Clothes collar flower hole punching machine

A technology of punching machine and perforation, which is applied to sewing tools, textiles and papermaking, and cutting of textile materials, etc. It can solve the problems of thread stripping, low production efficiency, and low precision, and achieve increased production efficiency and improved production efficiency. Production efficiency, the effect of meeting production needs

Inactive Publication Date: 2008-10-15

JIHUA 3502 PROFESSIONAL GARMENT

View PDF0 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It is relatively difficult to use manual ironing holes, it is easy to cause thread stripping, fluffing on the edge of the hole, inaccurate position of the three holes, low precision, and even scalding on the edge of the hole, which seriously affects the product quality, especially the production efficiency is very low, resulting in manpower. , Waste of material resources, increase production cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

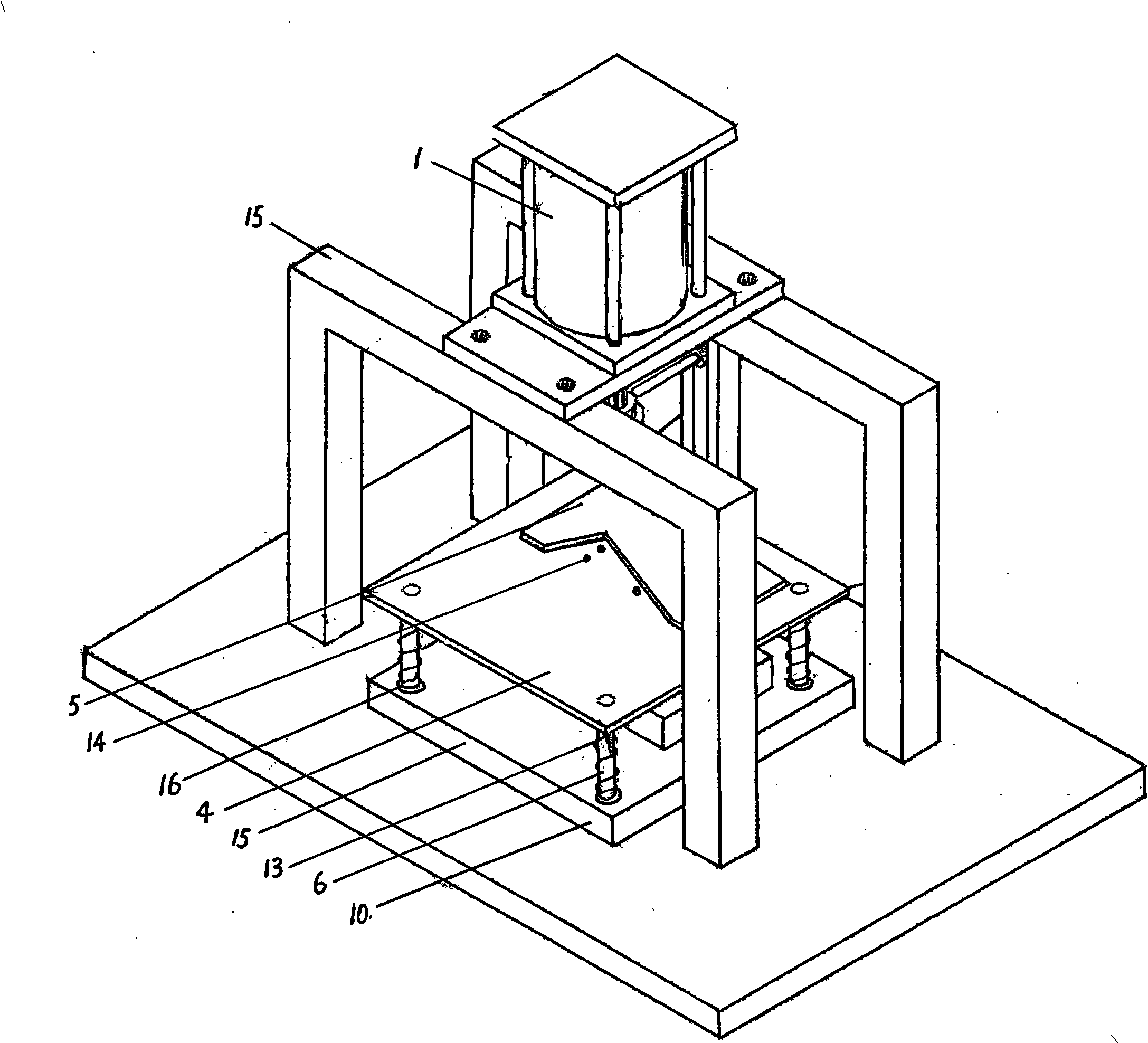

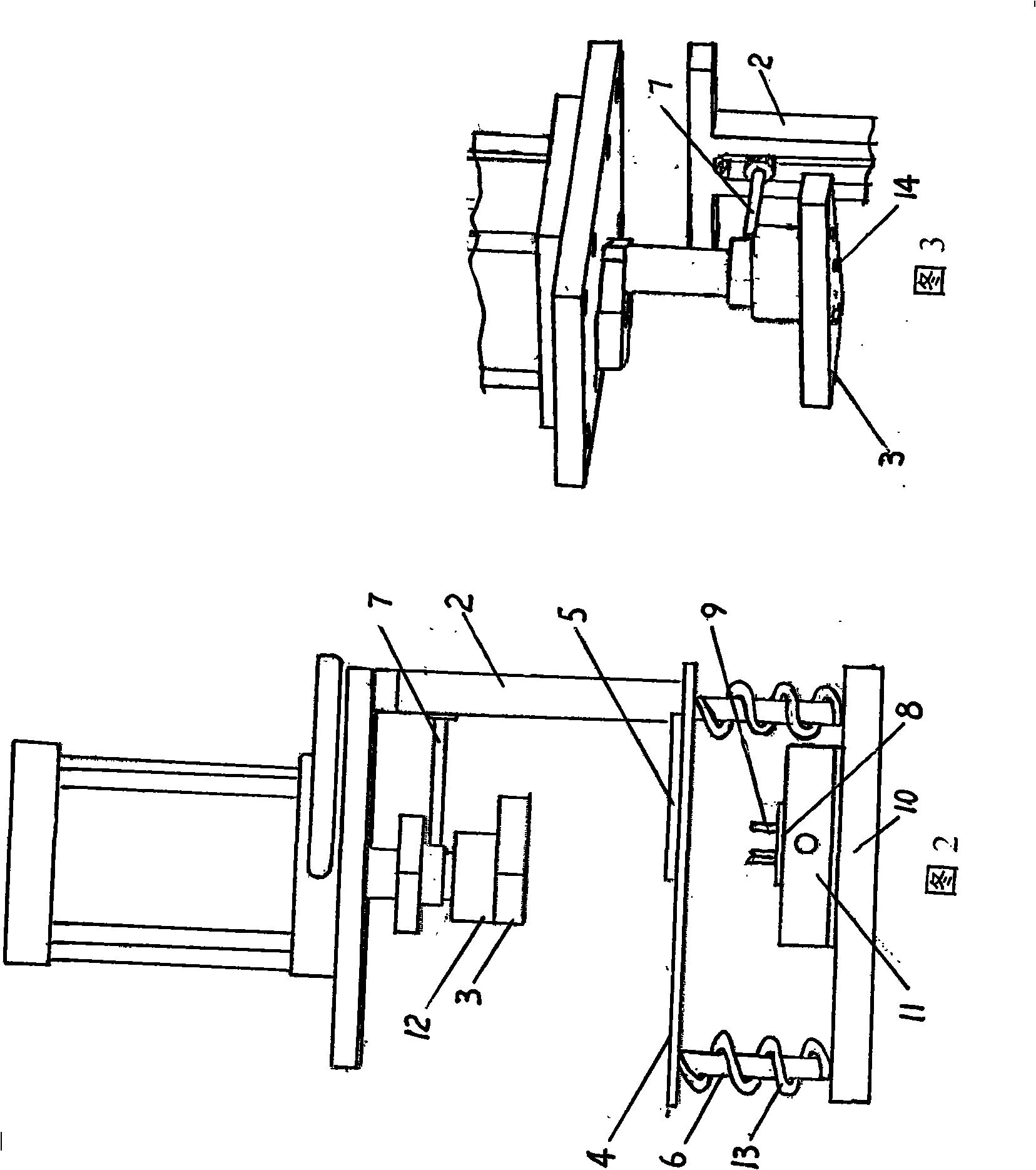

The invention relates to a punching machine for collar badges on military uniforms, which comprises a cylinder arranged on a frame, an upper mold fixing frame connected with the piston rod of the cylinder, an upper mold arranged on the upper mold fixing frame, a retainer plate fixedly connected with a guide post, a positioning mold arranged on the retainer plate, a lower mold arranged on a pedestal below the retainer plate, and a punching pin arranged on the lower mold. The punching machine can greatly improve the production efficiency, and can punch the hole of a collar by 2 to 3 seconds while the manual operation costs 30 seconds. The production accuracy is ensured by the mold. The punching machine completely overcomes the problems in quality of manual operation and greatly improves the production efficiency to meet the production requirement of 07 novel military uniforms.

Description

Clothing collar flower hole punching machine technical field The invention relates to a punching machine for collar holes of military uniforms. Background technique In 2007, holes for wearing collar flowers must be made during the production process of the 07 new military uniforms. It is relatively difficult to use manual ironing holes, it is easy to cause thread stripping, fluffing on the edge of the hole, inaccurate position of the three holes, low precision, and even scalding on the edge of the hole, which seriously affects the product quality, especially the production efficiency is very low, resulting in manpower. , Waste of material resources, increase production cost. Contents of the invention The technical problem to be solved by the present invention is to provide a collar punching machine for military uniforms with high punching precision, no scald marks on the punching edge and high production efficiency. The present invention adopts following technical sc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A41H25/00D06H7/22

Inventor 刘旭明马永树

Owner JIHUA 3502 PROFESSIONAL GARMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com