Rotor engine

A rotary engine and engine technology, applied to engine components, combustion engines, machines/engines, etc., can solve the problems of insufficient low-speed torque and high fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

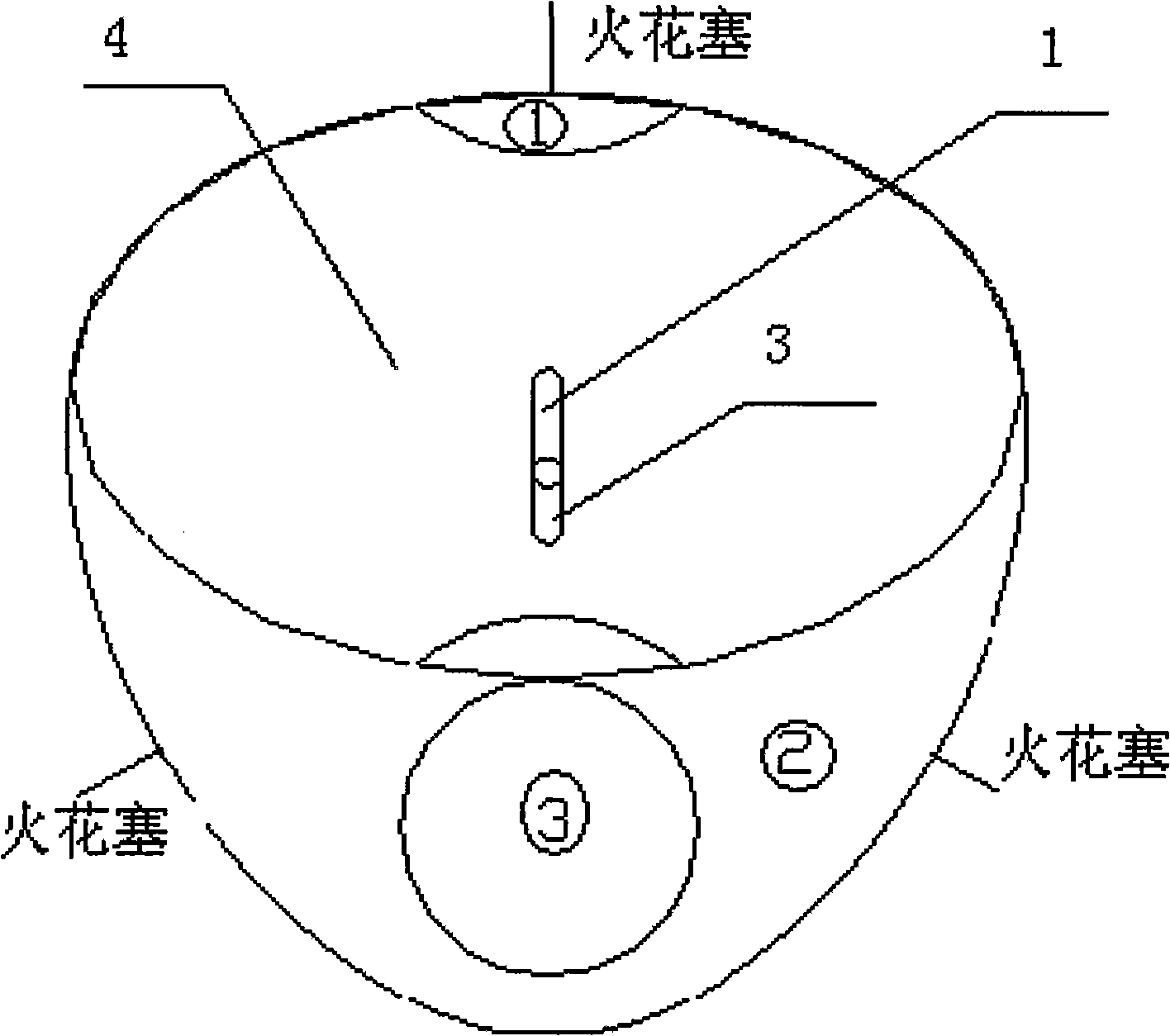

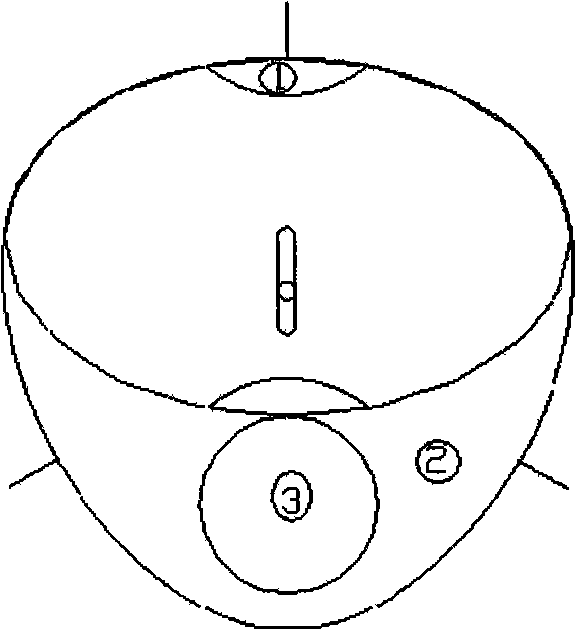

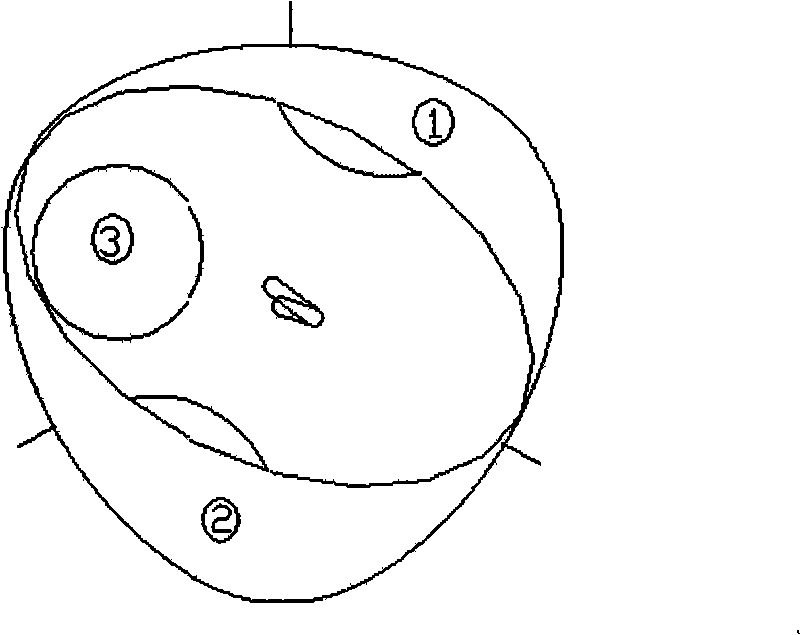

[0020] As shown in Figure 1, the elliptical rotor 4 divides the three-arc cylinder space into two working chambers, and each working chamber alternately completes the working cycle of the two-stroke engine. ③Represents the ventilation channel of the engine, which is composed of intake ventilation holes and exhaust ventilation holes. From Figure 1B → Fig. 1K, ① chamber is in: reaching the maximum gas compression state → the combustion gas expands to do work → the combustion gas just completes the work → is exchanging air → just completes the air exchange, and the gas begins to enter the compressed state → the gas continues to be compressed → the gas reaches the maximum compression state and start to ignite → the gas expands to do work → the combustion gas just completes the work → is exchanging air, these several states, at the same time, the ② chamber is in: exchanging air → just completed the air exchange, the gas begins to enter the compressed state → the gas continues to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com