Calibration compensation method for rotating transformer angle observation error based on velocity rotating platform

A technology of resolver and rate turntable, which is applied in the direction of instruments, uses electric/magnetic devices to transmit sensing components, etc., can solve the problems of discontinuity, inability to describe the short-cycle variation law of resolvers, and unsatisfactory calibration results, and achieves improved performance. The effect of angle measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

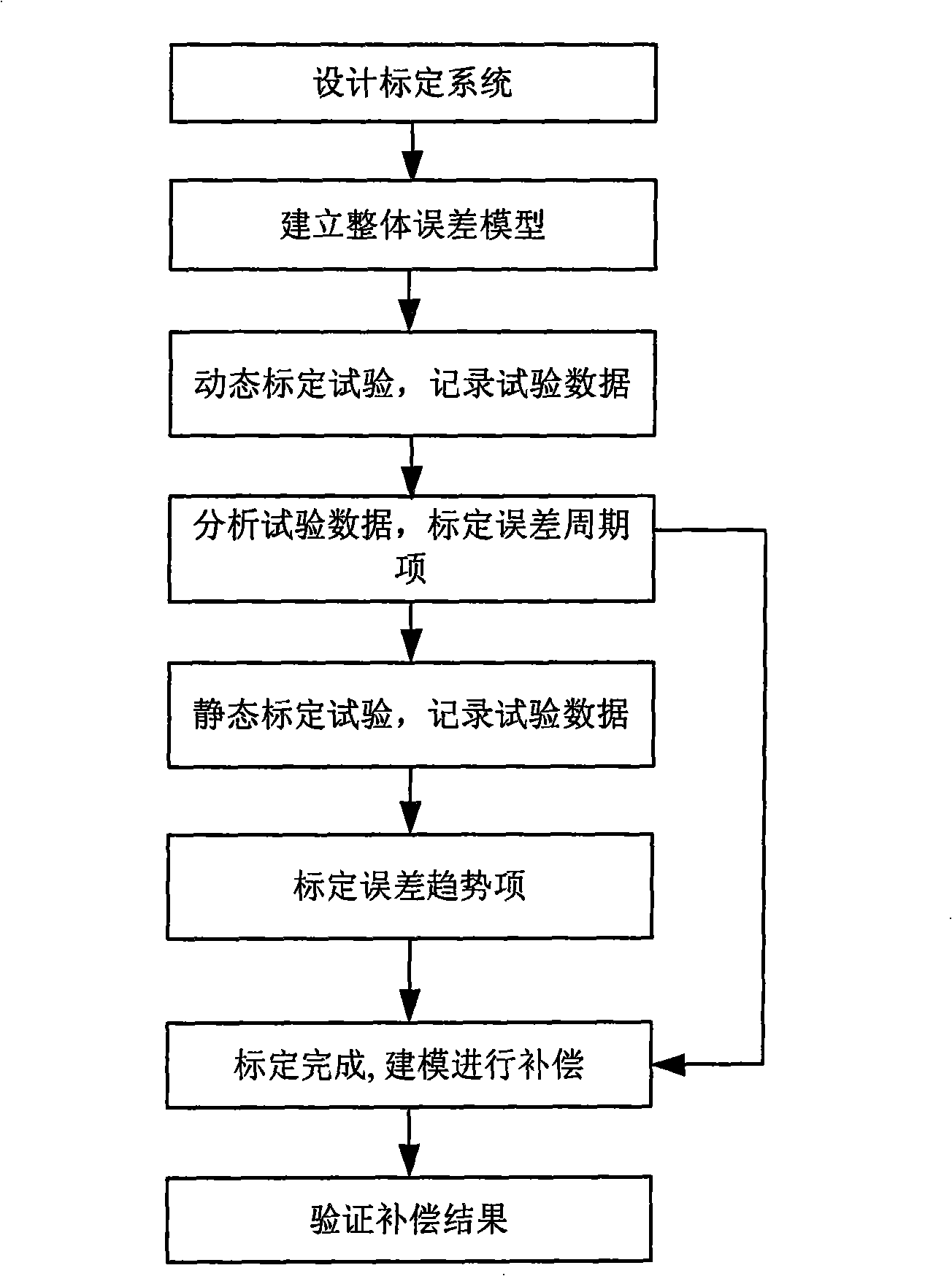

[0016] Such as figure 1 As shown, the present invention firstly designs the digital calibration system of the resolver, and then establishes the overall error model of the resolver. Through the dynamic calibration test of the digital calibration system, the dynamic continuous output of the resolver can be obtained, and the periodic error term coefficient of the resolver can be calibrated , and then through the static calibration test, the angle-related first-order and zero-order errors of the resolver are calibrated. The specific steps are as follows:

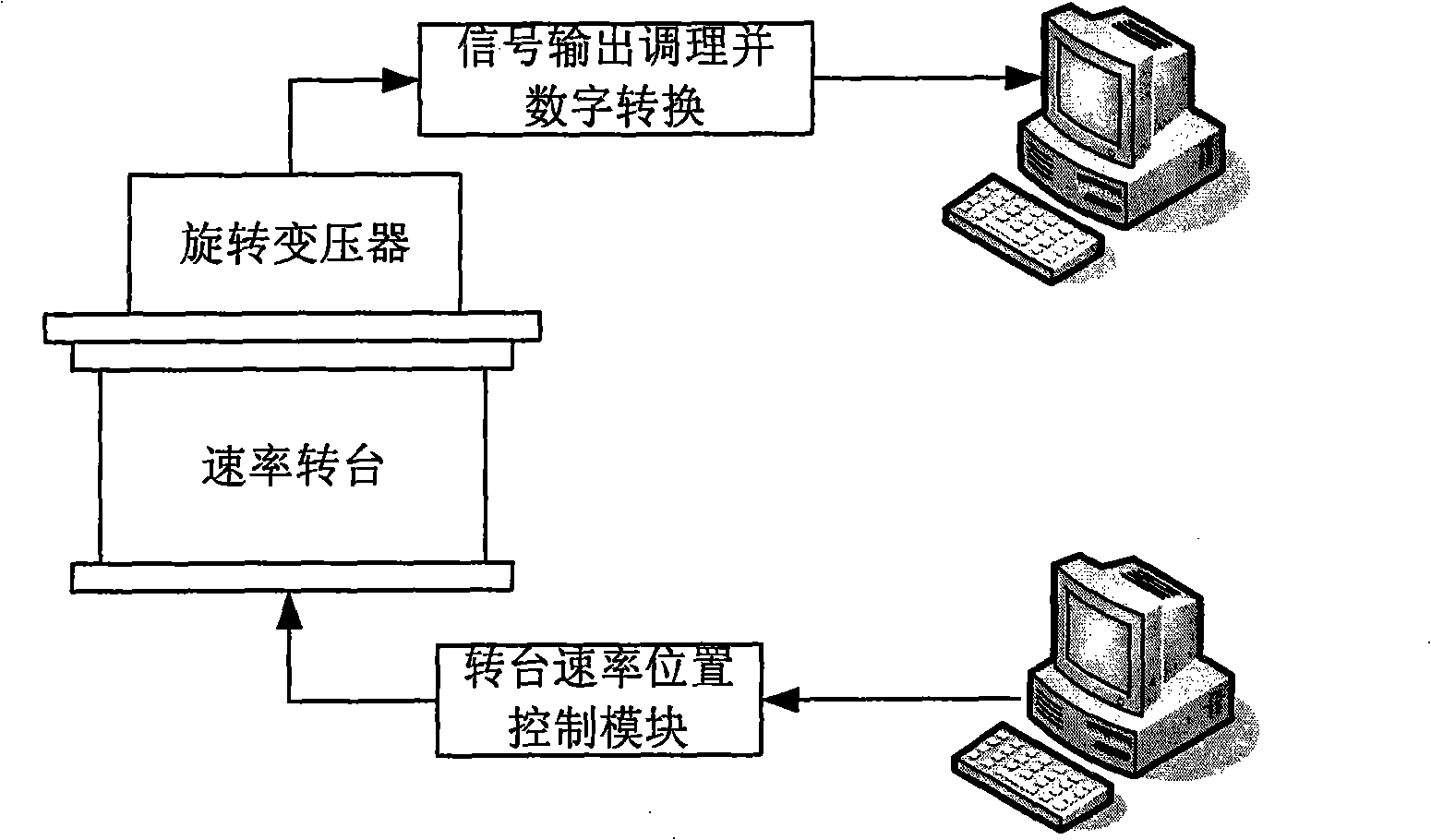

[0017] 1. Design a set of digital calibration system for resolver, such as figure 2 As shown, the digital calibration system is composed of a speed turntable, a turntable speed position control module, a resolver signal output conditioning and a digital conversion module. The speed and position control module adopts a closed-loop method to precisely control the rotation of the turntable according to the given parameters. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com