Thermal power generating unit deep peak regulation and backheating energy saving method

A technology for thermal power units and cogeneration units, which is applied in the directions of chemical instruments and methods, separation methods, lighting and heating equipment, etc., can solve problems such as increasing power generation load, reduce coal consumption, save operating energy consumption, and reduce the amount of heating steam Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

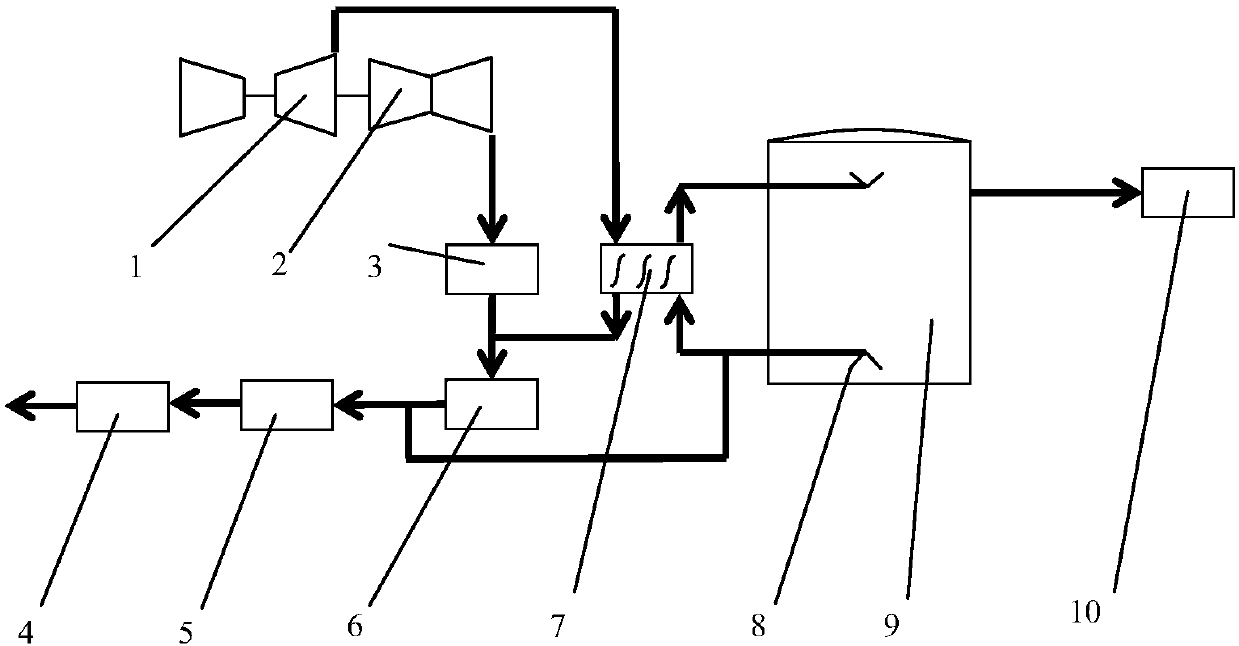

[0035] The deep peak regulation and heat recovery energy-saving method of the thermal power unit in this embodiment is based on the following figure 1 system shown. The thermal power unit of this embodiment is described by taking the thermal power unit system transformed by the micro-oil ignition and stable combustion system as an example. Such as figure 1 As shown, the thermal power unit system includes: medium pressure cylinder 1; low pressure cylinder 2; condenser 3; deaerator 4; low pressure heater 5; finishing processor 6; steam water heat exchanger 7; water distributor 8; Hot water storage tank 9; primary pipe network 10.

