Straight-through current transformer convenient for measuring voltage

A current transformer and core-through technology, applied in the field of transformers, can solve the problems of not easy to prevent electricity theft, complex structure, high cost, etc., and achieve the effects of labor time saving, safe operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

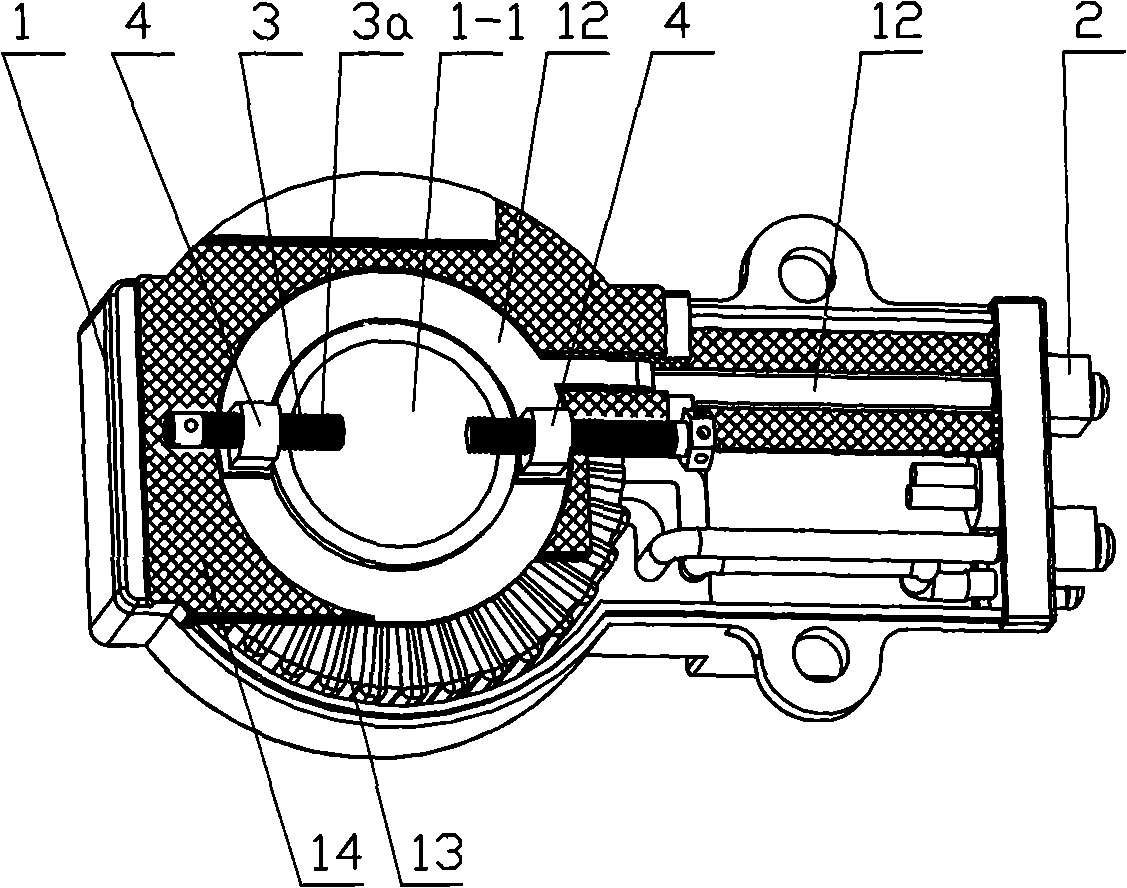

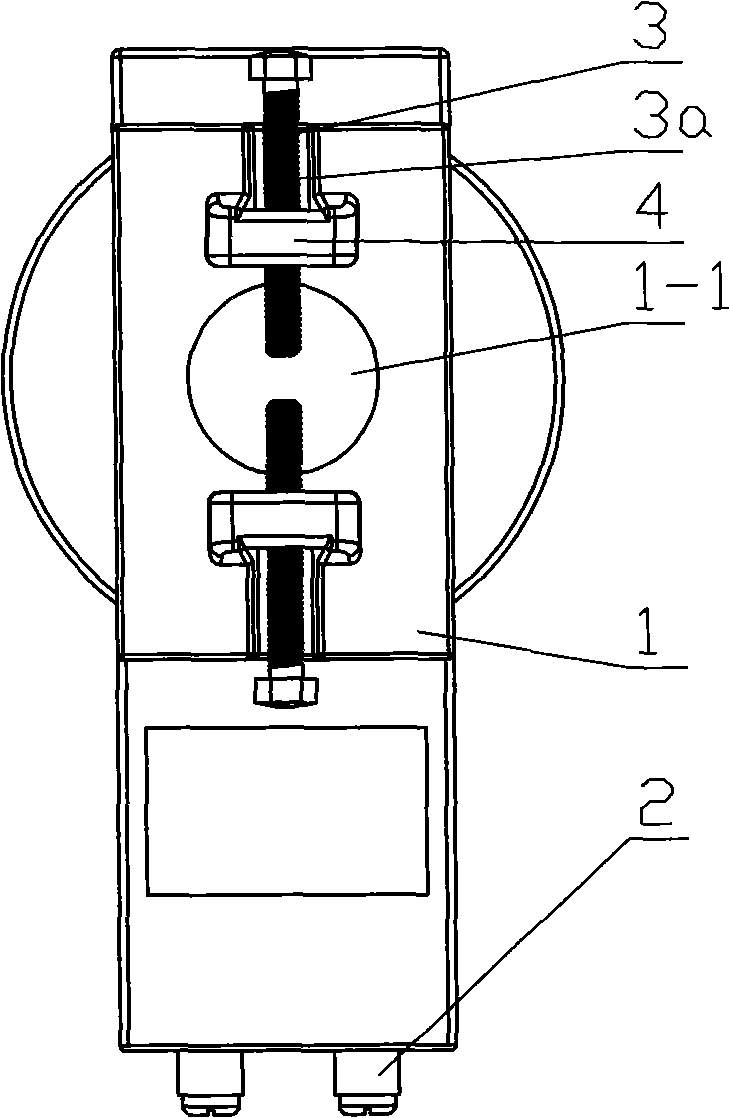

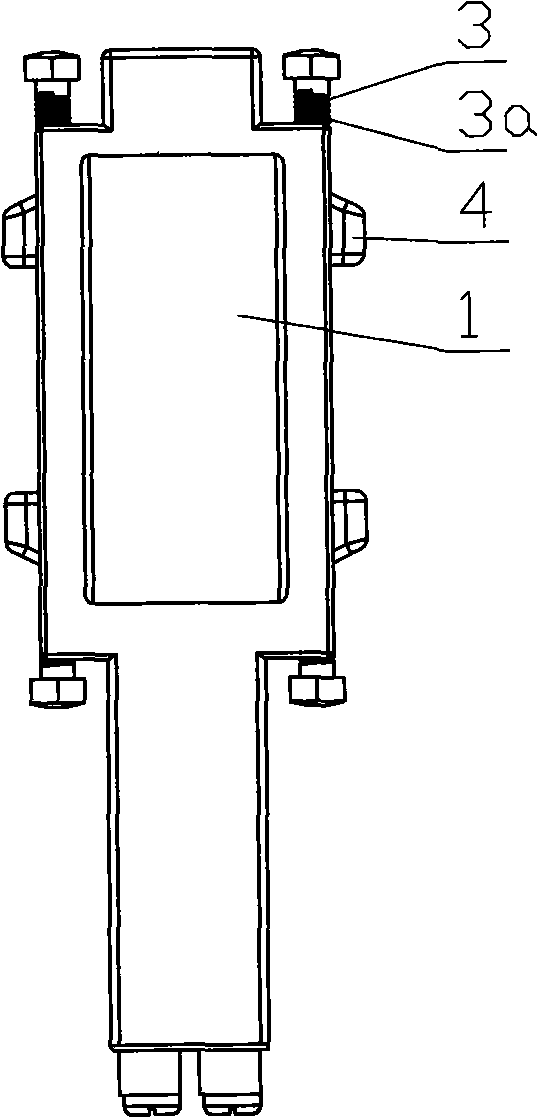

[0057] The current transformer described in this embodiment is mainly used in the case of taking voltage from a bare metal bar. It includes a transformer body 1 with a through hole 1-1. The transformer body 1 is provided with a voltage line terminal 2 and a voltage-taking component 3 that are electrically connected to each other. The voltage-taking component 3 is arranged on the through-center One side of the hole 1-1, and the voltage-taking part 3 can move along the through-hole 1-1, preferably this movement is radial movement, the moved voltage-taking part 3 and the conductor passing through the through-hole Direct contact to obtain the voltage signal.

[0058] Setting the voltage-taking part 3 on one side of the through-hole can prevent the voltage-taking part from occupying the position of the through-hole and affecting the use of the transformer. At the same time, the radial movement of the voltage-taking part along the through-hole can make the mutual inductance of this ...

Embodiment 2

[0066] The current transformer described in this embodiment is mainly used in the case of taking voltage from a bare transformer guide rod. Unless otherwise specified, the structure described in this embodiment is the same as that in Embodiment 1.

