Cold air heating and flue gas waste heat comprehensive utilization system for power station boiler

A technology for flue gas waste heat and power station boilers, which is applied to feed water heaters, lighting and heating equipment, preheating, etc. High system flexibility and reduced heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

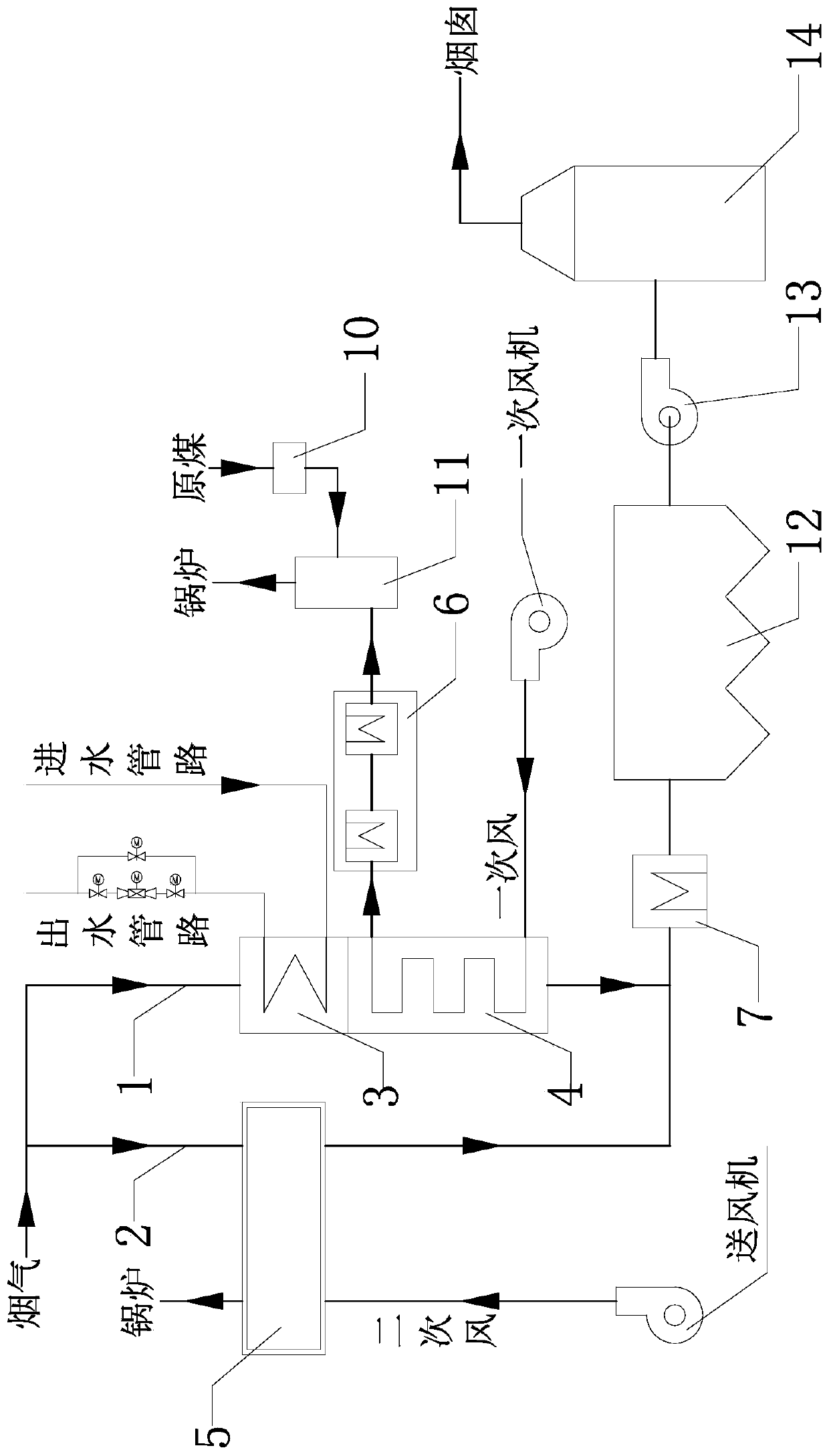

[0021] The invention relates to a system for comprehensive utilization of cold wind heating of power plant boilers and waste heat of flue gas. The high-temperature flue at the tail of the boiler is branched into the first flue gas channel 1 and the second flue gas channel 2 arranged in parallel, and the ends of the two are merged into a low-temperature flue, which respectively realizes heat exchange with the primary air and the secondary air.

[0022] Such as figure 1 As shown, the first flue gas passage 1 sequentially passes through the flue gas inlet and flue gas outlet of the flue gas-feed water heat exchanger 3 and the flue gas inlet and flue gas outlet of the primary air preheater 4 according to the flue gas flow direction. The water inlet pipeline and the water outlet pipeline of the water supply pipeline are respectively connected to the water inlet and the water outlet of the flue gas-feedwater heat exchanger 3 to realize the heat exchange between the water supply pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com