Phosphates composite brick

A phosphate and composite brick technology, applied in furnaces, lighting and heating equipment, furnace components, etc., can solve the problems of easy loosening, collapse in the kiln, and difficulty in masonry, so as to improve the quality of masonry, ensure the heat insulation effect, Avoid easy loosening effects

Inactive Publication Date: 2008-10-15

XINXING ENERGY EQUIP

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

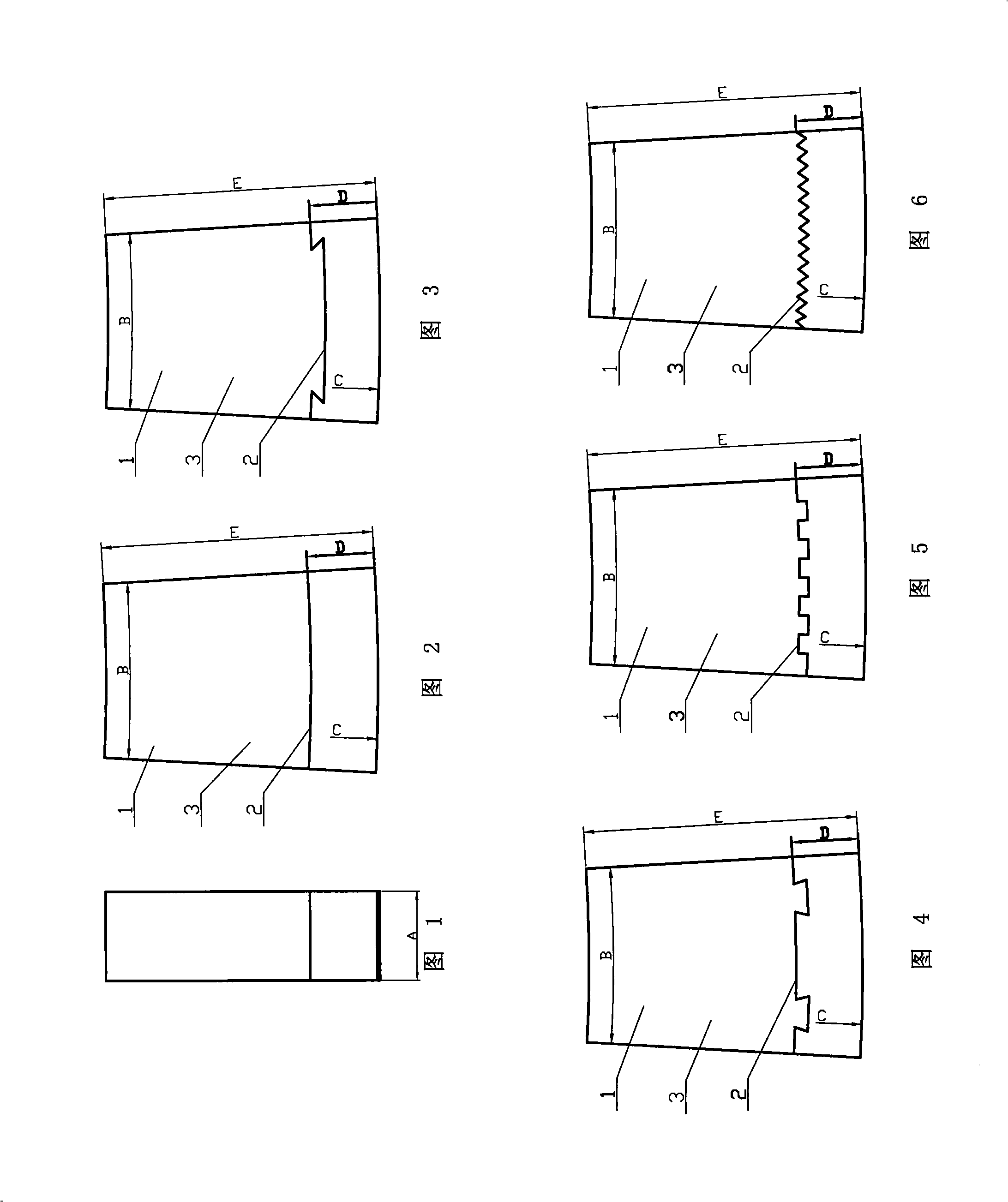

The invention provides a phosphate composite brick, which is a sector block and consists of a little end phosphate layer and a big end light heat-insulation layer. The thickness A is 98 millimeters, the sector angle B is 6.53 degrees, the radius of an outer circle of the light heat-insulation layer is 2000 millimeters, the radial length of the light heat-insulation layer is 60 millimeters, and the total radial length of the phosphate layer and the light heat-insulation layer is 230 millimeters. The service life is longer than 2 years.

Description

Phosphate composite brick technical field The invention relates to a phosphate composite brick, which is especially suitable for building a rotary kiln. Background technique The existing phosphate bricks lining the rotary kiln are of two-layer structure. The outer layer near the kiln skin is made of lightweight heat-insulating bricks, and the inner layer is made of phosphate bricks depending on the material. Lightweight insulation bricks and phosphate bricks are separate. On the one hand, it is difficult to build masonry, on the other hand, it is easy to loosen. With the thinning of the phosphate layer, it is easy to cause collapse accidents in the kiln. The service life of the refractory lining of the rotary kiln is within one year. Invention content: In order to overcome the disadvantages of the prior art, the invention provides a phosphate composite brick with a service life of more than two years. The technical scheme adopted by the present invention to solve its...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F27D1/06C04B35/66

Inventor 杨彬宋富强宋彦洪李文勇赵冬梅刘长河马敬军

Owner XINXING ENERGY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com