Projector and projector heat radiation fan running status control method

A technology of a cooling fan and a control method, applied in the field of projectors, can solve problems such as affecting the life of the machine, energy waste, etc., and achieve the effect of ensuring the life of the machine and optimizing the running time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

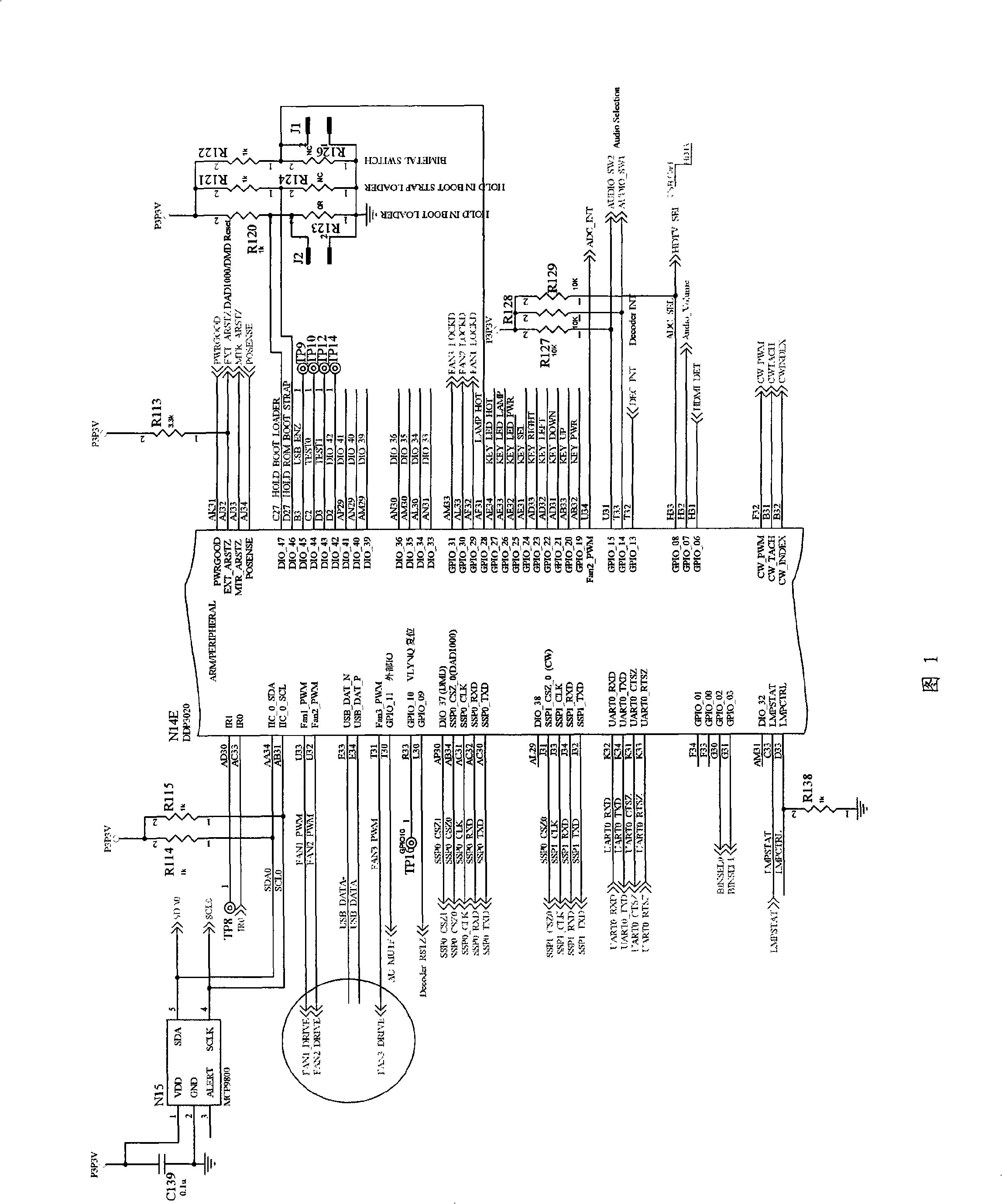

[0039] Embodiment 1, with reference to the figure, is a DLP projector, and the key components of the machine chassis include a DMD, a light source and a circuit board. Each of the above key components can be provided with a temperature detection chip (temperature detector), each temperature detection chip corresponds to a cooling fan configured on the component, such as setting a cooling fan connected to the corresponding FAN1_DRIVE, FAN2_DRIVE and FAN3_DRIVE pins, Each temperature detection chip controls the corresponding cooling fan through the main chip (central controller), and writes the lowest temperature in the main chip in advance through software. If it is set for one of the key components, MCP9800 is the temperature detection chip, and DDP3020 is the main chip. Connect the FAN1_DRIVE pin of DDP3020 to the cooling fan corresponding to the component, and control the operation of the cooling fan and / or the PWM pulse. Stop, DDP3020 reads out the current temperature infor...

Embodiment 2

[0040] Embodiment 2, a method for controlling the operation state of the above-mentioned projector cooling fan, detects the current temperature of the key components in the chassis, such as the heat dissipation area of the DMD. It is assumed that the cooling fan corresponding to the DMD is the cooling fan connected to the FAN1_DRIVE pin, and a MCP9800 is used as the temperature detection chip in the heat dissipation area of the DMD. The DDP3020 controls the operation and / or stop of the cooling fan through PWM pulses, and the DDP3020 reads out the current temperature information detected by the MCP9800 in real time through the IIC bus. If the current temperature is lower than the minimum temperature preset in the software, the FAN1_DRIVE pin The duty cycle of the PWM signal becomes zero, the cooling fan stops running; otherwise, the cooling fan will continue to run. After the cooling fan stops running, the projector can be instructed to shut down, and the projector can be c...

Embodiment 3

[0041] Embodiment 3, a method for controlling the operation state of the above-mentioned projector cooling fan, detects the current temperature of the key components in the chassis, such as the DMD and the heat dissipation area of the circuit board. It is assumed that the cooling fan I corresponding to the DMD is the cooling fan connected to the FAN1_DRIVE pin, and the cooling fan II corresponding to the circuit board is assumed to be the cooling fan connected to the FAN2_DRIVE pin. The DMD and the heat dissipation area of the circuit board respectively use a MCP9800 as a temperature detection chip. The DDP3020 controls the operation and / or stop of the cooling fan I through PWM pulses, and the DDP3020 reads out the first current temperature information detected in real time by one of the MCP9800s through the IIC bus. If the first current temperature is lower than the preset value in the software At the first preset temperature (minimum temperature), the duty cycle of the PW...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com