Cutter-head of machine for making furrows in farmland

A trencher and cutter head technology, applied in agricultural machinery and implements, agriculture, farming implements and other directions, can solve the problems of poor reliability, large load, easy damage to the keyway of the single-key shaft, etc., and achieves convenient disassembly and assembly and simple structure. , the effect of easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

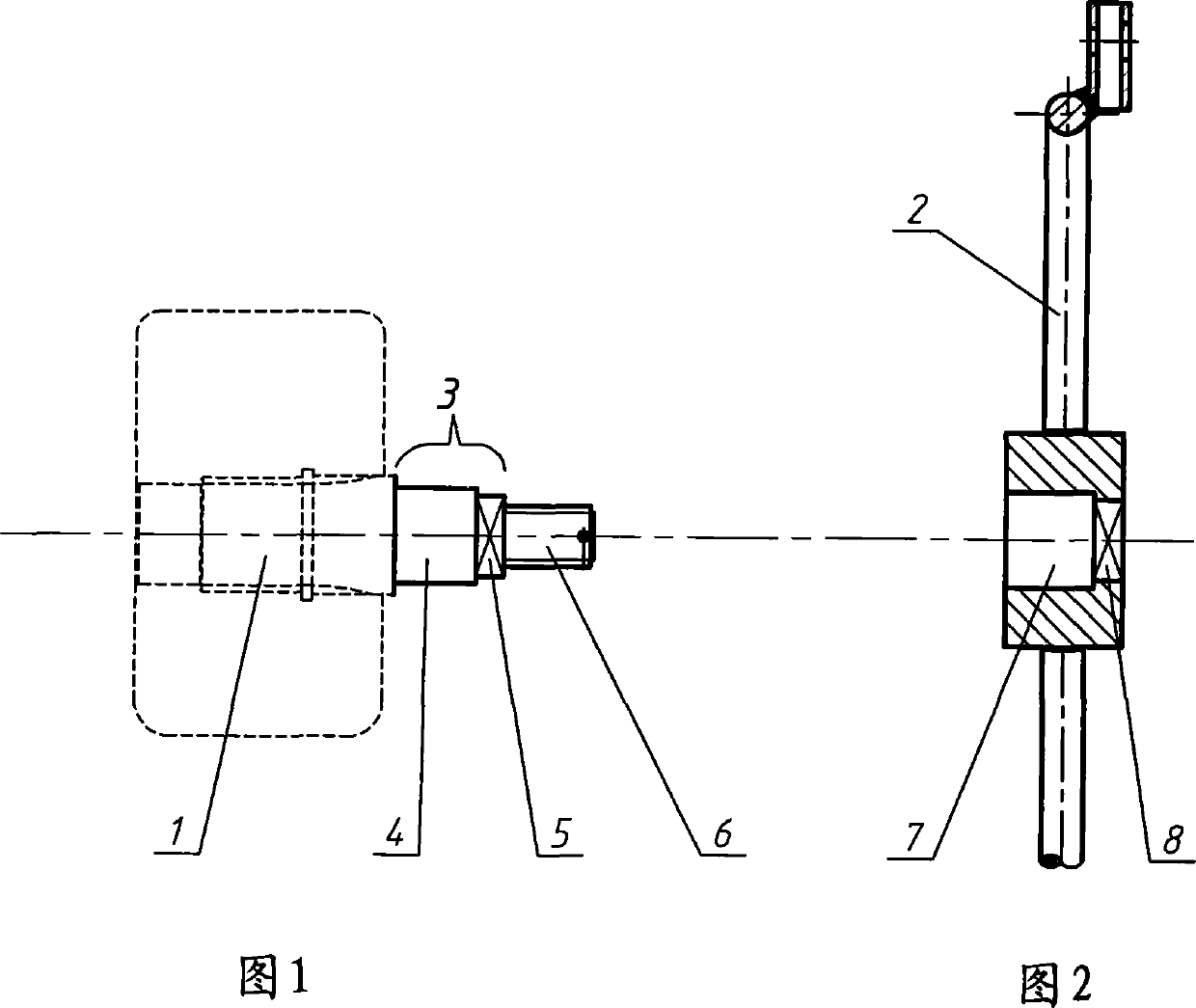

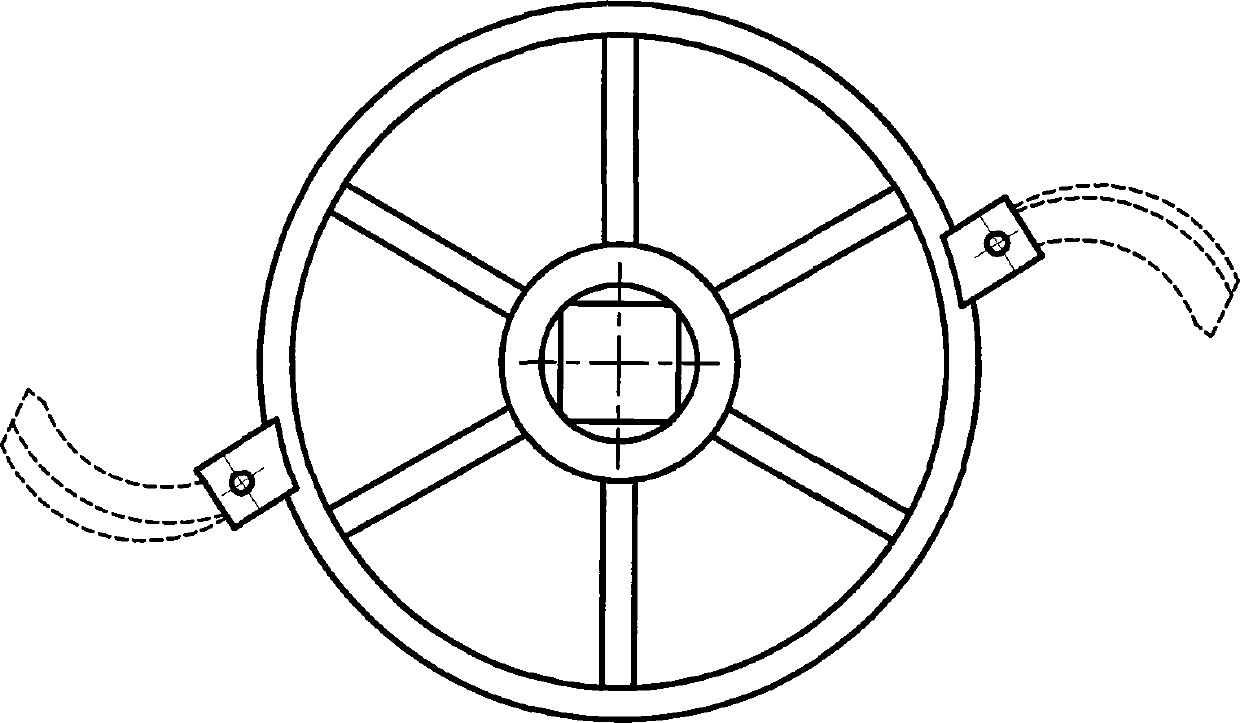

