Multistage rectification process for high-purity thionyl chloride

A thionyl chloride, high-purity technology, applied in the field of multi-stage rectification of high-purity thionyl chloride, can solve problems such as difficult to obtain high-purity thionyl chloride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

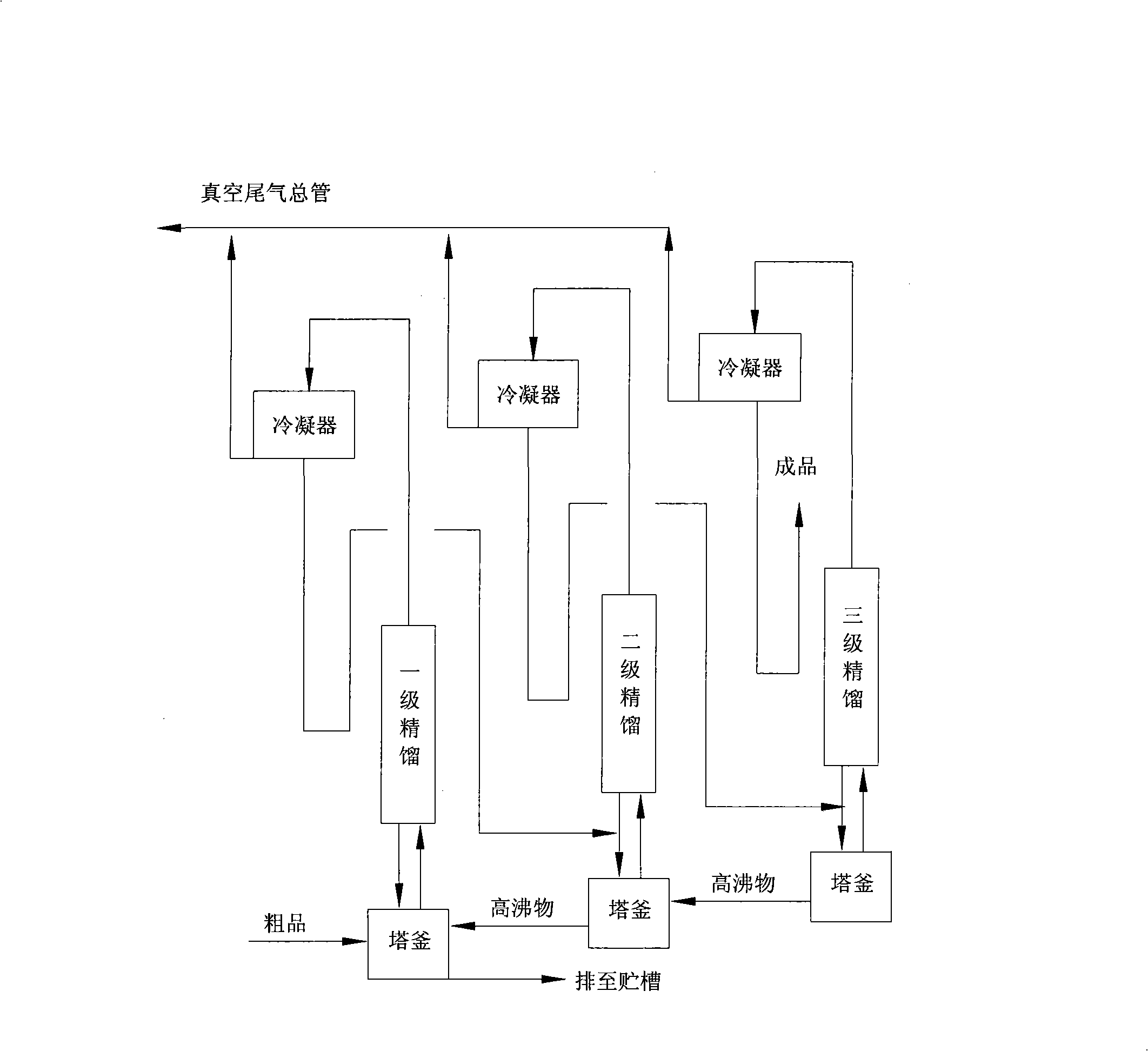

Image

Examples

Embodiment 1

[0048] 1. Primary distillation

[0049] Pass 50% thionyl chloride into the first-stage rectification column, the temperature of the tower bottom is 110°C, and 80% of the thionyl chloride is obtained at the top of the tower, and the high boiler S in the bottom of the tower is 2 Cl 2 discharge to storage tanks;

[0050] 2. Secondary distillation

[0051] Pass 80% thionyl chloride into the secondary rectification tower. The process parameters are: the temperature of the tower still is controlled at 78-89°C. When the tower still reaches 3 / 4 of the still liquid level and the temperature reaches 89°C, the tower The high mixture in the still is discharged to the still of the primary distillation tower, and about 98% SOCl is obtained from the top of the tower 2 .

[0052] 3. Three-stage distillation

[0053] 98% SOCl 2 Add to the three-stage rectifying tower still by metering, control the tower still temperature at 78-89 ℃, 72-75 ℃ at the top of the tower, and the pressure at th...

Embodiment 2

[0056] Others are the same as embodiment 1, and the difference is that in this embodiment, the following parameters are selected:

[0057] 1. Primary distillation

[0058] Pass 70% thionyl chloride into the first-stage rectification column, the temperature of the tower bottom is 130°C, and 92% of the thionyl chloride is obtained at the top of the tower, and the high boiler S in the bottom of the tower is 2 Cl 2 discharge to storage tanks;

[0059] 2. Secondary distillation

[0060] Pass 92% thionyl chloride into the secondary rectification tower. The process parameters are: the temperature of the tower bottom is controlled at 78-89°C. The high mixture in the still is discharged to the still of the primary distillation tower, and about 98% SOCl is obtained from the top of the tower 2 .

[0061] 3. Three-stage distillation

[0062] 98% SOCl 2 Add to the three-stage rectifying tower still by metering, control the tower still temperature at 78-89 ℃, 76-80 ℃ at the top of th...

Embodiment 3

[0064] Others are the same as embodiment 1, and the difference is that in this embodiment, the following parameters are selected:

[0065] 1. Primary distillation

[0066] Pass 75% thionyl chloride into the primary distillation column, the temperature of the tower bottom is at 120°C, and 95% of the thionyl chloride is obtained at the top of the tower, and the high boiler S in the bottom of the tower is 2 Cl 2 discharge to storage tanks;

[0067] 2. Secondary distillation

[0068] Pass 95% thionyl chloride into the secondary rectification tower. The process parameters are: the temperature of the tower bottom is controlled at 78-89°C. The high mixture in the tower bottom is discharged to the first-stage rectification tower bottom, and about 99% SOCl is obtained from the top of the tower 2 .

[0069] 3. Three-stage distillation

[0070] 99% SOCl2. is metered into the three-stage rectification tower still, and the temperature of the tower still is controlled at 78-89 ° C, 72...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com