Directly-down backlight module as well as LCD device using the same

A liquid crystal display device and backlight module technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of increased handling costs, weak strength, unfavorable light and thin design, etc., to achieve cost reduction, waste avoidance, and weight reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

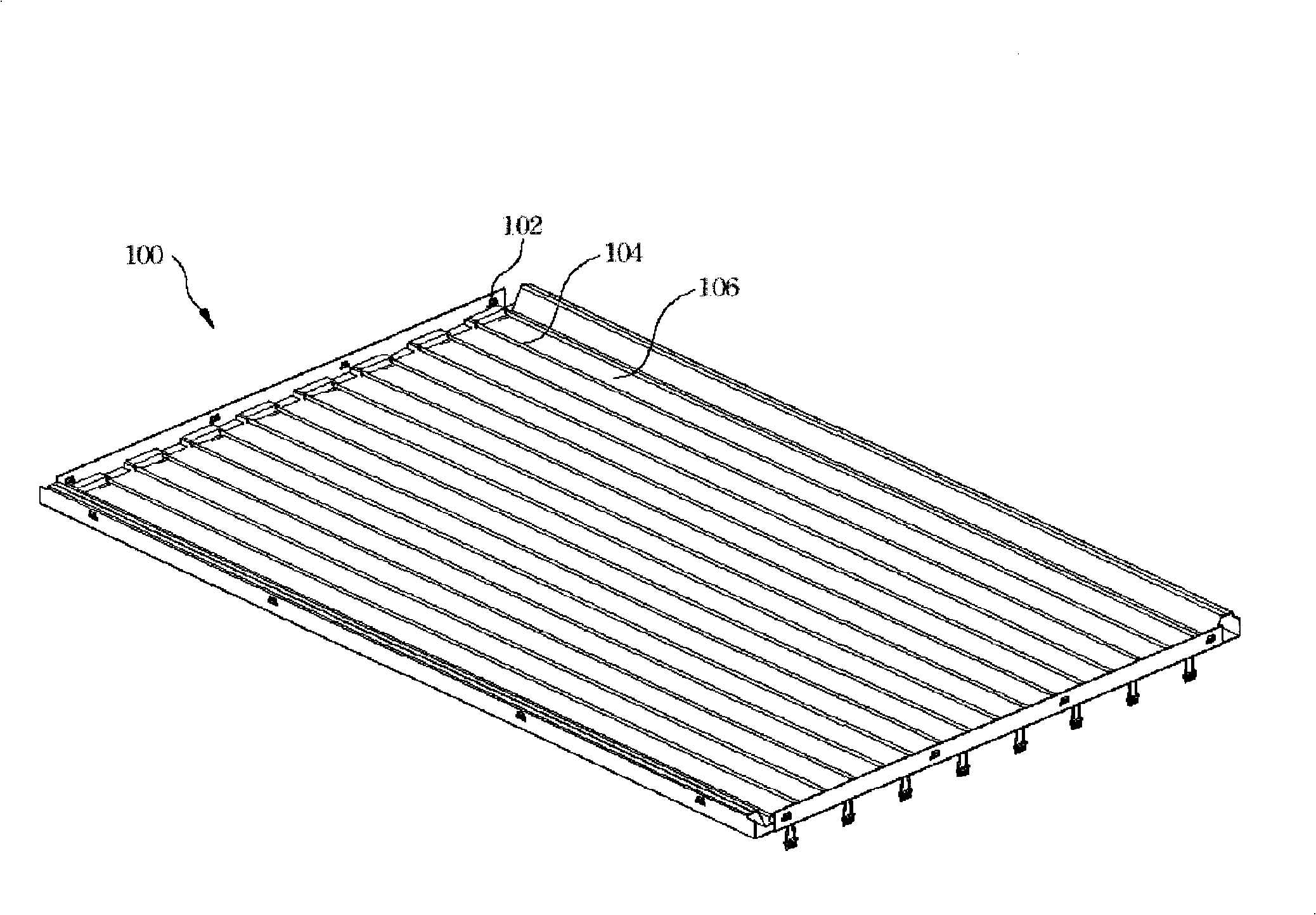

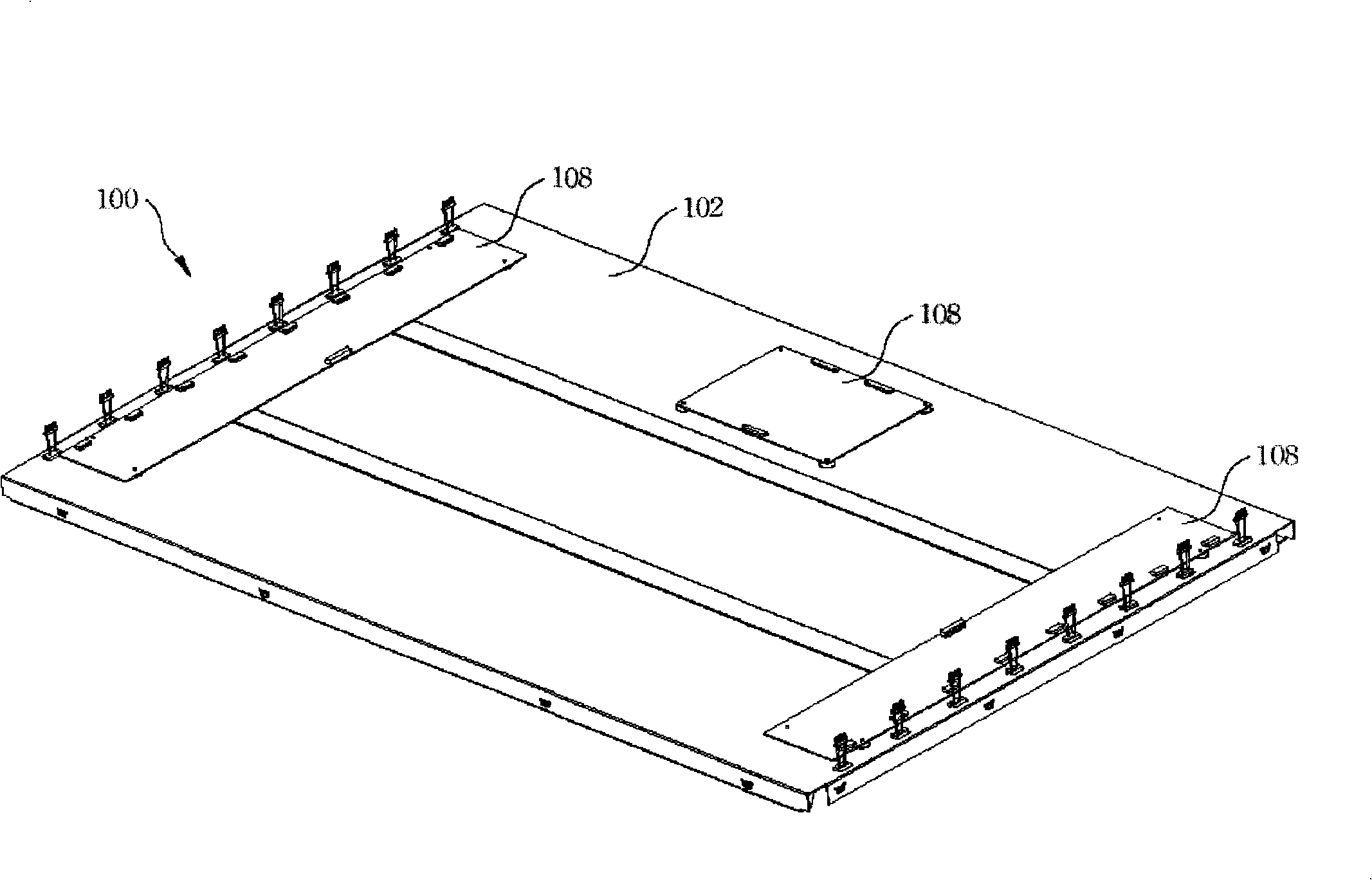

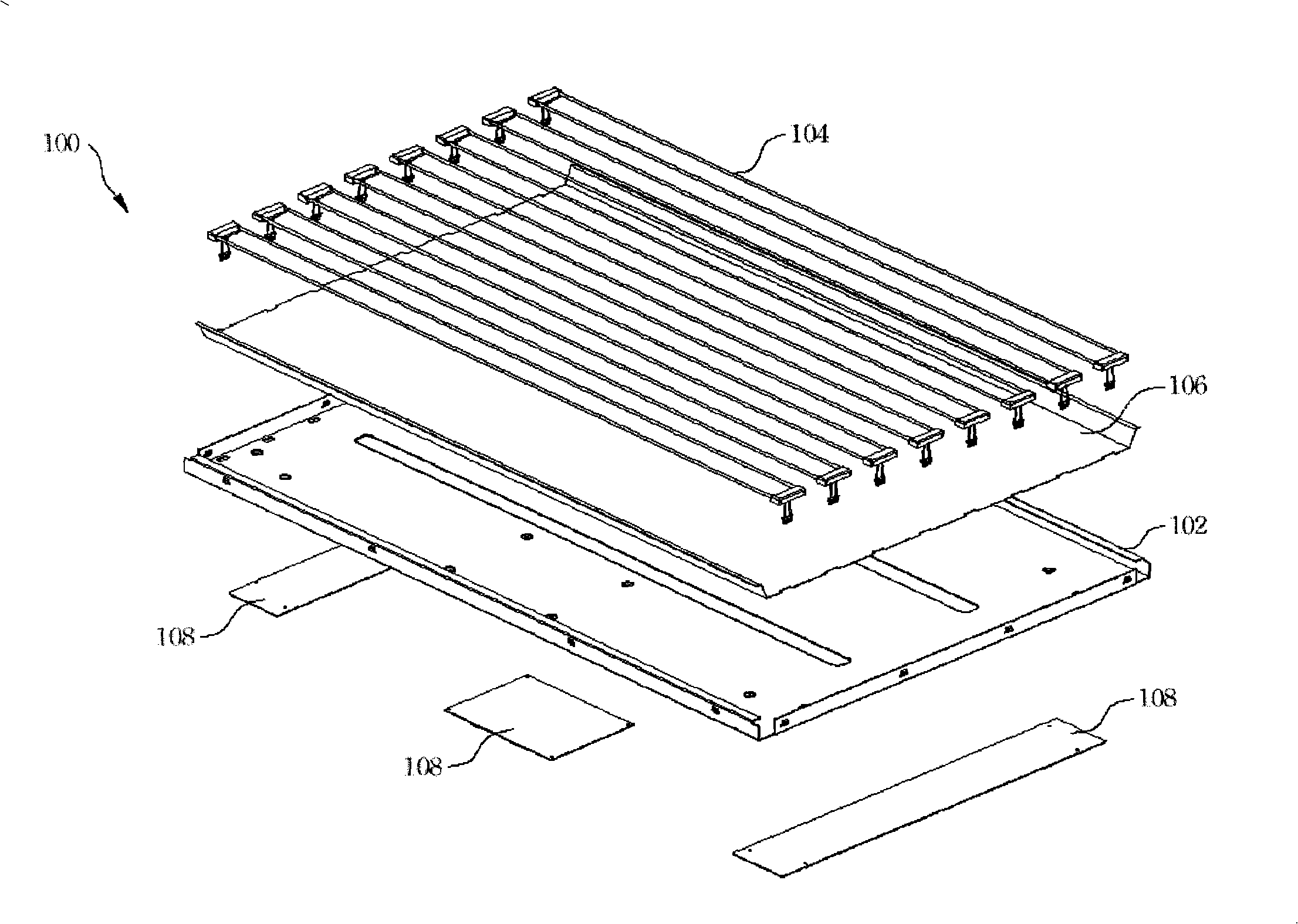

[0043] The present invention discloses a direct-type backlight module and its application. It has a frame-type back frame module to replace the traditional backplane, so that the weight of the backlight module can be reduced, the material of the backplane can be saved, and the cost of the backlight module can be reduced. A thinner and lighter liquid crystal display device is obtained. In order to make the description of the present invention more detailed and complete, refer to the following description and cooperate Figure 4A to Figure 7 icon of the .

[0044] Please also refer to Figure 4A 4B , which respectively show a schematic diagram of a back frame module of a direct type backlight module according to a preferred embodiment of the present invention, and an exploded view of the rear side of the back frame module device. The direct type backlight module of the present invention is mainly composed of a back frame module 200a and a light source disposed on the front of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com