Device for managing the displacement of a hydraulic motor or a group of hydraulic motors

A hydraulic motor and motor technology, applied in the field of displacement devices, can solve the problems of poor braking efficiency, insufficient braking of small displacement, low braking torque, etc., and achieve the effect of compact design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

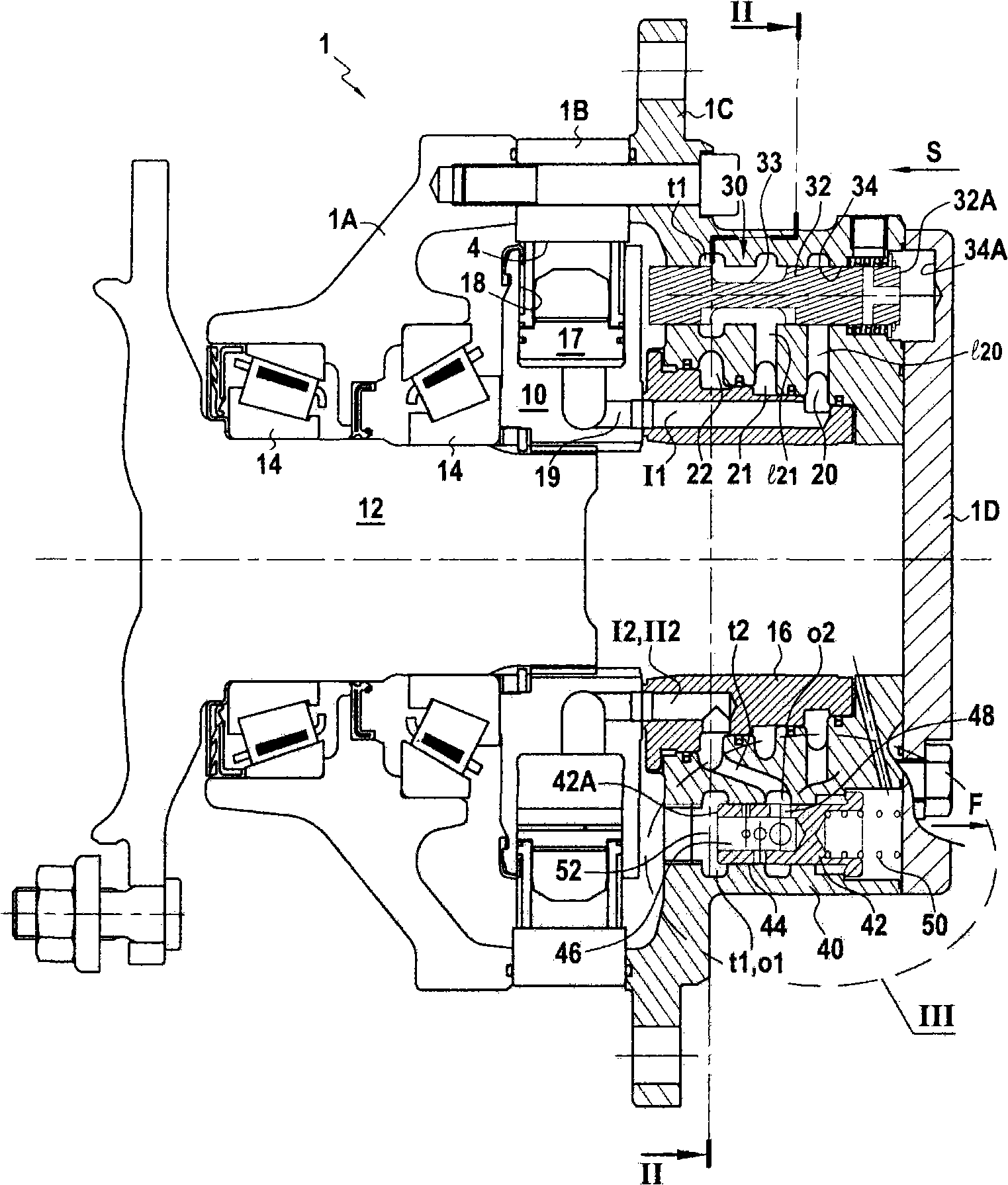

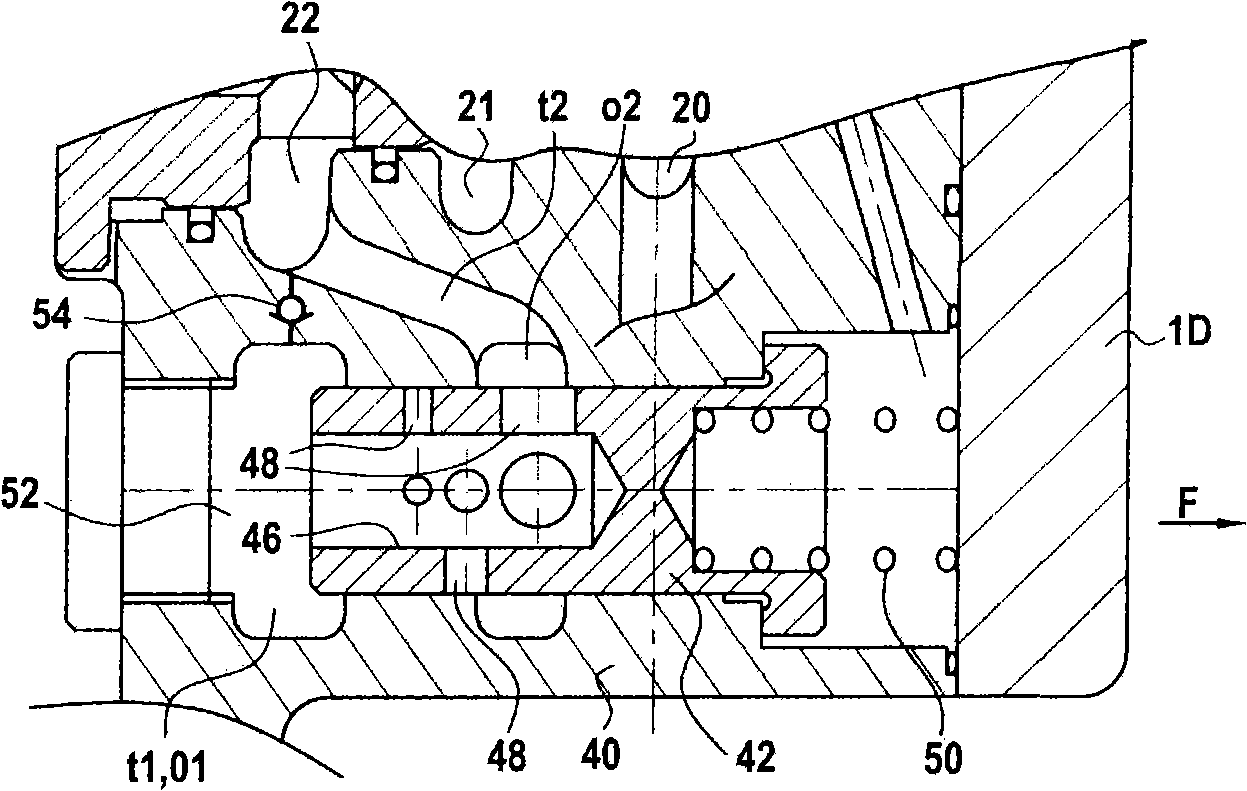

[0052] figure 1 The motor 1 in comprises a housing having four parts 1A, 1B, 1C and 1D, inside which is mounted a rotating cylinder block 10 capable of rotatably driving a main shaft 12 which is held by a bearing 14 relative to the housing part 1A support. Inside the housing part 1C there is provided an internal distributor 16 with distribution ducts, with which the cylinders 18 of the cylinder block can communicate successively through their cylinder ducts 19 during the rotation of the cylinder block, wherein the distributor is in rotation fixed relative to the housing. The piston 17 of the cylinder block 10 is supported by the bellows cam 4 formed at the inner periphery of the housing portion 1B. Although the motor shown is of the fixed housing type with a rotating spindle, the invention is also applicable to rotating housing motors.

