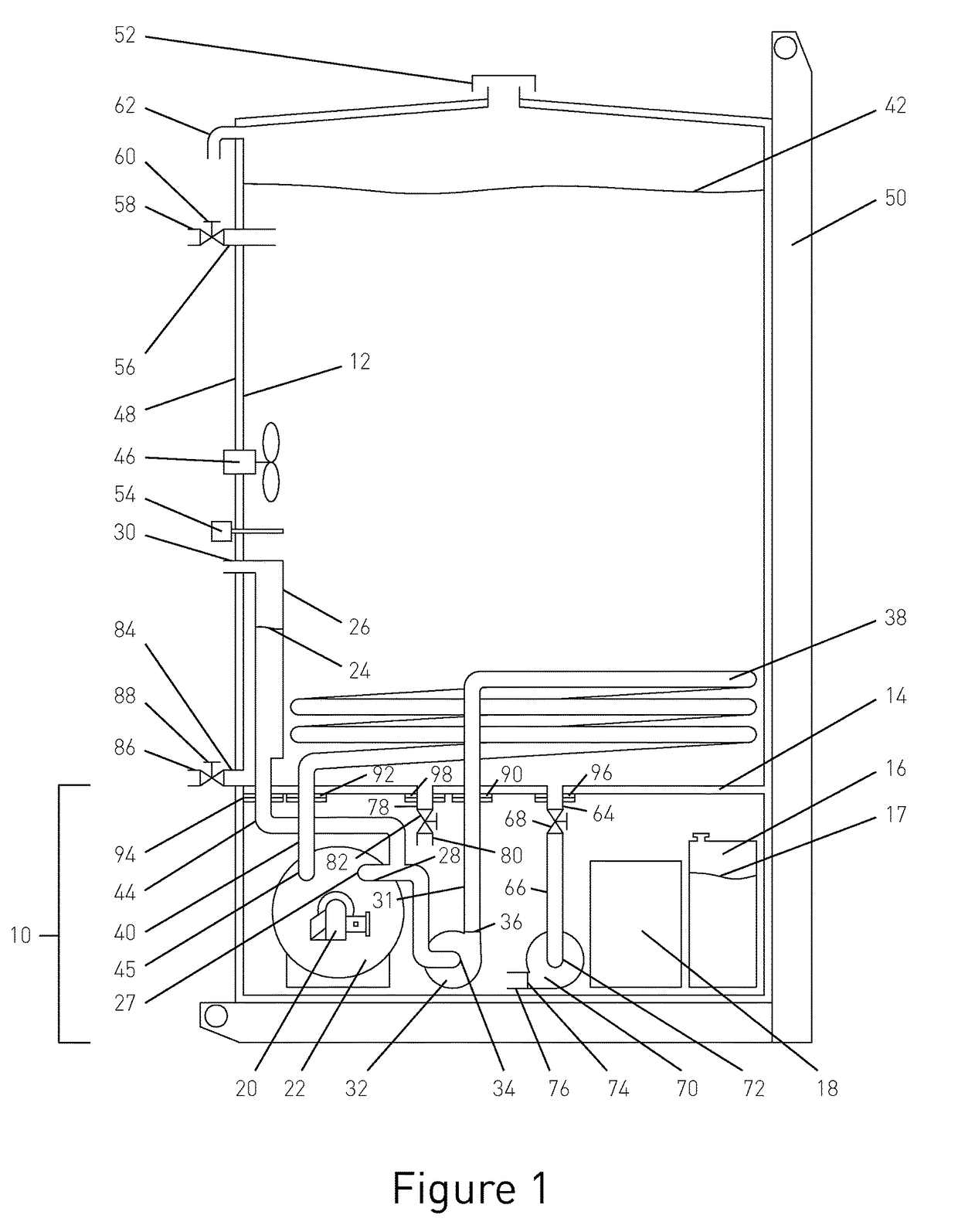

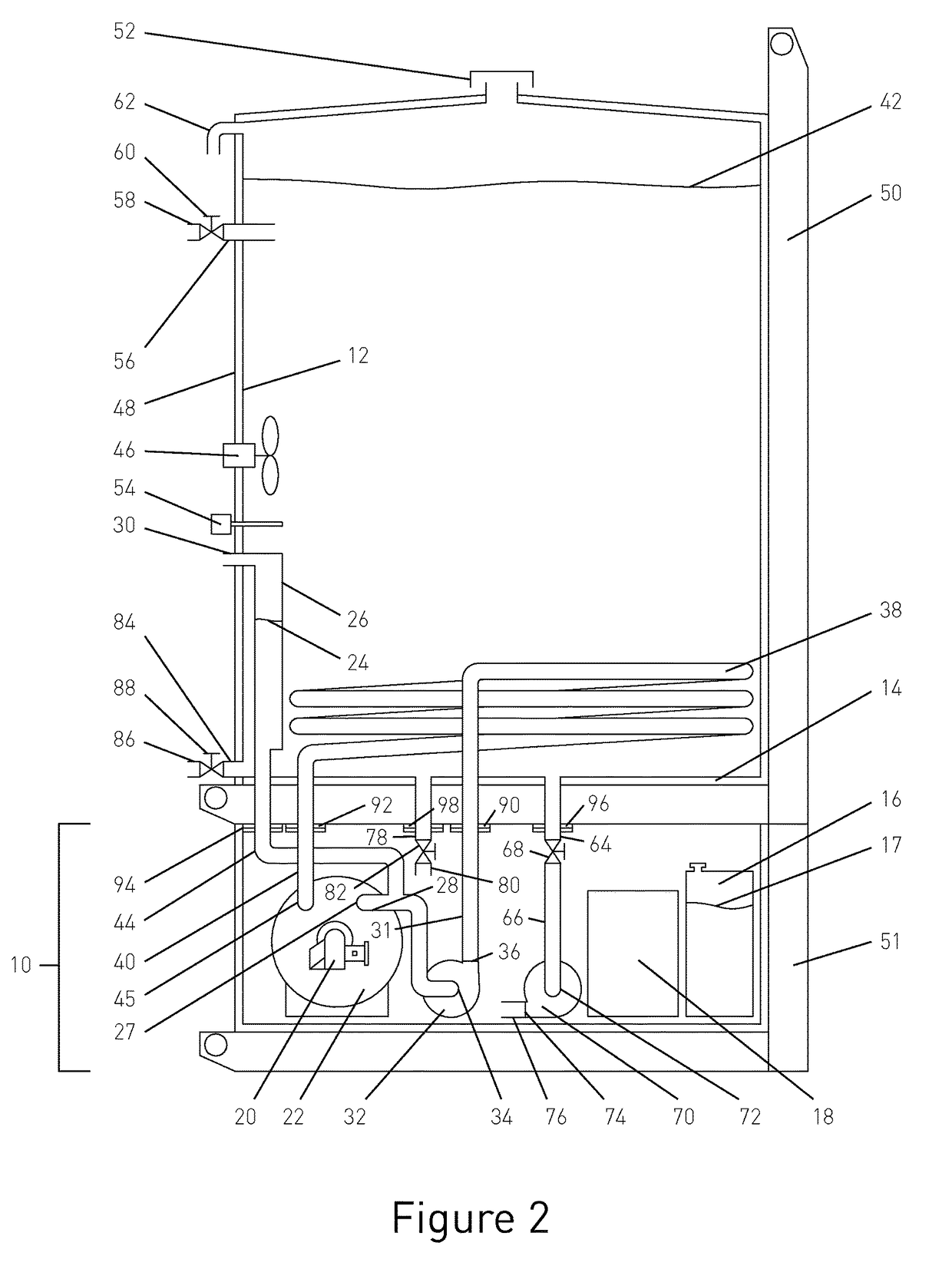

Method and Apparatus for Heating a Stored Liquid

InactiveUS20130220237A1Prevent freezingWater heatersHeat transfer modificationExpansion tankCombustor

A self-contained portable heating system to heat a stored liquid in a storage tank to a desired temperature is provided. The system can comprise operatively connected components such as a generator to power a burner that can transfer energy from a combustion product, from for example, a fuel supplied by an attached fuel tank, to a heat transfer fluid through the use of a boiler. The heat transfer fluid can transfer heat from the boiler 24 to a heat exchanger which can then transfer heat to the stored liquid in the tank. The tank can also comprise a circulating pump that can circulate the heat transfer fluid and an expansion tank that can receive the heat transfer fluid when it expands as a result of being heated. In some embodiments, the heating components can be supplied separately from storage tank so that they can be retrofit onto an existing tank.

