Composite etchant for 409L ferritic stainless steel and use method thereof

An etchant, stainless steel technology, applied in the field of stainless steel, can solve the problems of difficulty in grasping the erosion time of the sample, unstable metallographic display quality, short continuous use time, etc., to achieve easy analysis and research work, reduce corrosion in place, and Long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

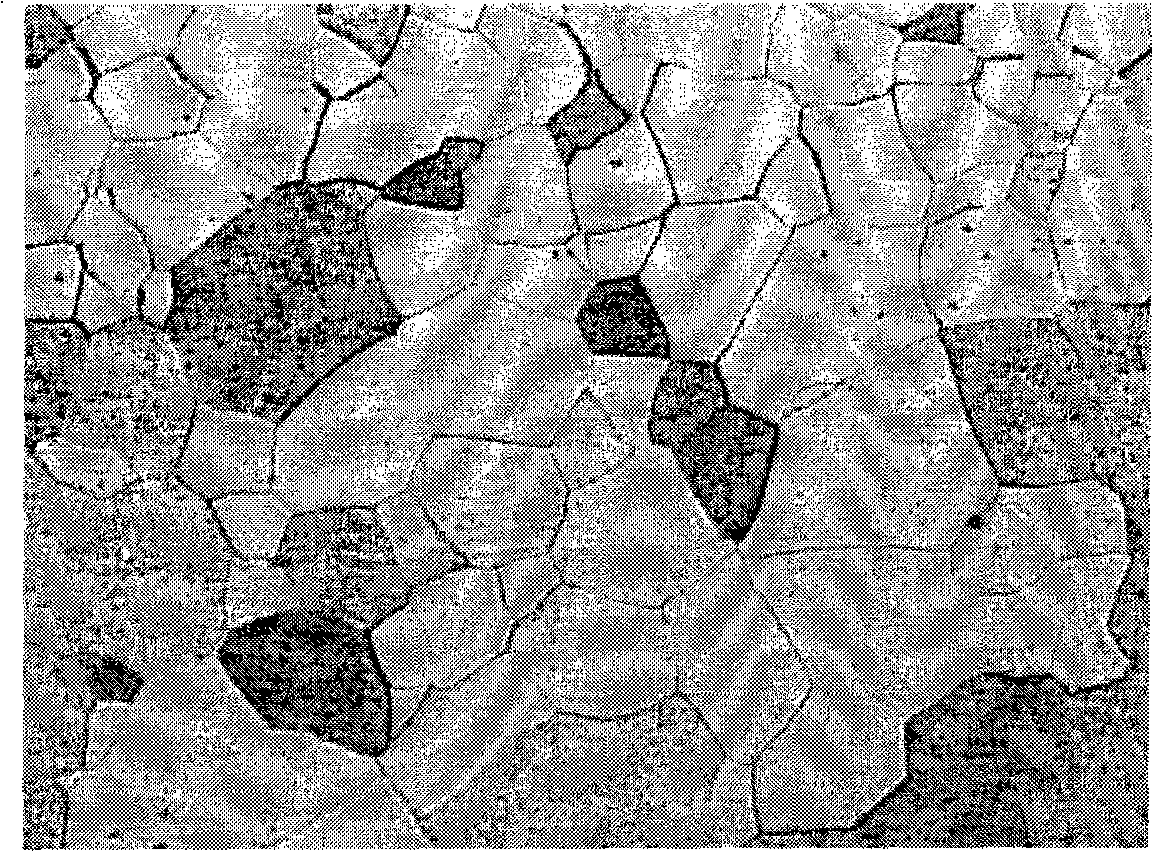

[0047] Embodiment 1. (see Figure 4 )

[0048] Compound etchant ratio:

[0049] Etching agent 1: picric acid (supersaturated) + 37% hydrochloric acid aqueous solution 5.2% + benzalkonium chloride 4.9% + ethanol 85.4%

[0050] Etching agent 2: hydrochloric acid 19%

[0051] Residence time in etchant 1 is 70, 60, 50 seconds

Embodiment 2

[0052] Embodiment 2. (see Figure 5 )

[0053] Compound etchant ratio:

[0054] Etching agent 1: picric acid (supersaturated) + 37% hydrochloric acid aqueous solution 14.9% + benzalkonium chloride 1% + ethanol 79.6%

[0055] Etching agent 2: hydrochloric acid 20%.

