Sliding type bumper and lifting arm, buffering device and SRS sensing facilities

A buffer device and bumper technology, which is applied to bumpers, transportation and packaging, pedestrian/passenger safety layout, etc., can solve the problems of poor vehicle protection performance, bumper height misalignment, and high price of SRS system, so as to achieve less failure, better structure Simple, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

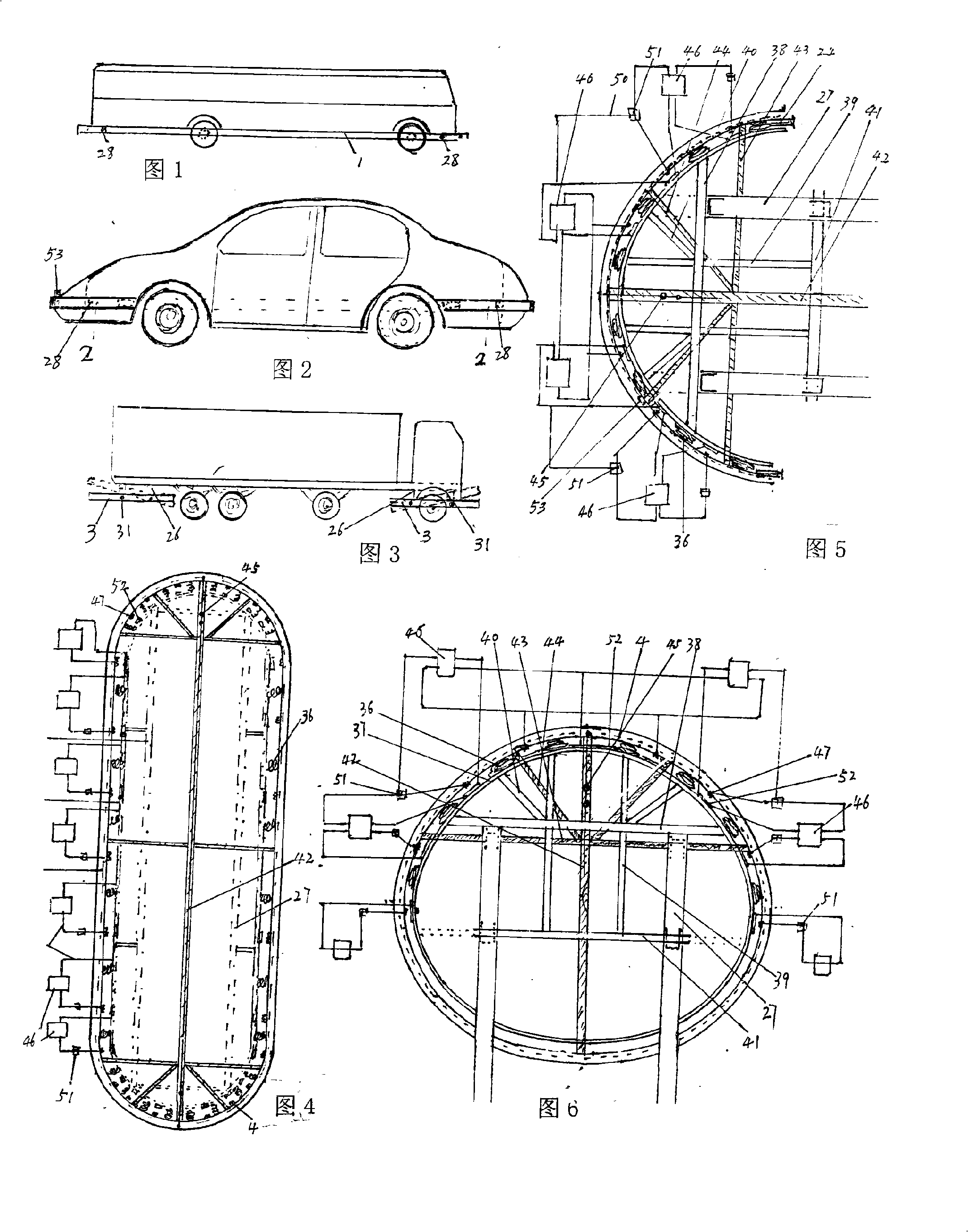

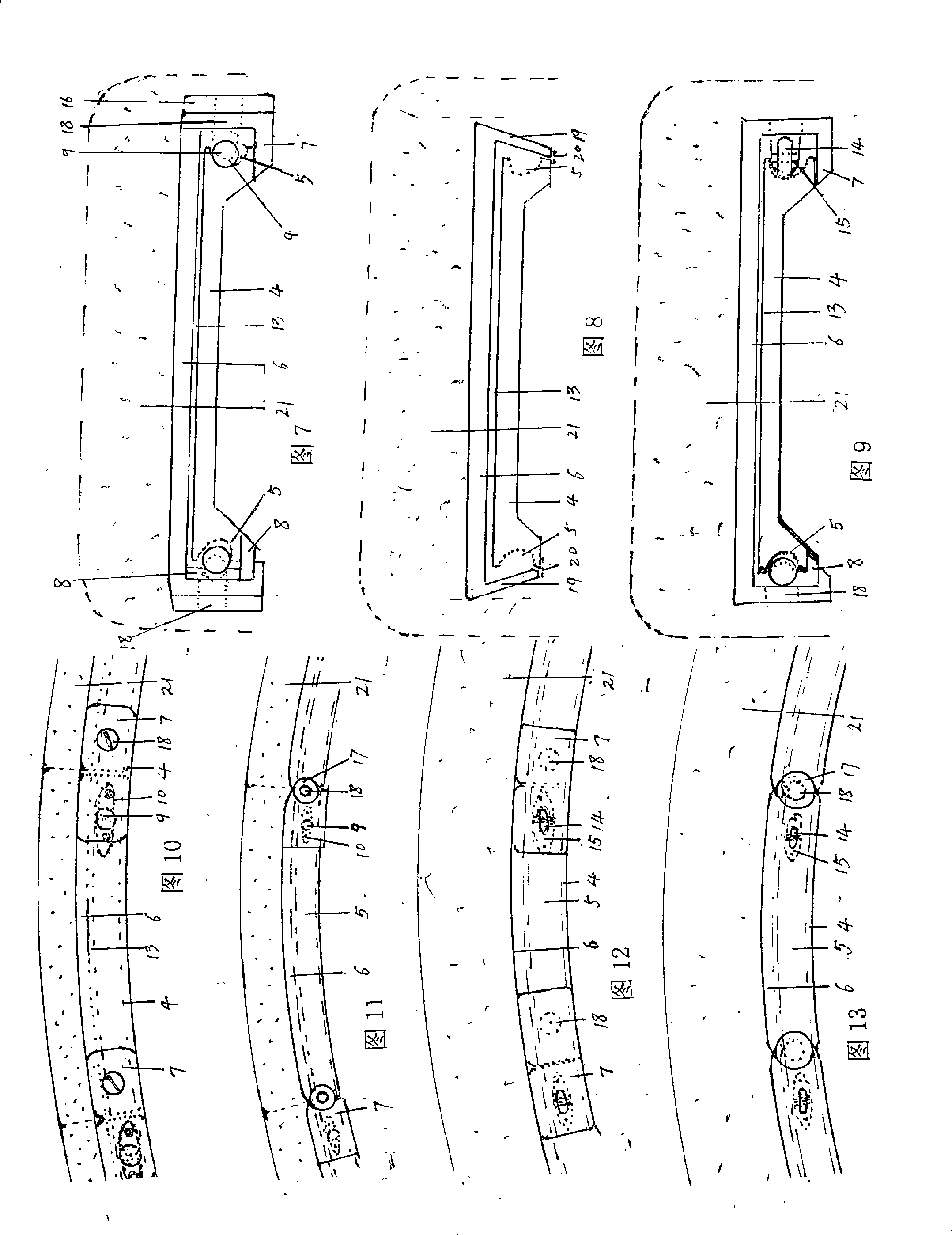