Owner:PITYU CONTROLS INC

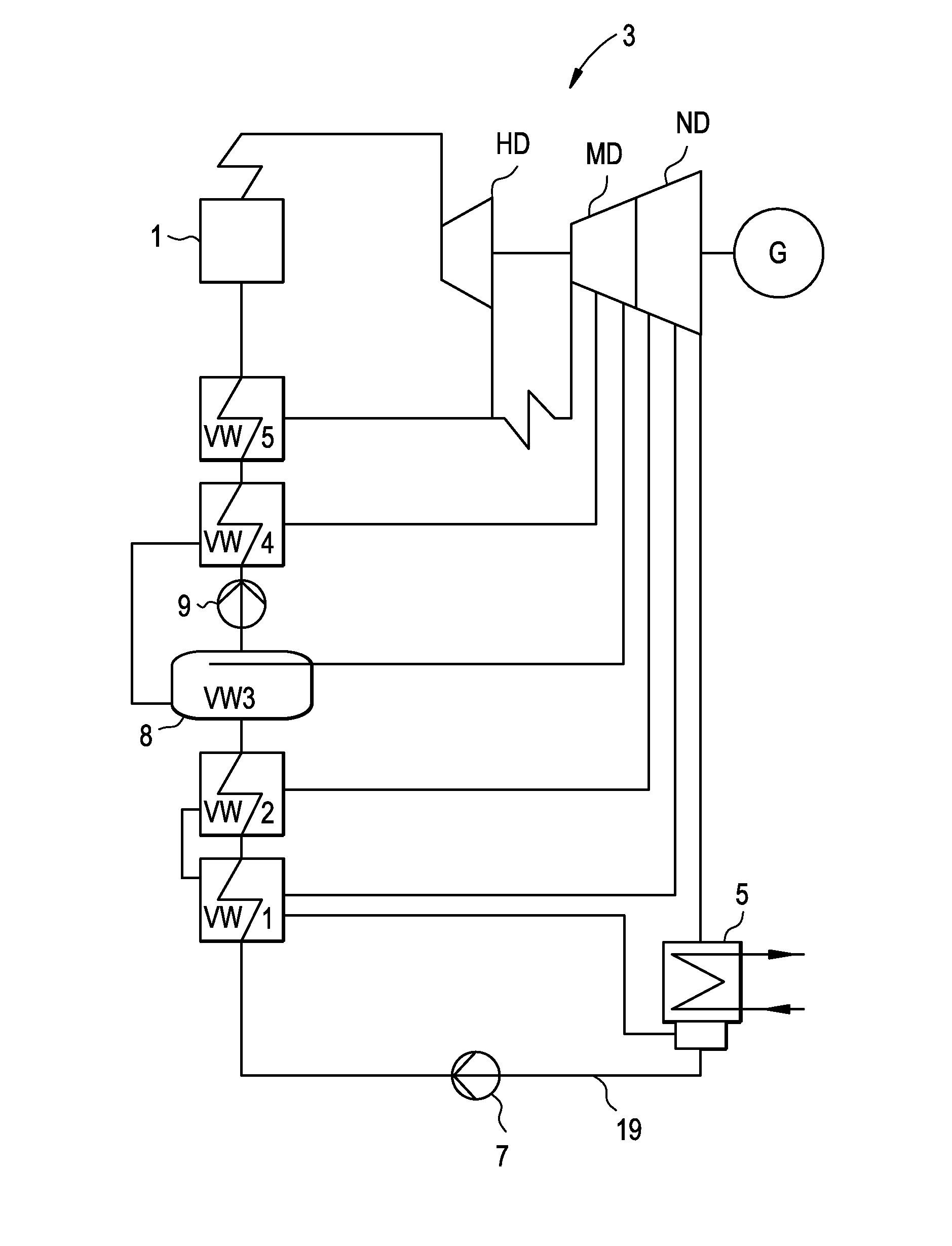

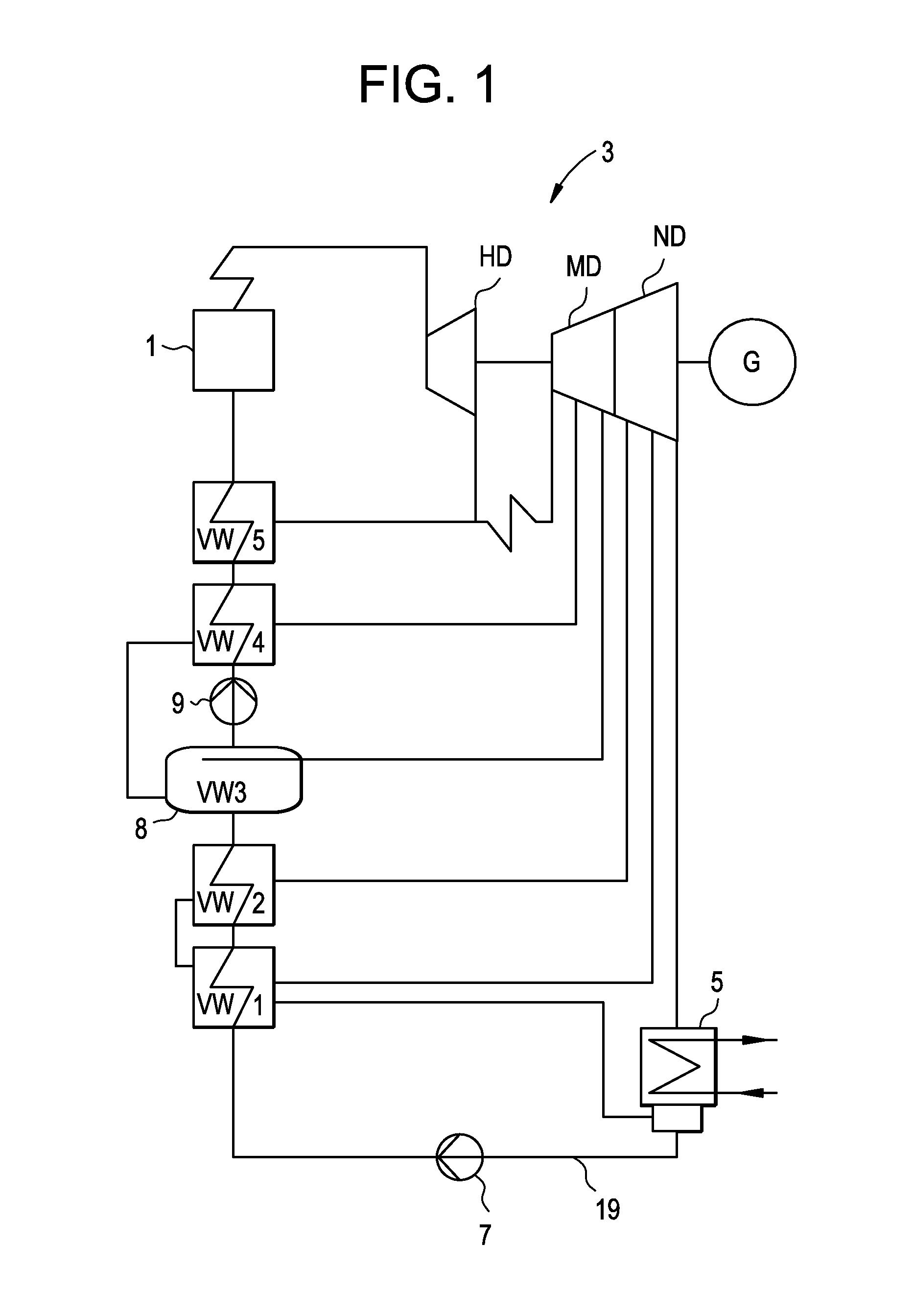

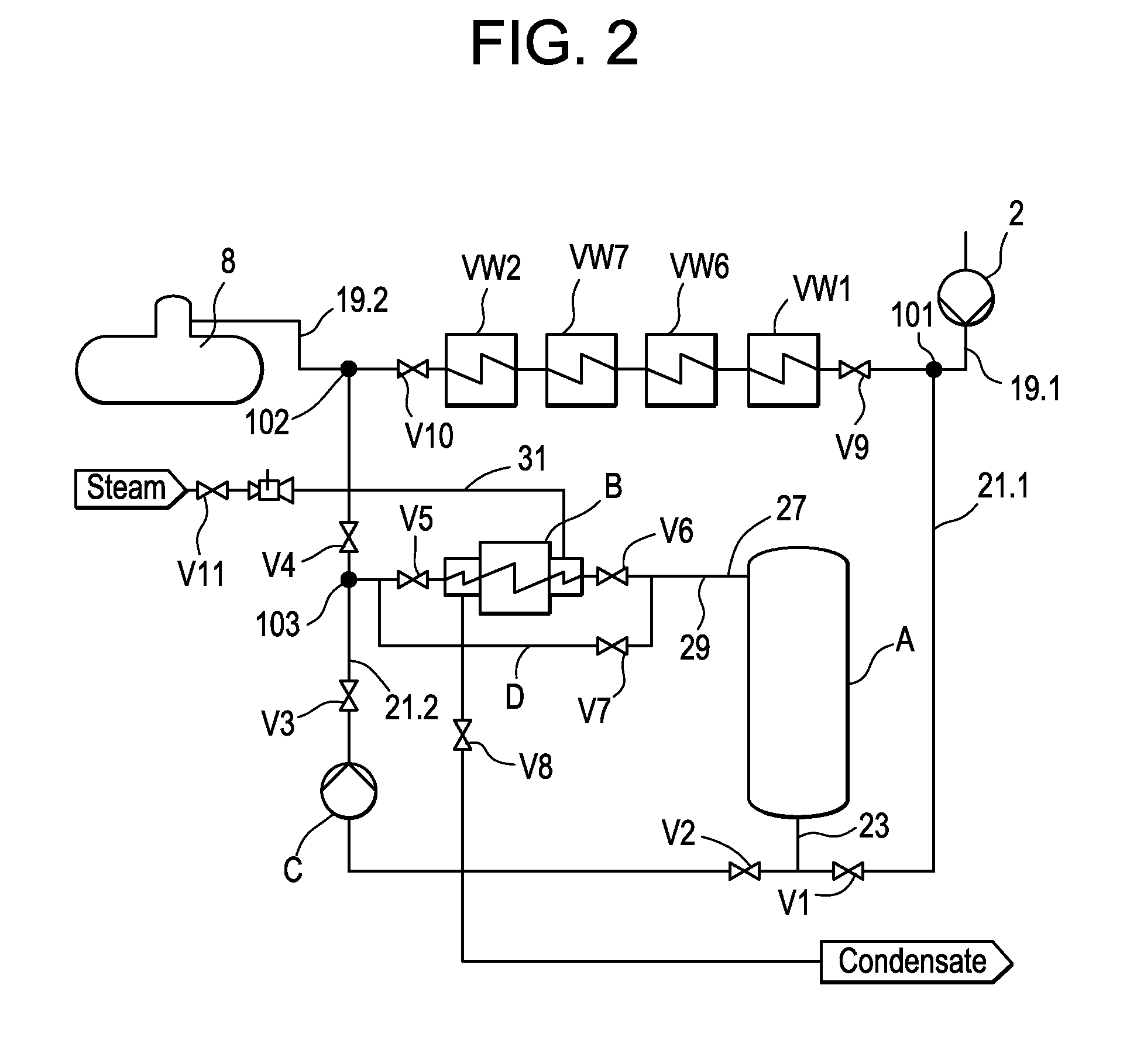

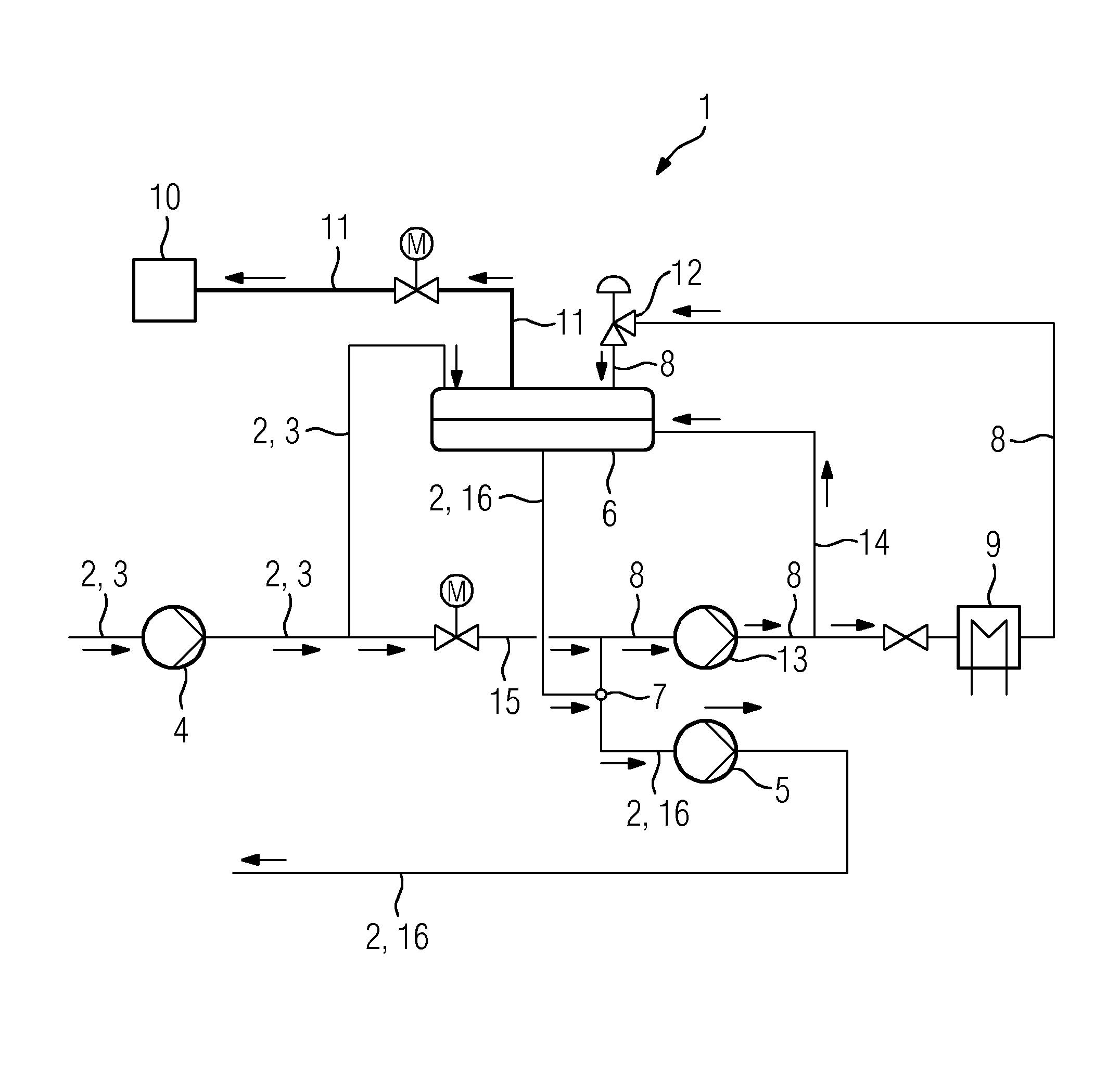

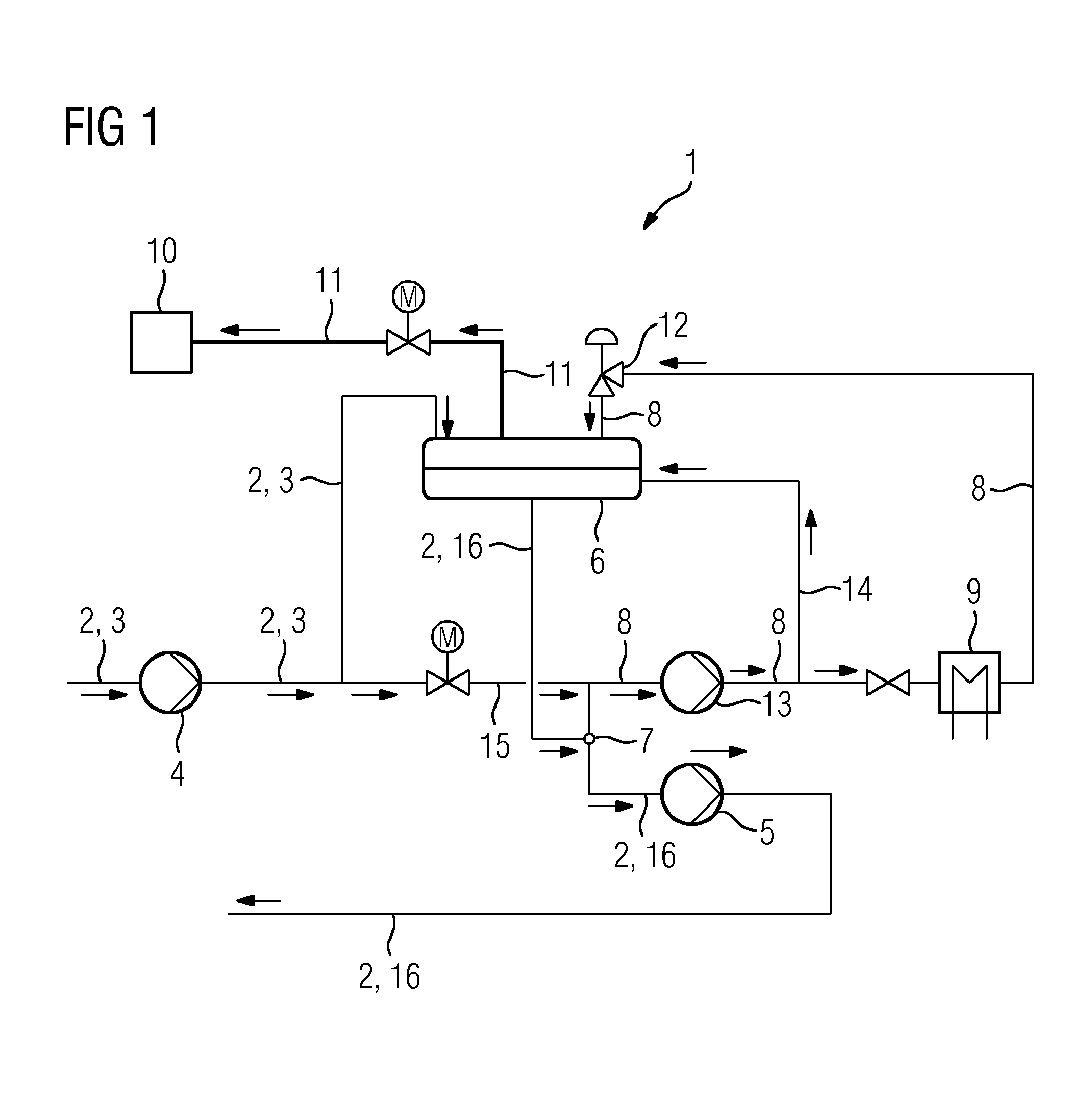

Steam power plant with heat reservoir and method for operating a steam power plant

ActiveUS20130298558A1Easy to controlSuitable solutionSteam accumulatorsSteam engine plantsPower stationLoad time

A steam power plant is suggested having, parallel to the low-pressure passage (VW1 to VW2), a heat reservoir (A) which is loaded with preheated condensate in weak-load times. This preheated condensate is taken from the heat reservoir (A) for generating peak-load and inserted downstream of the low-pressure preheater passage (VW1 to VW2) into the condensate line (19.2) resp. the feed water container (8). Thus it is possible to quickly control the power generation of the power plant in a wide range without significantly having to change the heating output of the boiler of the steam generator (1). A steam power plant equipped according to the invention can thus be operated with bigger load modifications and also provide more control energy.

Owner:GENERAL ELECTRIC TECH GMBH

Apparatus and method for heat storage and associated heat transfer and exchange for latent heat phase change

ActiveCN103890322BSteam generation heating methodsFrom solar energyThermal energy storageEngineering

The present invention, in various embodiments, discloses a method of phase change and heat exchange between heat collection, heat transport, heat exchange, heat storage, and heat application systems. In a specific embodiment, the heat transfer fluid / heat exchange fluid, heat storage medium, and working medium in the system are all phase-change materials whose transition temperatures are close to each other, and they are arranged in descending order and within a relatively narrow temperature range They perform their respective functions by undergoing phase transitions. The present invention also provides methods for arbitrary control of the rate of heat transfer, heat exchange, and / or charge / discharge rates between heat collection, thermal energy storage, and heat application devices. The invention also provides a method of controlling such a system.

Owner:BLUELAGOON TECH

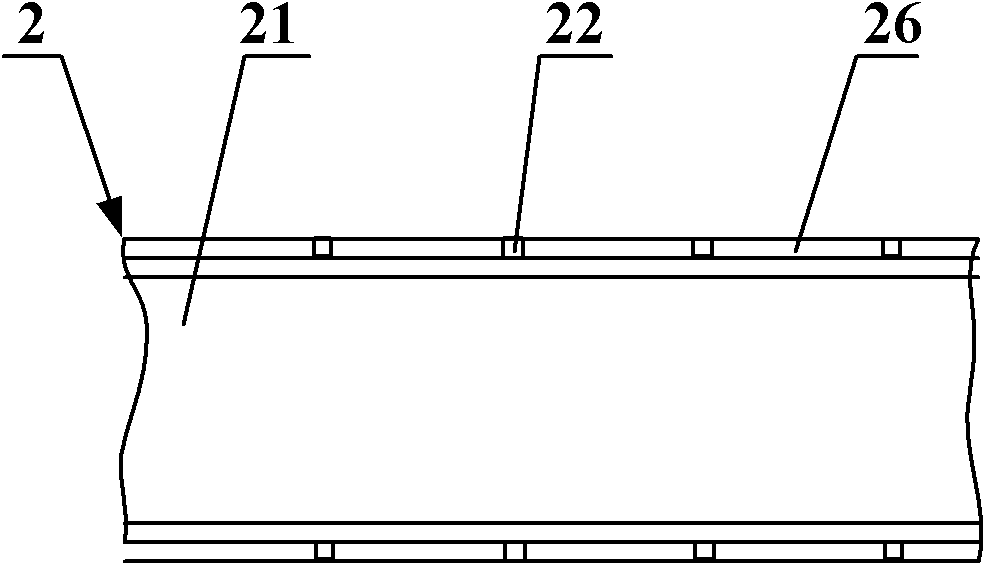

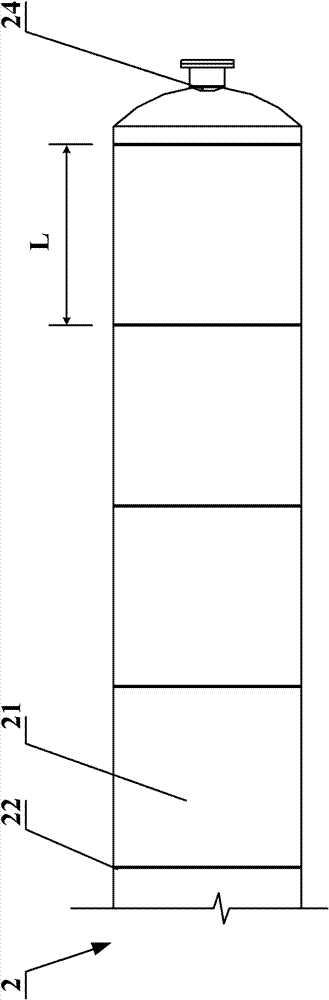

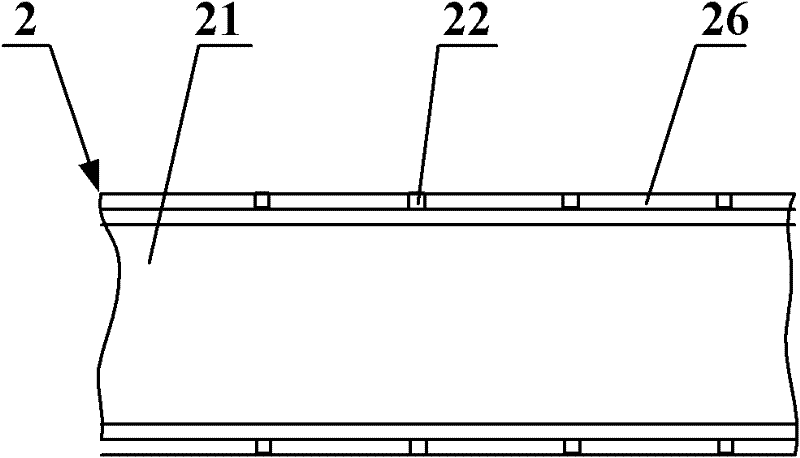

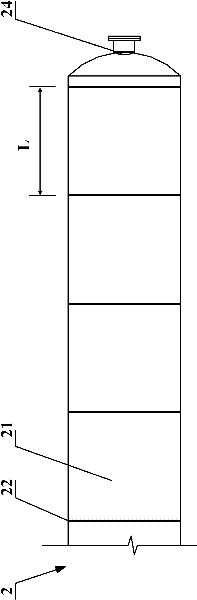

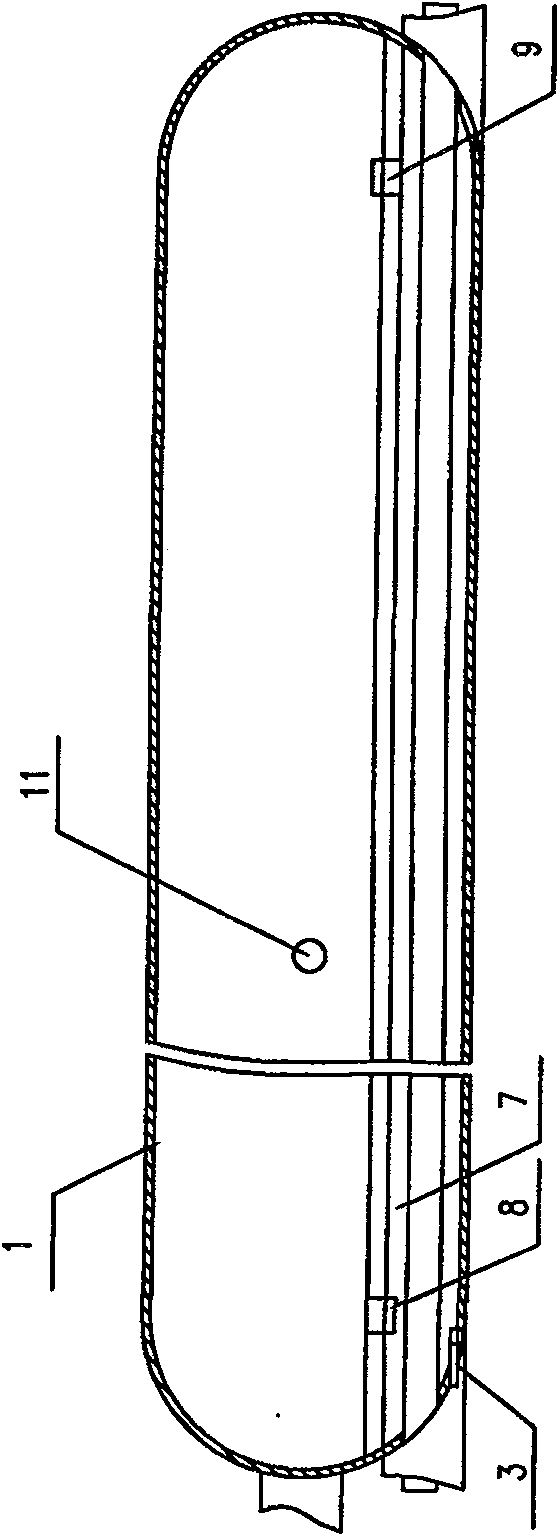

Steam heat accumulator and method for fixing thermal insulating layer thereof

InactiveCN102261645BGuaranteed insulation effectSmoothly fixedThermal insulationPipe protection by thermal insulationThermal insulationEngineering

An embodiment of the invention discloses a steam heat accumulator comprising a tank body, wherein a thermal insulating layer is arranged on the tank body; a plurality of hoops, end rings, longitudinal braces and radial braces are further arranged between the thermal insulating layer and the tank body; the end rings are arranged at the end portions of the tank body; the hoops are arranged on the tank body; the longitudinal braces are arranged between adjacent hoops; each radial brace is arranged between one end ring and the hoop adjacent to the end ring; and the thermal insulating layer is fixed to the longitudinal braces and the radial braces. In the embodiment of the invention, the thermal insulating layer can be smoothly fixed to the steam heat accumulator by means of the hoops arrangedon the tank body of the steam heat accumulator; and the thermal insulating layer is not needed to be welded on the outer surface of the steam heat accumulator by way of fixing using the hoops; therefore, the thermal insulation performance of the steam heat accumulator in the embodiment of the invention can be ensured.

Owner:SICHUAN DAZHOU IRON & STEEL GROUP

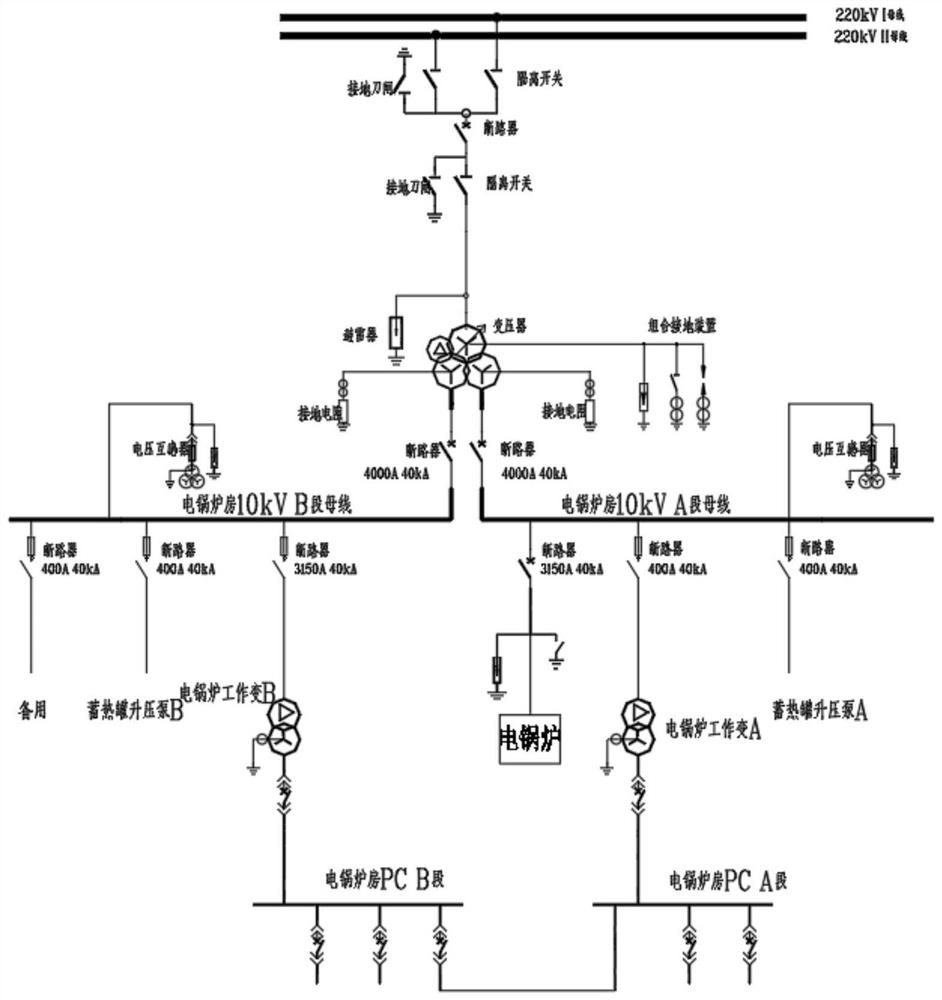

Electric thermal storage preheating steam generator

PendingCN108506914ARealize cascade heatingSolve the problem of energy consumptionSteam generation heating methodsWater accumulatorElectricityEngineering

The invention discloses an electric thermal storage preheating steam generator. The electric thermal storage preheating steam generator comprises a thermal storage open type water tank. A water outletof the thermal storage open type water tank is connected with a suction inlet of a pressure pump. An outlet of the pressure pump is connected with a water inlet of a heating pressure-bearing water pot. A heating device and a second temperature sensor are arranged inside the thermal storage open type water tank. A first electric heater, a liquid level sensor, a pressure sensor and a first temperature sensor are arranged inside the heating pressure-bearing water pot. A safety valve and a steam outlet are arranged on the top of the heating pressure-bearing water pot. The electric thermal storagepreheating steam generator can preheat water with low-price electricity at the periods of valley electricity at night and common-price electricity during daytime, steam is generated through preheatedhot water when steam is needed for use, the electrical load during steam generation is decreased, the operating cost of a system is reduced then, and the electrical load of the system is decreased aswell.

