Brombutyl curing bladder and production method thereof

A technology of bromobutyl rubber and vulcanization bladder, which is applied in the direction of coating, etc., can solve the problem of no advantage in production efficiency, and achieve the effects of reducing raw material costs, saving energy consumption, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

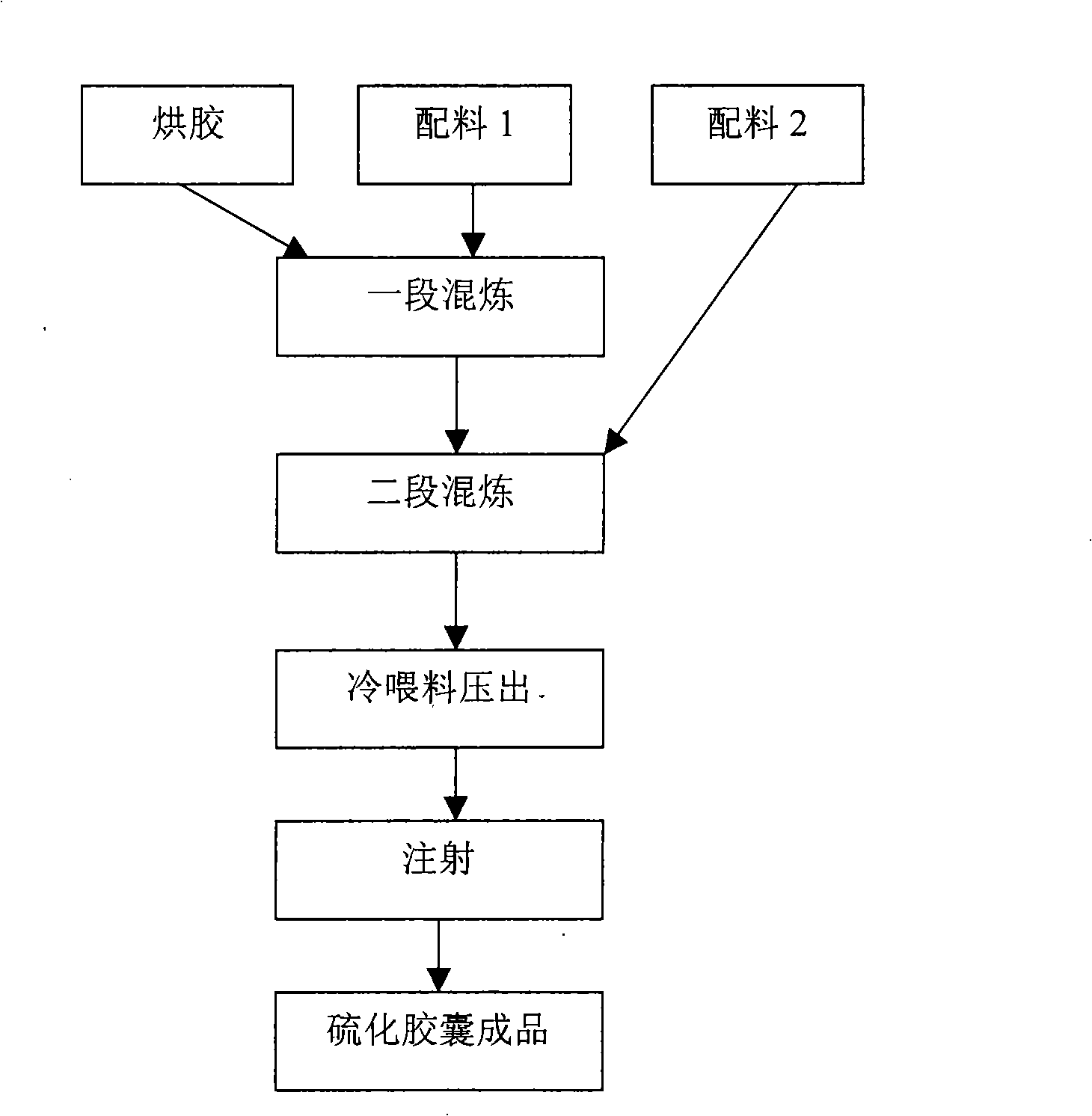

[0012] Further elaborate content of the present invention below in conjunction with accompanying drawing

[0013] As shown in Table 1, the bromobutyl vulcanization bladder of the present invention is characterized in that it uses bromobutyl rubber and butyl rubber as the main body of raw rubber, based on 100g of raw rubber main body, wherein the butyl rubber is 50g to 90g ; Bromobutyl rubber is 10g ~ 50g; the bromobutyl vulcanization capsule also contains zinc oxide, stearic acid, 7530E vulcanization resin, magnesium oxide, protective wax, super wear-resistant carbon black, castor oil, and their weights are respectively For: 3g~5g, 0.2g~2g, 5g~9g, 0.1g~0.5g, 0.5g~2g, 43g~50g, 2g~5g. In a specific embodiment of the present invention, the indirect zinc oxide is used for zinc oxide, tertiary stearic acid is used for stearic acid, light magnesium oxide is used for magnesium oxide, and the model of Zhongchao wear-resistant carbon black is N220. The paraffin wax is used as the prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com