[0067] The difference in structure between the current transformer described in this embodiment and the transformer described in Embodiment 1 is that, refer to Figure 6A , Figure 6B , Fig. 7, Fig. 8, it also comprises nut 5, and described nut 5 is connected on the exposed cylindrical conductor 15 that passes through hole 1-1 by screw thread, and the side of described nut 5 is provided with hole 5-1, the hole is provided with an internal thread matched with the front end of the metal stud 3a.

[0068] When in use, first penetrate the central hole of the transformer into the guide rod 15 of the transformer, then screw the nut 5 on the guide rod 15 of the transformer, and then screw the front end of the metal stud 3a threaded with...

Embodiment 3

[0072] The current transformer described in this embodiment is mainly used in the case of taking voltage from a conductor wrapped with an insulating skin. Unless otherwise specified, the structure described in this embodiment is the same as that in Embodiment 1.

[0073] The difference from Embodiment 1 is that the metal stud 3a has a sharp front end, or a sharp conductor 3a-1 is fixedly arranged on the front end of the metal stud 3a to penetrate the insulation of the conductor Instead, it is in direct contact with the inner conductive core. The front end of the metal stud 3a can be used to fix the spiked conductor by any connection method such as welding, rivet connection, etc., as long as the conduction between the metal stud and the spiked conductor can be ensured. The sharp front end of the voltage-taking component is a group of front ends with needle-like or saw-tooth structures. It can be understood that the shape of the front ends with needle-like or saw-tooth structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com