Owner:中建环能建筑工程有限公司

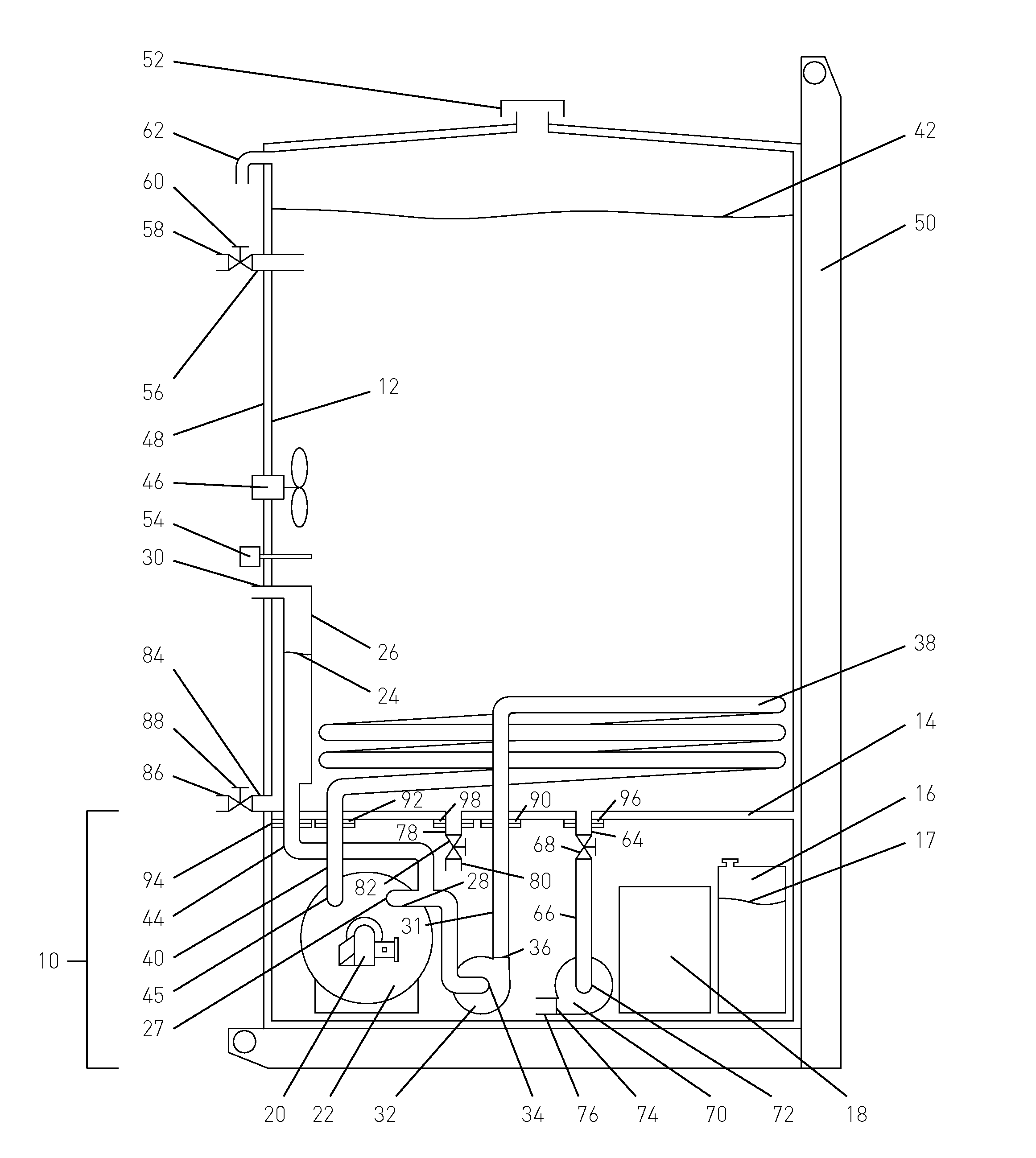

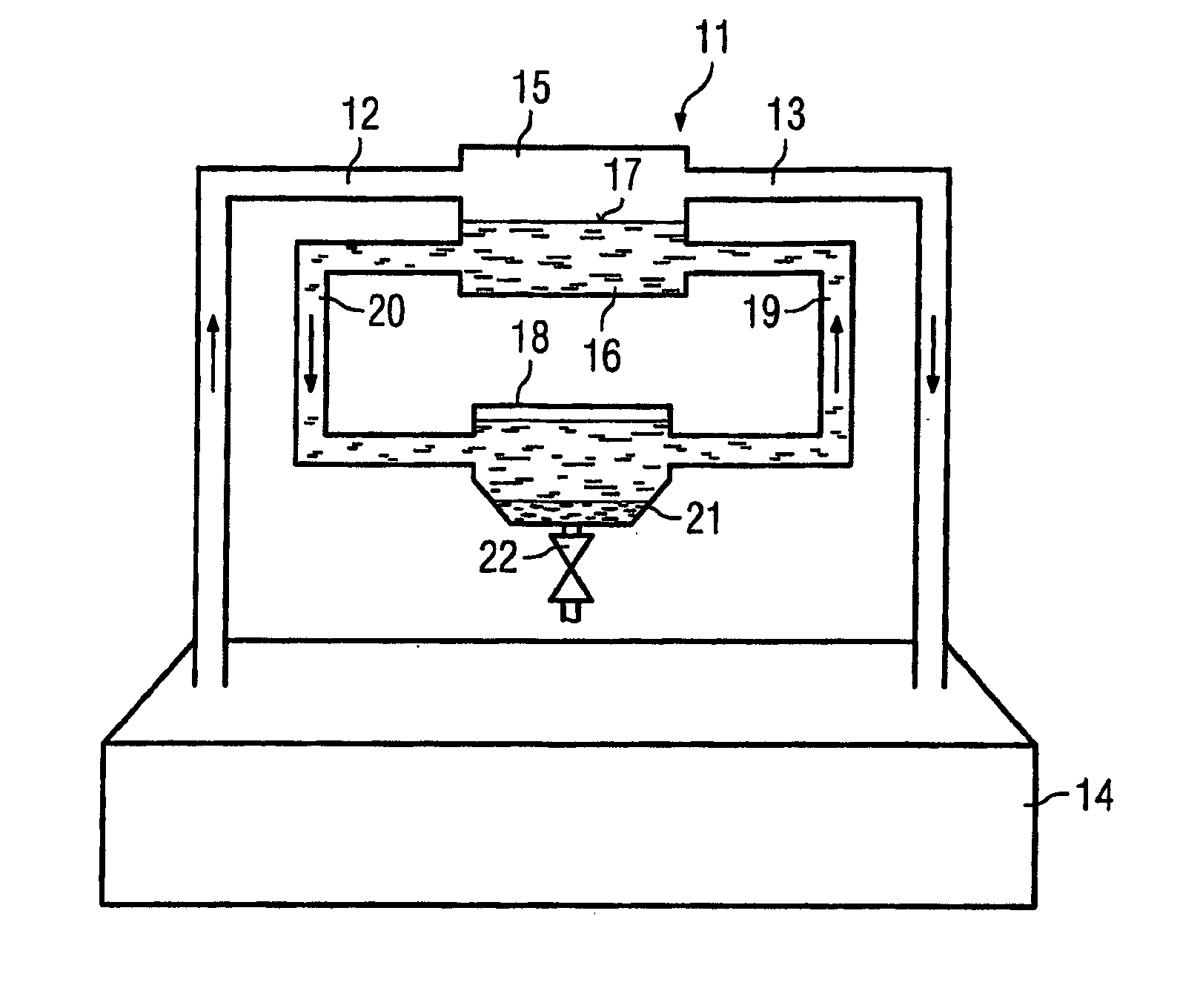

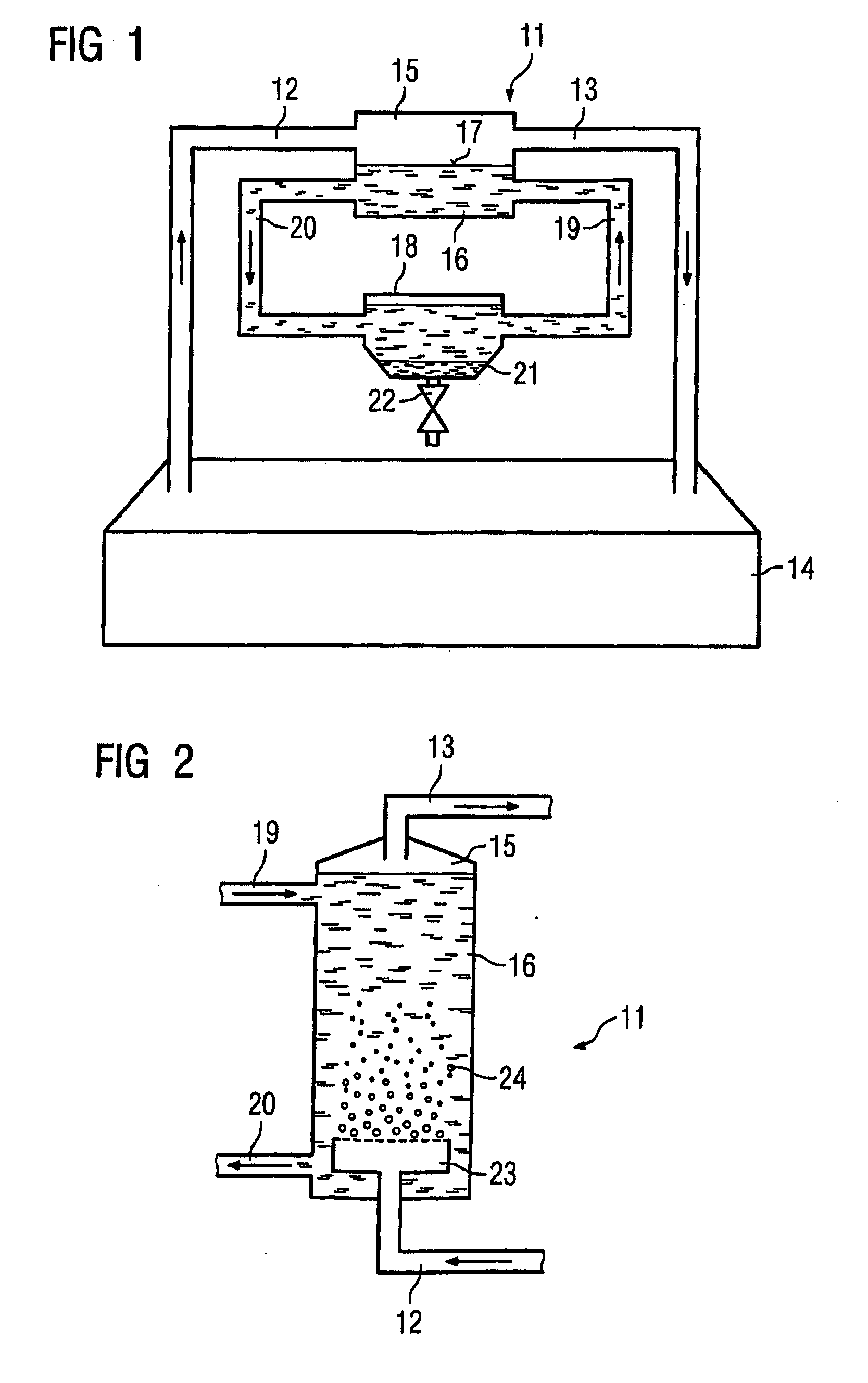

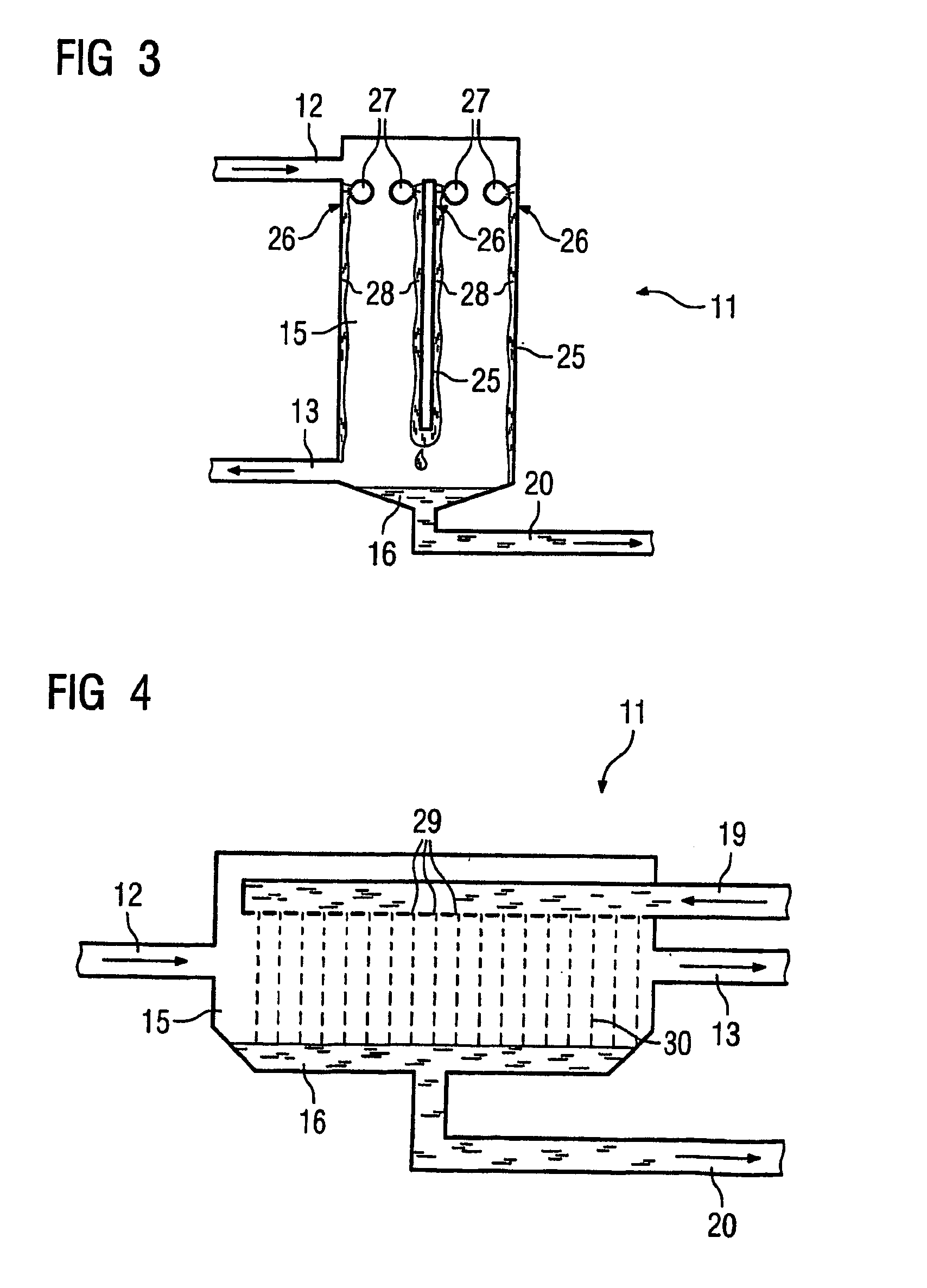

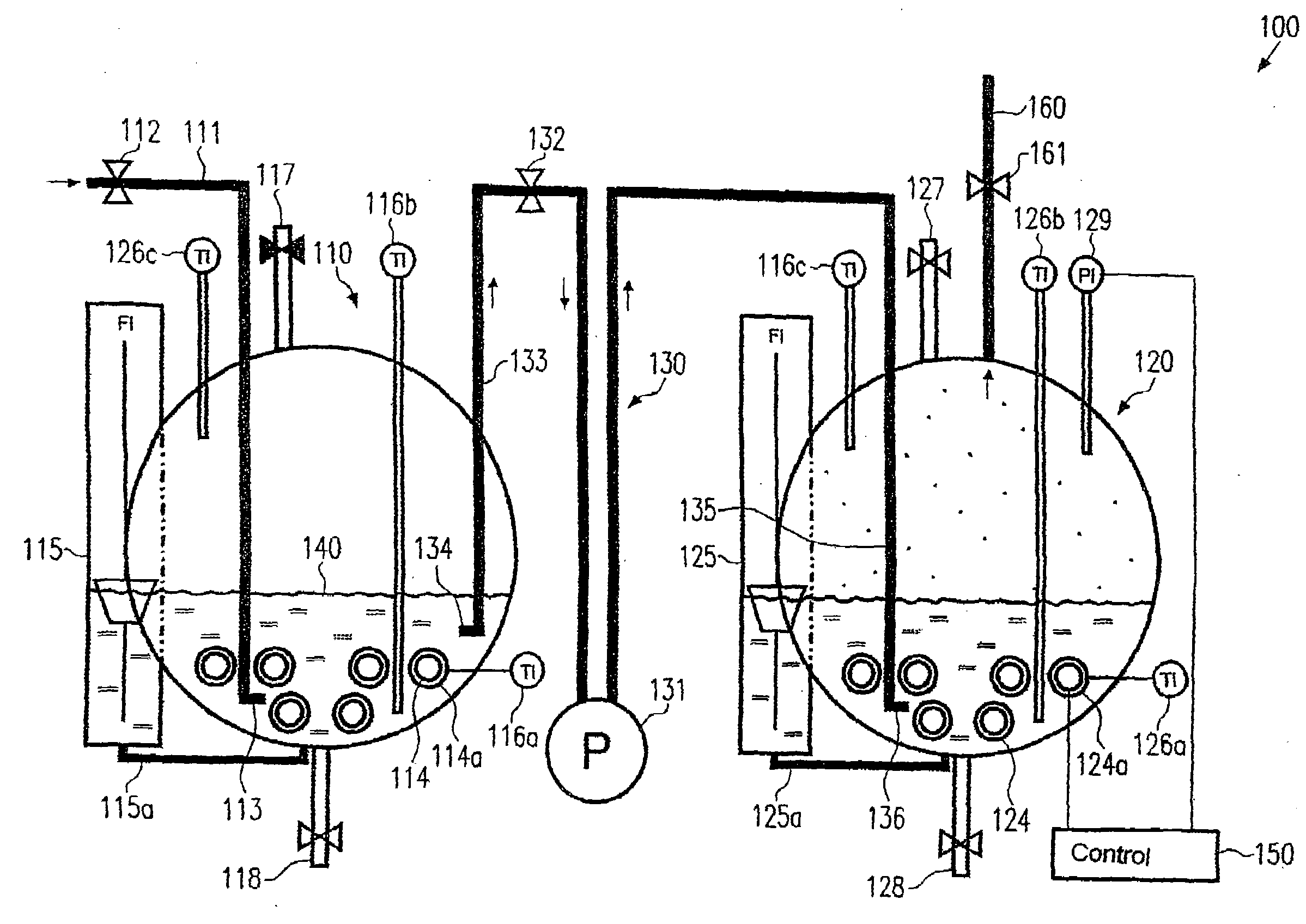

Vapor-operated soldering system and vapor generation system for a soldering system

InactiveUS20050242163A1Automatic control devicesPrecision positioning equipmentEvaporationProcess engineering

Thermodynamic fluctuations caused conventionally during introduction of a relatively cold liquid into the vapor generator can be reduced considerably or eliminated by providing a preheating region, so that the necessary amount of vapor can be provided in a substantially continuous manner. Vapor generation can here be controlled on the basis of the vapor pressure in the evaporation region, wherein advantageously during operation of a soldering system the pressure in the corresponding process chamber can also be used for control in such a manner that there is always a pressure gradient and additional conveying means, such as pumps for the vapor supply, can thereby be avoided.

