Wig and method of producing the same

A manufacturing method and technology of wigs, applied in the direction of wigs, bald wigs, hair pieces, etc., can solve the problems of sticking position deviation, failure to stick smoothly, troubles, etc., and achieve the effect of preventing exposure

Inactive Publication Date: 2008-10-22

ADERANS CO LTD

View PDF5 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In Patent Document 3, even if it is intended to make a curved wig that covers the entire head with an extremely thin artificial skin, the extremely thin artificial skin is too soft to form a curved model of the head, so it cannot be made to match the wig wearer. Wigs that conform to the shape of the head

In the method described in Patent Document 3, in which an adhesive layer is provided on the entire back of the wig base and directly attached to the head, the position of the wig may be shifted or wrinkled, and sometimes it may not be pasted smoothly. Disadvantages of pasting

In addition, the adhesive layer of the wig base of Patent Document 3 includes: a first adhesive layer for fixing the base end of the hair implanted on the wig base; The second adhesive layer pasted on the head. At this time, the adhesive layer is composed of two layers, so it has the disadvantage of thickening the base of the wig

In the method of preventing hairline exposure in Patent Document 4, an extremely thin artificial skin is provided only on the hair part, and no measure is taken on the horizontal hairline of the forehead so that the difference between the head and the wig is not obvious

In the wig of Patent Document 5, when the contour line of the hairline protrudes greatly in a wavy shape and the angle of the tip portion is sharp, the height of the contour line rising from the head is higher than expected, and when hair is planted on the contour line , the hair is coiled and knotted with the outline, so the outline becomes more exposed, and the hairline of the wig may become unnatural

In addition, in order to prevent the exposure of the contour line, soft hair like baby hair must be planted, and the hair to be planted on the contour line must be prepared separately, so the preparation of the hair is time-consuming and troublesome.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

