Opposed piston four-stroke engine based on air valve ventilation

A four-stroke engine and opposed piston technology, which is applied to engine components, engine lubrication, machine/engine, etc., can solve problems such as short ventilation time, large pollutant discharge, uncontrollable ventilation performance of two-stroke engines, etc. , to achieve the effect of increasing fuel air utilization rate, improving thermal efficiency, and improving air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and examples.

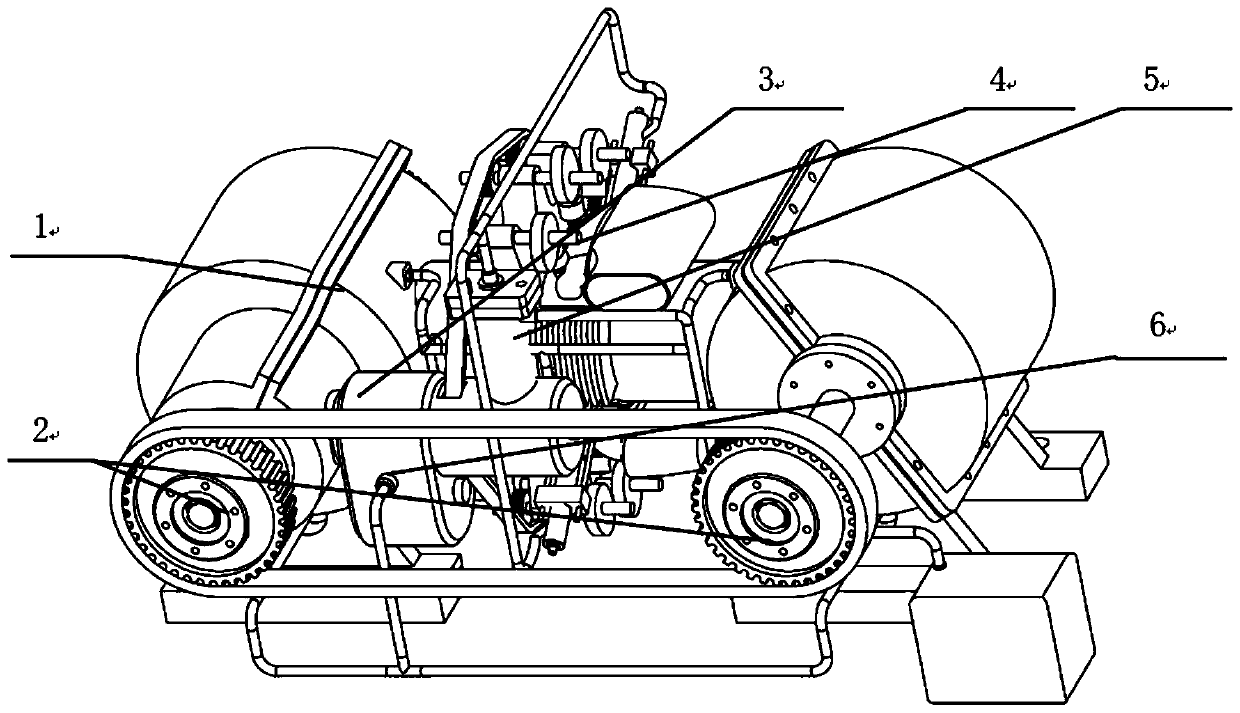

[0031] This embodiment provides a kind of opposed-piston four-stroke engine based on valve ventilation, such as figure 1 As shown, it includes a body 1 , a crank linkage mechanism 2 , an accessory driving device 3 , a gas distribution mechanism 4 , a fuel supply system 5 and a lubrication system 6 .

