High crustal stress genuine three-dimensional load model trial system

A loading system and three-dimensional loading technology, used in instruments, measuring devices, scientific instruments, etc., can solve the problems of large test frame size, small sample size, large lateral deflection and deformation of the test frame, etc., to ensure stable test pressure, The effect of high degree of automation and high loading accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

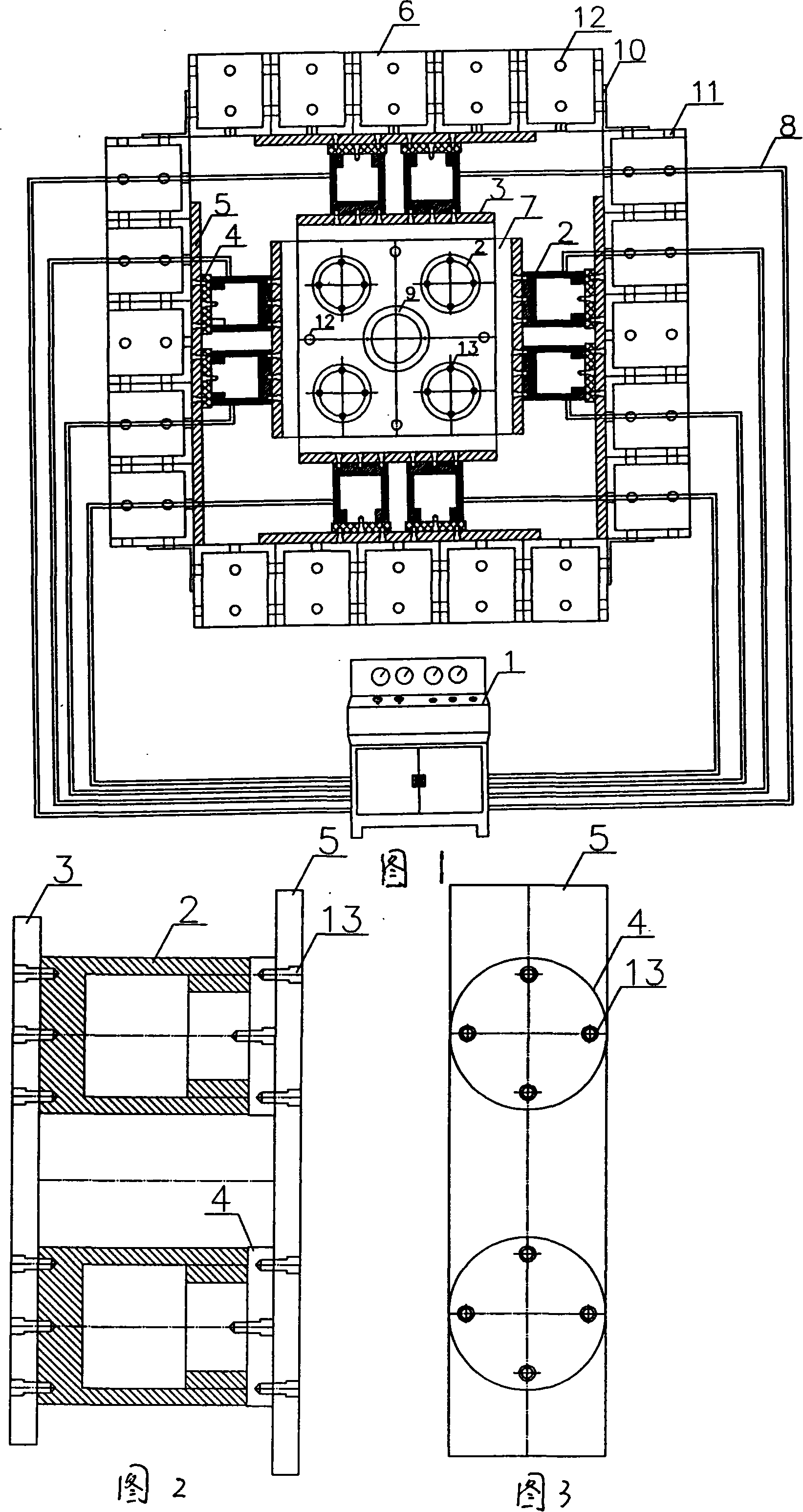

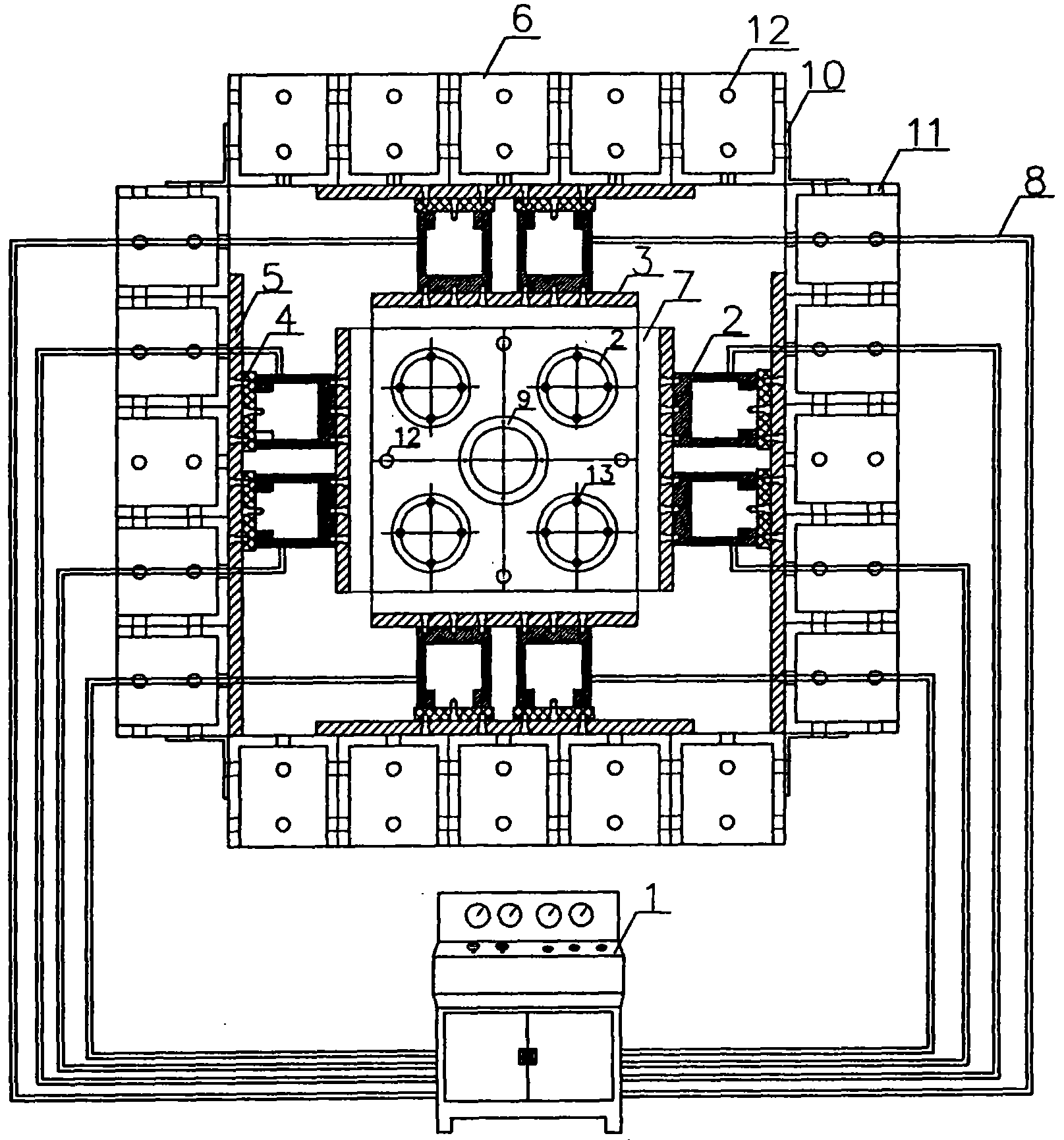

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0034] Figure 1-Figure 3 Among them, the high-pressure loading system is set in the reaction device system. The intelligent hydraulic control test bench 1 is connected to the high-pressure loading system through the high-pressure oil pipe 8. The high-pressure loading system includes a jack 2 and a loading plate 3. One end of the jack 2 is connected to the One side of the loading plate 3 is connected, and the other end is connected with the reaction force device system. The loading plate 3 is provided with a lead hole 12, and the other side of the six loading plates 3 connected to the jack 2 is respectively close to the six sides of the test model 7. on one side.

[0035] The reaction force device system includes a model reaction force device 6, a flange 4 and a reaction force transmission plate 5. The model reaction force device 6 is composed of a box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com