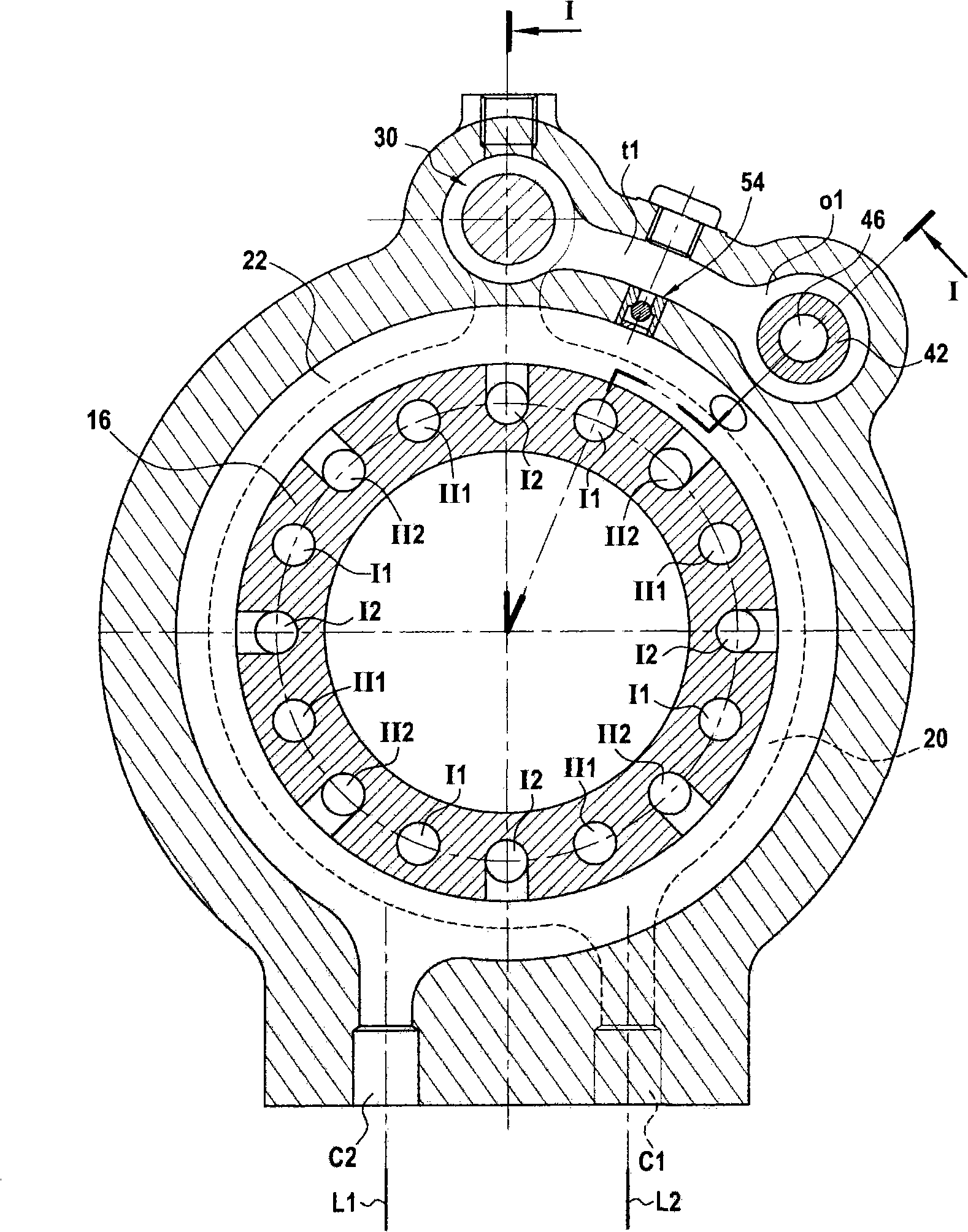

[0053] The motor consists of at least two main conduits C1 and C2 (see figure 2 ), which serve as the input and discharge of the motor, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com