Line laser sensor space pose calibration piece and calibration method

A pose calibration and sensor technology, applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problems of guaranteeing the processing accuracy of key geometric features and the difficulty of processing acceptance, and achieves simple and easy calibration operation, accurate calibration, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described below in conjunction with concrete processing example:

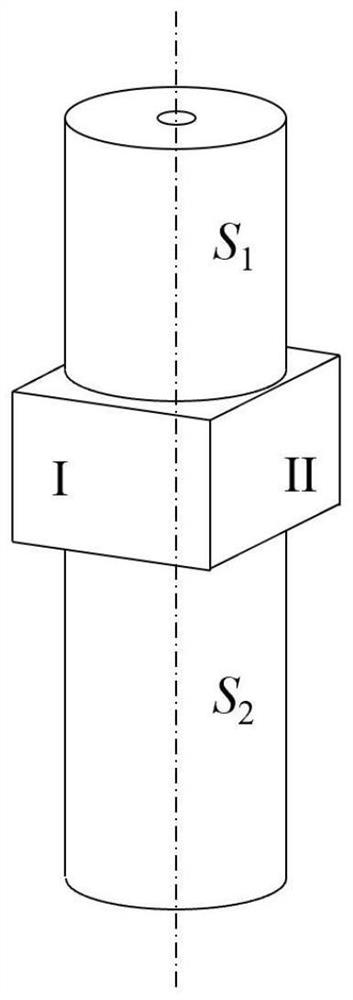

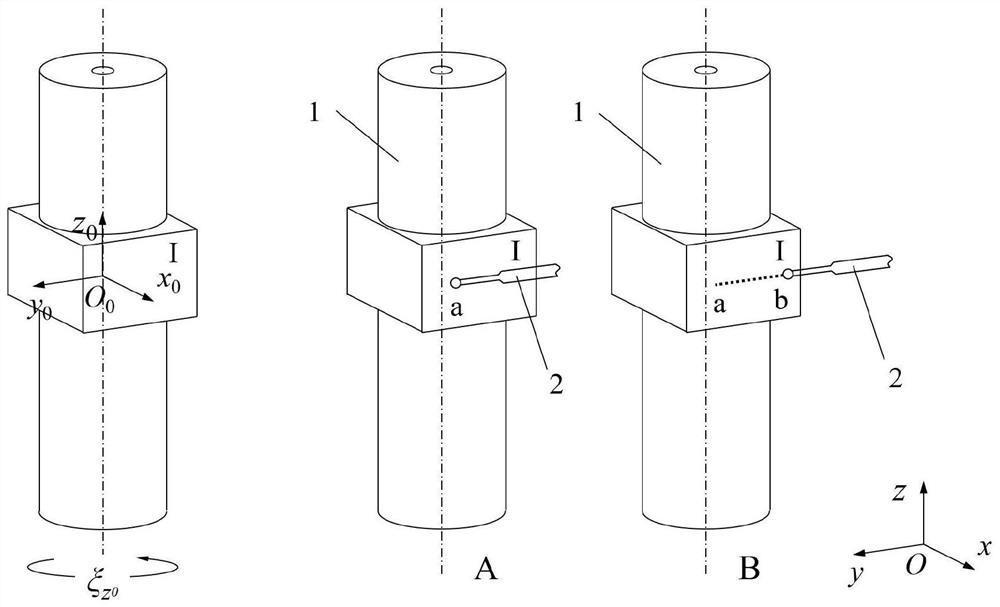

[0029] The line laser sensor space pose calibration part involved in the present invention, such as figure 1 As shown, on the basis of a standard mandrel, a cuboid metal block is arranged in the middle of the axis, and a tapered hole is provided in the center of the upper and lower end faces of the standard mandrel for fixing. The upper shaft section S1 and the lower shaft section S2 of the standard mandrel part of the calibration piece require both coaxiality and cylindricity to be 1 μm. The cuboid metal block has strict requirements only on two adjacent planes I and II. The perpendicularity between plane I and plane II is 1 μm, and the parallelism between plane I and plane II and the axis of the standard mandrel is 1 μm.

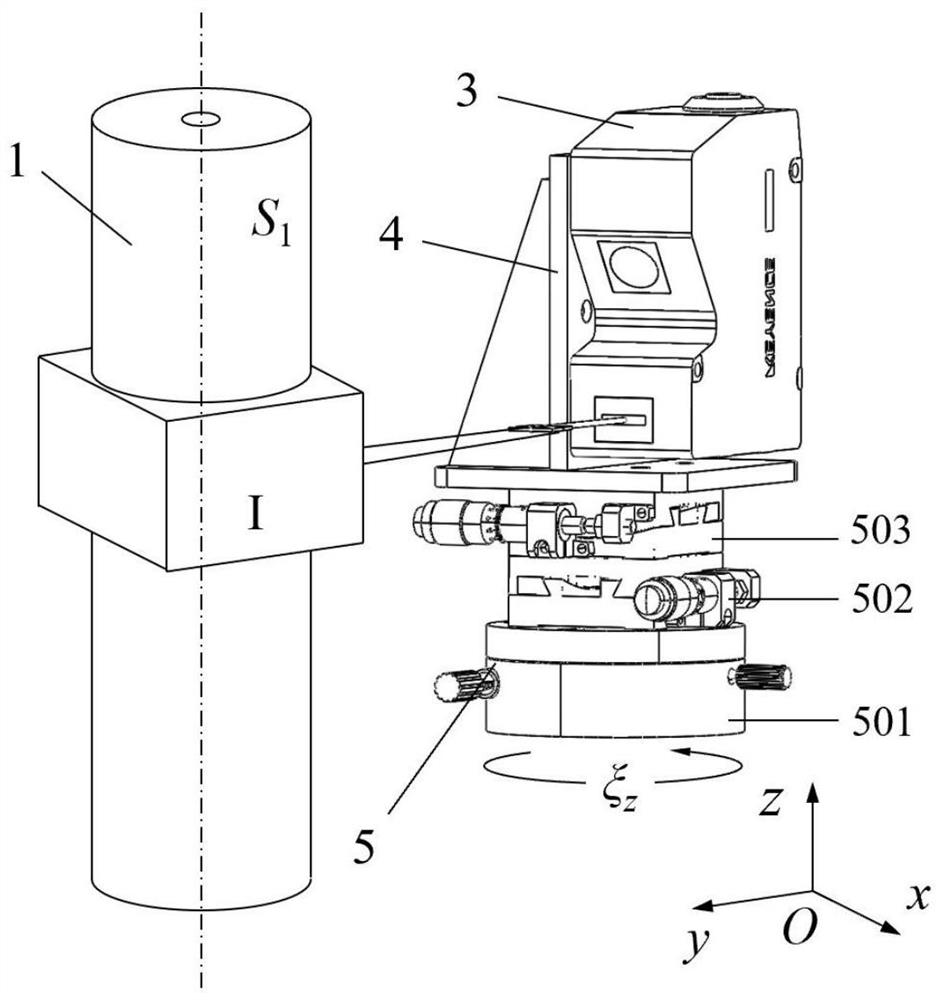

[0030] The line laser sensor 3 is connected with the three-dimensional angle micro-motion platform 5 through the connecting mechanism 4. The three-dimension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com