Owner:REHM THERMAL SYST

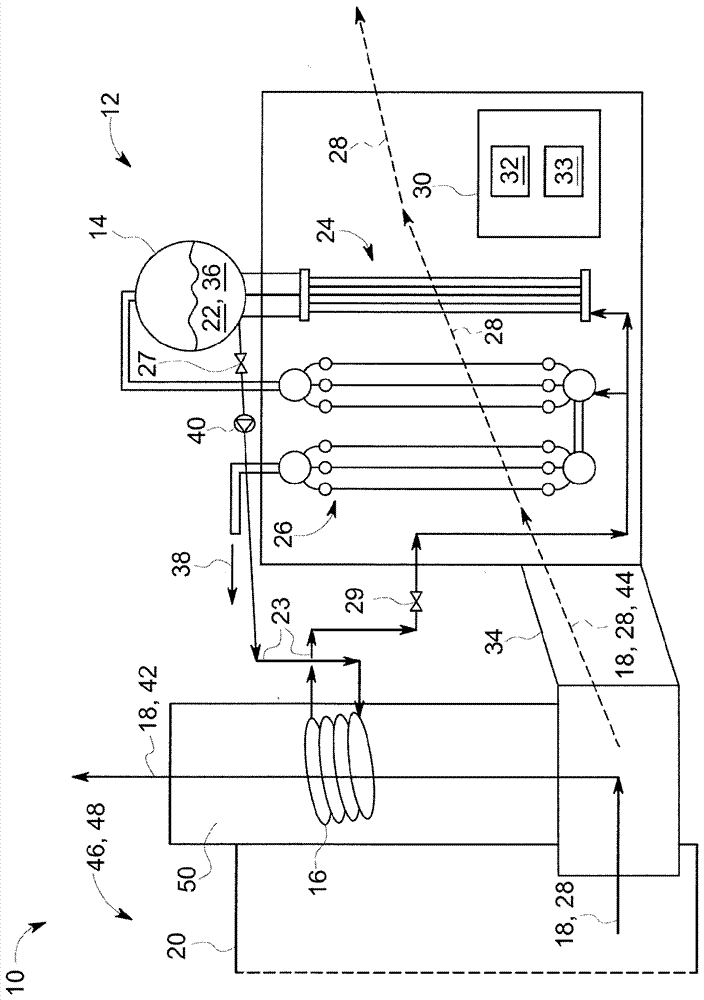

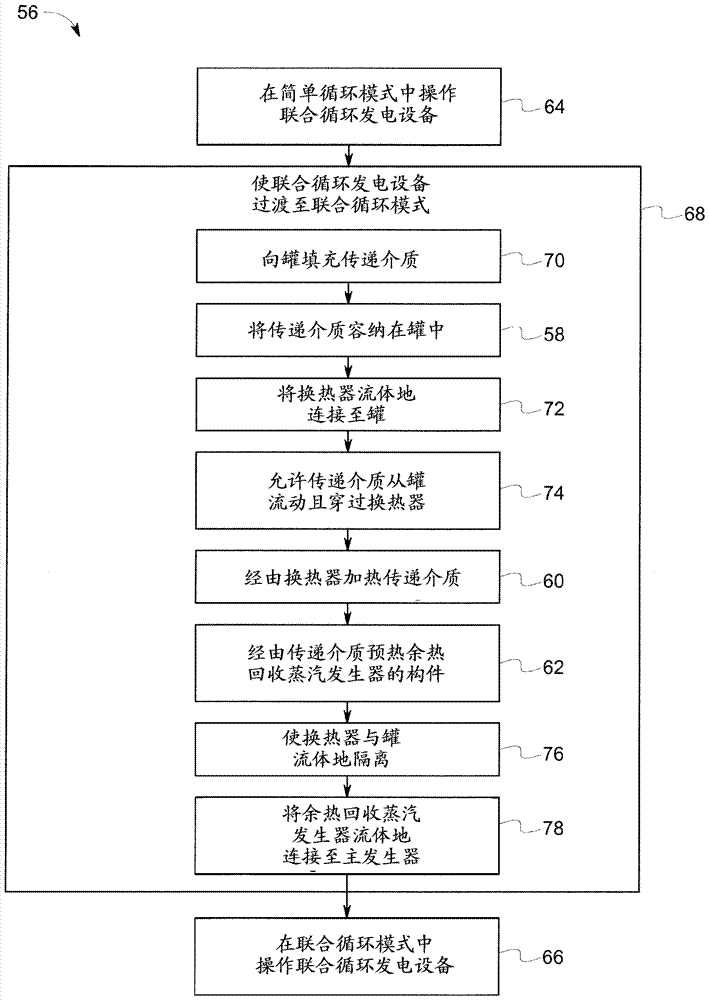

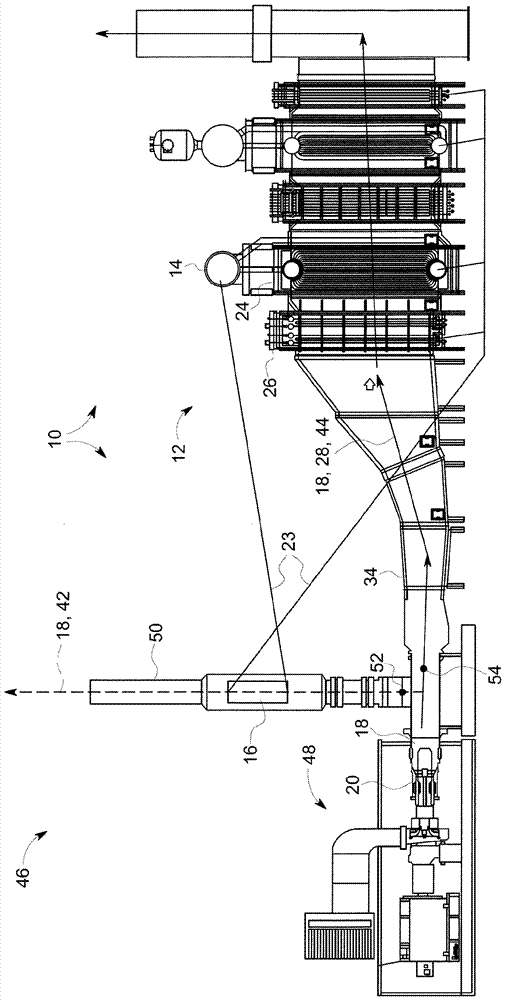

System and method for preheating a heat recovery steam generator

A system for preheating a heat recovery steam generator is provided. The system includes a tank and a heat exchanger. The tank contains a transferring medium. The heat exchanger is disposed in a flow path of a flue gas produced by a combustion chamber, and is fluidly connected to the tank such that the transferring medium flows through the heat exchanger and is heated by the flue gas. The transferring medium preheats one or more components of the heat recovery steam generator.

Owner:GENERAL ELECTRIC TECH GMBH

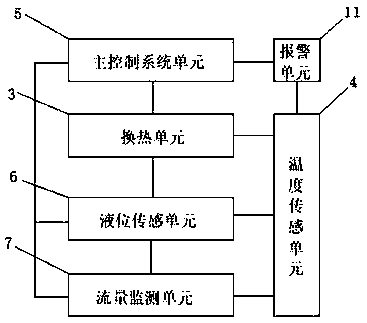

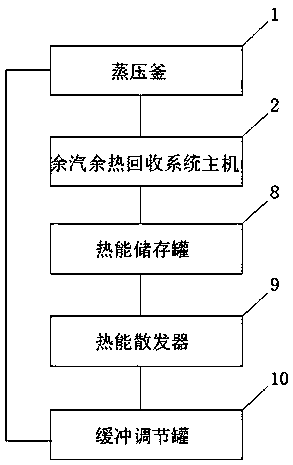

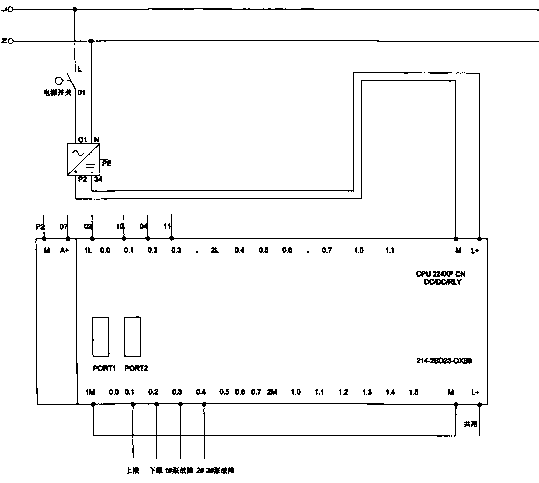

Control system and method based on residual steam and residual heat recovery device

PendingCN110529837AGuaranteed safety and reliabilityGuarantee safety and reliabilityWater circulationWater accumulatorControl systemTransfer procedure

The invention discloses a control system based on a residual steam and residual heat recovery device, which comprises a still kettle, a residual steam and residual heat recovery system host, a heat exchange unit, a temperature sensing unit, a main control system unit, a liquid level sensing unit and a flow monitoring unit, wherein the heat exchange unit is arranged in the residual steam and residual heat recovery system host, the residual steam and residual heat recovery system host is connected with a heat energy storage tank, and the liquid level sensing unit and the flow monitoring unit arearranged in the heat energy storage tank; the heat energy storage tank is connected with a heat energy radiator, and the heat energy radiator is connected with a buffer adjusting tank; according to the invention, different parameter data when the medium is conveyed to each stage are obtained through each monitoring unit, so that no heat loss of the medium is ensured in the transmission process, and resource utilization maximization is achieved.

Owner:常州绿资环保设备有限公司

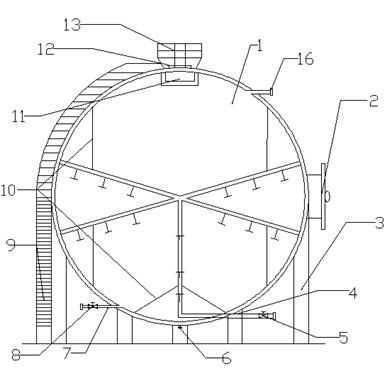

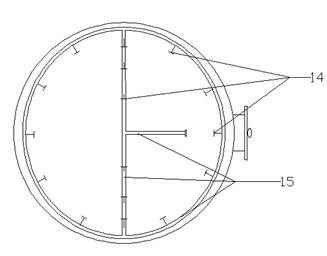

Ball heat accumulator for steam and hot water

InactiveCN102278740ATake advantage ofReduce labor intensityWater accumulatorFeed-water heatersEngineeringThermal water

The invention discloses a spherical heat accumulator for supplying steam and hot water. The tank body of the spherical heat accumulator is spherical, and a heat release device is arranged inside the tank body, and a water supply and discharge device is arranged outside the tank body. There is also a three-ring nozzle device inside the body to fully mix water and steam. In addition to the advantages of ordinary spherical heat accumulators: large land utilization rate, small relative heat dissipation area, stable and safe structure, etc., this invention also has the characteristics of high steam-water mixing rate compared with previous heat accumulators, which greatly improves heat storage efficiency. Improvement, the use of the accumulator can realize the supply of steam and hot water.

Owner:SHENGHUO TECH HENAN +1

Vapor-Operated Soldering System and Vapor Generation System for a Soldering System

Owner:REHM THERMAL SYST

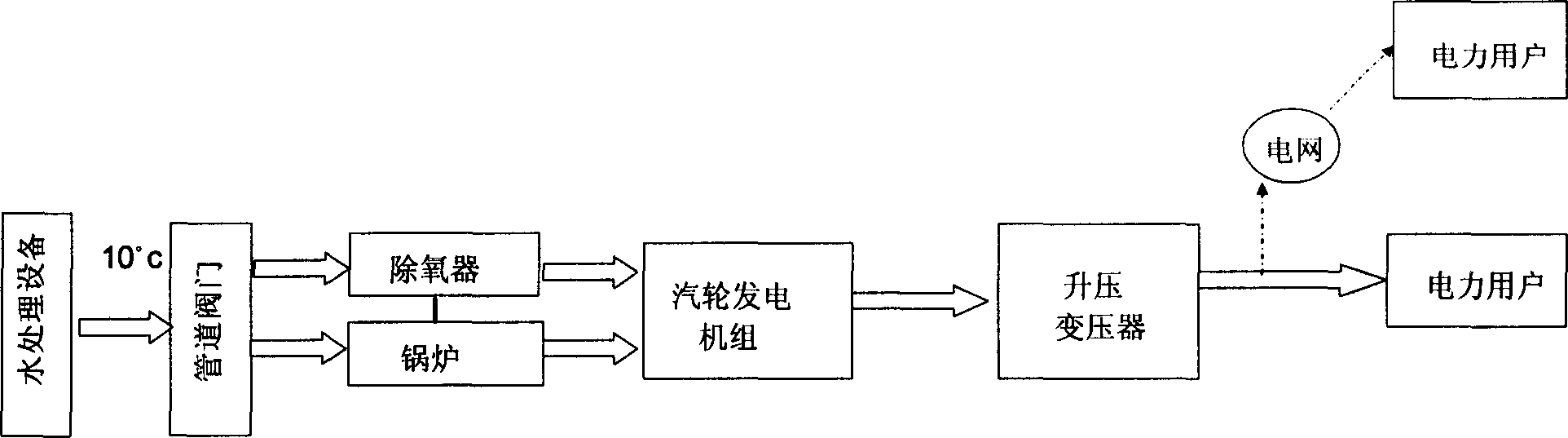

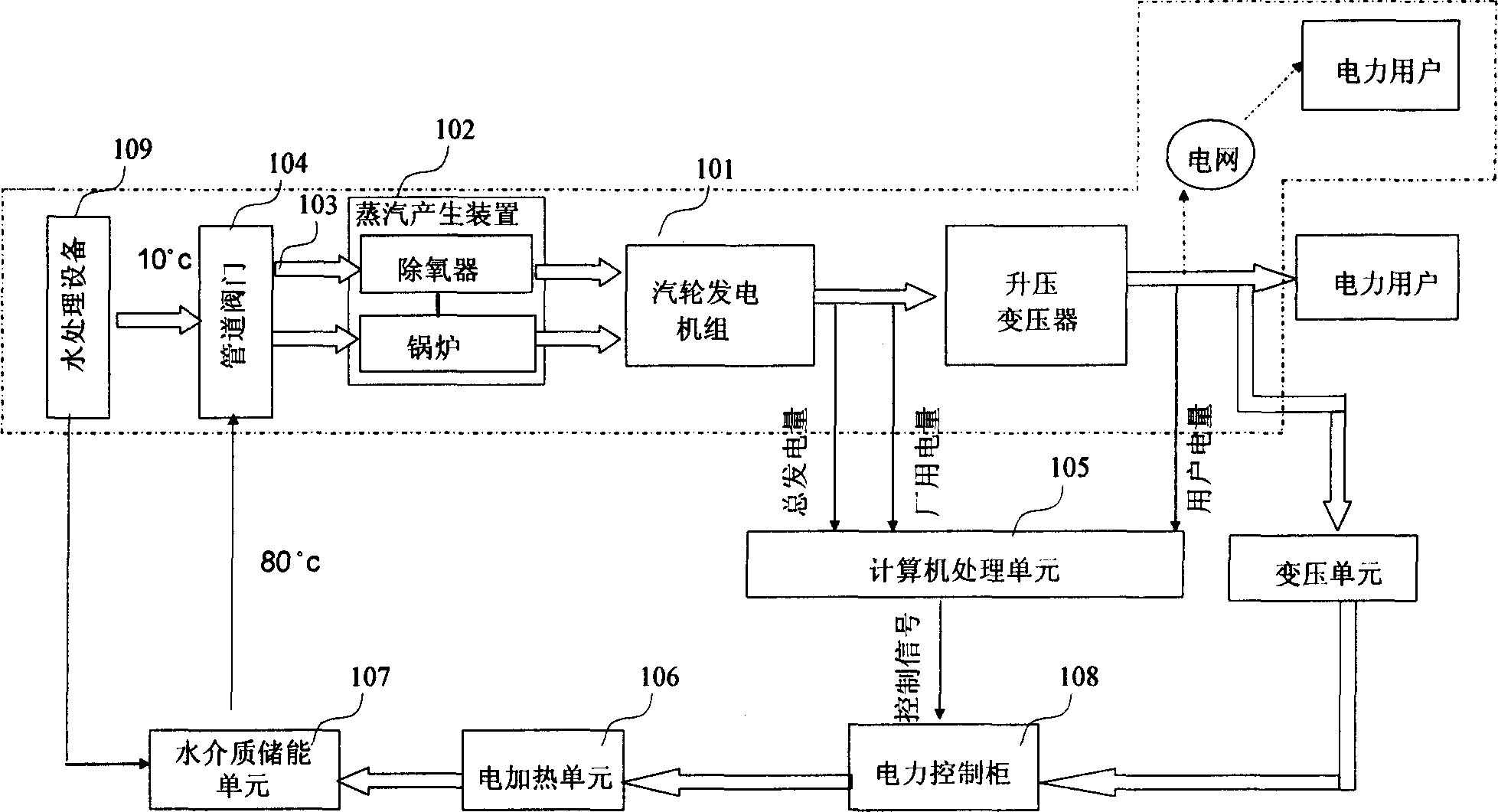

Electric power load regulating system and method

InactiveCN1838500ASave energyFlexible power load adjustmentLoad balancing in dc networkAc network load balancingElectricityControl signal

This invention discloses a power charge adjusting system and method with energy storage cell. The system includes steamer generator units, steam producing device, water delivering pipe, control cell, electric heating cell and aqueous medium storage cell, wherein the aqueous medium storage cell is connected with water delivering pipe and is used to store high temperature water heated by the electric heating cell, and it transfers the high temperature water to the steam producing device through water delivering pipe according to the control sign of the control cell. This invention also discloses a power load adjusting method. The power load adjusting method store and reuse aqueous medium by aqueous medium storage cell, when the system needs power load adjusting, it absorbs a great deal of energy by aqueous medium's temperature rising, when the system needs generating, it changes stored high temperature water into steam needed by steamer generator units to achieve the aim of adjusting power load.

