Safety energy-saving electric heating cooker

An electric heating pot, a safe technology, applied to the shell/cover of the cooker, cooking utensils, household appliances, etc., can solve the inconvenience of assembly and disassembly and maintenance of the heating structure, the low thermal efficiency of the pot liner manufacturing and molding accuracy, and the unreliable electrical connection of the electric heater In order to avoid the unreliability of electrical connection, improve the life of the pot and ensure the effect of cooking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention is further elaborated:

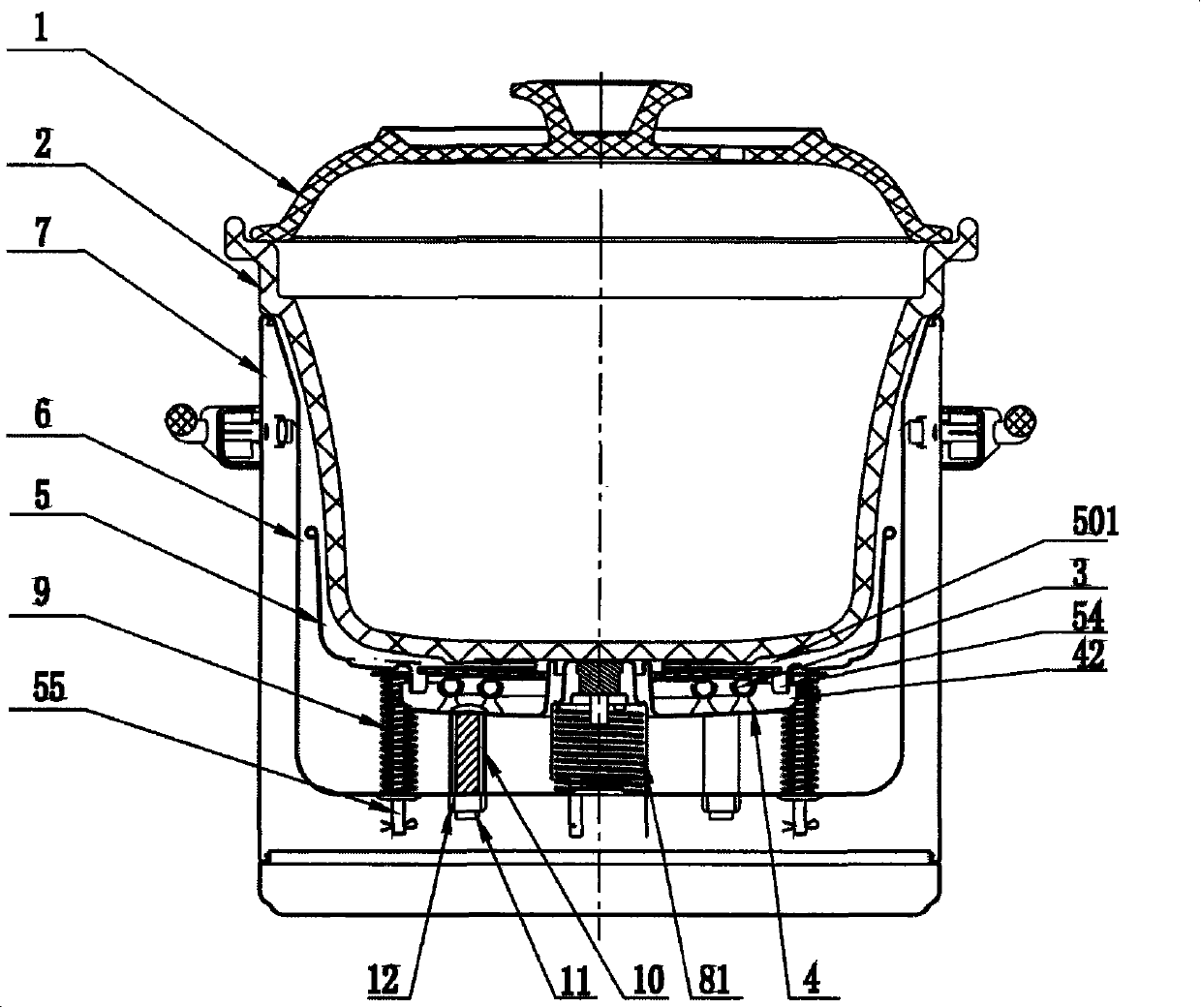

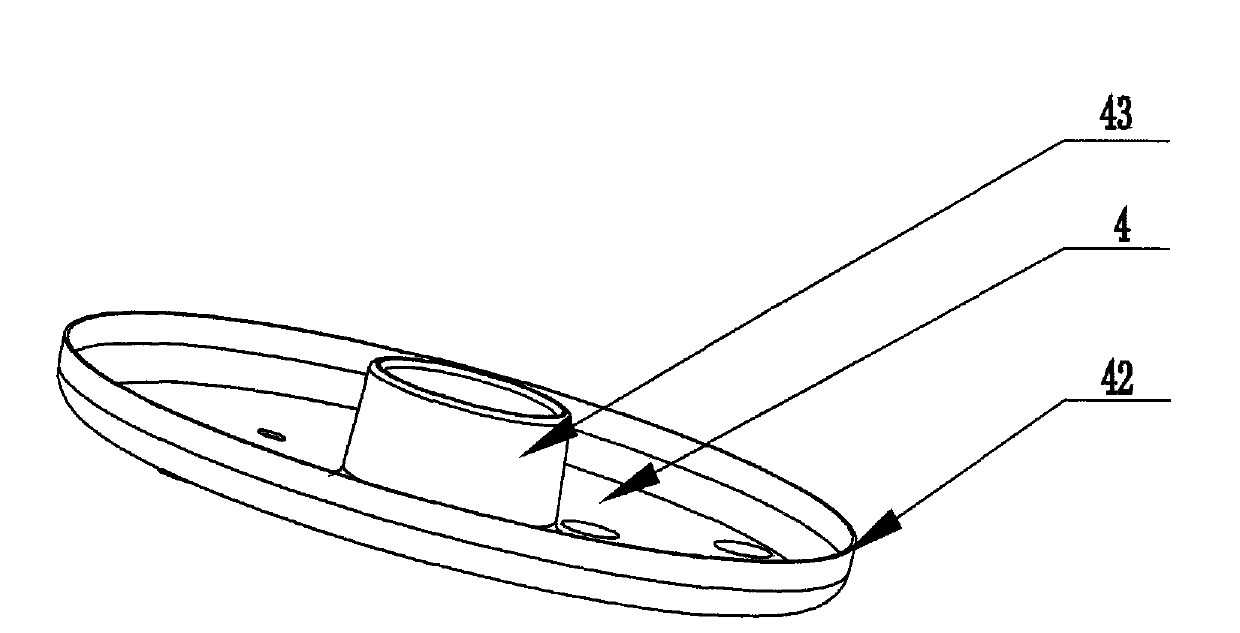

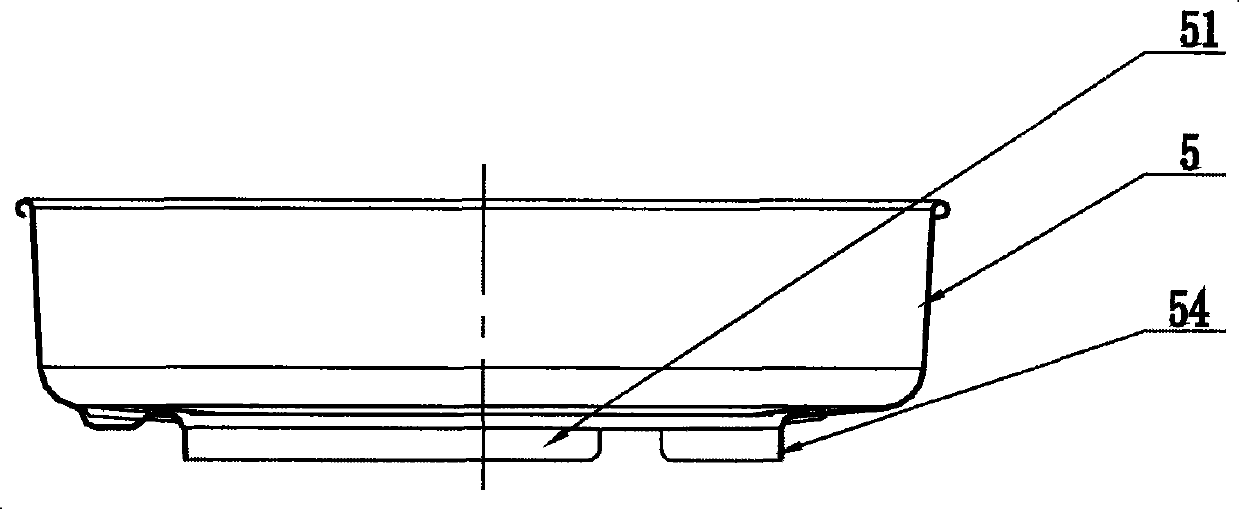

[0023] Such as figure 1 , figure 2 As shown, the present invention is a safe and energy-saving electric heating pot, including a pot cover 1, a pot liner 2, an electric heater 3, a reflector 4, a heat conduction sleeve 5, a heat insulation sleeve 6, a casing 7 and a control device 8, etc., the inside of the casing 7 Fix the heat insulation sleeve 6, the bottom of the pot liner 2 is placed in the heat conduction sleeve 5, the heat conduction sleeve 5 is connected to the bottom of the heat insulation sleeve 6 through an elastic device, the electric heater 3 is fixed above the bottom of the heat insulation sleeve 6, and the bottom of the electric heater 3 is A reflector 4 is provided, the bottom of the heat conduction sleeve 5 corresponds to the opening 51 of the electric heater 3, and the closed heating and heat preservation chamber 501 formed between the pot gal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com