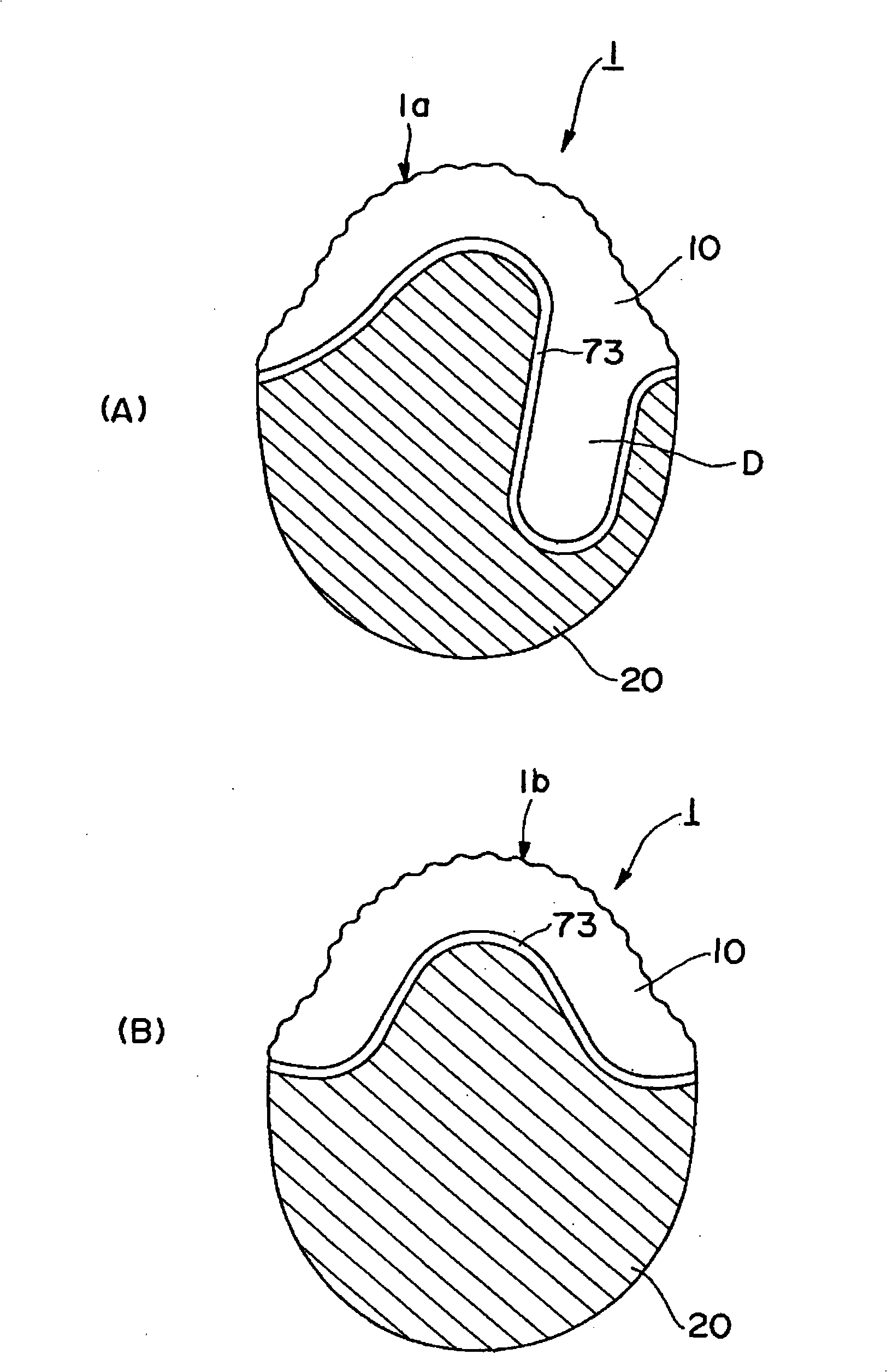

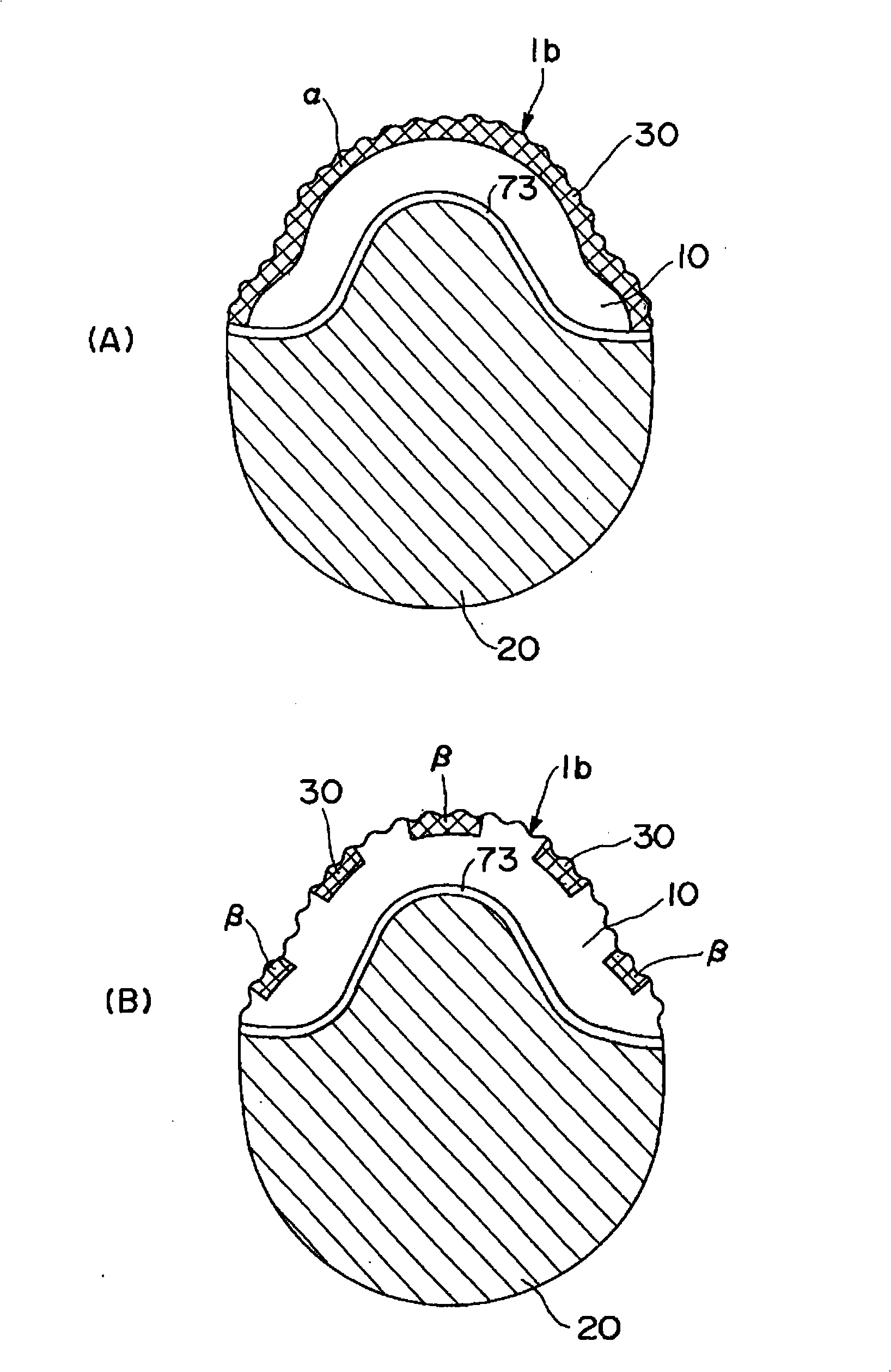

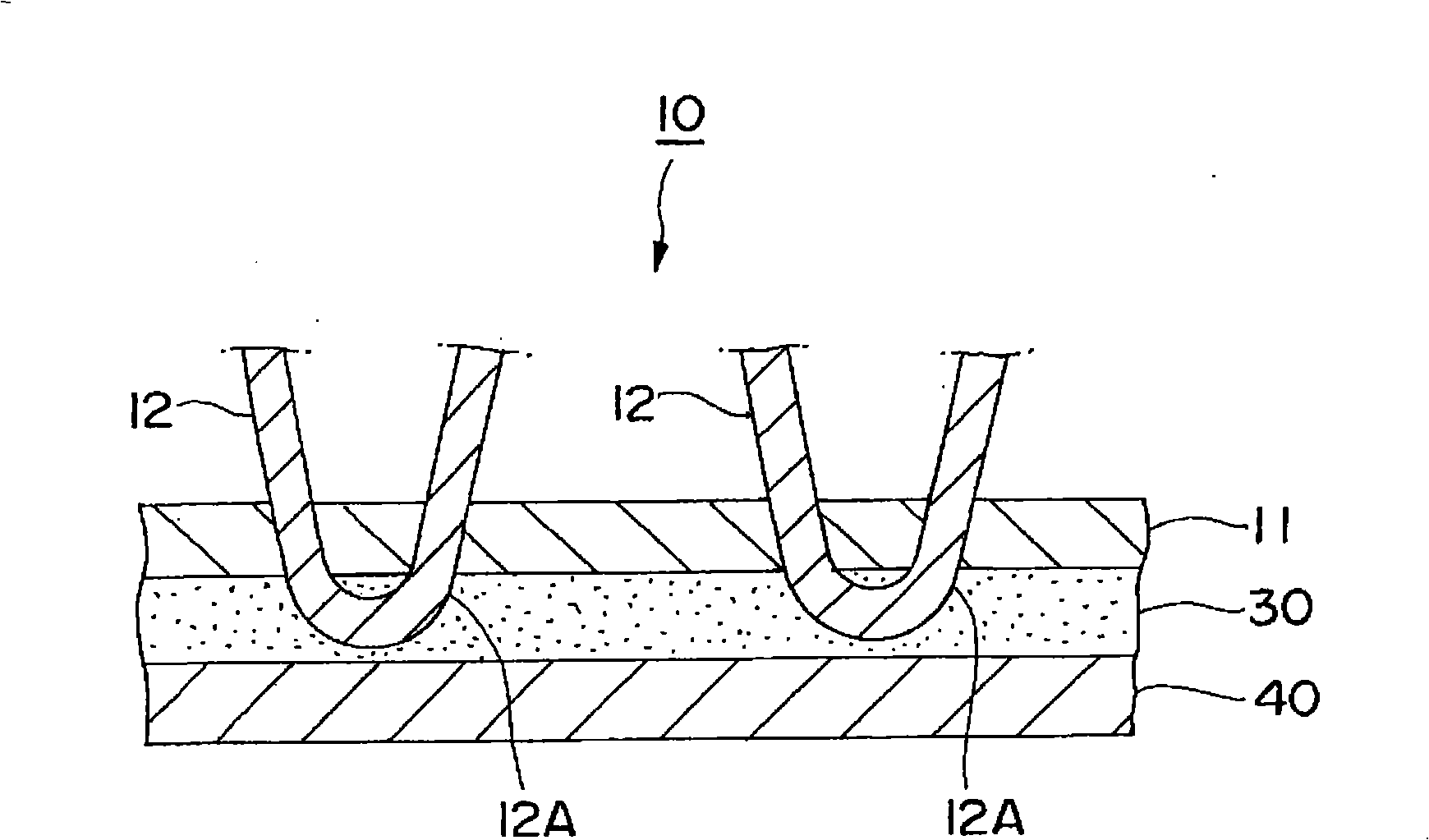

A wig (1) comprising of a wig base (1a, 1b) and hair (12) implanted in the wig base, wherein the wig base is composed of a front part, which is made of an artificial skin (10) and the front edge of which is to be located at the forehead of a wig wearer, and a rear part comprising a cap member which is connected to the front part and in a shape similar to the head shape of the wig wearer. The front part has an artificial skin material (11) and an adhesive layer (30) which has such pressure-sensitive adhesion functions as allowing the adhesion to the back face of the artificial skin material in a non-peelable manner so as to fix the wire roots of the hair and further allowing the repeated adhesion to the scalp in a peelable manner.

Description

Wig and its manufacturing method Technical field The present invention relates to a wig that covers at least a part of the head from the hairline of the head to the back of the head, and a method of manufacturing the wig, in particular to the camouflage of the front edge of the wig corresponding to the forehead hairline of the wearer Wig with improved effect and its manufacturing method. Background technique Conventionally, wigs worn when the hair on the head becomes thinner include artificial skin made of synthetic resin, a wig base composed of a mesh-like mesh, or a wig base composed of a combination of artificial skin and mesh. The wig base is shaped to follow the shape of the wig's head as much as possible, and is made by planting human hair or artificial hair. However, as we all know, hair loss generally occurs through the retreat of the forehead hairline. Therefore, when wearing a wig, the front edge of the wig must be worn exactly at the position corresponding to the use...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A41G3/00

CPCA41G3/00A41G3/0041A41G3/0075A41G5/00

Inventor 佐藤贵丸山慎一近藤康弘小川良枝须贝宽子

Owner ADERANS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com