Sealing device

A technology of sealing device and shaft sleeve, which is applied in the field of yachts, can solve the problems of low mechanical shock resistance, seal leakage, short service life, etc., and achieve the effects of enhanced mechanical shock performance, convenient installation and adjustment, and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

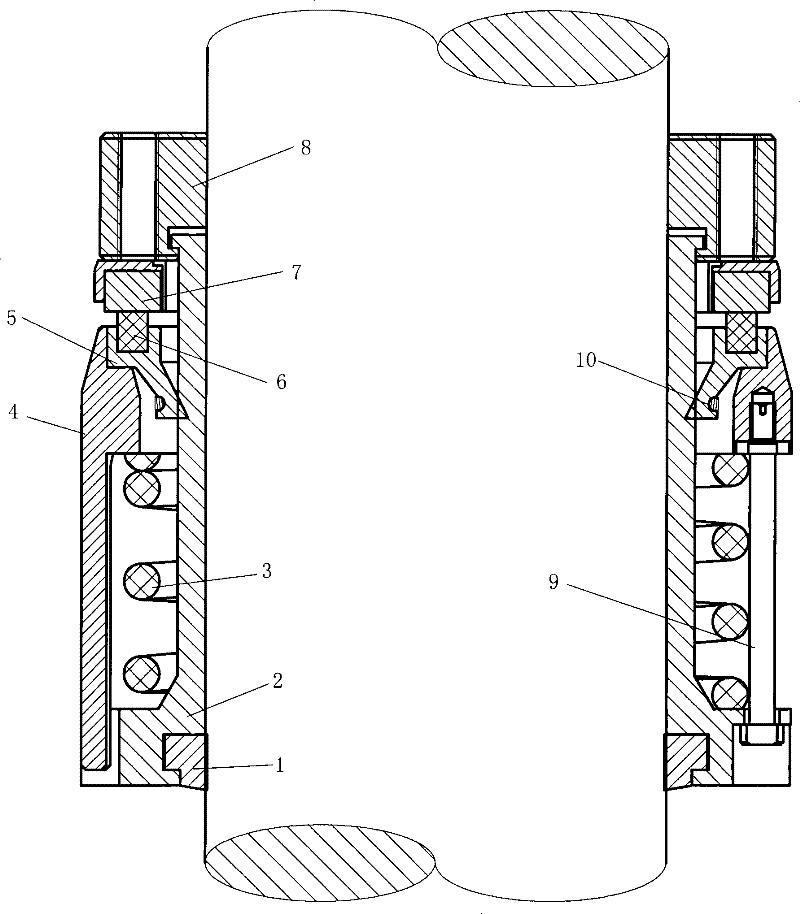

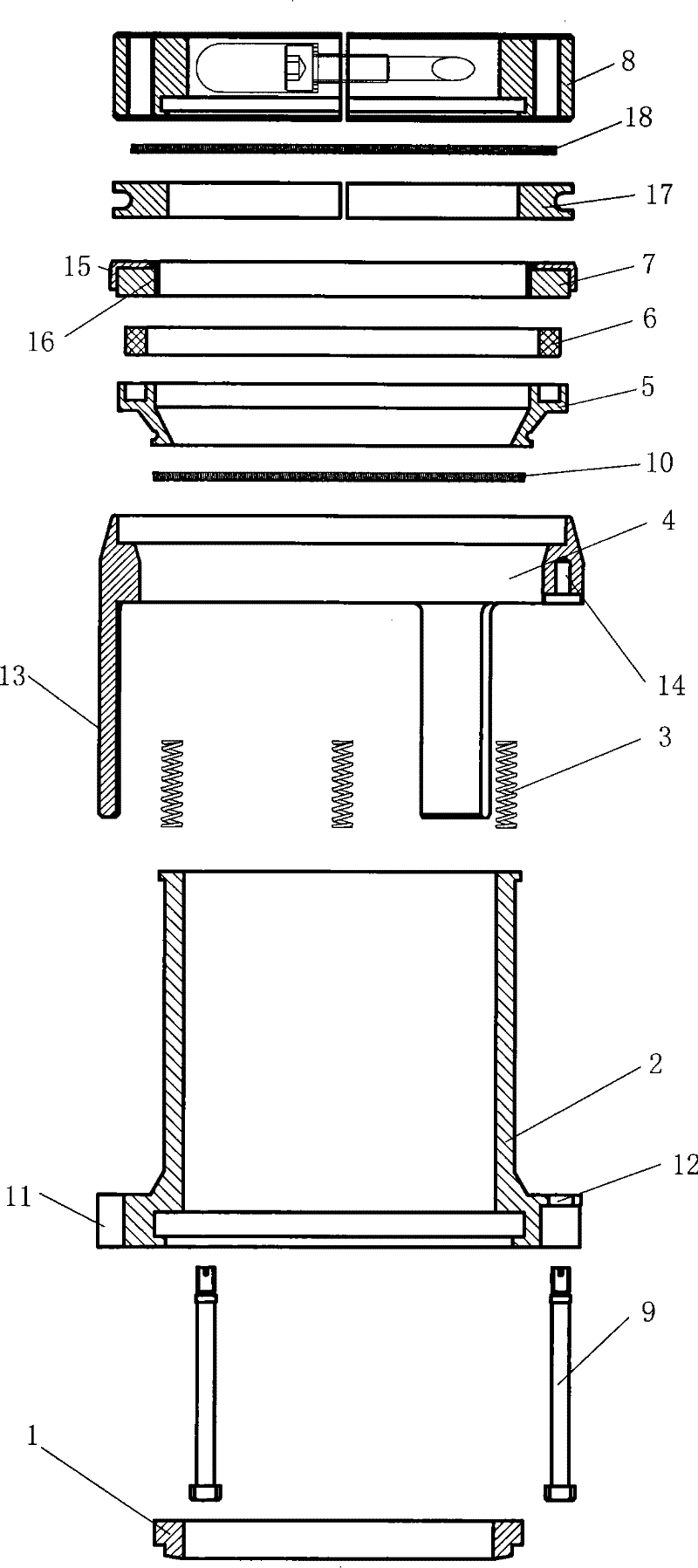

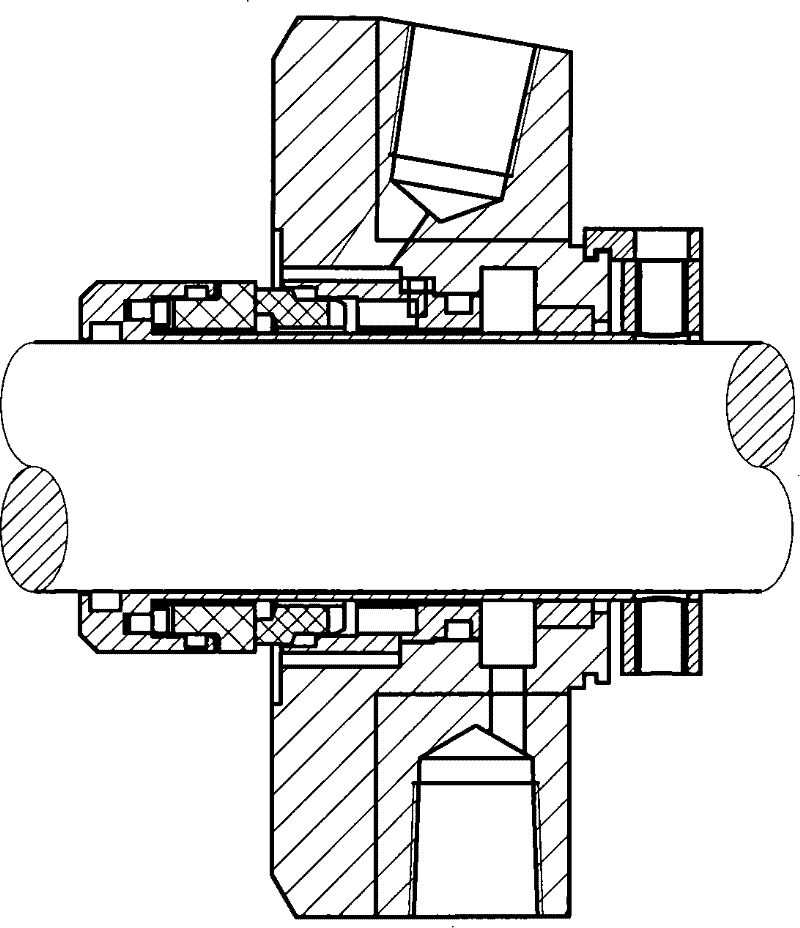

[0025] see figure 1 , figure 2 : A sealing device whose structure is mainly composed of a shaft sleeve 2, a moving ring seat 4, a moving ring 6, a static component 4, a split half ring 2, etc.

[0026] The inner side of the sleeve 2 is provided with a seal 1, the seal 1 is a fluorine rubber ring, the outer side of the sleeve 2 is provided with an elastic component 3, and the top of the elastic component 3 is against the moving ring seat 4, The bottom is on top of the shaft sleeve 2. The movable ring seat 4 and the shaft sleeve 2 are provided with an anti-relative rotation device, and the structure of the anti-relative rotation device is that the movable ring seat 4 is provided with a fork foot 13 and a threaded hole 14 , The fork foot 13 extends into the transmission groove 11, the bolt 9 passes through the hole 12 and the top end is screwed togethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com