Single-tower multilayer non-pressure high-temperature superheated steam furnace

A superheated steam, high temperature technology, applied in steam boilers, steam superheating, steam generation methods using pressure combustion, etc., can solve problems such as hidden safety hazards, complex equipment, and huge size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

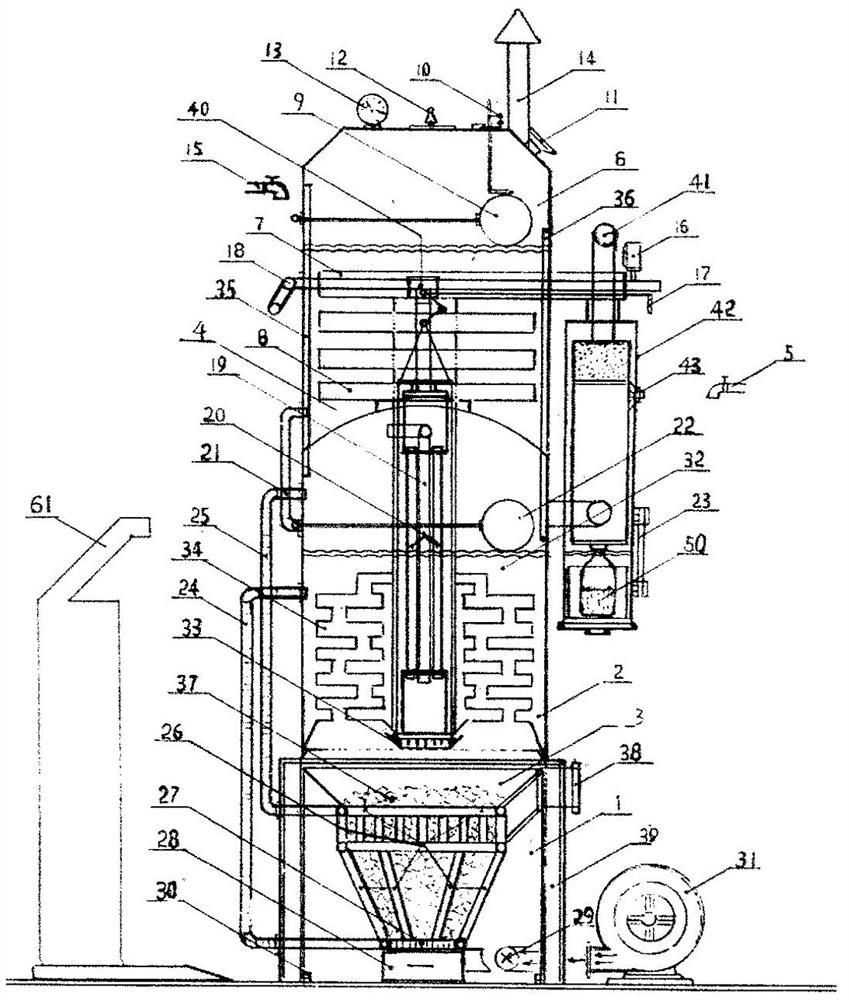

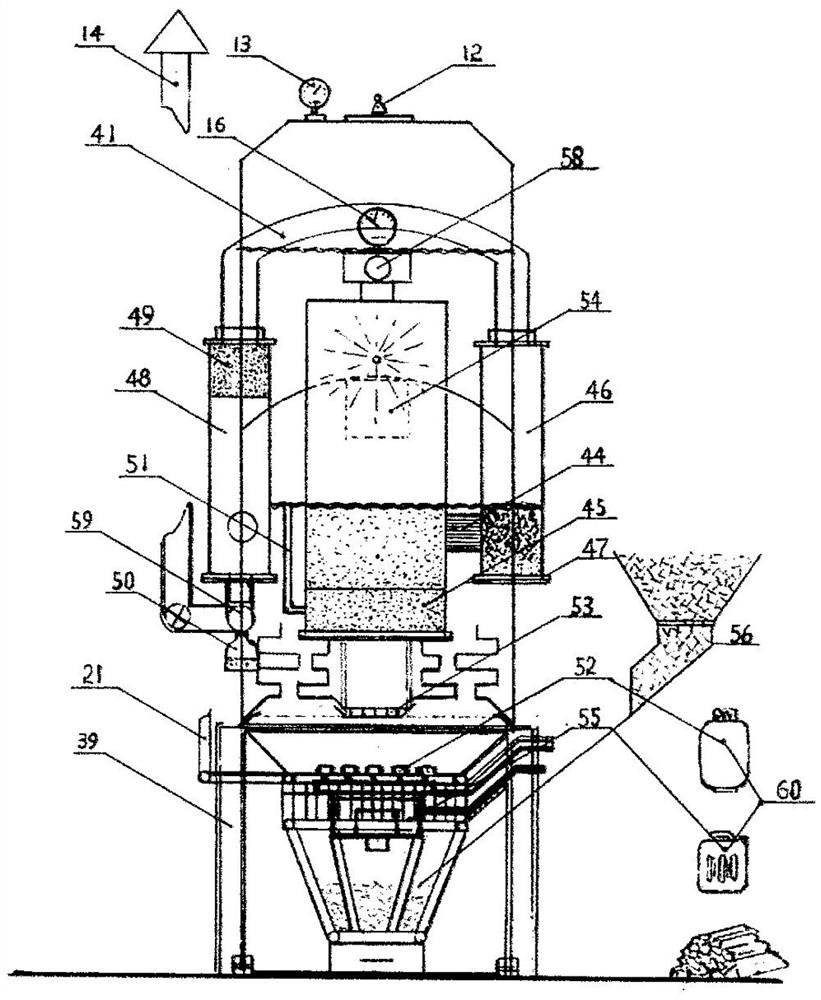

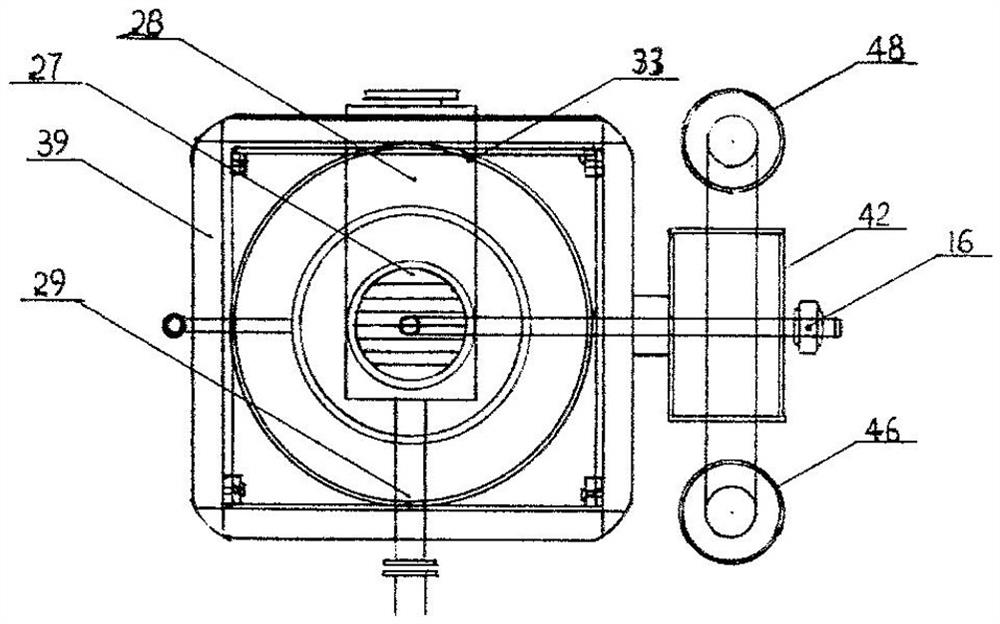

[0021]Further explanation below in combination with the accompanying drawings and the implementation plan: Looking at the accompanying drawings, a single-tower multi-layer pressureless high-temperature superheated steam furnace of the present invention includes: the upper section is a pot, and the lower section is a furnace, which are connected into a tower barrel shape. It is called a single tower, and its characteristics are: multiple towers can be used in conjunction, and the pot and furnace can be separated and used alone. The lower part of the single tower is the seat of the furnace. The middle part of the tower is the main combustion chamber, and above the fire chamber are multi-layered, 34, 7, 8 heat-gathering chambers, as shown in the figure, they are layer by layer, circular, overlapping. The heat energy crosses and repeats in the sealed condition, and flows in the warehouse. The purpose is: to allow the heat energy to be blocked for a long time, to prolong the radiat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com