Electric thermal storage preheating steam generator

A technology of steam generator and electric heat storage, which is applied in the direction of steam generation, steam generation method, preheating water accumulator, etc., which can solve the problems of large electric load impact, large electric load impact, and high operating cost, and achieve reduction Power load, high foresight, and the effect of improving the overall thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

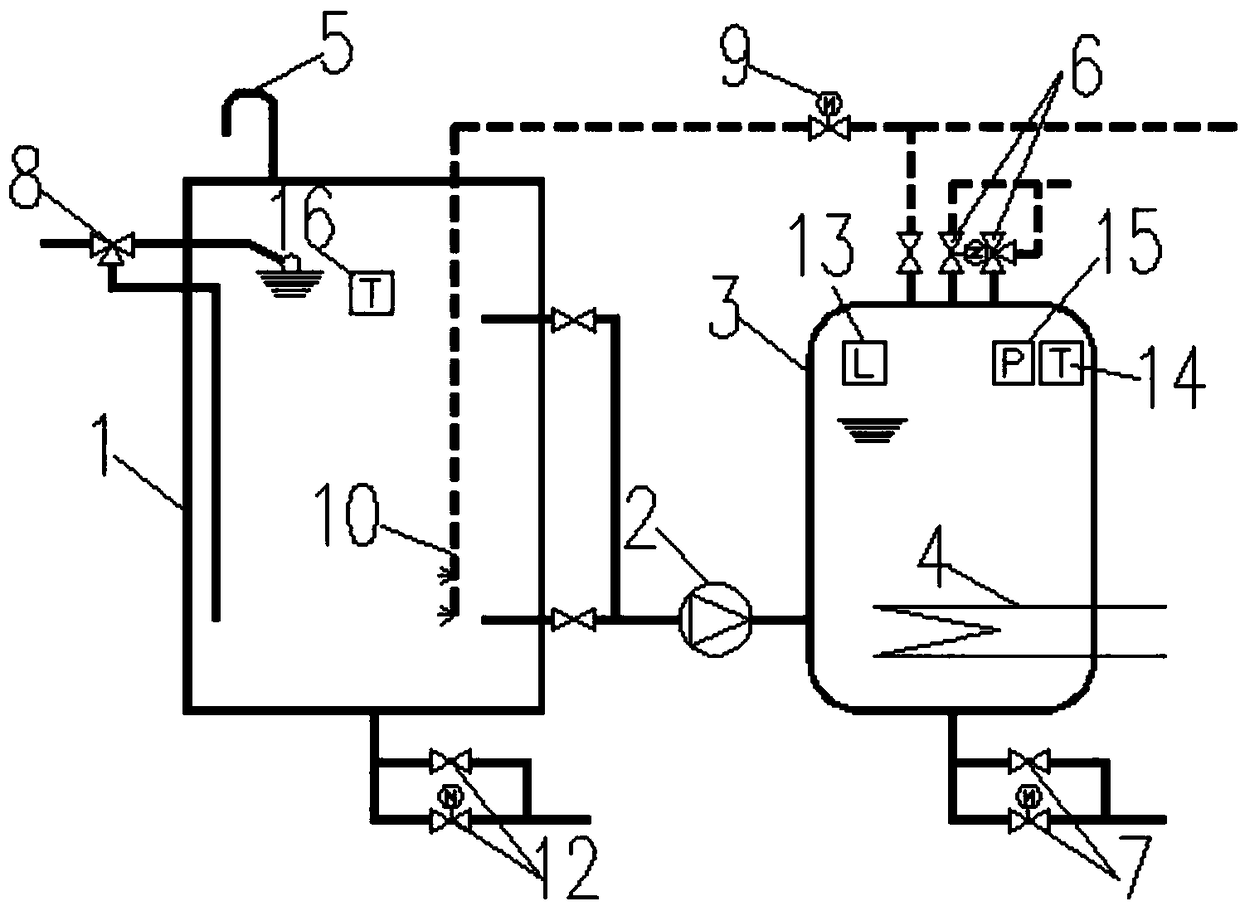

Embodiment 1

[0026] like figure 1 As shown, an electric heat storage preheating steam generator includes a heat storage open water tank 1, and the heat storage open water tank 1 is a device for heat storage and preheating of the steam water replenishment system during the night low valley electricity and daytime parity electricity period. The heat-opening water tank 1 is provided with an upper water outlet and a lower water outlet, both of which are connected to the suction port of the booster pump 2. Since the water temperature at the top of the heat-storage open water tank 1 is relatively high, the booster pump usually 2. The upper water outlet is pumped, and the lower water outlet is used as an emergency water outlet. The outlet of the pressurizing pump 2 is connected to the water inlet of the heating pressurized water tank 3 for replenishing the heated pressurized water tank 3 . The top of the heat storage open water tank 1 is provided with a breathing tube 5, which is used as a means ...