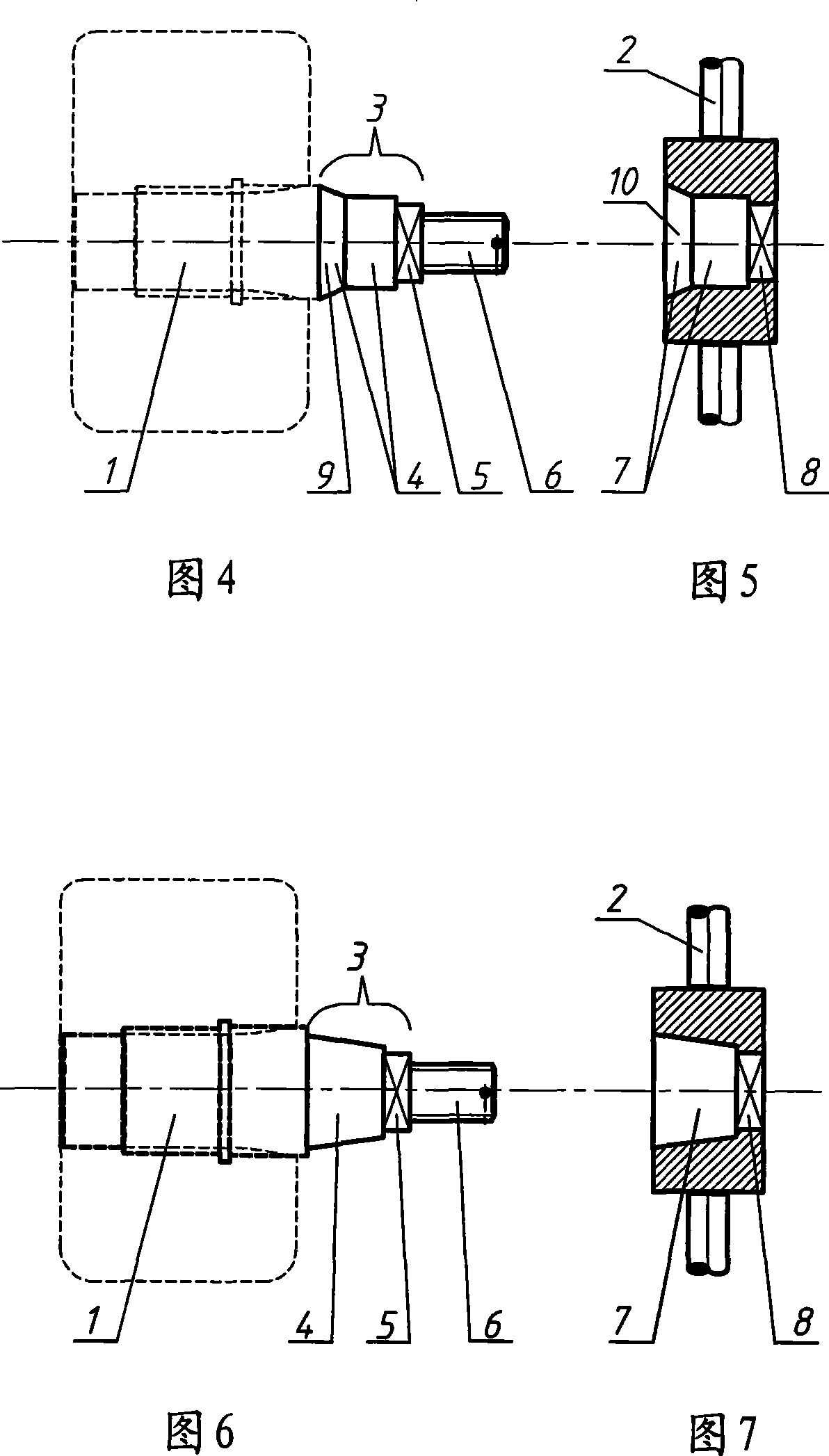

[0024] Embodiment 1 is shown in Figures 1, 2 and 3. The cutter head device of the farmland ditching machine includes cutter head shaft 1 and cutter head 2. The cutter head shaft is divided into two parts: the cutter head assembly section 4 and the cutter head positioning section 5 from the inside to the outside in the section 3 that matches the cutter head shaft hole. , the outermost end is the screw segment 6. The ratio of the length of the cutterhead assembly section to the cutterhead positioning section is 4:1. The cutterhead positioning section is a quadrangular prism; corresponding to the cutterhead assembly section and the cutterhead positioning section of the cutterhead shaft, the cutterhead shaft hole is also divided into two sections, the cutterhead assembly hole 7 and the cutterhead positioning hole 8, and the cutterhead assembly The hole is an inner cylindrical hole, and the positioning hole of the cutter head is an inner quadrangular prism hole. The coupling gap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com