Owner:山西磐控微型电网技术有限公司

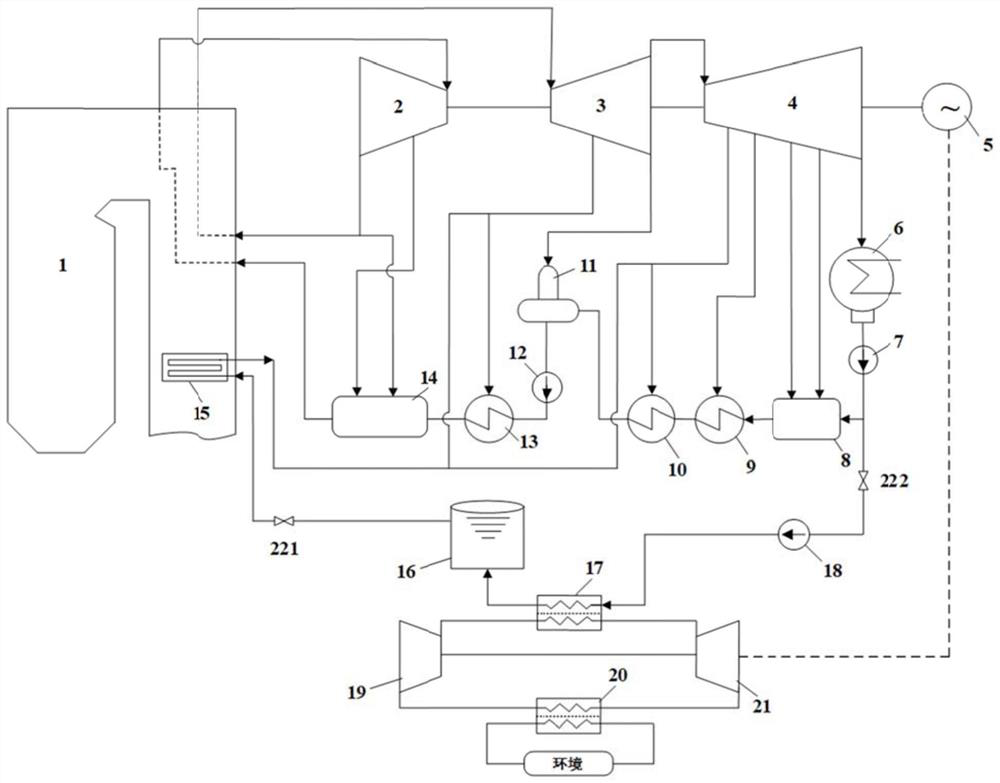

Integrated heat storage coal-fired power generation system and working method

ActiveCN114776411AIncrease the variable load rateIncrease flexibilitySteam generation plantsPiston pumpsFlue gasProcess engineering

According to the integrated heat storage coal-fired power generation system and the working method, when a unit operates at a low load, a carbon dioxide compressor is driven by excess electric power to compress a carbon dioxide working medium to a high-temperature and high-pressure state, so that part of supplied water shunted by the coal-fired power generation system absorbs heat of carbon dioxide and then is conveyed to a hot water storage tank; and when the load of the unit is increased, the stored pressurized water working medium in the heat storage water tank is released and is heated to a saturated state through the low-temperature flue gas heat exchanger to replace steam extraction of a steam turbine to heat feed water, so that steam extraction is reduced, and rapid load increasing is achieved. The lower-load operation of the unit is realized, the variable load rate is improved, and the unit flexibility is improved. The low-temperature flue gas heat exchanger is arranged at the tail of the boiler, so that flue gas waste heat can be recycled.

Owner:HUANENG POWER INTERNATIONAL +2

Method and apparatus for heating a stored liquid

A self-contained portable heating system to heat a stored liquid in a storage tank to a desired temperature is provided. The system can comprise operatively connected components such as a generator to power a burner that can transfer energy from a combustion product, from for example, a fuel supplied by an attached fuel tank, to a heat transfer fluid through the use of a boiler. The heat transfer fluid can transfer heat from the boiler to a heat exchanger which can then transfer heat to the stored liquid in the tank. The tank can also comprise a circulating pump that can circulate the heat transfer fluid and an expansion tank that can receive the heat transfer fluid when it expands as a result of being heated. In some embodiments, the heating components can be supplied separately from storage tank so that they can be retrofit onto an existing tank.

Owner:PITYU CONTROLS INC

Fixing method of steam heat accumulator and its insulation layer

InactiveCN102261645AGuaranteed insulation effectSmoothly fixedWater accumulatorFeed-water heatersThermal insulationEngineering

An embodiment of the invention discloses a steam heat accumulator comprising a tank body, wherein a thermal insulating layer is arranged on the tank body; a plurality of hoops, end rings, longitudinal braces and radial braces are further arranged between the thermal insulating layer and the tank body; the end rings are arranged at the end portions of the tank body; the hoops are arranged on the tank body; the longitudinal braces are arranged between adjacent hoops; each radial brace is arranged between one end ring and the hoop adjacent to the end ring; and the thermal insulating layer is fixed to the longitudinal braces and the radial braces. In the embodiment of the invention, the thermal insulating layer can be smoothly fixed to the steam heat accumulator by means of the hoops arrangedon the tank body of the steam heat accumulator; and the thermal insulating layer is not needed to be welded on the outer surface of the steam heat accumulator by way of fixing using the hoops; therefore, the thermal insulation performance of the steam heat accumulator in the embodiment of the invention can be ensured.

Owner:SICHUAN DAZHOU IRON & STEEL GROUP

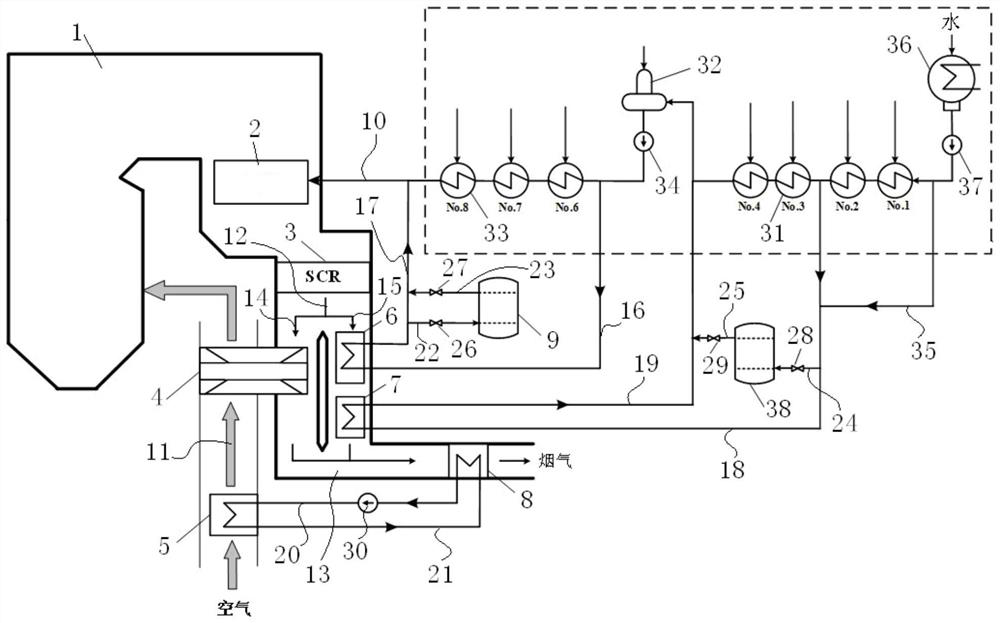

Flue gas waste heat recovery and energy storage system for thermal power plant

PendingCN114263924AIncrease temperatureIncrease the rate of lifting and lowering loadsLiquid degasificationCombustion processAir preheaterWater storage tank

The invention discloses a thermal power plant flue gas waste heat recovery and energy storage system which comprises a boiler, an economizer, a denitration device, an air preheater, a high-temperature flue gas heat exchanger, a medium-temperature flue gas heat exchanger, a high-temperature water storage tank, a low-temperature water storage tank, a water inlet main pipe, an air inlet channel and a smoke exhaust pipe. The air preheater is arranged on the air inlet channel, an outlet of the smoke exhaust pipe is divided into a first smoke exhaust branch and a second smoke exhaust branch, the first smoke exhaust branch is communicated with the air preheater, and the second smoke exhaust branch is sequentially communicated with the high-temperature smoke heat exchanger and the medium-temperature smoke heat exchanger. According to the system, the high-temperature water storage tank and the low-temperature water storage tank operate to be matched with a condensation water throttling mode on the water inlet main pipe, the load lifting speed of the unit can be increased, the gradeability of the unit can be improved, safe and stable operation of the system can be maintained, and during low-load operation, the temperature of flue gas in front of an SCR denitration device is increased through storage of the high-temperature water storage tank; the removal efficiency is improved.

Owner:湖南省湘电试验研究院有限公司

Auxiliary steam generator system for a power plant

InactiveUS9494054B2Reduce installation costsAvoid disadvantagesFrom solar energyFeed water supplyPower stationEngineering

An auxiliary steam generator system for a power plant, comprising a water-steam circuit, which has a condensate line and a feed-water line, wherein a condensate pump is connected in the condensate line and a feed-water pump is connected in the feed-water line, and wherein a pressure accumulating vessel is connected between the condensate pump and the feed-water pump, and wherein a feed-water take-off line is connected to the water-steam circuit at a branch-off point after the pressure accumulating vessel is provided. The feed-water take-off line is connected to the pressure accumulating vessel and a heating device is connected in the feed-water take-off line.

Owner:SIEMENS AG

Energy storage peak regulation system based on wind, light and thermal power generation multi-energy complementation

PendingCN114877301AImprove deep peak shaving abilityImprove peak capacityFeed water supplySteam generation using pressureNew energyPower grid

The invention discloses an energy storage peak regulation system based on multi-energy complementation of wind, light and thermal power generation, which comprises a steam-water heat exchanger, and the injection end and the discharge end of the steam-water heat exchanger are connected with a generator set through pipelines. By arranging the proper hot water heat storage tank, under the same peak shaving depth, the electric energy-heat energy conversion amount is reduced, so that the economical efficiency is better, the deep peak shaving capacity of the unit can be improved, the peak capacity of the unit can be improved, the two-way adjusting flexibility of the unit can be enhanced, the operation mode is flexible, and the service life of the unit is prolonged. Compared with the advantages of high fuel adjustment response speed and no adverse effect on boiler operation, the method solves the problems that a power grid in a conventional mode receives new energy electric quantity according to the accommodating capacity, and when the power grid cannot absorb the new energy electric quantity, the new energy generation power is limited to ensure the electric energy quality and safety of the power grid, and all electric energy is converted into heat energy through an electric heat storage peak regulation mode developed in recent years. And the efficiency is relatively low.

