Torsion screwing tool

A tool and wire threading technology, applied in the field of machinery, can solve problems such as easy detachment of steel wires, inconvenient use, damage, etc., and achieve the effect of easy use and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

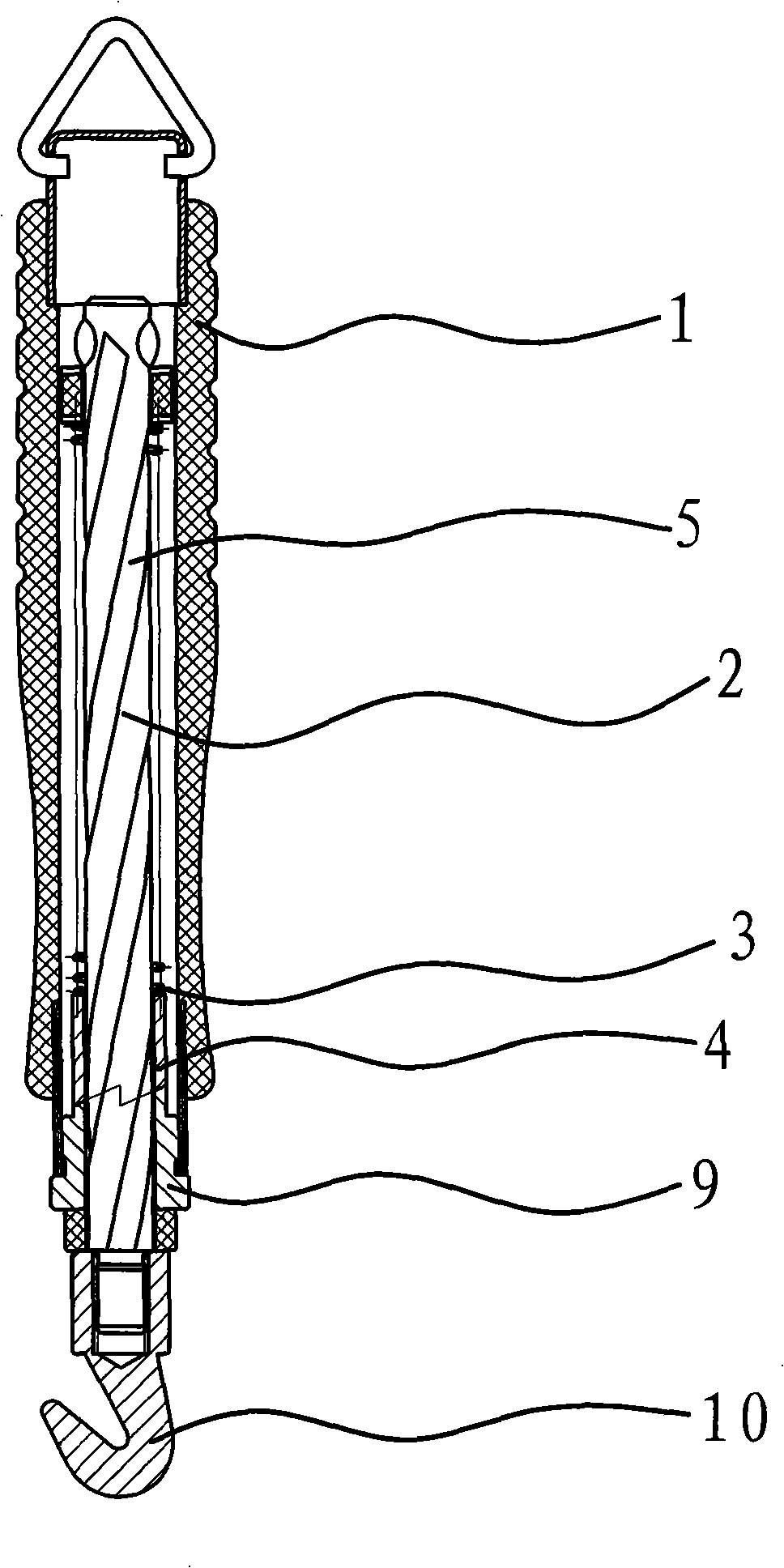

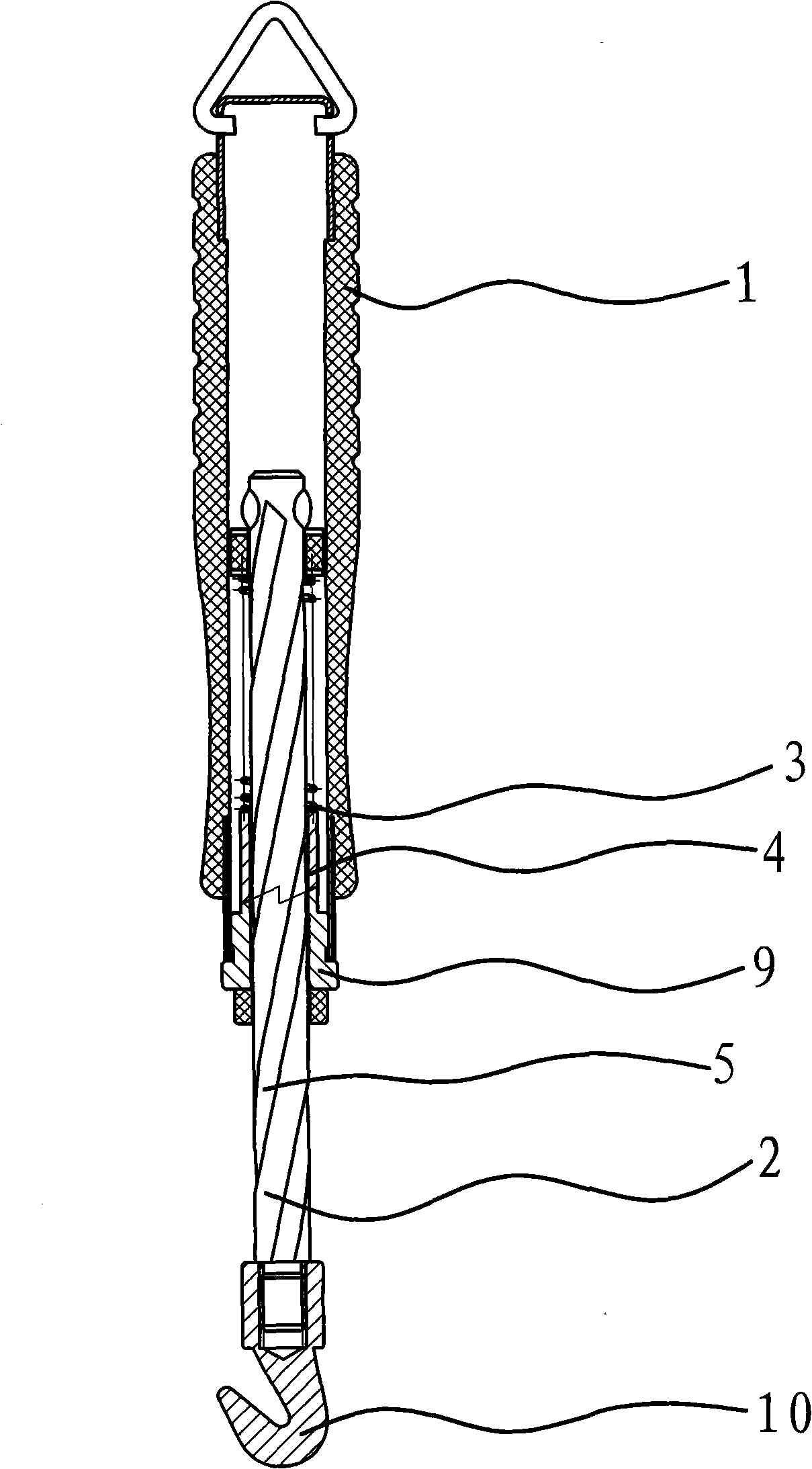

[0026] Such as figure 1 with figure 2 As shown, this torsion threading tool is used for binding ropes such as iron wires, and it is composed of a handle body 1, a pull bar 2, a guide 4 and a spring 3 and the like.

