Cylinder and piston co-rotating type engine

An engine and co-rotation technology, which is applied in variable displacement engines, internal combustion piston engines, reciprocating piston engines, etc., can solve the problems of high processing cost, insufficient fuel combustion, long and narrow, etc., and achieve high energy conversion efficiency and fuel combustion The effect of fully reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

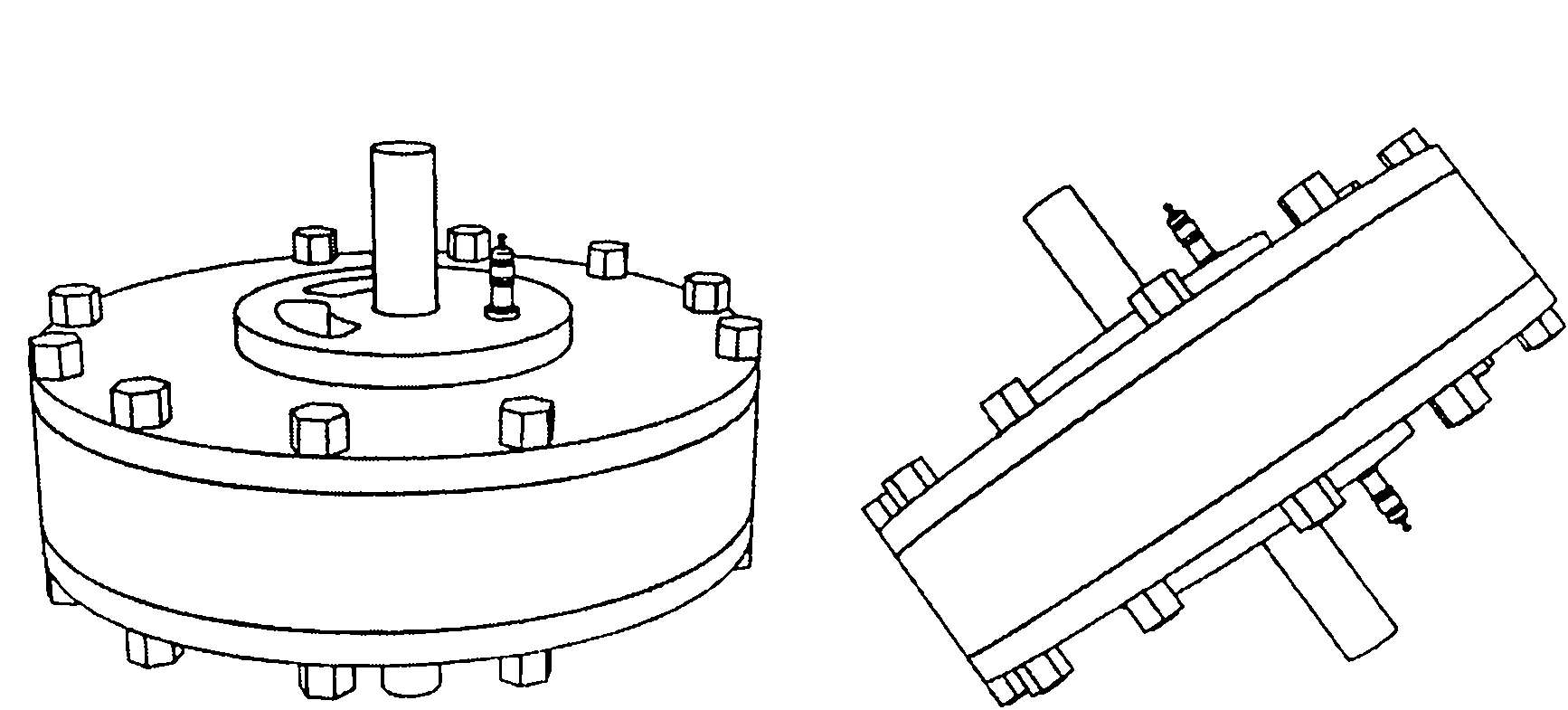

[0027] Such as figure 1 Shown is the schematic diagram of the appearance of the engine. From the figure, it can be understood that the shape of the engine of the present invention is a disk, and the output shaft (1) protrudes from the center point position of the upper and lower end faces of the disk, and is used to connect the load equipment. The stator of the engine is composed of upper, middle and lower shell components, and is fixed by a circle of multiple shell bolts. At the positions where the upper and lower ends of the disc are adjacent to the output shaft, two upper and lower spark plugs (4) are installed on one side of the output shaft, and two pairs of upper and lower arc-shaped air inlets and exhaust ports are arranged on the other side.

