Electromagnetic valve

A technology for solenoid valves and valve bodies, applied in valve details, valve devices, valve housing structures, etc., can solve problems such as shortening the service life of solenoid valves, stagnation of funds for manufacturers, and short circuits between coils and diodes, so as to improve quality stability and durability, reduce quality failures, and improve heat dissipation

Inactive Publication Date: 2008-10-22

ZHEJIANG FAS AUTOMOBILE PARTS

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

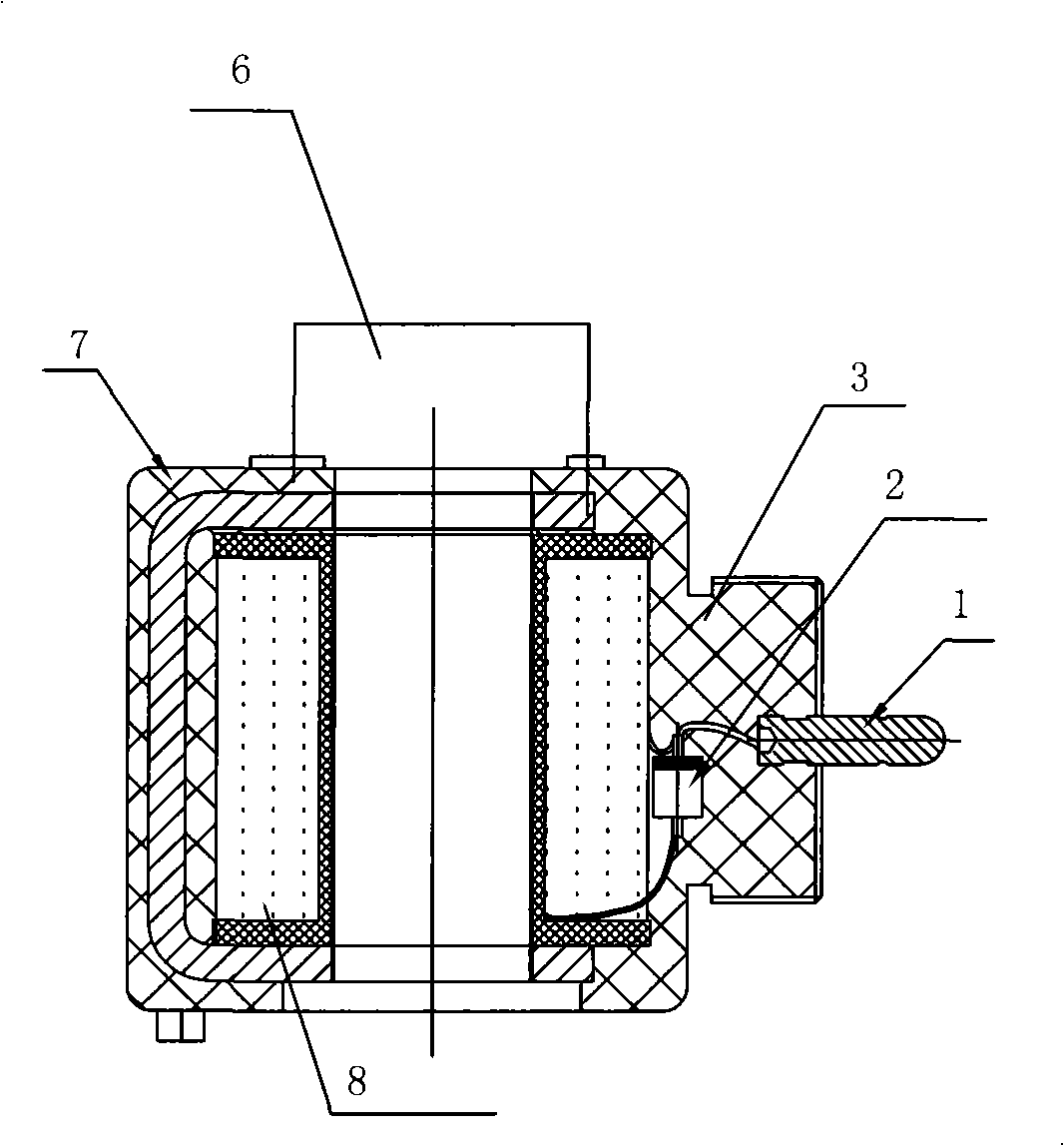

At present, solenoid valves are widely used in various production fields. The coil packages of existing solenoid valves are all made of plastic injection molding at one time (refer to Figure 1). Therefore, this kind of coil package is a non-detachable whole. Under the premise of the package, the parts in the coil package cannot be disassembled and taken out, so there is a problem that when a certain part in the solenoid valve coil package (such as electromagnetic coil, armature, plug, diode, etc.) is damaged, it cannot be aimed at. Instead of repairing or replacing damaged parts, the entire solenoid valve must be replaced, which causes waste and increases the economic burden on the user

And because the plug seat cannot be replaced, because some plugs on the plug seat are single-plug, two-plug, and three-plug, it is necessary to equip different types of coil packs. When the user needs a two-plug plug, it must be assembled and injected. The coil package for the plug, and the quantity must match the needs of the user, otherwise it will cause overstocking, and the shipment will not be delivered until the next time the user needs it, which will cause capital stagnation for the manufacturer, and due to the electromagnetic The coil package of the valve is one-time injection molding, so that the space between the diode and the coil is filled with plastic, which is affected by the heat dissipation performance of the plastic material, so the heat dissipation is extremely poor, and the coil and the diode are easily short-circuited, which also shortens the time for the user. The service life of the entire solenoid valve