[0027] The handle body 1 is cylindrical, and the pull rod 2 is rod-shaped.

[0028] A connection sleeve 9 is threadedly connected to the port of the handle body 1 , and the connection sleeve 9 is sleeved on the pull rod 2 . A cylindrical guide 4 is also set on the pull rod 2, and a spring 3 is also set on the pull rod 2. The two ends of the spring 3 are pressed against the inner end of the pull rod 2 and the guide 4 respectively, and the The guide piece 4 abuts against the connecting sleeve 9 under the action of elastic force.

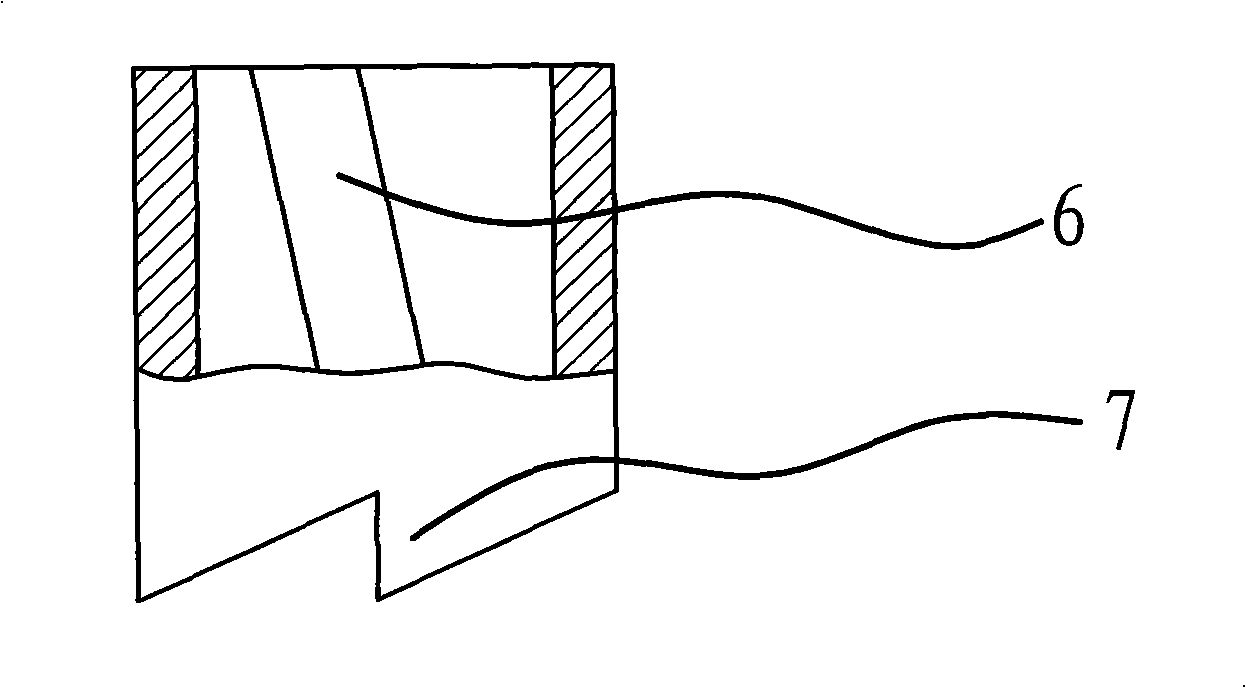

[0029] Such as image 3 with Figure 4 As shown, the end of the guide 4 has a ratchet 7, and the end of the connecting sleeve 9 has a ratchet 2 8, and under the elastic force of the spring 3, the ratchet 7 of the guide 4 and the ratch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com