[0036] Wherein, the medium-pressure cylinder 1 is connected with one side of the low-pressure cylinder 2 and one side of the steam-water heat exchanger 7 at the same time, and the other side of the low-pressure cylinder 2 is connected with one side of the condenser 3; One side is connected with the other side of the steam-water heat exchanger 7 and...

no. 2 example

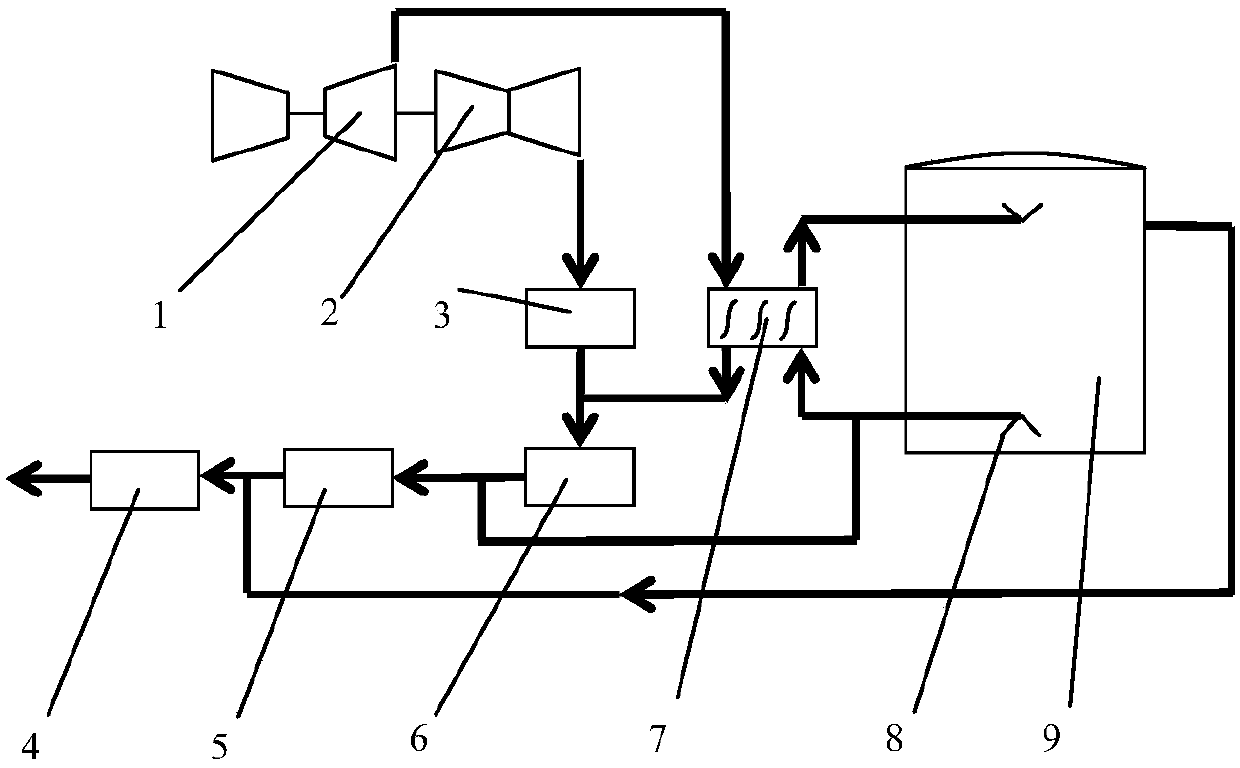

[0045] The deep peak regulation and heat recovery energy-saving method of the thermal power unit in this embodiment is based on the following figure 2 system shown. Such as figure 2 As shown, the thermal power unit system includes: medium pressure cylinder 1; low pressure cylinder 2; condenser 3; deaerator 4; low pressure heater 5; finishing processor 6; steam water heat exchanger 7; water distributor 8; Hot water storage tank 9.

[0046] The method for deep peak regulation and heat recovery energy saving of thermal power units in this embodiment is basically the same as that of the first embodiment, the difference is that the method for deep peak regulation of thermal power units in this embodiment is based on figure 2 system shown. figure 2 The system shown with figure 1 The difference of the shown system is that the hot water in the upper part of the hot water storage tank 9 in the first embodiment is supplied to the primary pipe network, while the hot water storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com