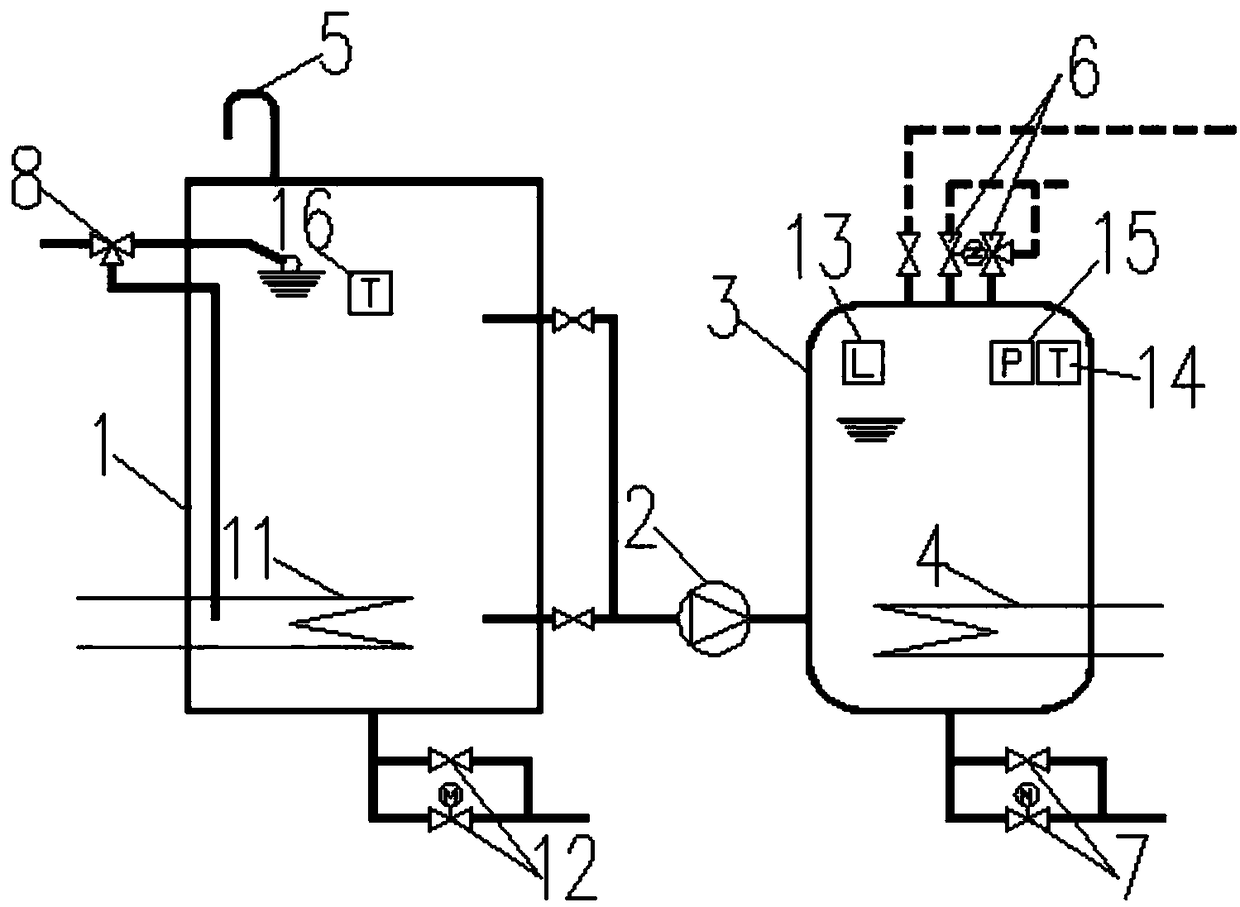

Embodiment 2

[0030] like figure 2 As shown, an electric heat storage preheating steam generator includes a heat storage open water tank 1, and the heat storage open water tank 1 is a device for heat storage and preheating of the steam water replenishment system during the night low valley electricity and daytime parity electricity period. The heat-opening water tank 1 is provided with an upper water outlet and a lower water outlet, both of which are connected to the suction port of the booster pump 2. Since the water temperature at the top of the heat-storage open water tank 1 is relatively high, the booster pump usually 2. The upper water outlet is pumped, and the lower water outlet is used as an emergency water outlet. The outlet of the pressurizing pump 2 is connected to the water inlet of the heating pressurized water tank 3 for replenishing the heated pressurized water tank 3 . The top of the heat storage open water tank 1 is provided with a breathing tube 5, which is used as a means...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com