Porcelain colored drawing technique

A kind of craft and painting technology, applied in the field of porcelain painting technology, can solve the problems of long pattern life, single color of bottle body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

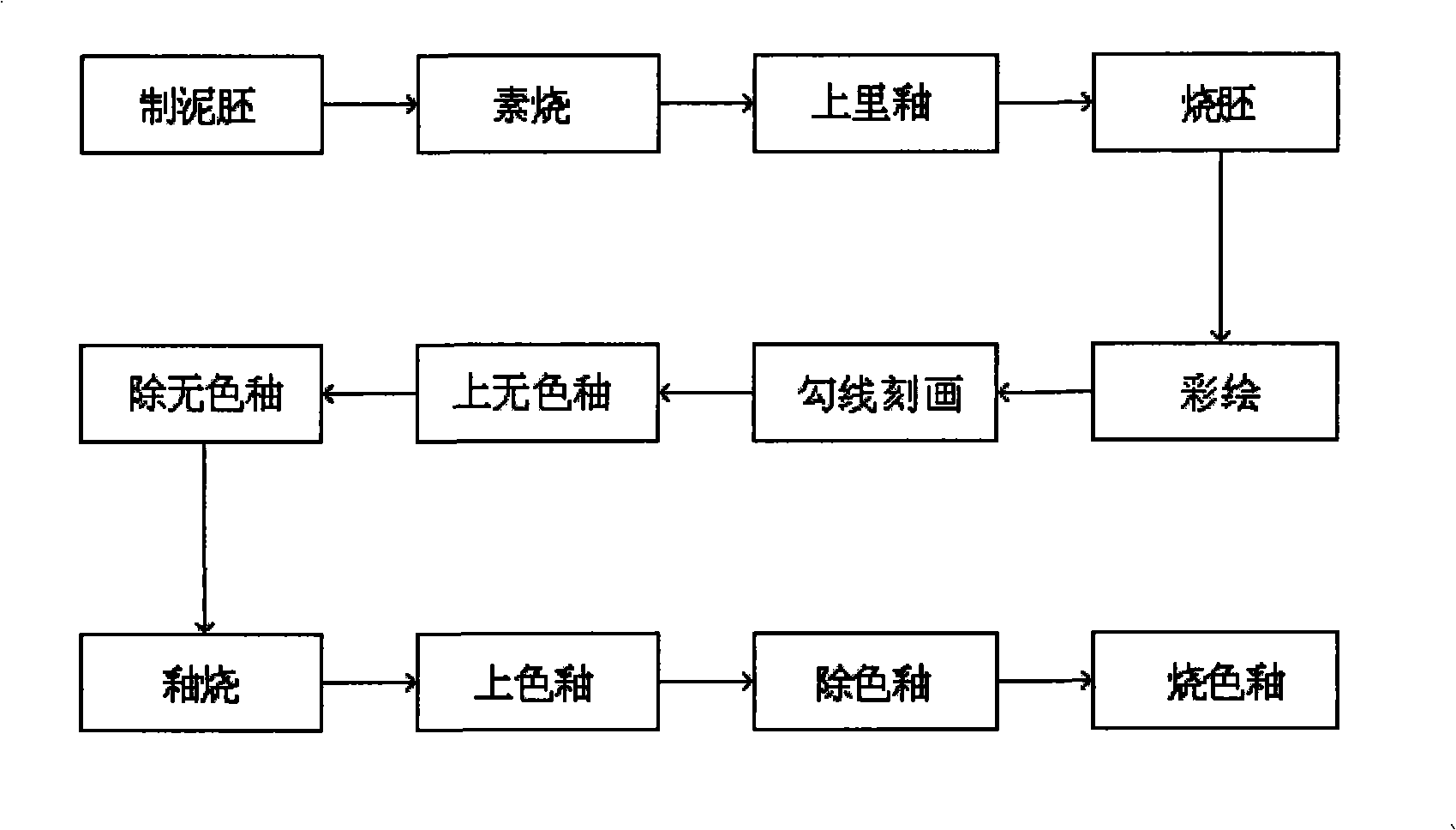

[0021] See accompanying drawing, porcelain color painting process comprises the following steps:

[0022] 1. Underglaze or inglaze color clay embryo;

[0023] 2. Underglaze or inglaze biscuit firing;

[0024] 3. Underglaze or underglaze glaze;

[0025] 4. Under-glaze or in-glaze fired embryos;

[0026] 5. Painting: drawing patterns on the underglaze or inglaze fired embryo;

[0027] 6. Hook line depiction: use utensils to carve imprints along the edge of the pattern on the plain embryo to form a pattern hook line;

[0028] 7. Apply colorless glaze: apply colorless glaze to the pattern part on the plain embryo;

[0029] 8. Except for the colorless glaze: after the colorless glaze is dry, remove the colorless glaze other than the pattern hook line on the plain embryo;

[0030] 9. Glaze firing: According to the underglaze or inglaze color process, the plain embryo is put into the kiln and fired at a temperature of 800°C-1400°C to obtain the underglaze or inglaze color embryo...

Embodiment 2

[0036] After step 9 of embodiment 1, polish the sideline: polish the sideline of the pattern hook line on the color embryo of firing underglaze or in-glaze color, and then continue the step 10 of embodiment 1 to remove the colorless glaze;

[0037] Other steps are the same as in Example 1 to obtain a finished product.

Embodiment 3

[0039] According to the steps of embodiment 2, repeat the steps of applying colored glaze three times, removing the colored glaze in the pattern hook line, and burning the colored glaze.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com