Owner:沈阳汇智源电力发展集团有限公司 +1

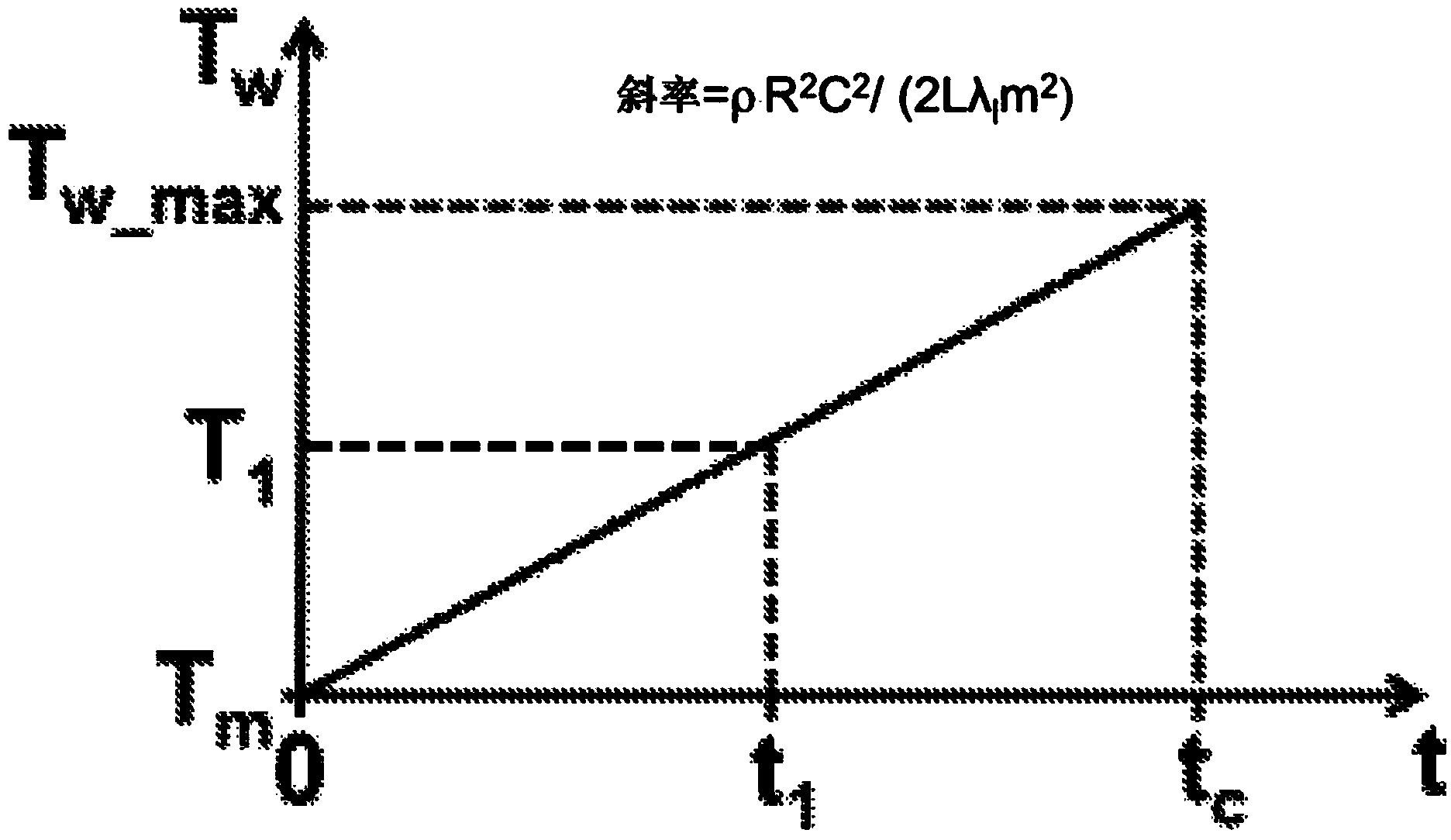

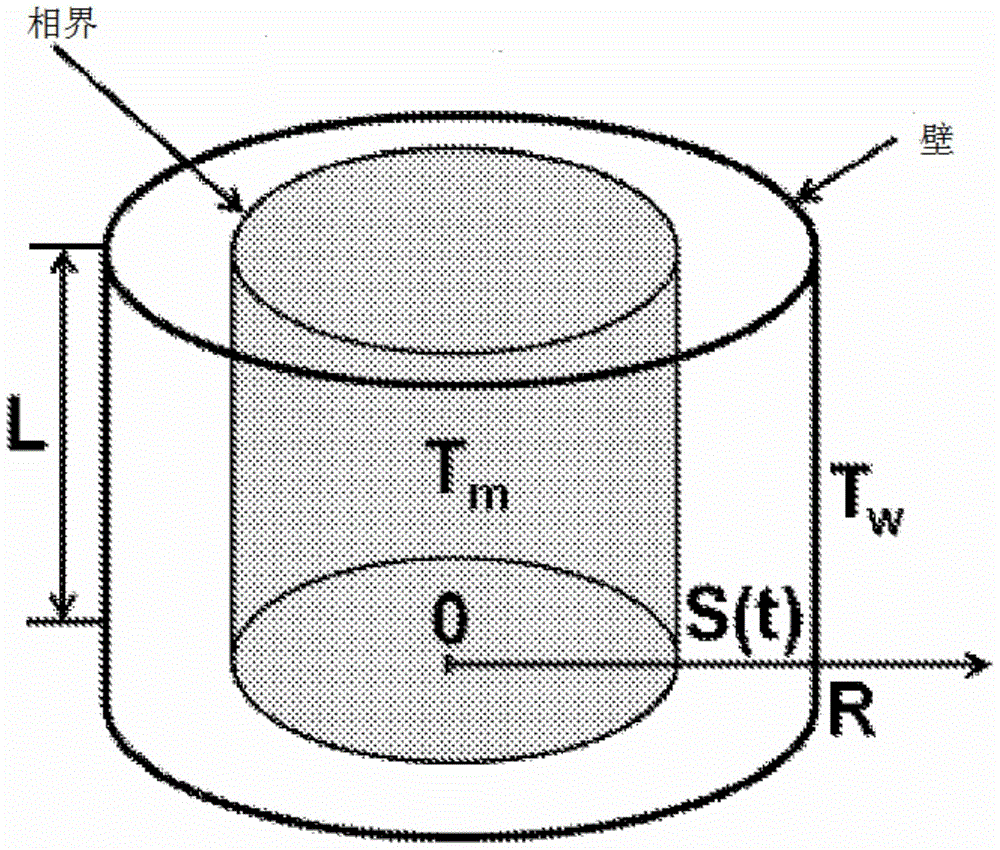

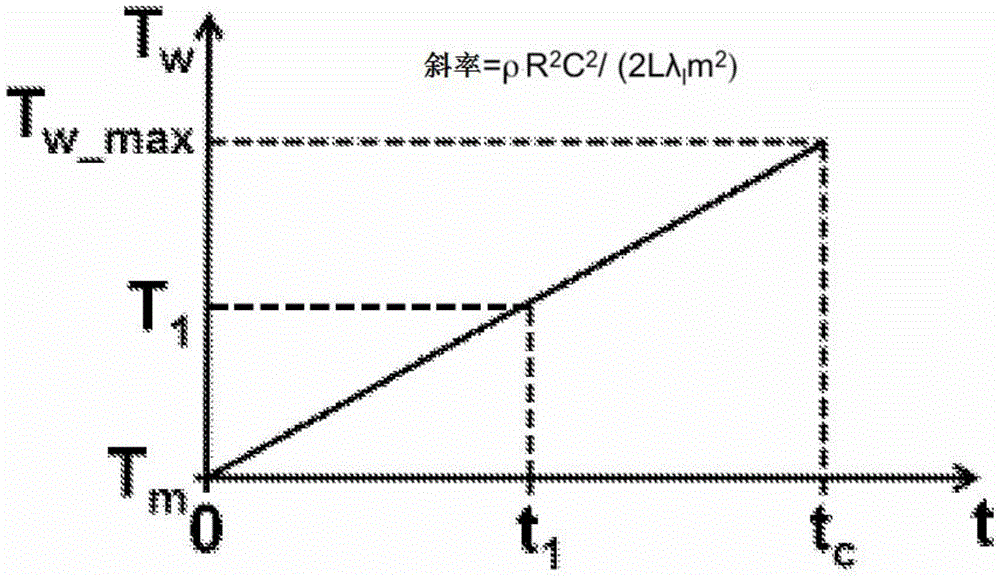

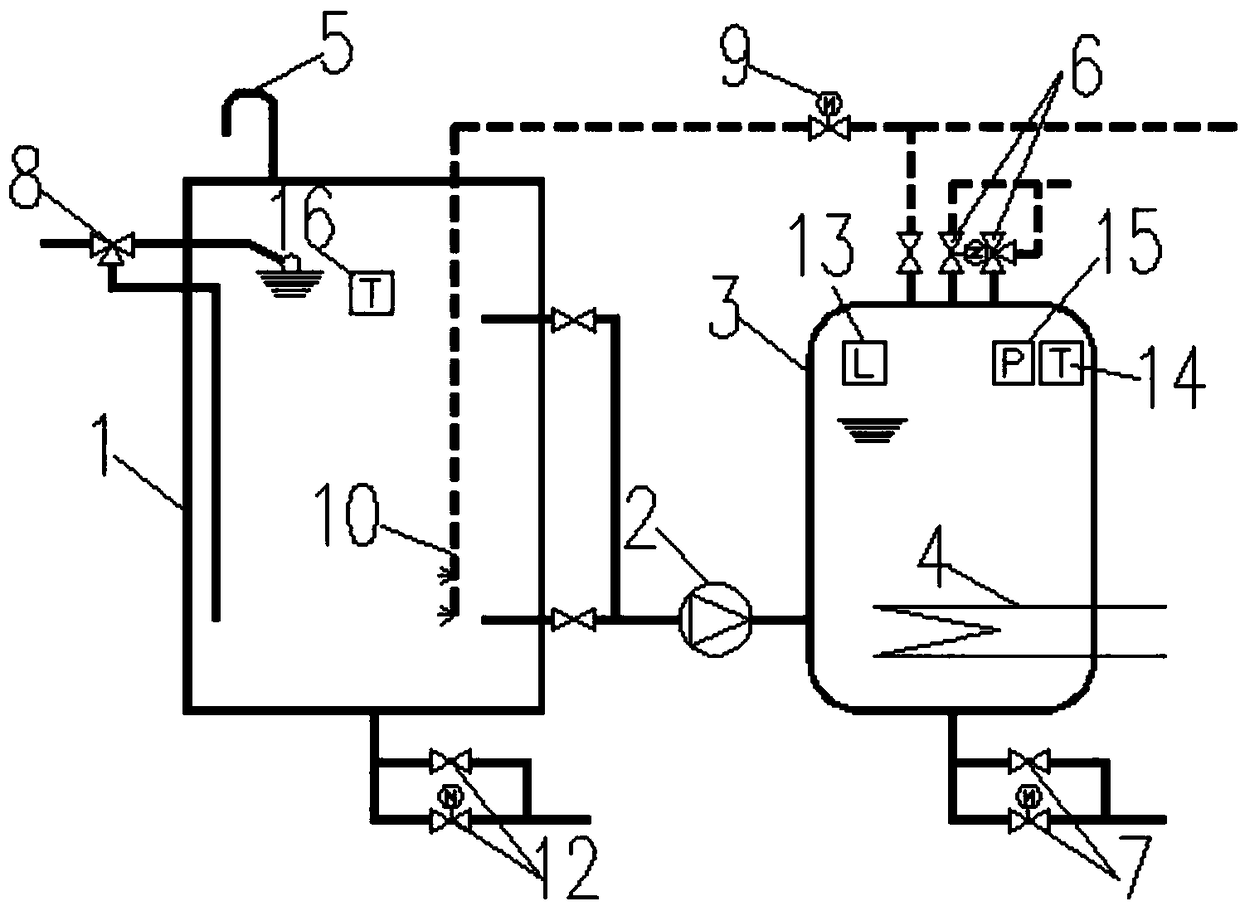

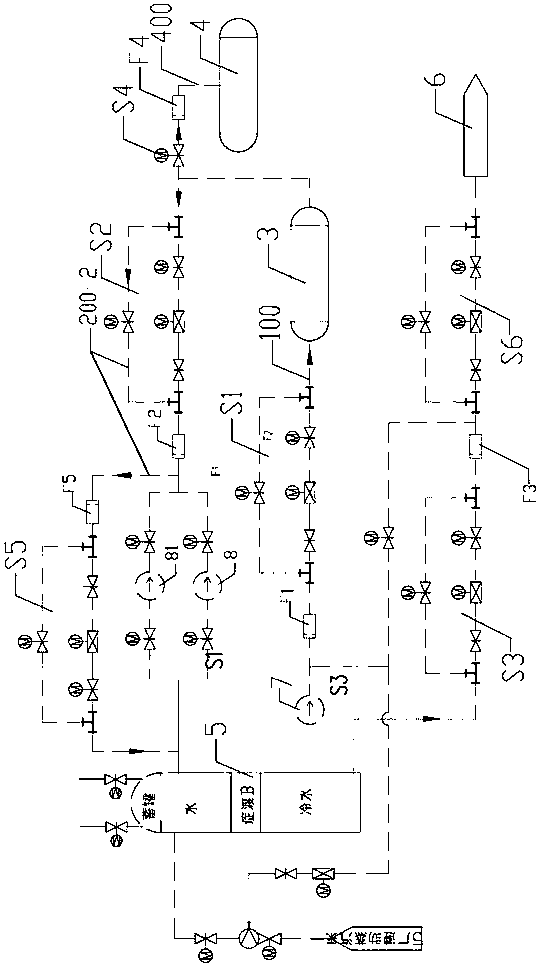

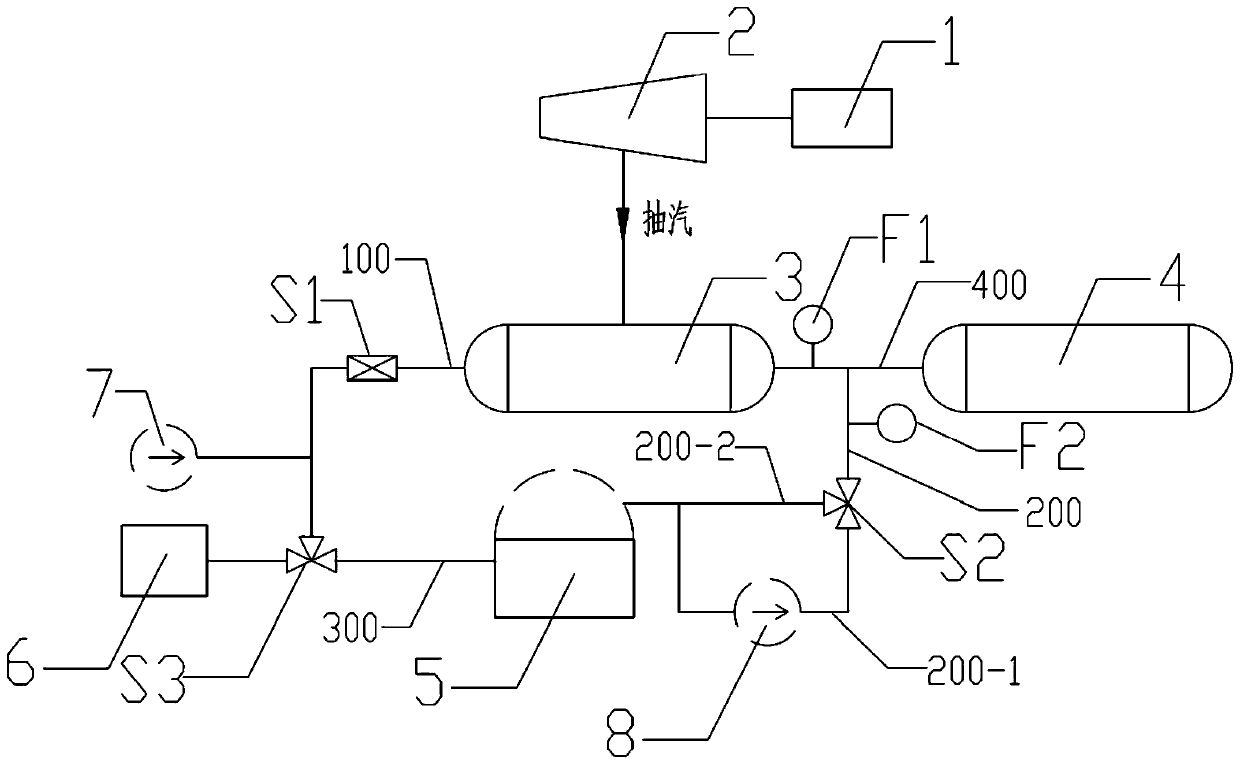

Power control method of heat storage peak shaving system under heat storage and heat release working conditions

PendingCN111412453APower reductionIncrease power generationLiquid degasificationSteam/vapor condensersWater storageThermodynamics

The invention provides a power control method of a heat storage peak shaving system under heat storage and heat release working conditions. The heat storage peak shaving system is included. In a heatstorage mode, after condensed water (cold water) sent out by a condensed water pump passes through a heater, the cold water is changed into hot water, one path of hot water enters a deaerator, the other path of hot water enters a water storage tank, and the equal amount of cold water is discharged to a condenser from the water storage tank. Due to the fact that the total amount of hot water entering the deaerator is relatively fixed, the flow entering the water storage tank is increased, the flow passing through the heater is also increased, the generating power of a unit is reduced, and viceversa. In a heat release mode, one path of condensed water sent out by the condensed water pump passes through the heater to enter the deaerator, the other path of the condensed water sent out by thecondensed water pump enters the water storage tank, and the equal amount of hot water is pumped to the deaerator from the water storage tank through a booster pump. Due to the fact that the total amount of hot water entering the deaerator is relatively fixed, the flow pumped out of the water storage tank is increased, the flow passing through the heater is reduced, the generating power of the unitis increased, and vice versa. An applicant proposes a heat storage technology by using the water storage tank, the ramp rate of the unit is increased, a power grid dispatching instruction is rapidlyresponded, and the power control method of the heat storage peak shaving system under heat storage and heat release working conditions is a new mode for increasing the ramp rate of the unit.

Owner:NORTH CHINA POWER ENG

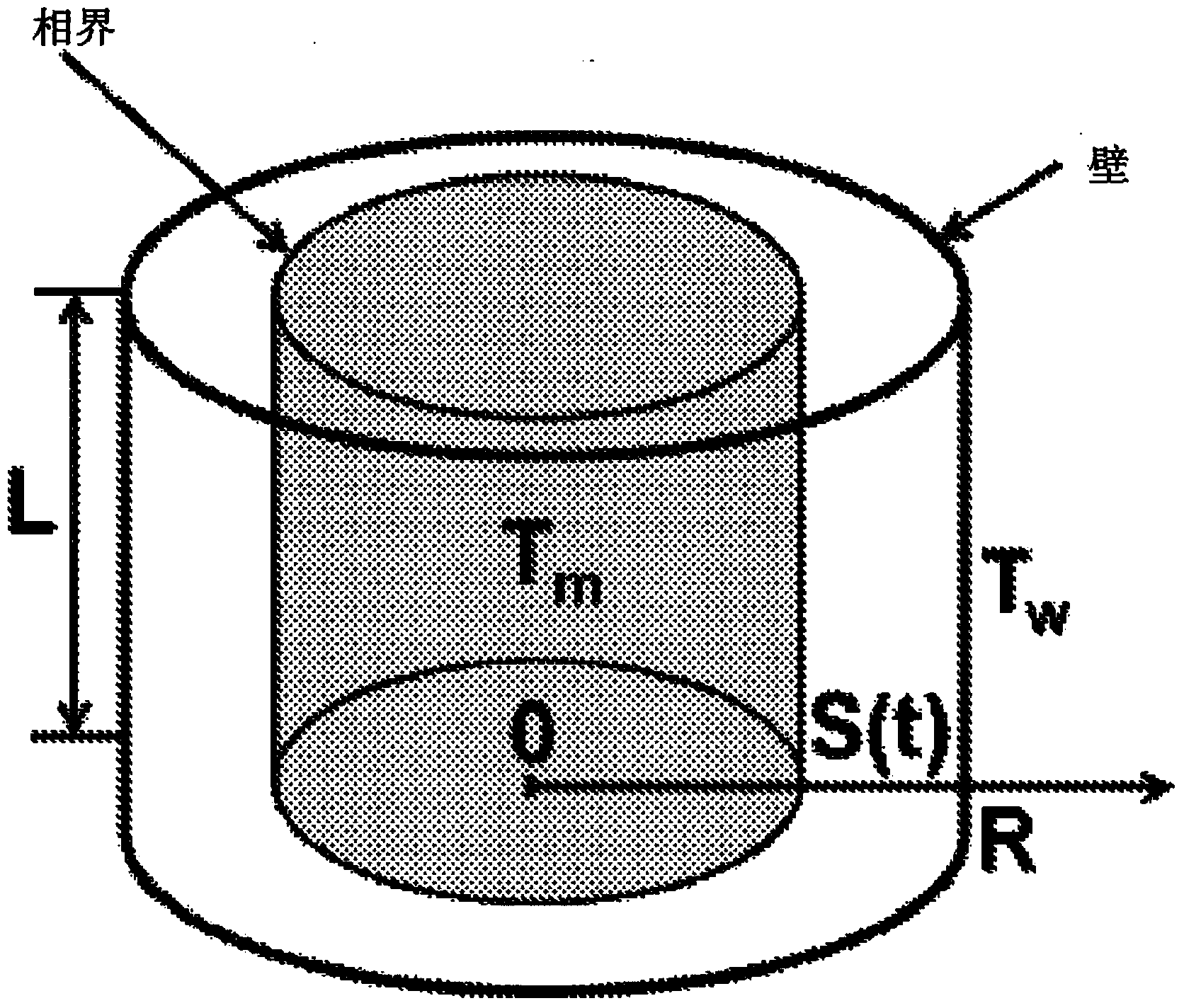

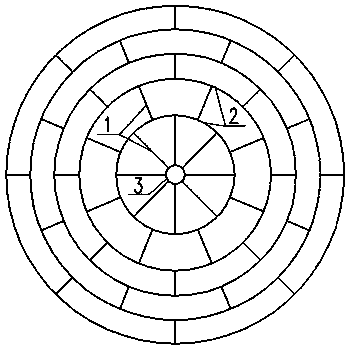

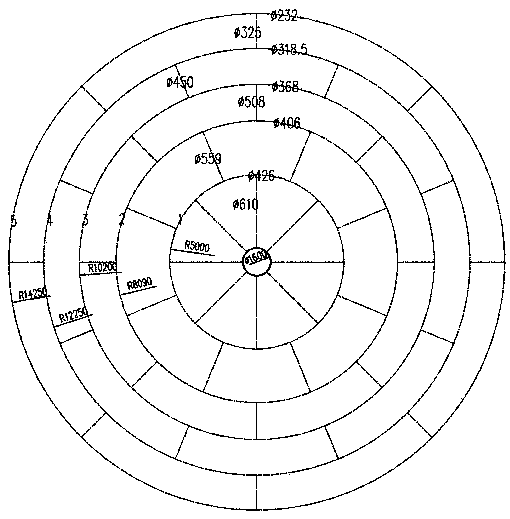

Large-diameter water storage tank with labyrinth type water distribution function and water distribution method for keeping thermocline stable

InactiveCN108954292AReduce the impact of disturbanceAvoid destructionWater accumulatorThermoclineDistribution method

The invention provides a large-diameter water storage tank with a labyrinth type water distribution function and a water distribution method for keeping a thermocline stable. The phenomenon that the water temperature in a tank is likely to be uneven in the water inflow and outflow processes of the large-diameter water storage tank, the thermocline at the cold water and hot water juncture is easilydamaged due to water inflow and outflow disturbance, and normal use of a system is severely affected. The large-diameter water storage tank comprises a water storage tank body, and two labyrinth typewater distribution devices are arranged in the water storage tank body and are arranged at the upper part and the lower part of the water storage tank body respectively. Each labyrinth type water distribution device comprises a group of branch pipes (1), a set of annular pipes (3) and a header (3), wherein the adjacent annular pipes are connected through the branch pipes, the annular pipe at theinnermost layer is connected with the header through the corresponding branch pipe, and a group of small holes with the same diameter are uniformly formed in the annular pipes. The small holes are opposite to the thermocline of the water storage tank body. The drilling range of the small holes is limited between 90 degrees and 120 degrees in the circumferential direction, and the directions of thesmall holes of the annular pipes are consistent. The large-diameter water storage tank is applied to large storage containers with media having temperature gradients.

Owner:HARBIN BOILER

Energy storage peak regulation system based on thermal Rankine cycle

PendingCN114687819ALow powerIncrease power generationSteam generation plantsSteam engine plantsWater storage tankNew energy

A Rankine cycle energy storage peak regulation system based on heating power mainly comprises a medium-pressure heat storage tank, a low-temperature water storage tank, a flash tank, a medium-pressure heat storage tank circulating pump, a heat storage water feeding pump and an electric steam boiler. The method is characterized in that steam heat energy during a new energy peak regulation period of a pure condensing power plant boiler is stored in a medium-pressure heat storage tank in a saturated water state; new energy electric power energy is converted into saturated water to be stored in the medium-pressure heat storage tank; in the non-new energy peak regulation period of a pure condensing power plant boiler, saturated water in a medium-pressure heat storage tank is pressurized and mixed into boiler feed water, regenerative extraction steam of a steam turbine heater is squeezed, stored energy is recycled, the power capacity of a steam turbine is increased, the coal burning amount of the boiler is reduced, and energy storage and energy release of boiler steam and new energy electric energy in a thermal Rankine cycle system are achieved; and the system serves deep peak regulation of new energy.