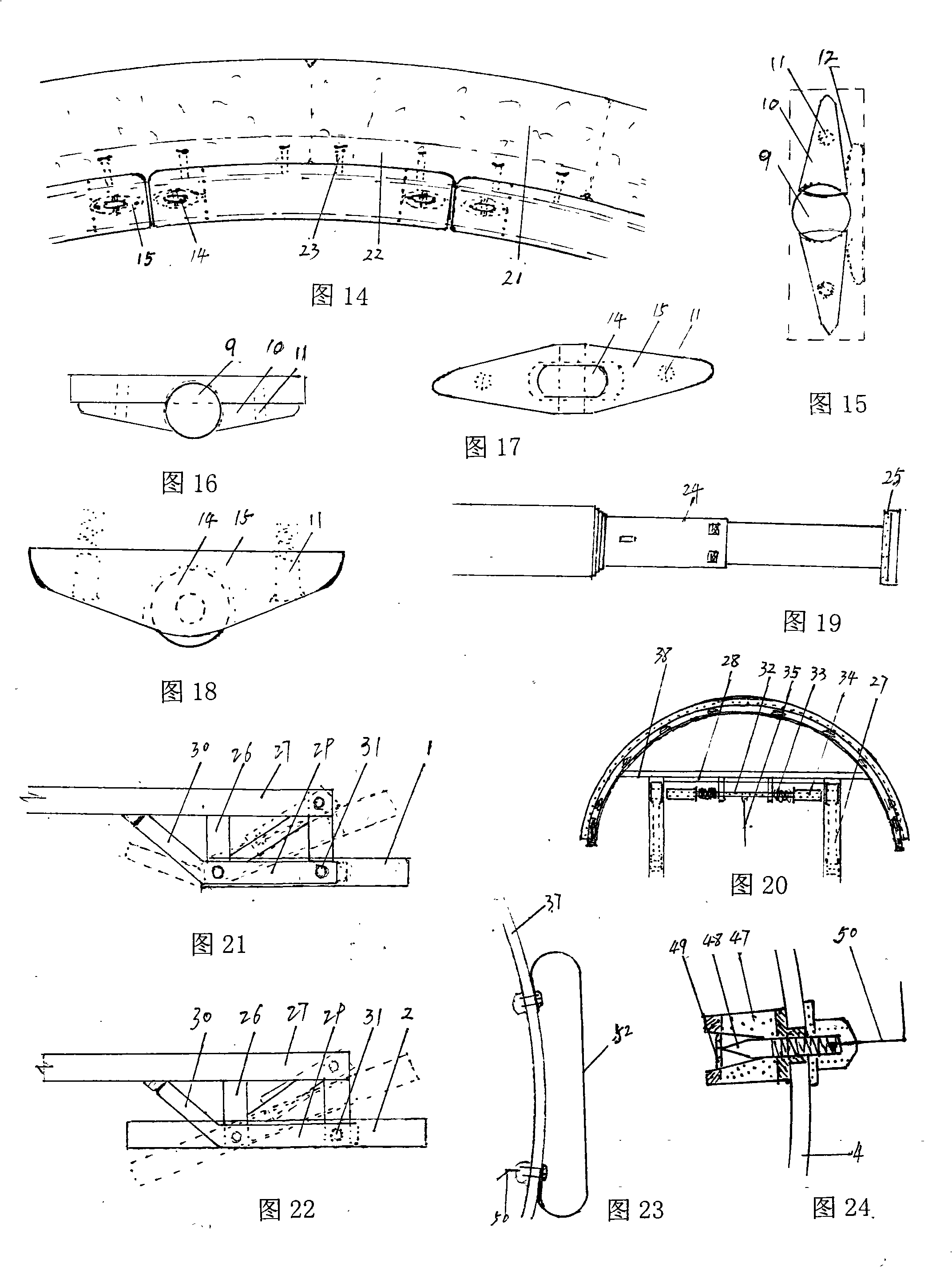

[0047] The full-circle (1), arc (2), circular (3) bumper inner layer (4) made of steel whose strength is compatible with the vehicle type, the front and rear sections are arc-shaped, and the two sides of the car body In a kissing position, the outer surface of the inner layer (4) is smooth and coated with lubricant, and the upper and lower sides of the inner layer are provided with ball slideway grooves (5). The groove is slightly deeper on the inside. The outer layer of the bumper is composed of dozens of "movable frames" (6) that fill the inner layer. The two ends or one end of the movable frame are provided with upper and lower card edges, and balls (9) or rollers are arranged in the upper card edge (7). (14), the lower card edge (8) is loosely fixed in the lower shell card of the movable frame, balls are arranged in the card edge, the balls in the upper card edge are positioned with the front and rear bead guards (10), and the upper roller is positioned with the axle frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com