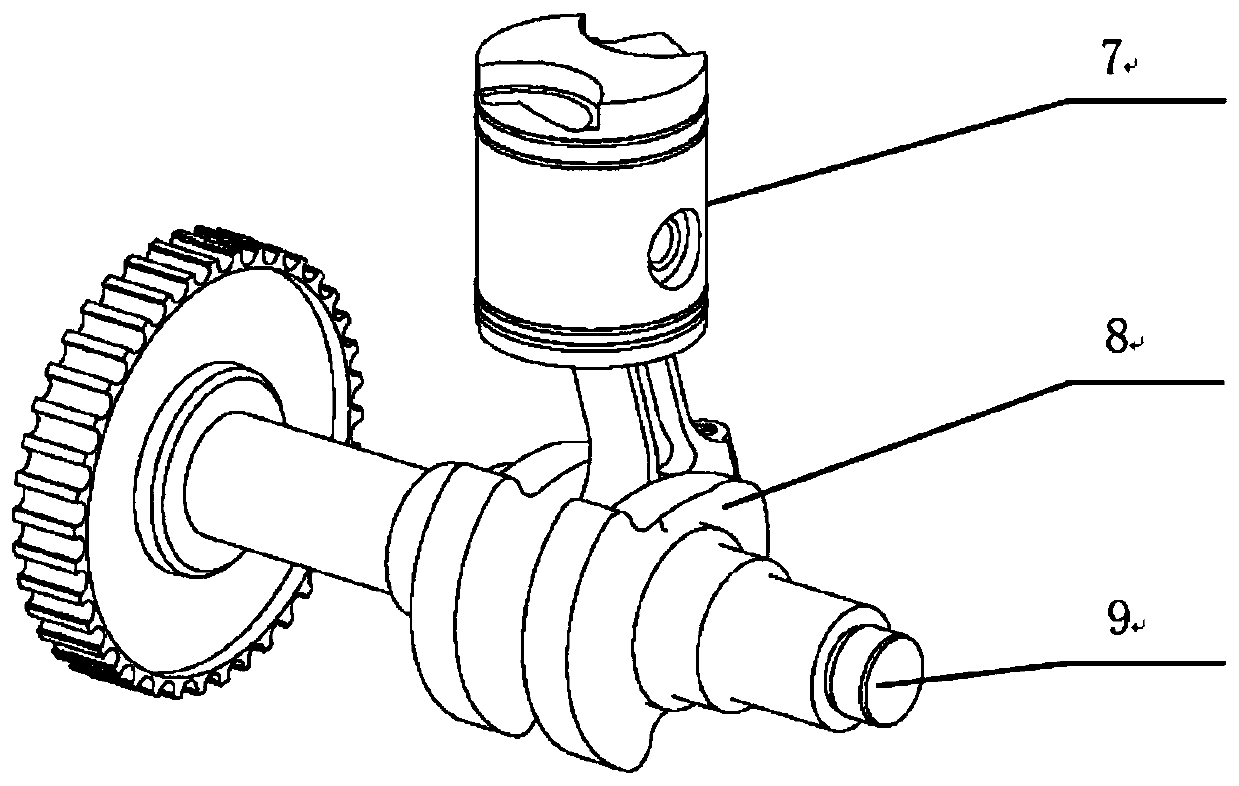

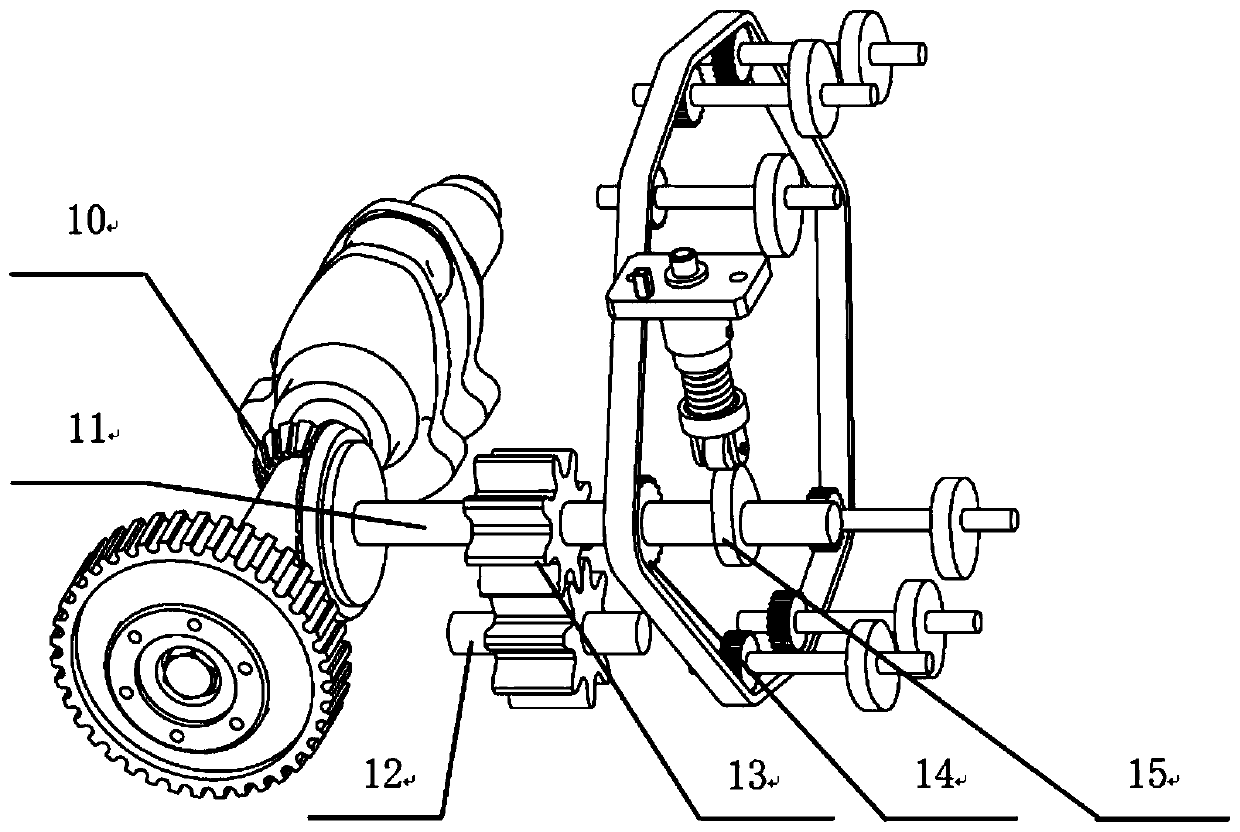

[0032] The main body of the body 1 is a cylindrical structure with openings at both ends, and the internal cavity is used as a cylinder. Valve mounting holes distributed along its circumference are processed, and camshaft mounting brackets are provided on both sides of the valve 19 mounting position, and the middle part of the main body of the body 1 is processed into a cylinder liner that guides the movement of the piston. The engine is air-cooled, and the middle part of the body 1 is provided with multiple rows of cooling fins. An electrically driven or me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com