[0056] Residence time in etchant 1 is 40, 30, 20, 10, 10, 10 seconds

Embodiment 3

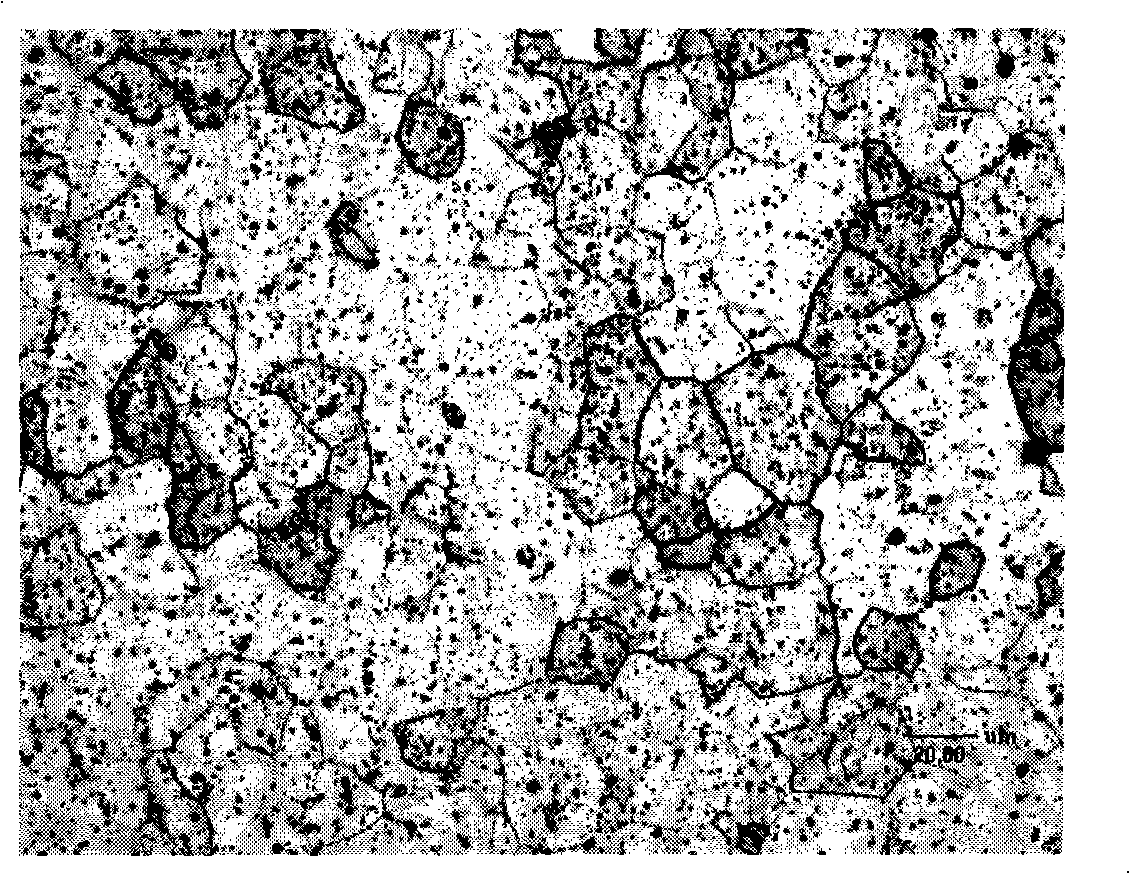

[0057] Embodiment 3. (see Image 6 )

[0058] Compound etchant ratio:

[0059] Etching agent 1: picric acid (supersaturated) + 37% hydrochloric acid aqueous solution 7.8% + benzalkonium chloride 1% + ethanol 86.7%

[0060] Etching agent 2: hydrochloric acid 22%.

[0061] Residence time in etchant 1 is 55, 45, 35, 25 seconds

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com