Loading device for geotechnical engineering large-sized three-dimensional comprehensive simulation test bed

A technology for simulating test benches and loading devices. It is used in measurement devices, testing of machine/structural components, instruments, etc. It can solve the problems of inability to use physical model tests, small scale, and inability to model triaxial loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

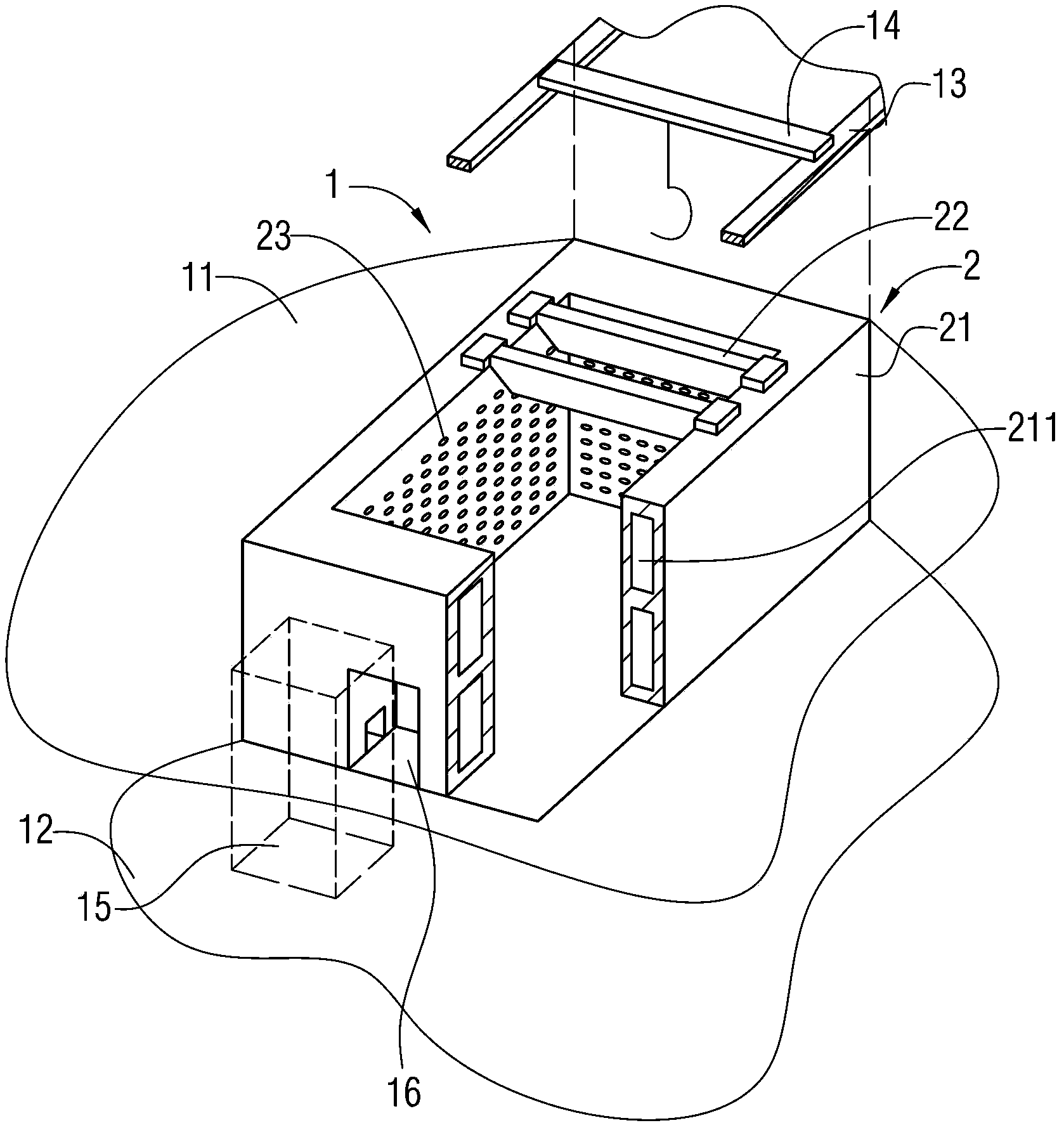

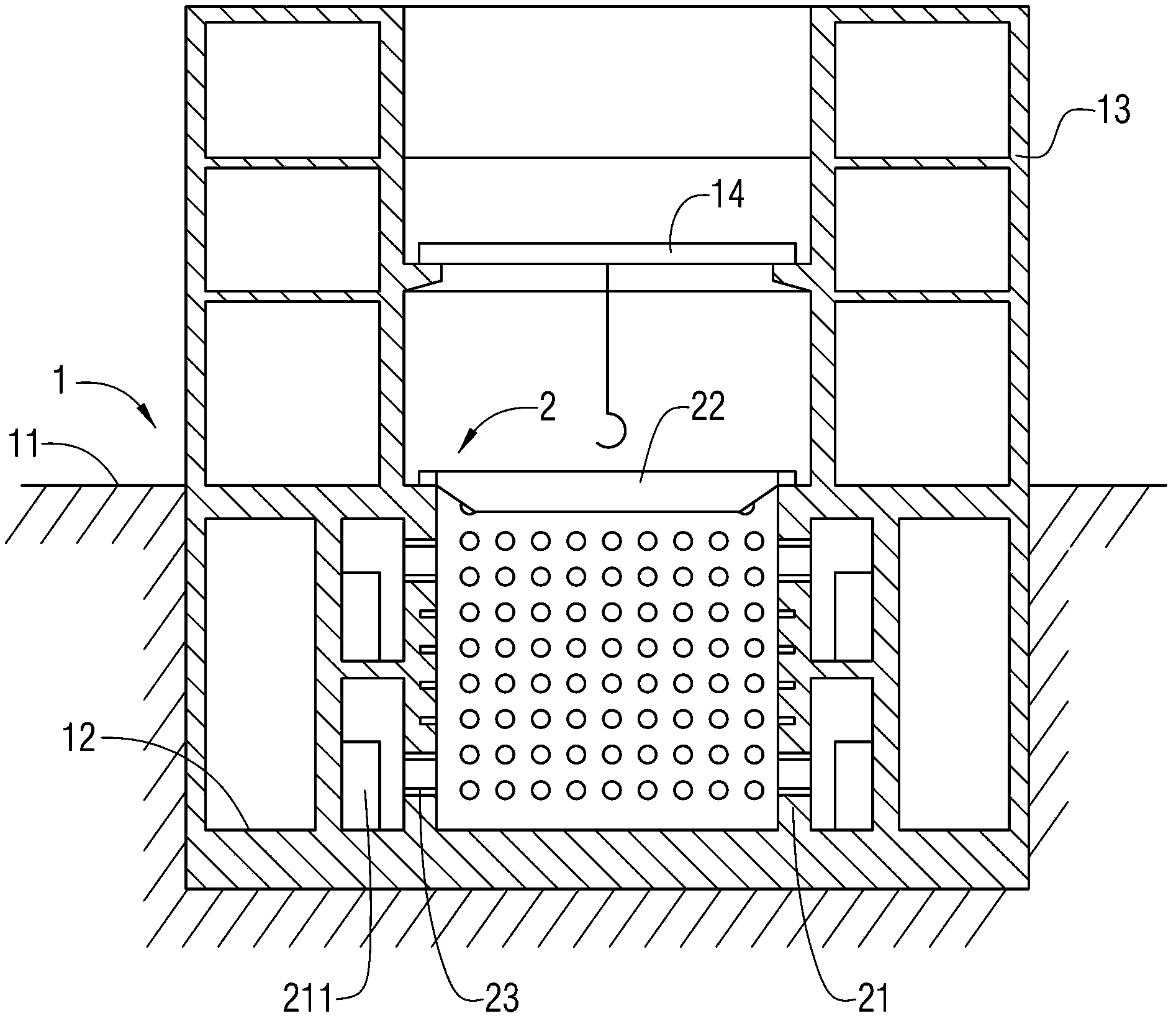

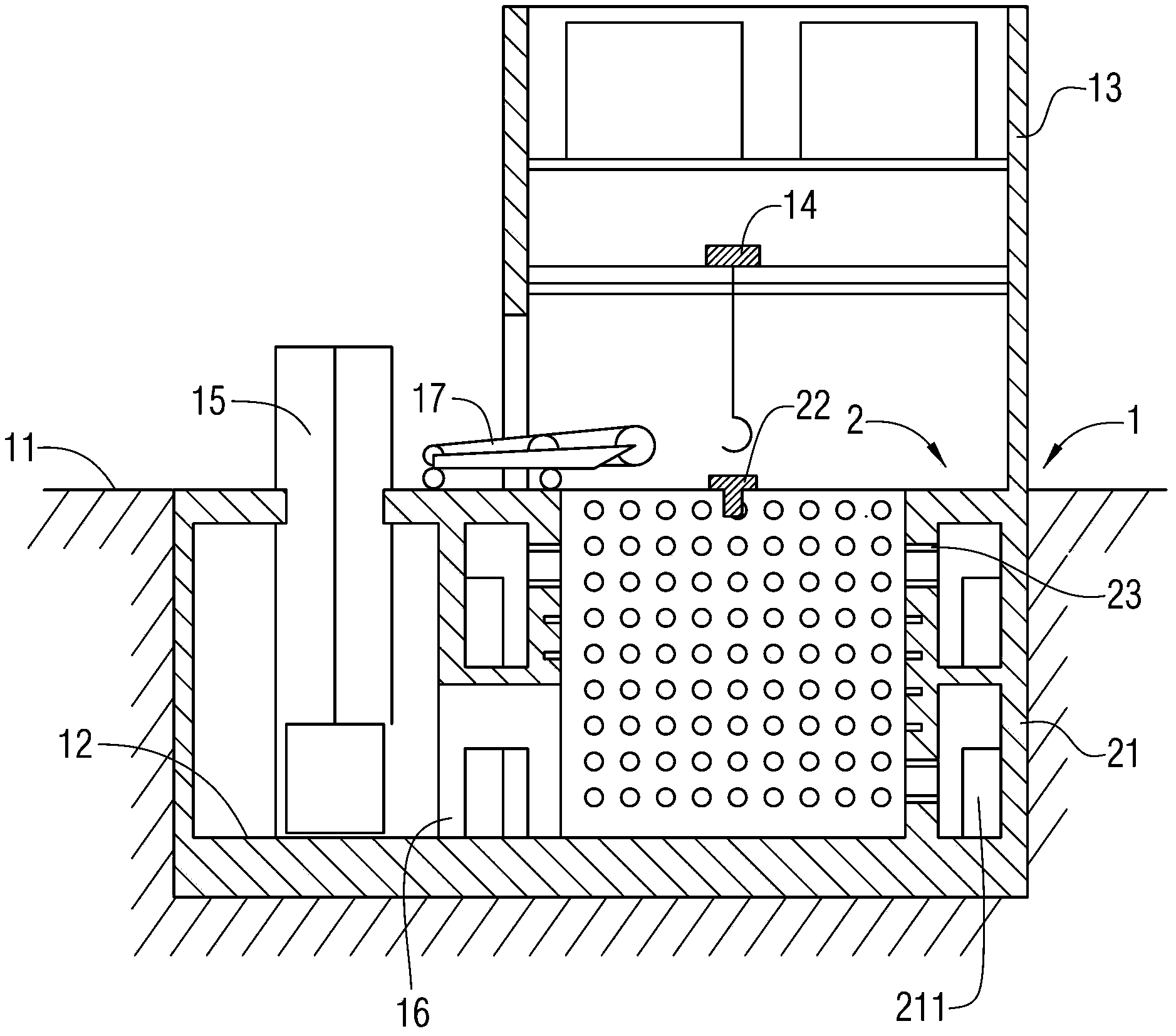

[0024] figure 1 Shown is a schematic diagram of the three-dimensional structure of a large-scale three-dimensional comprehensive simulation test bench for geotechnical engineering proposed according to a specific implementation case of the present invention, and what is roughly shown in the figure is the general structure of the large-scale three-dimensional comprehensive simulation test bench for geotechnical engineering of the present invention , emphatically showing the main differences between it and the prior art mentioned in the relative background art section.

[0025] see figure 1 A significant difference between the large-scale three-dimensional comprehensive s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com