Owner:丁峰

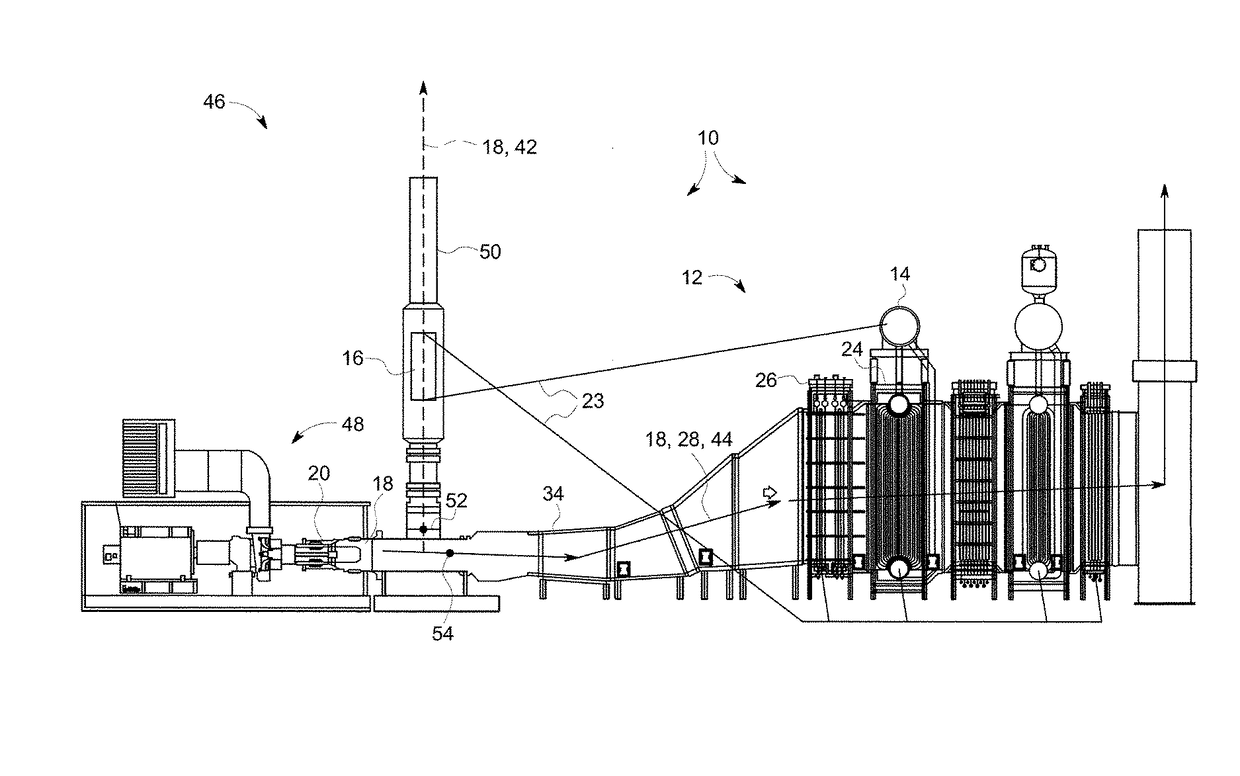

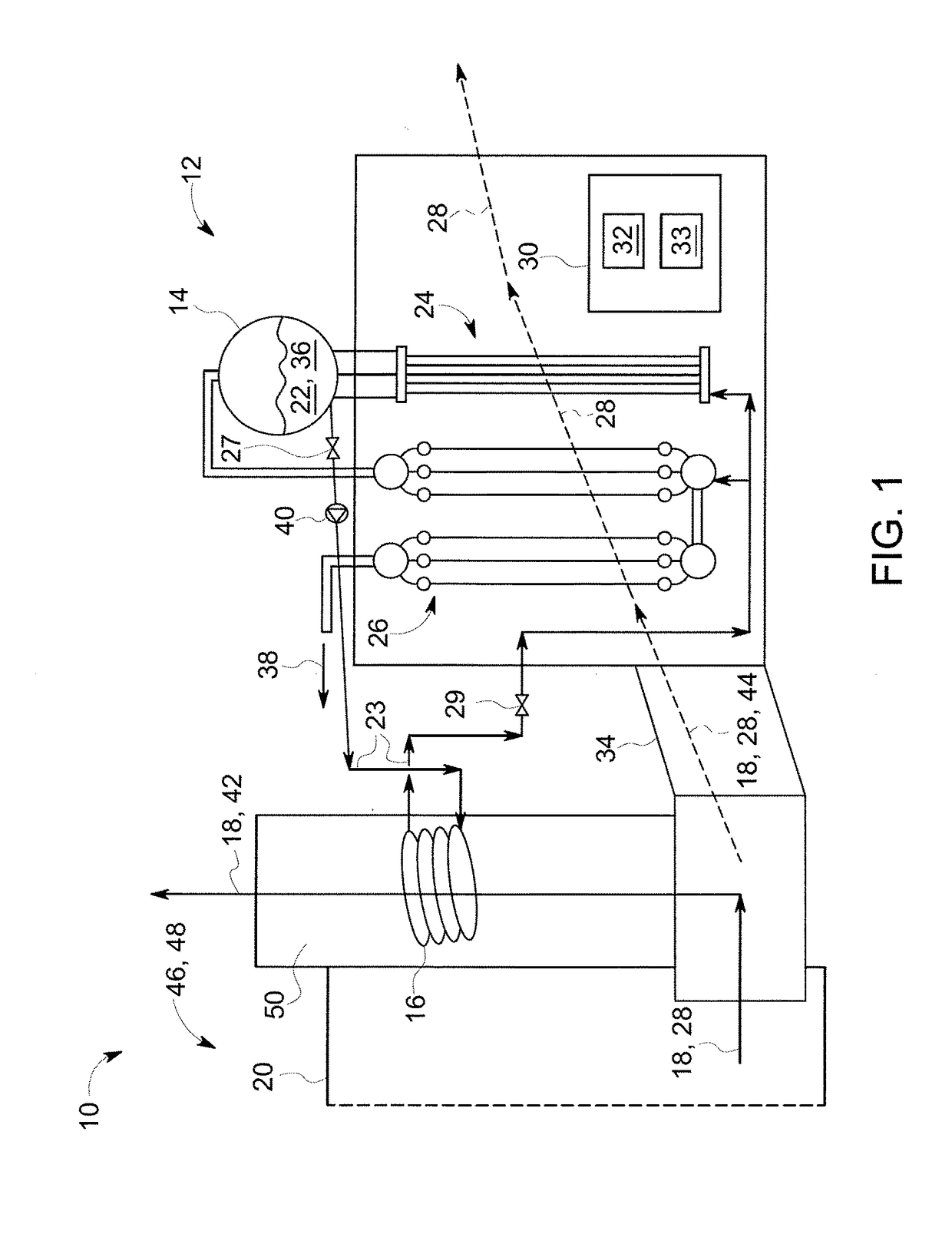

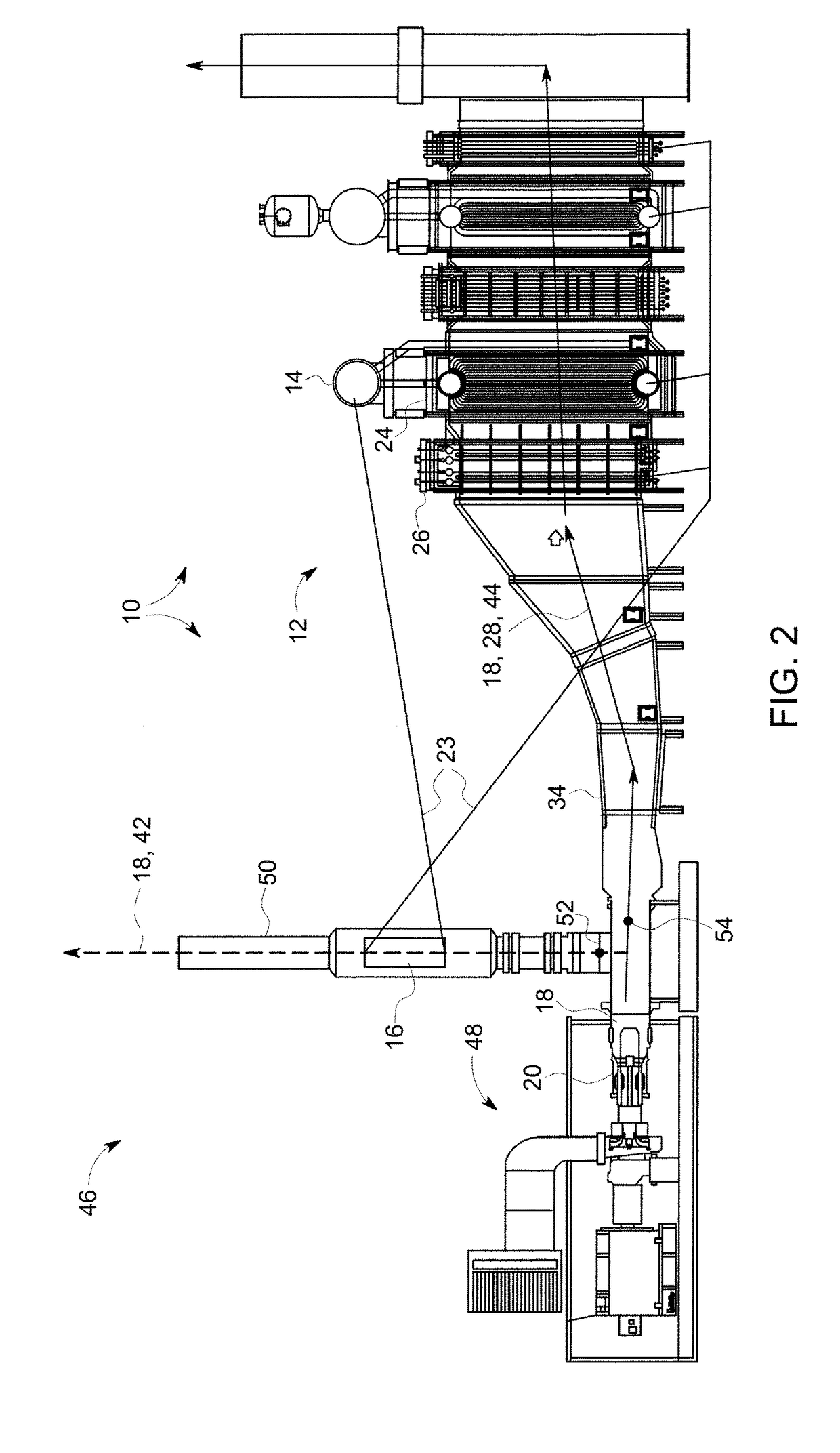

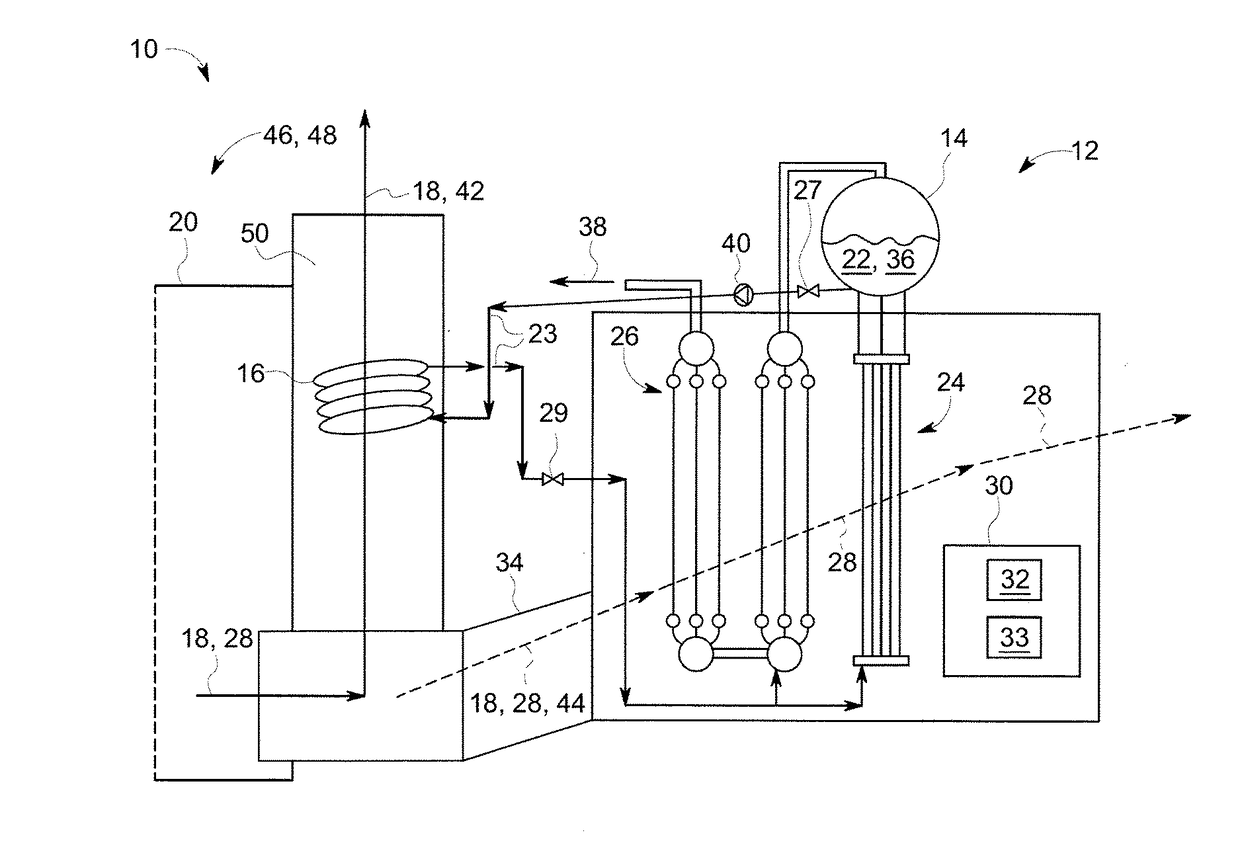

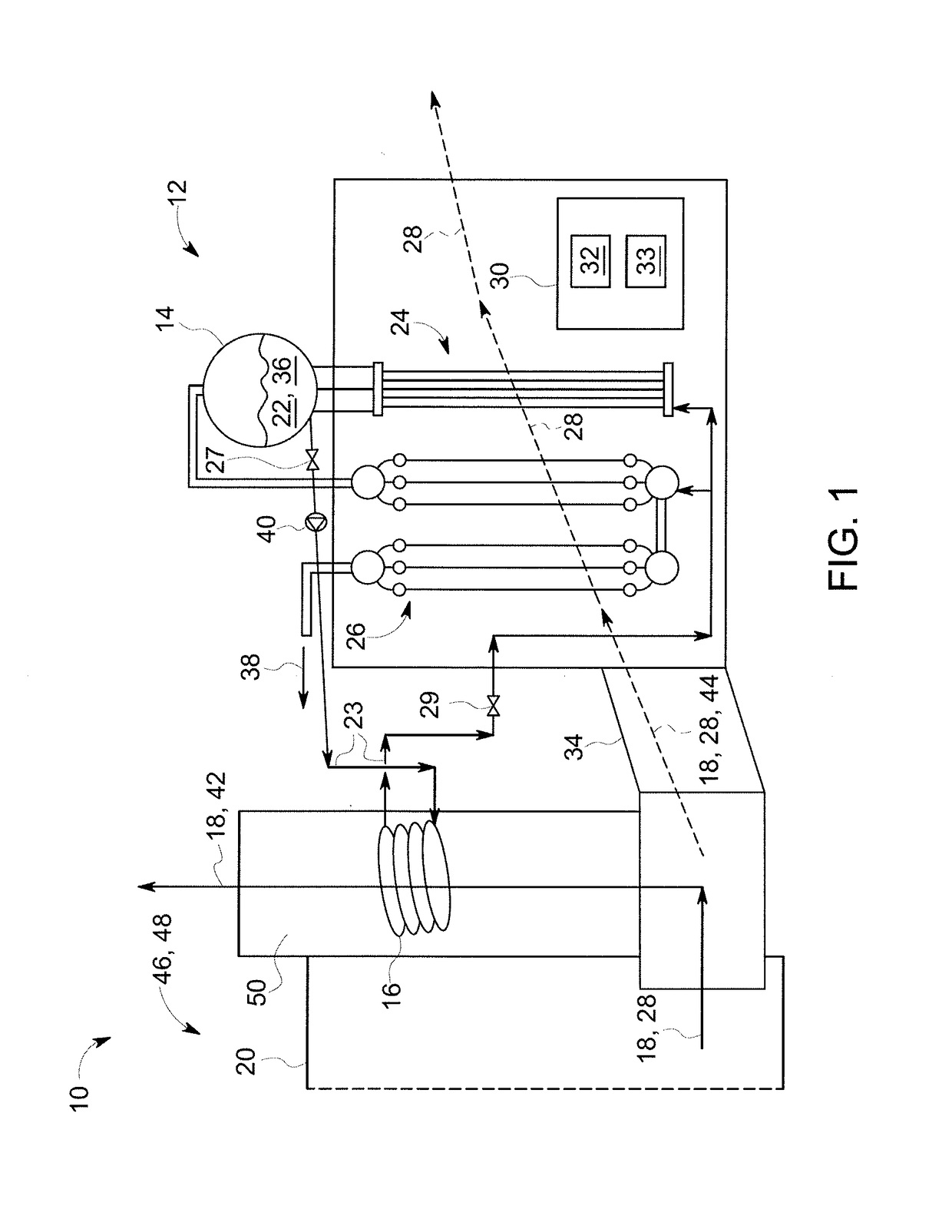

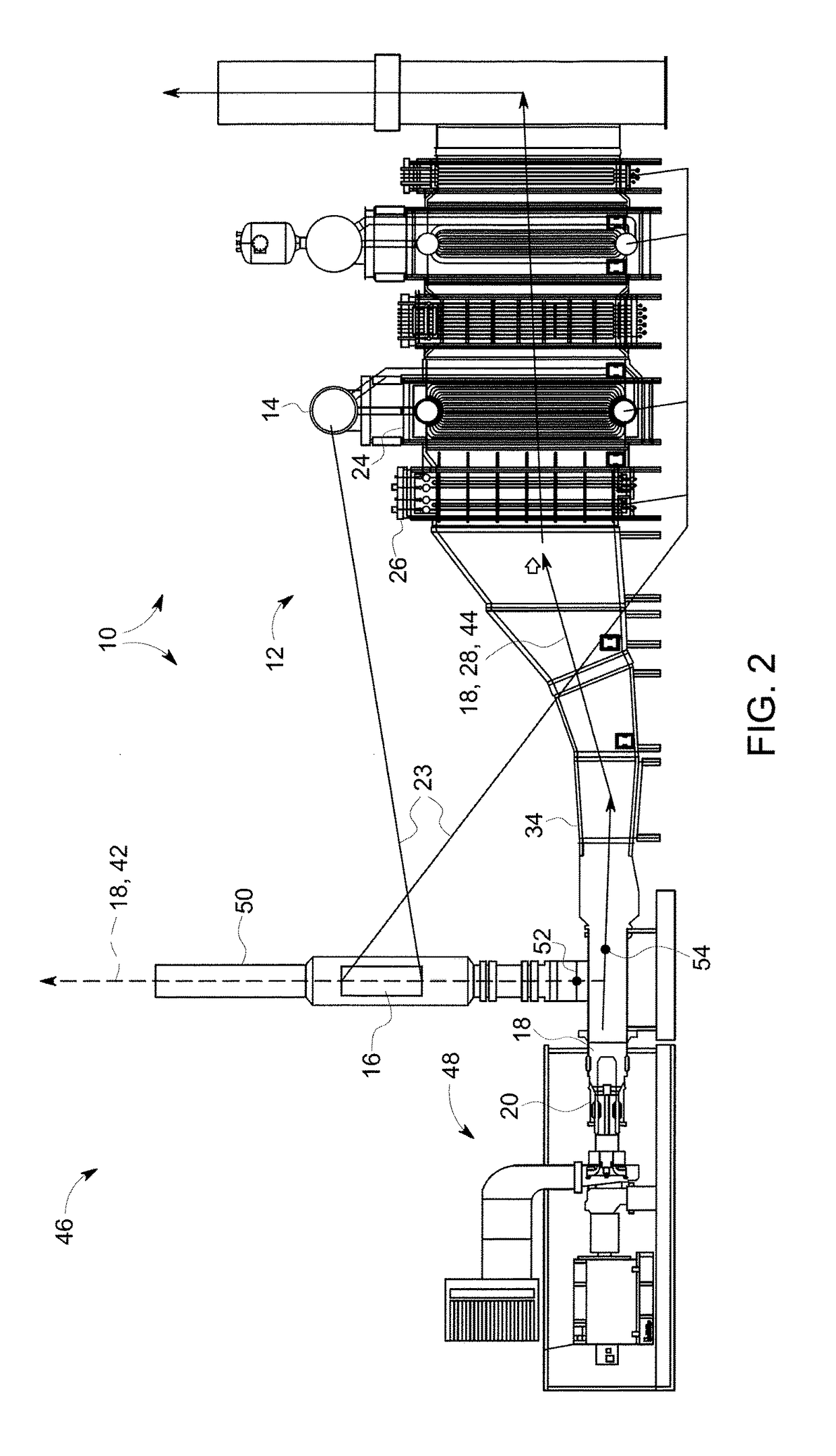

System and method for preheating a heat recovery steam generator

A system (10) for preheating a heat recovery steam generator (12) is provided. The system (10) includes a tank (14) and a heat exchanger (16). The tank (14) contains a transferring medium (22). The heat exchanger (16) is disposed in a flow path of a flue gas (18) produced by a combustion chamber (20), and is fluidly connected to the tank (14) such that the transferring medium (22) flows through the heat exchanger (16) and is heated by the flue gas (18). The transferring medium (22) preheats one or more components (14, 24, 26) of the heat recovery steam generator (12).

