Control system and method based on residual steam and residual heat recovery device

A technology of waste heat recovery device and waste heat recovery system, which is applied in the control of water supply, preheating, steam generation, etc., can solve the problems of monitoring and dredging of the discharge process, and it is difficult to ensure the utilization of heat energy, and achieves the effect of ensuring safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

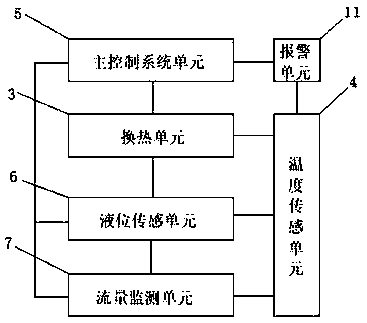

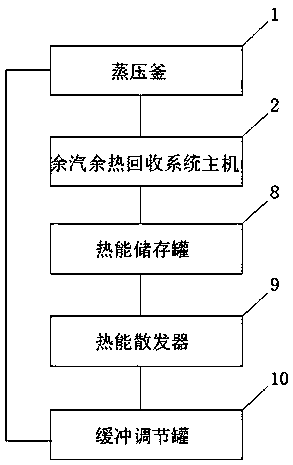

[0024] A control system based on a steam and heat recovery device, including an autoclave 1 and a steam and heat recovery system host 2, and also includes a heat exchange unit 3, a temperature sensing unit 4, a main control system unit 5, and a liquid level sensing unit 6 and a flow monitoring unit 7; the heat exchange unit 3 is set in the main unit 2 of the waste steam and heat recovery system, the main unit 2 of the waste steam and heat recovery system is connected to the thermal energy storage tank 8, and the liquid level transmitter The sensing unit 6 and the flow monitoring unit 7 are arranged in the thermal energy storage tank 8 ; the thermal energy storage tank 8 is connected to a thermal energy distributor 9 , and the thermal energy distributor 9 is connected to a buffer regulating tank 10 .

[0025] The temperature sensing unit 4 is also arranged on the main unit 2 of the steam and heat recovery system, the heat radiator 9 and the buffer regulating tank 10 . The main ...

Embodiment 2

[0028] The main control system unit 5 presets the start-up temperature value of the power delivery pump, and obtains the temperature parameter transmitted by the thermocouple in the main engine; when the main control system unit 5 detects that the temperature of the medium in the main engine has reached the output temperature, the medium will be delivered Enter the thermal energy storage tank 8, and obtain the liquid level information in the thermal energy storage tank 8; at the same time, monitor the real-time flow of the thermal energy storage tank 8 to the outside, and transport it to each production section according to the corresponding flow rate. When the liquid level in the thermal energy storage tank 8 reaches the set maximum value or minimum value, combined with the temperature sensing unit 4 to obtain the real-time temperature of the production line at this time, the output flow rate is controlled to avoid danger caused by excessive temperature of one of the devices ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com