Preparation method of carbonized flame-retardant double-sided invisible camouflage fabric

A double-sided, fabric technology, applied to building components, textiles and papermaking, etc., can solve the problems of single-sided stealth that cannot adapt to changing environments, restricts field applications, and lacks protective performance, so as to improve camouflage capabilities and increase applicability range, the effect of enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The invention discloses a method for preparing a carbonized flame-retardant double-sided stealth camouflage fabric, which comprises the following steps:

[0039] (1): The high-strength low-shrinkage polyester fabric is refined and coated with polyurethane on both sides, and dried at 150°C-180°C for 1-3min to obtain a high-temperature resistant base fabric;

[0040] (2): Coating the two sides of the high-temperature-resistant base cloth with a flame-retardant heat-insulating material to obtain a high-temperature-resistant flame-retardant cloth; the specific steps are:

[0041] a. The following components in parts by weight: 10-30 parts of expanded graphite, 10-30 parts of phosphorus nitrogen flame retardant, 5-15 parts of airgel, 40-60 parts of polyurethane, 10-20 parts of adhesive and 0.05-2 parts of nano-zirconium, mixed and stirred for 15-30 minutes to obtain a flame-retardant and heat-insulating material;

[0042] b. Coating the flame-retardant and heat-insulating m...

Embodiment 2

[0062] The invention discloses a method for preparing a carbonized flame-retardant double-sided stealth camouflage fabric, which comprises the following steps:

[0063] (1) High-strength and low-shrinkage polyester fabric is refined and coated with polyurethane on both sides, and dried at 150°C-180°C for 1-3min to obtain a high-temperature resistant base fabric;

[0064] (2): The double-sided coating of the high-temperature-resistant base cloth with flame-retardant and heat-insulating material to obtain a high-temperature-resistant flame-retardant cloth, the specific steps are:

[0065] a. The following components in parts by weight: 10-30 parts of expanded graphite, 10-30 parts of phosphorus nitrogen flame retardant, 5-15 parts of airgel, 40-60 parts of polyurethane, 10-20 parts of adhesive and 0.05-2 parts of nano-zirconium, mixed and stirred for 15-30 minutes to obtain a flame-retardant and heat-insulating material;

[0066] b. Coat both sides of the high-temperature-resis...

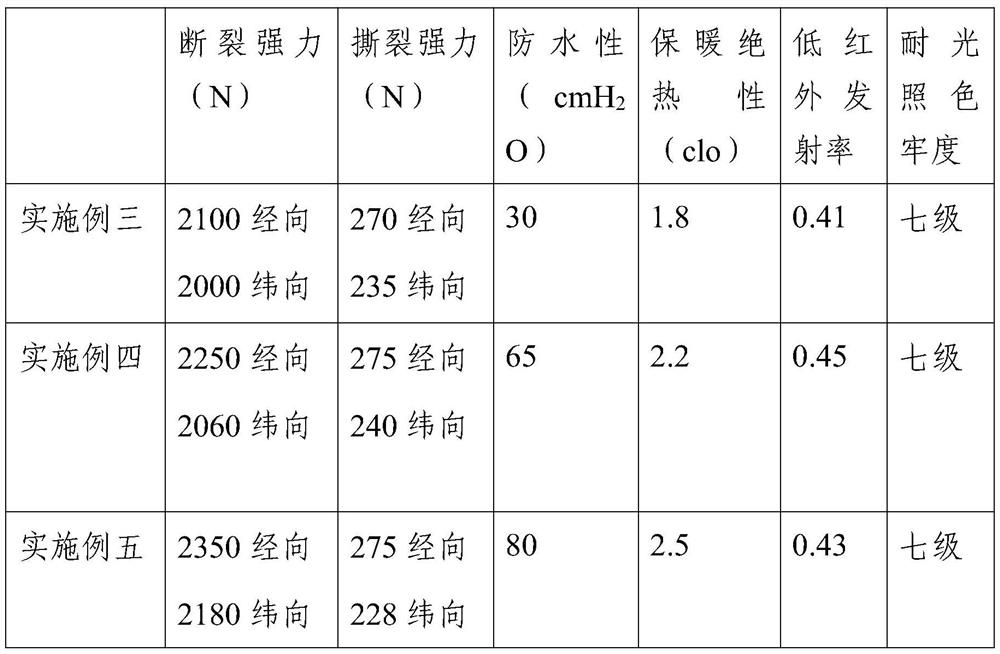

Embodiment 3

[0076] The invention discloses a method for preparing a carbonized flame-retardant double-sided stealth camouflage fabric, which comprises the following steps:

[0077] (1) High-strength and low-shrinkage polyester fabric is refined and coated with polyurethane on both sides, and dried at 165°C for 2 minutes to obtain a high-temperature resistant base fabric;

[0078] (2): The double-sided coating of the high-temperature-resistant base cloth with flame-retardant and heat-insulating material to obtain a high-temperature-resistant flame-retardant cloth, the specific steps are:

[0079] a. The following components in parts by weight: 20 parts of expanded graphite, 20 parts of phosphorus nitrogen flame retardant, 10 parts of airgel, 50 parts of polyurethane, 15 parts of adhesive and 1 part of nano-zirconium, mixed and stirred for 22.5 minutes , to obtain a flame-retardant heat-insulating material;

[0080] b. Coat both sides of the high-temperature-resistant base cloth with the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| 100% modulus | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Gain weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com