Owner:GENERAL ELECTRIC TECH GMBH

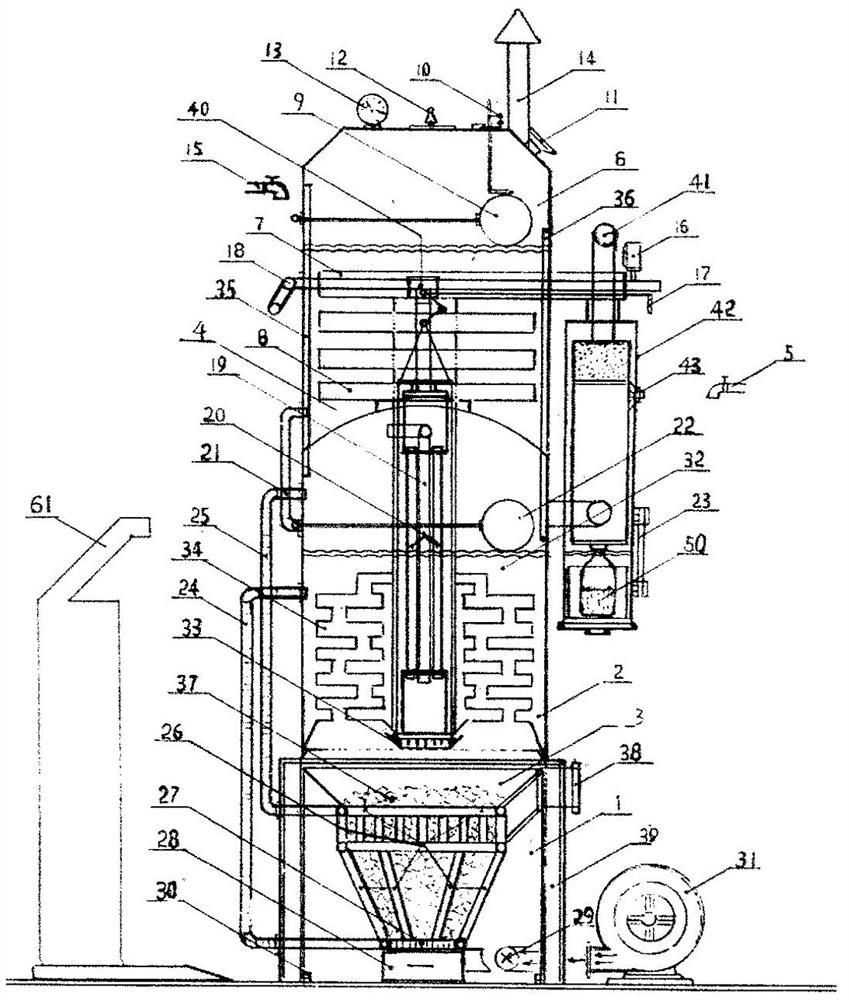

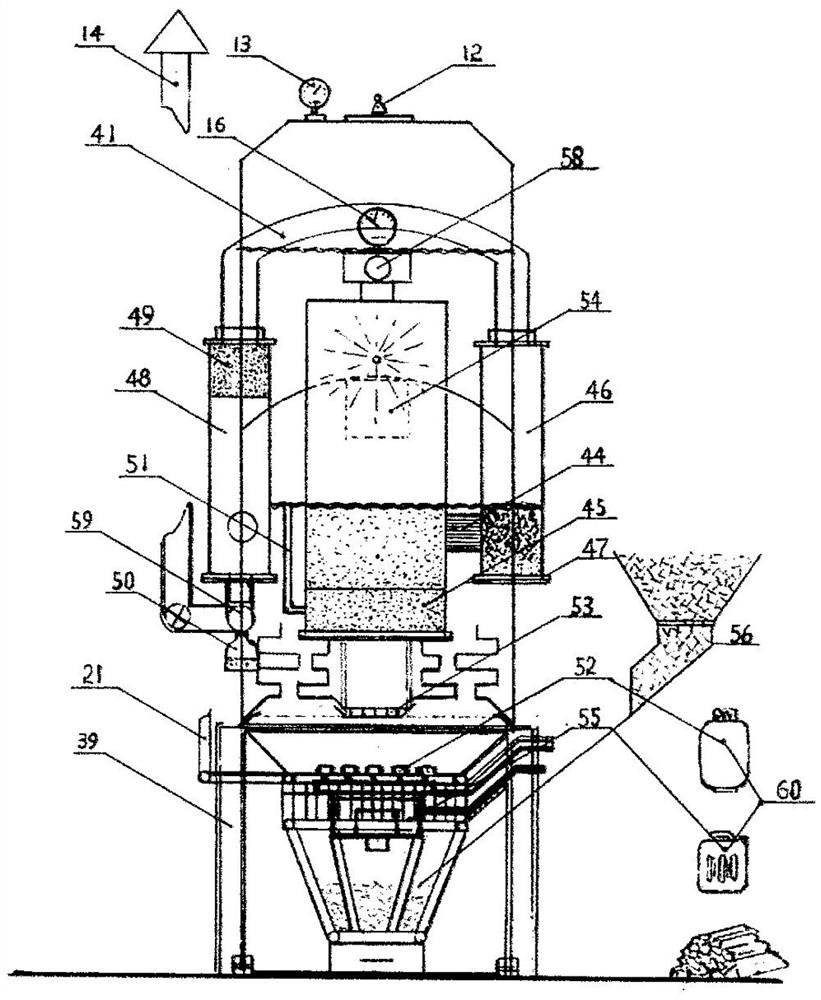

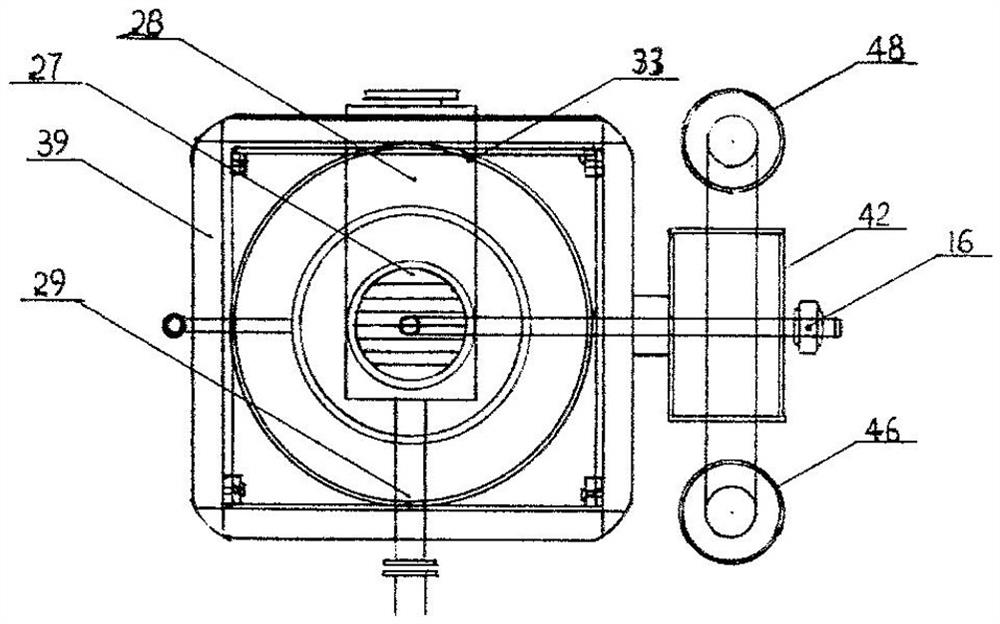

Single-tower multilayer non-pressure high-temperature superheated steam furnace

PendingCN113154346ALow costSimple structureSteam generation using pressureBoiler controlCombustion chamberEngineering

The invention provides a single-tower multilayer non-pressure high-temperature superheated steam furnace. The single-tower multilayer non-pressure high-temperature superheated steam furnace comprises a pot body, a furnace body, a main flue, a combustion chamber, a multilayer energy-gathering high-temperature superheated bin, a cast steel non-pressure energy-gathering and multi-pipe superheated steam chamber. The single-tower multilayer non-pressure high-temperature superheated steam furnace is characterized in that according to the local policy, the production cost is calculated by combining the local geothermal energy resources, the seats are matched, various fuel energy sources can be conveniently used, any structure of the boiler does not need to be changed, the gas consumption is large or small, a single tower and multiple towers are connected in parallel for use, the air temperature can be high or low by 100-500 DEG C, and the steam furnace is manually matched with an electric appliance and is controllable and adjustable. The single-tower multilayer non-pressure high-temperature superheated steam furnace has the advantages that the universality and flexibility are achieved, various fuel energy sources can be used, the steam furnace is suitable for industrial and agricultural production and is suitable for various aspects of life of people, and the advantages are summarized into twenty characters: the structure is simple, flexibility and convenience are achieved, energy conservation and low consumption are achieved, safety and environmental protection are achieved, and time and labor are saved.

Owner:朱常陵

Vapor recovery warehouse

InactiveCN100540996CZero emissionReduce power generation costsWater circulationSteam engine plantsElectricityPower station

The invention discloses a steam recovery chamber, which is characterized in that it comprises a steam recovery chamber respectively connected with a boiler, a circulating water chamber and a low-pressure chamber. The steam recovery chamber is provided with a pipeline outlet leading to the circulating water chamber, a low-pressure chamber to The outlet pipe of the steam to the storage chamber and several air inlets and outlets. The air outlet communicates with the low-pressure chamber. The air inlet is provided with a vapor compression pipe connected to the circulating water chamber. The vapor compression pipe is connected to the position of the circulating water chamber and The air inlets are respectively provided with compressors. The invention abolishes the condenser and its auxiliary system, one of the main equipment in the traditional power generation process, recovers all the large amount of low-temperature and low-pressure steam originally discharged into the condenser, and recovers the waste steam and condensed water produced by other parts. etc. are also all recycled for power generation, suitable for power plants or ordinary thermal equipment that use boilers to generate water vapor for work. It has a wide range of applications, simple structure, safety, environmental protection and energy saving, and has good promotion value.

Owner:冼泰来

System and method for preheating a heat recovery steam generator

ActiveUS20170248037A1Recuperative heat exchangersBoiler water tubesCombustion chamberNuclear engineering

A system for preheating a heat recovery steam generator is provided. The system includes a tank and a heat exchanger. The tank contains a transferring medium. The heat exchanger is disposed in a flow path of a flue gas produced by a combustion chamber, and is fluidly connected to the tank such that the transferring medium flows through the heat exchanger and is heated by the flue gas. The transferring medium preheats one or more components of the heat recovery steam generator.

Owner:GENERAL ELECTRIC TECH GMBH

Device for controlling supply of working fluid

ActiveUS10385737B2Efficiently and economicallySteam regenerationWater accumulatorWorking fluidProcess engineering

A device for controlling a supply of a working fluid to a power generation cycle with a compressor compressing the working fluid and a precooler cooling the working fluid supplied to the compressor comprises a storage tank storing the working fluid supplied to the power generation cycle and a flotation tank disposed between the precooler and the compressor to flow or temporarily store the working fluid, wherein a pressure within the flotation tank and a flow rate of the working fluid are controlled based on pressures at an inlet of the compressor and an outlet of the precooler.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

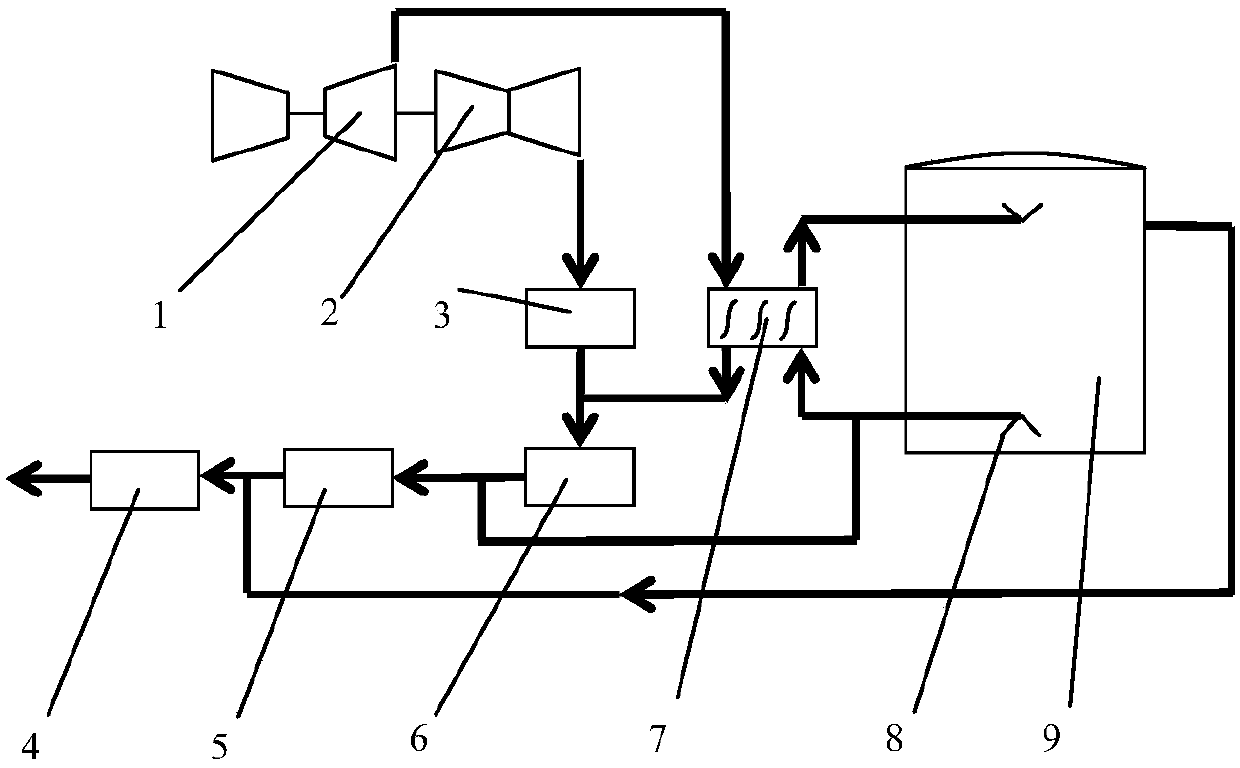

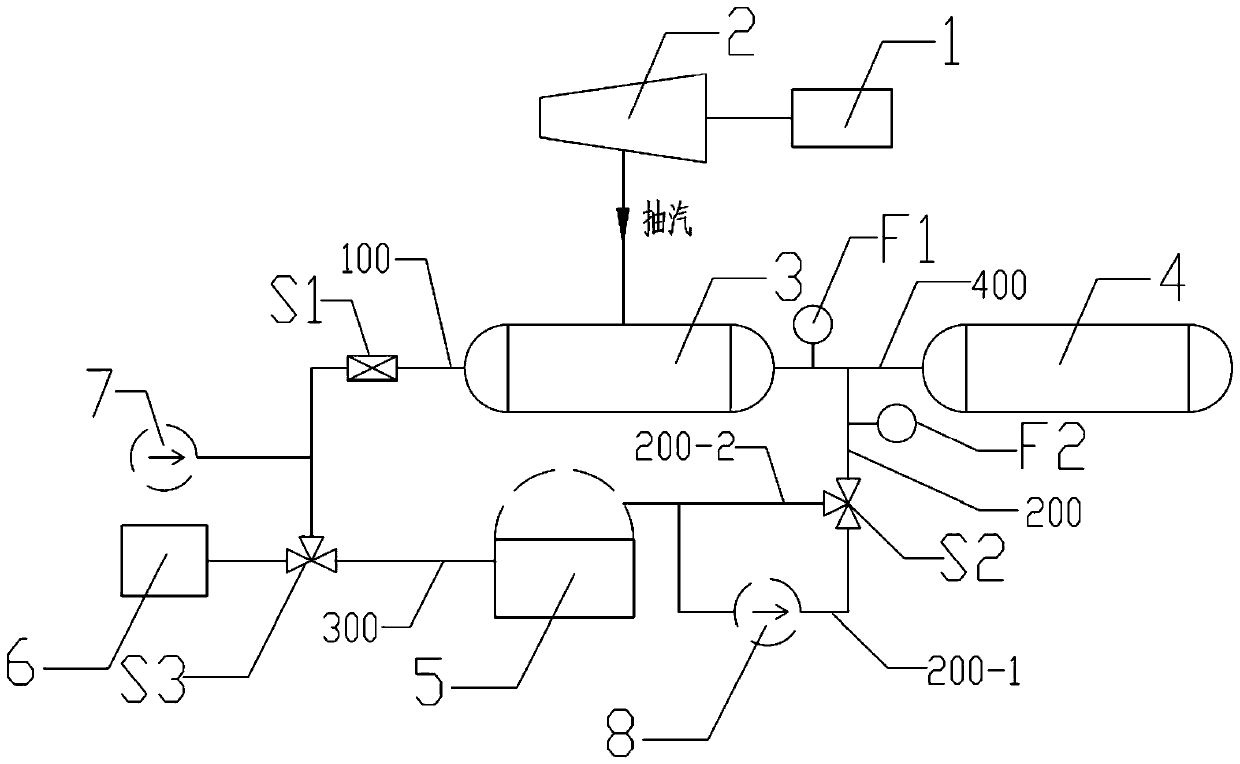

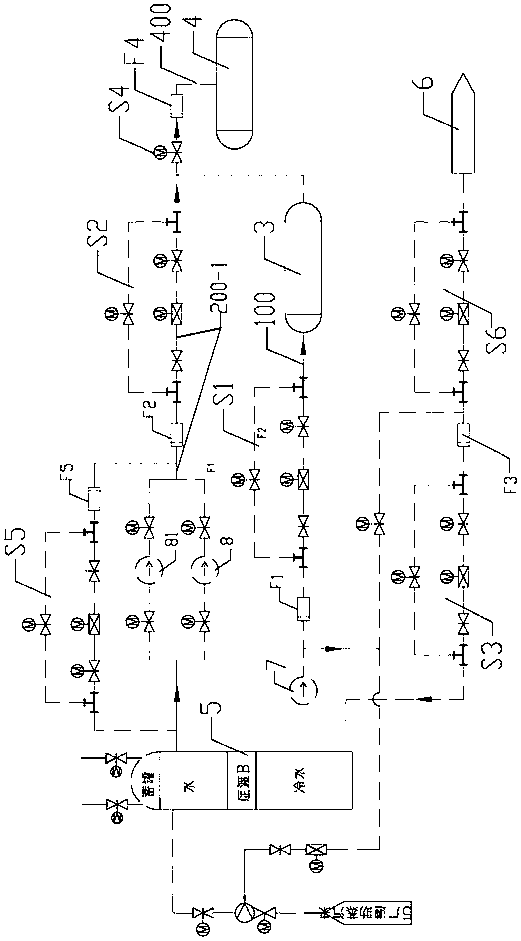

Heat storage peak shaving system

PendingCN111412454APower reductionIncrease power generationLiquid degasificationSteam/vapor condensersWater storageWater storage tank

The invention provides a heat storage peak shaving system. The heat storage peak shaving system comprises a generator set, a heater, a deaerator, a water storage tank, a condenser, a condensate pump and a booster pump. The condensate pump is connected to the heater to form a water supply adjusting pipeline of the heat storage peak shaving system. The heater is connected to the deaerator. The watersupply adjusting pipeline is provided with a first valve set and a first flow monitoring device. The heater is connected to a steam turbine generator set. A hot water pipeline of the heat storage peak shaving system is formed between the water storage tank and the deaerator. The water storage tank is connected with the booster pump to form a heat release branch line of the hot water pipeline. Theheat release branch line is further connected with a heat storage branch line in parallel. The heat release branch line and the heat storage branch line are gathered to a hot water pipeline main line. The hot water pipeline main line is provided with a second valve set and a second flow monitoring device and finally connected to a deaerator main line. The condensate pump is connected to the waterstorage tank to form a cold water pipeline of the heat storage peak shaving system. The heat storage peak shaving system further comprises a third valve set. The condensate pump, the condenser and the water storage tank communicate with one another through the third valve set.

Owner:NORTH CHINA POWER ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com