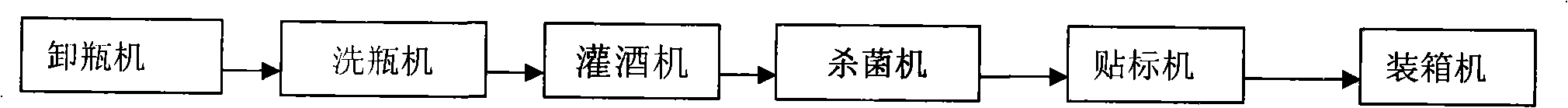

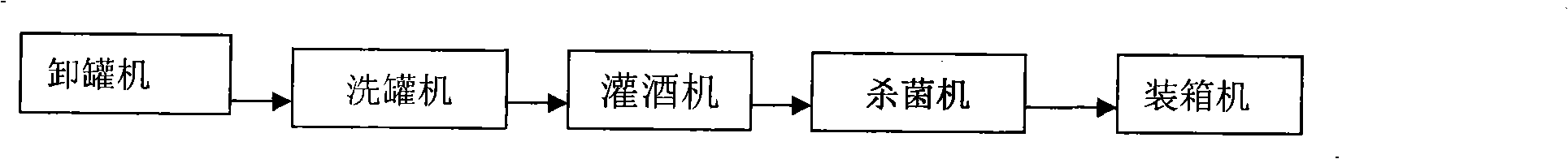

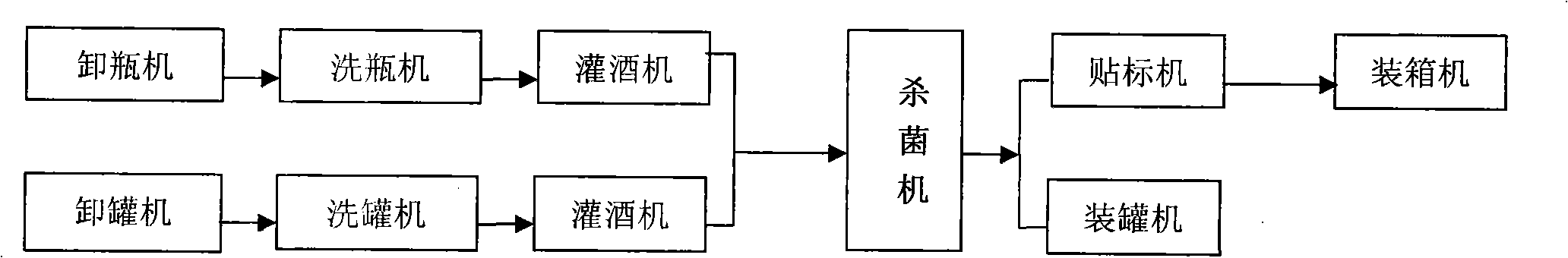

Method for simultaneously producing products on beer can production line and bottle (small bottle) production line sharing one sterilization machine

A technology of cans and sterilizers, which is applied in bottling machines, bottle filling, transportation and packaging, and can solve the problems of large investment, idle equipment, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Improving the existing production process of the sterilizer

[0055] · Process improvement plan 1:

[0056] Set the glass vials to be sterilized on the upper layer of the sterilizer, and the cans to be sterilized on the lower layer.

[0057] ●Process improvement plan 2:

[0058] The design temperature is close to the sterilization quality temperature of both cans and glass vials

[0059] Between these two sterilization temperatures, the upper limit temperature of cans (such as 61.5°C area), the lower limit temperature of glass vials (such as 63°C area), find a reasonable temperature between the two, which can meet the requirements of simultaneous production and meet or be close to the upper level. The PU value of the sterilization quality standard for glass vials and lower cans.

[0060] ●Process improvement plan 3:

[0061] Assemble the lower cooling pipe

[0062] In actual production, it is necessary to take into account the downtime caused by various factors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com