PCA-based robot wire drawing high-speed railway white vehicle body workpiece accurate calibration method

A calibration method and robot technology, applied in manufacturing tools, metal processing equipment, grinding machines, etc., can solve the problem of insufficient calibration accuracy of the workpiece coordinate system, and achieve the effect of improving surface quality and accurate calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

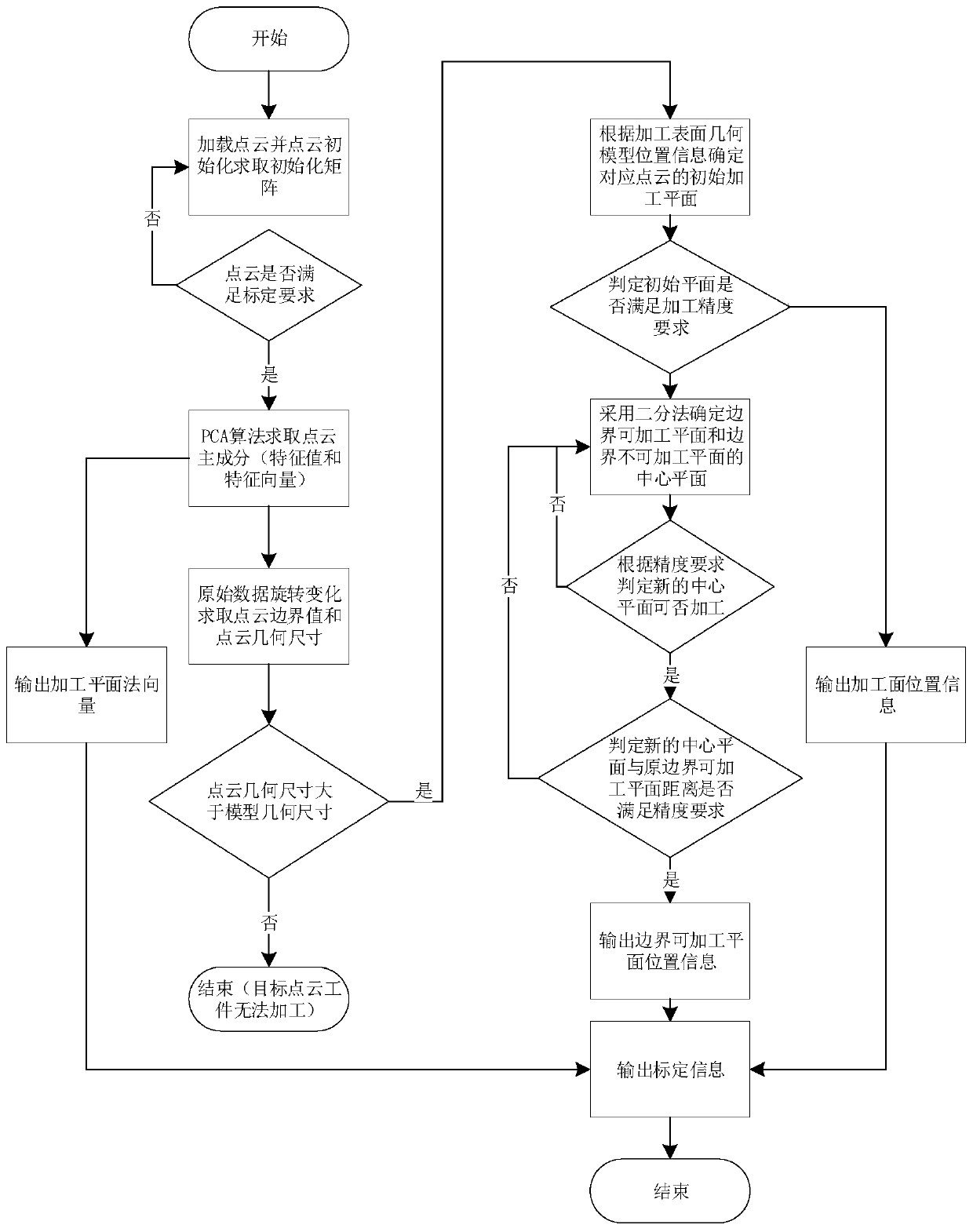

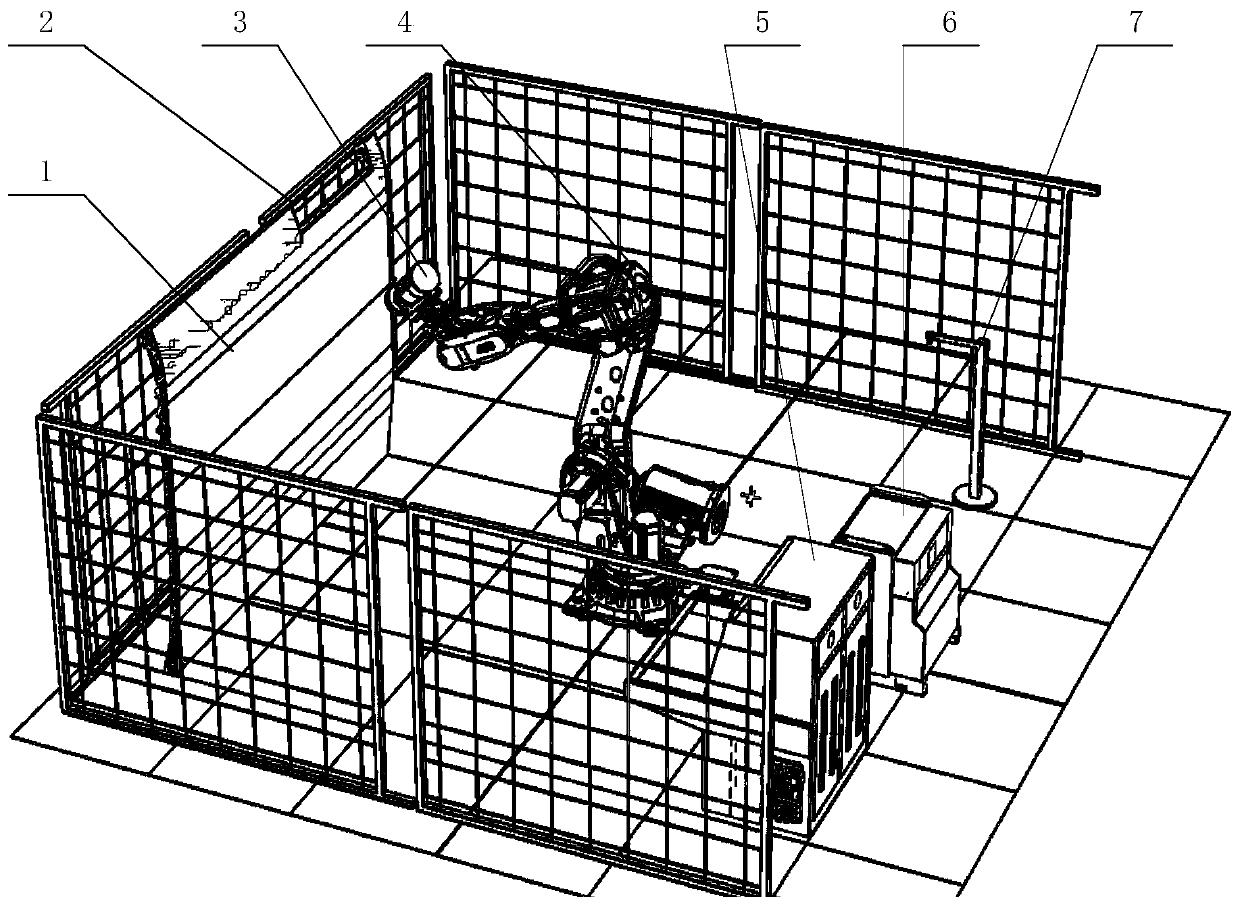

[0040] The present invention proposes a PCA-based method for precise calibration of robot-drawn high-speed rail body-in-white workpieces. The main workflow is as follows: figure 1 Shown, the actual processing equipment schematic diagram that the present invention adopts is as figure 2 As shown, including the safety fence, the terminal scanner, the robot body, the robot console, the robot control cabinet and the calibration rod, the operation is performed on the robot console, and the terminal mechanical arm of the robot body is controlled to drive the terminal scanner to scan and obtain the high-speed rail body-in-white. 3D point cloud model, and then process the point cloud data, and perform workpiece calibration based on PCA.

[0041] The traditional calibration method mainly completes the calibration through the "three-point method" or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com