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

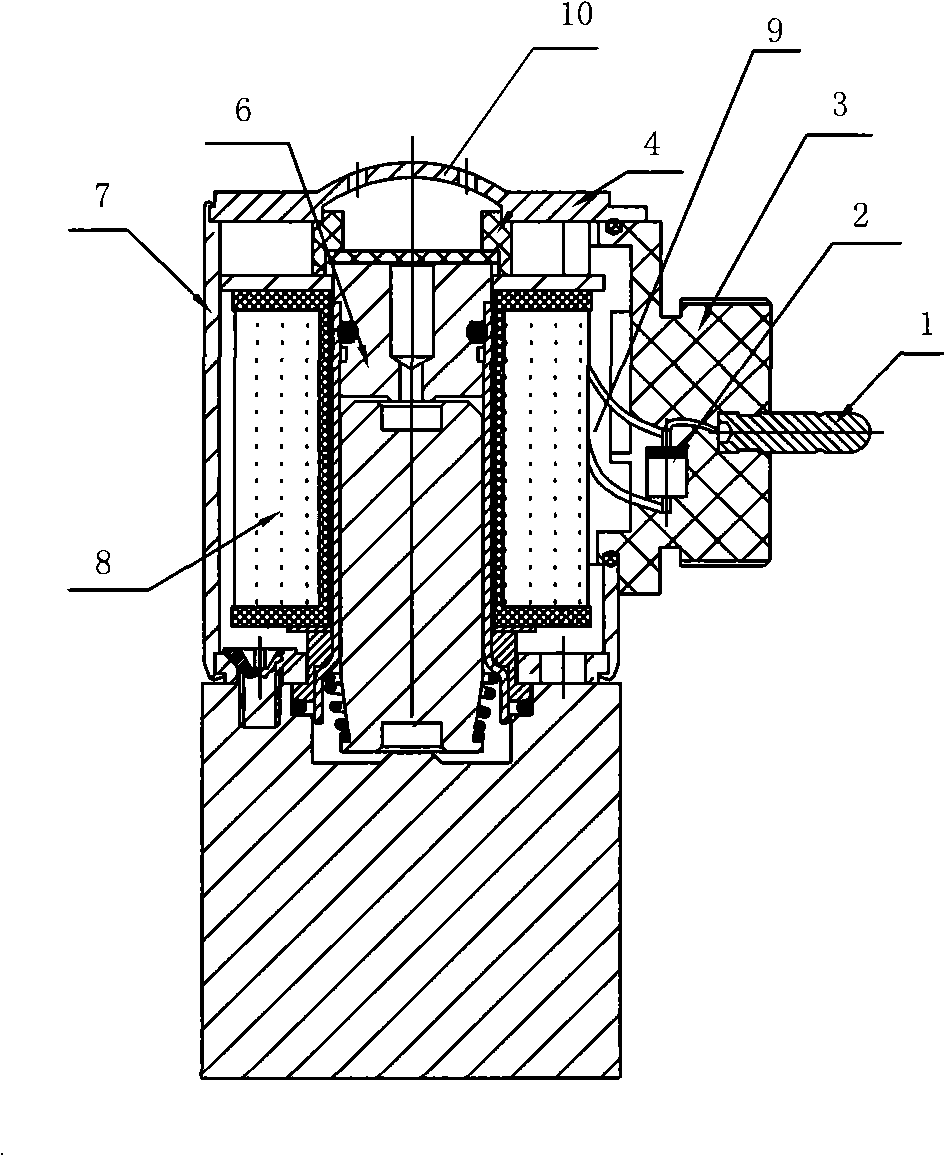

The invention discloses improvement and invention of an electromagnetic valve. The invention comprises a valve body and a coil package, wherein the coil package comprises a housing, an exhaust hood and a plurality of parts which are arranged in the housing to constitute the electromagnetic valve, such as a coil, a plug and a diode and so on, wherein the coil and the diode are arranged on a connector assembly which is characterized in that the connector assembly is embedded on housing wall and a heat dissipating chamber is arranged between the connector assembly and the coil. The coil of the invention does not need cast processing and a heat dissipating chamber is arranged between the connector assembly and the coil, thereby heat dissipation performance of the coil and the diode is effectively improved and the stability and durability of the quality of the products are improved.

Description

a solenoid valve technical field The present invention relates to an improved invention of a solenoid valve, in particular to an improved invention of a solenoid valve used in motor vehicles. Background technique At present, solenoid valves are widely used in various production fields. The coil packages of existing solenoid valves are all made of plastic injection molding at one time (refer to Figure 1). Therefore, this kind of coil package is a non-detachable whole. Under the premise of the package, the parts in the coil package cannot be disassembled and taken out, so there is a problem that when a certain part in the solenoid valve coil package (such as electromagnetic coil, armature, plug, diode, etc.) is damaged, it cannot be aimed at. Instead of repairing or replacing damaged parts, the entire solenoid valve must be replaced, which causes waste and increases the economic burden on the user. And because the plug seat cannot be replaced, because some plugs on the plug...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16K31/06F16K27/00

Inventor 林式楷

Owner ZHEJIANG FAS AUTOMOBILE PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com