Self-sealing joint

A self-sealing and joint technology, applied in the direction of mechanical equipment, couplings, etc., can solve the problems of uneven force distribution of the sealing spool, wear of the sealing spool, sealing gap of the self-sealing joint, etc., to prevent wear and natural inclination , to ensure the effect of verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

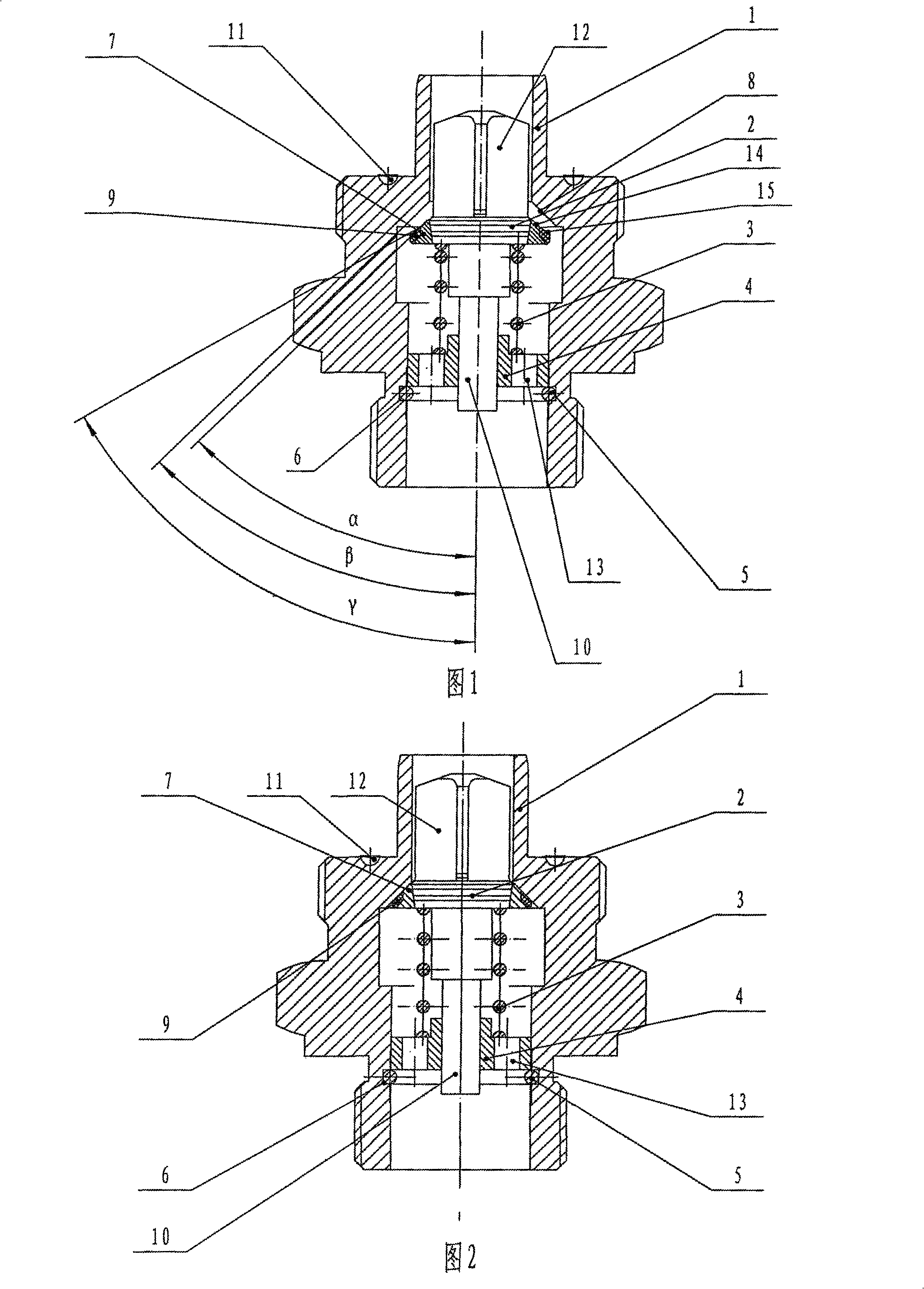

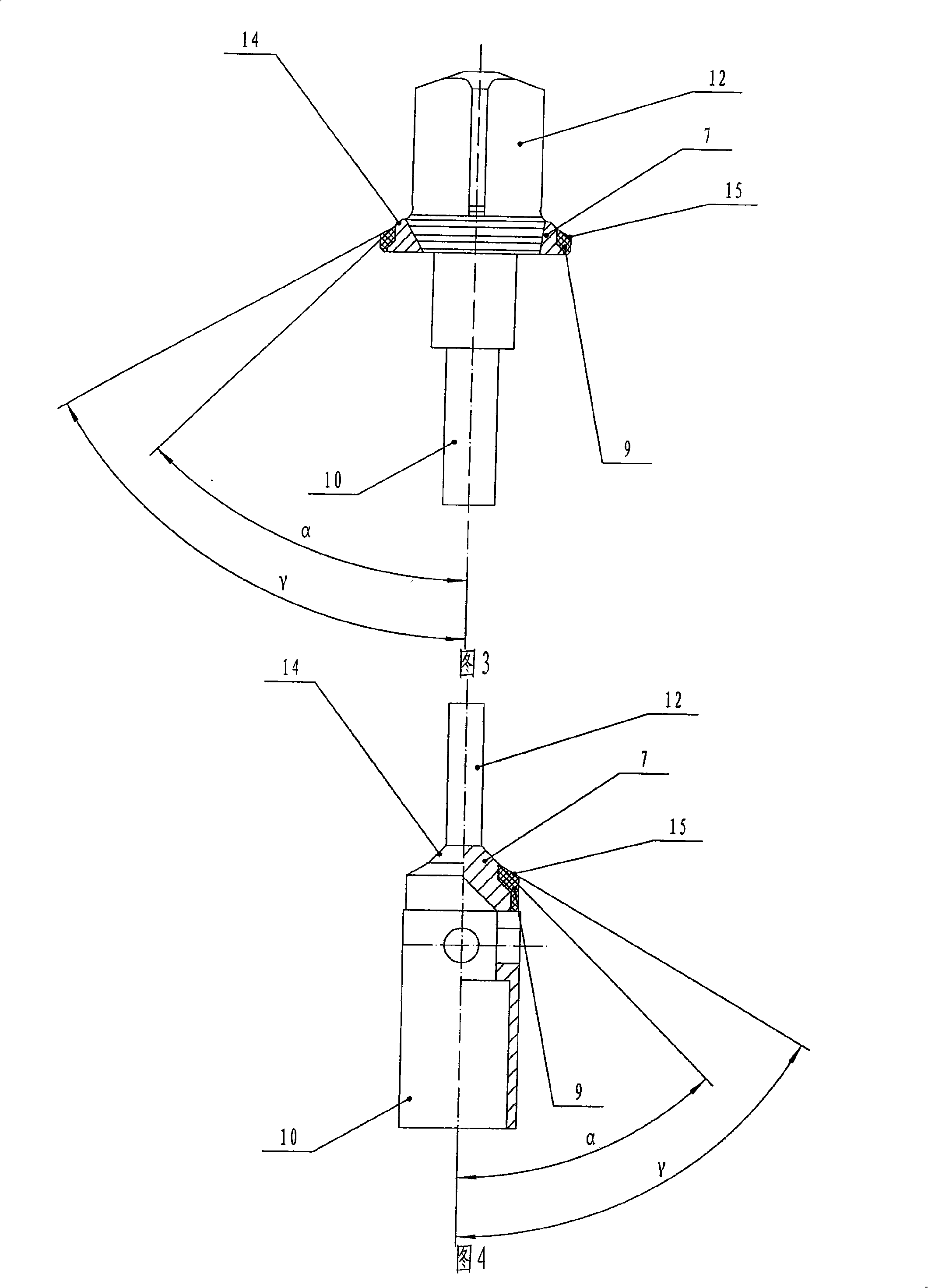

[0017] As shown in Figure 1, Figure 2 and Figure 3, in this specific embodiment, the self-sealing joint of the present invention includes a joint body 1, a sealing valve core 2 located in the joint body 1, a return spring 3, and a valve for liquid circulation. The spring seat 4 of the through hole 13 and the limit retaining ring 5; the limit retaining ring 5 is placed on the groove 6 of the inner wall of the joint body 1; The concave seal groove 11 used in cooperation with the protrusion on the not shown in the middle); the spring seat 4 is connected to the top of the stop ring 5; the guide rod 10 of the sealing valve core 2 is slidably matched with the center hole of the spring seat 4 The top of the back-moving spring 3 rests on the middle part of the sealing valve core 2, and the bottom of the back-moving spring 3 rests on the spring seat 4; the jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com