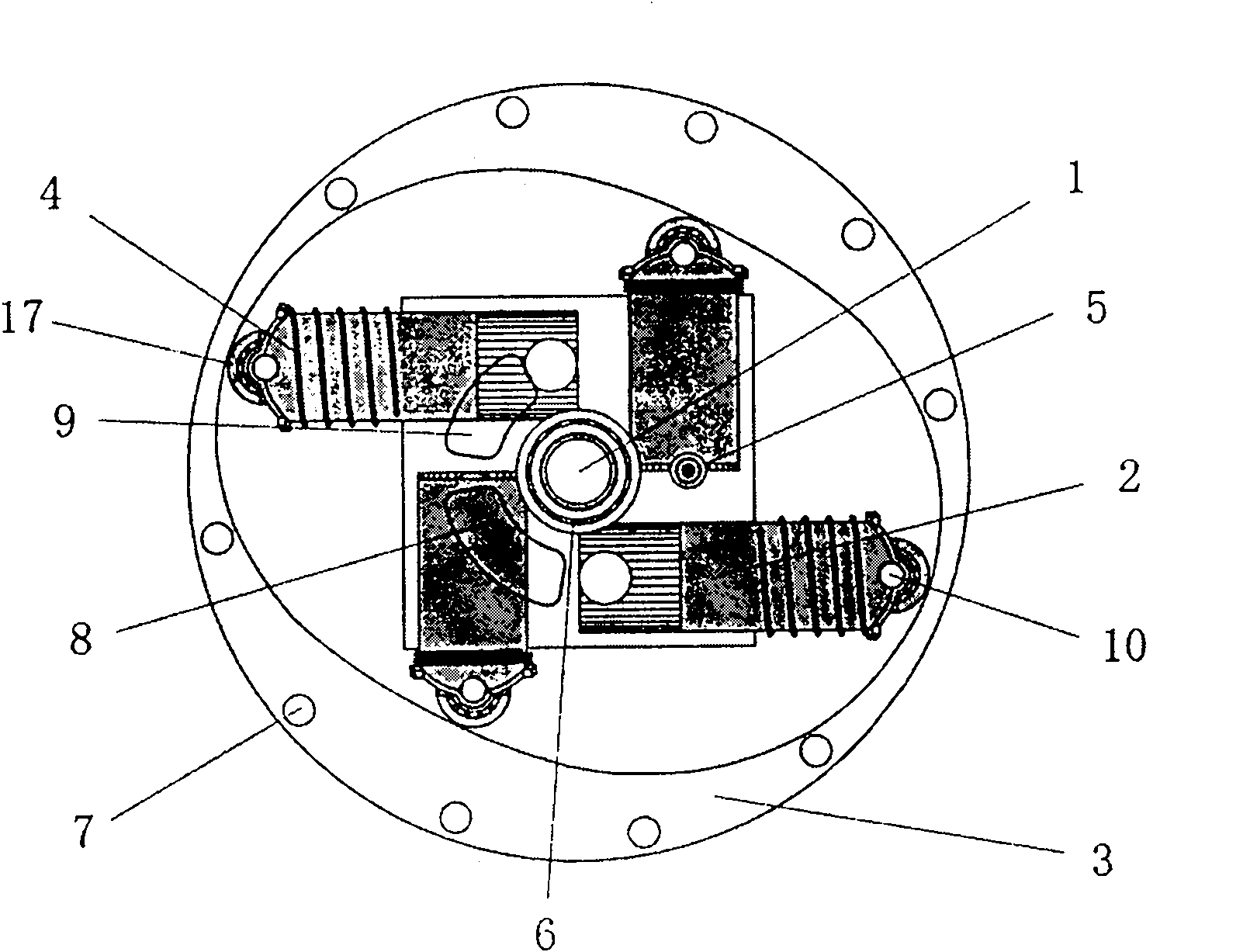

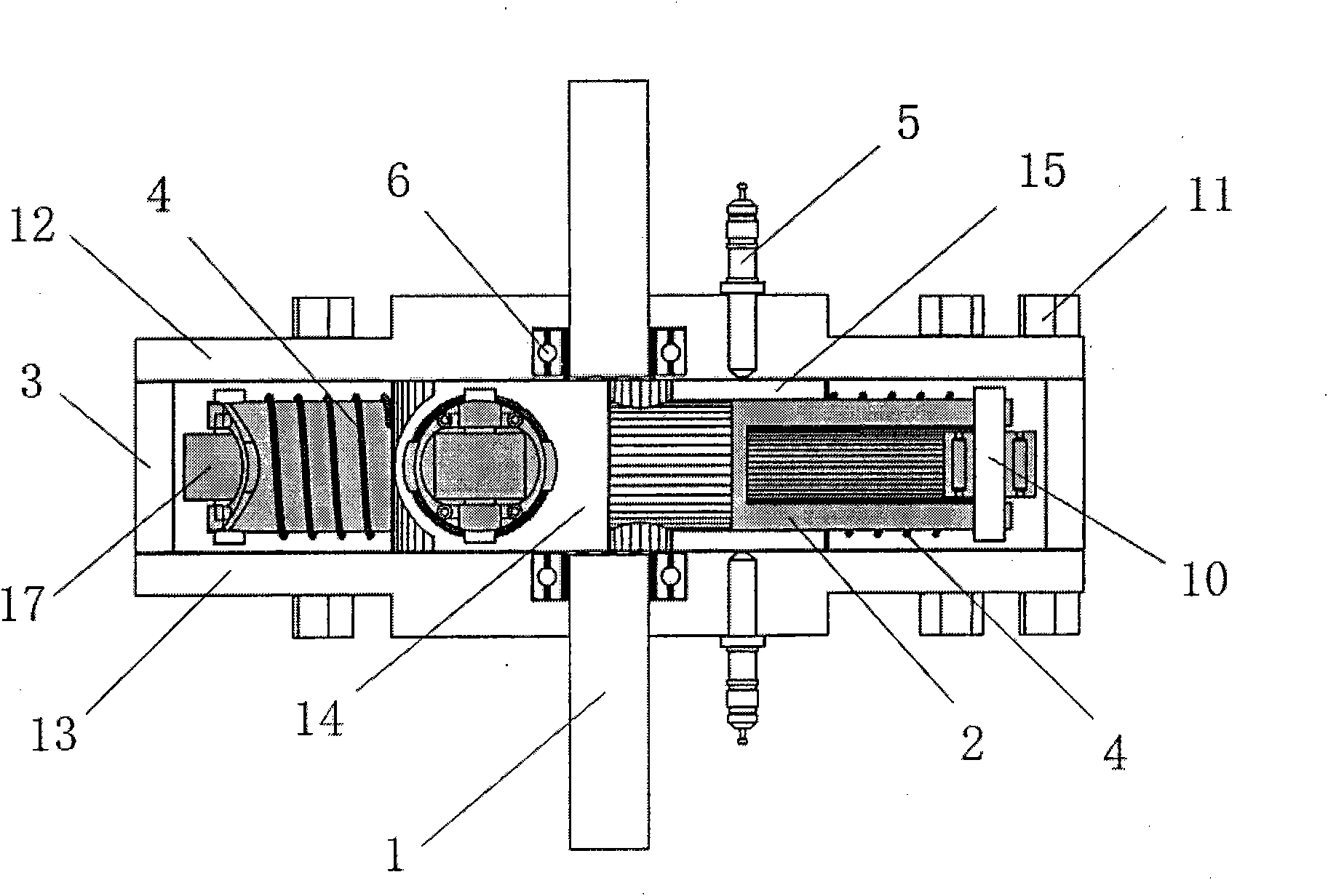

[0028] Such as figure 2 Shown is the cross-sectional schematic diagram of the present invention, has marked several important members of the present invention among the figure, observes schematic diagram and can understand, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com