Robot for industry and collection processing device

An industrial robot and arm technology, applied in the directions of transportation and packaging, manipulators, manufacturing tools, etc., can solve the problems of shortening the handling time, complicated action mechanism, etc., and achieve the effect of shortening the handling time, improving the sealing performance, and shortening the cycle time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

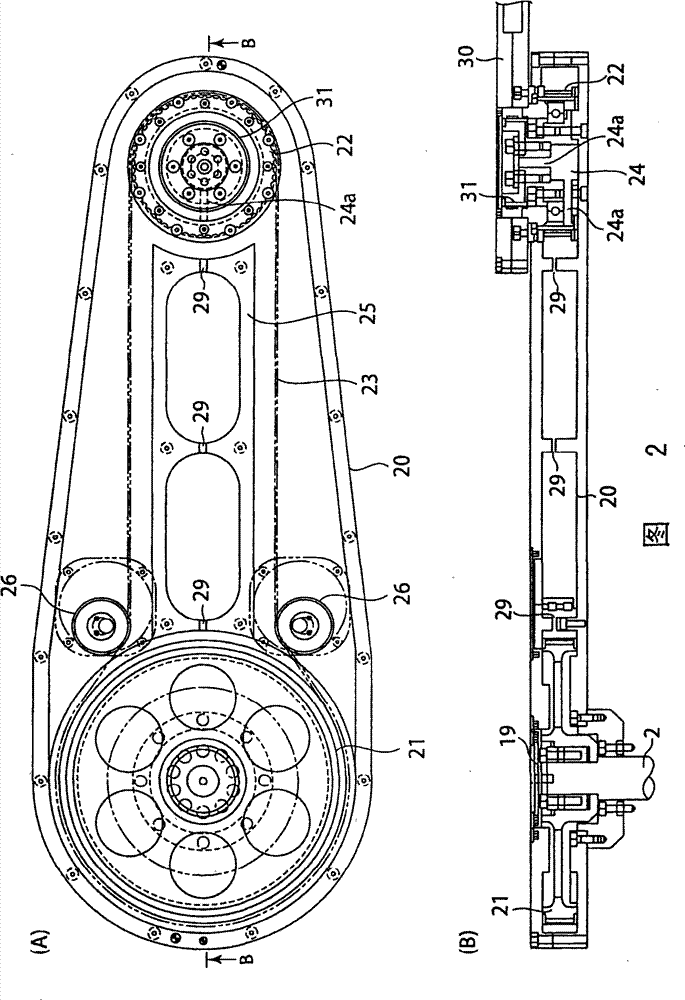

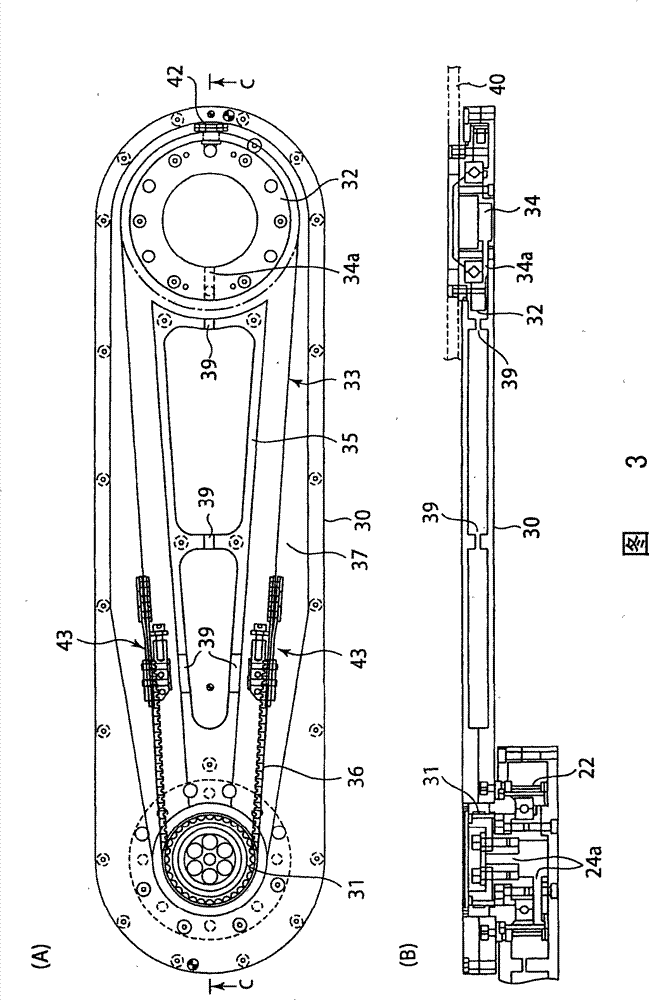

[0080] Hereinafter, best embodiments of the present invention will be described with reference to the drawings. The industrial robot and collective processing apparatus of the present invention are not limited to the following description and drawings insofar as they have their technical features.

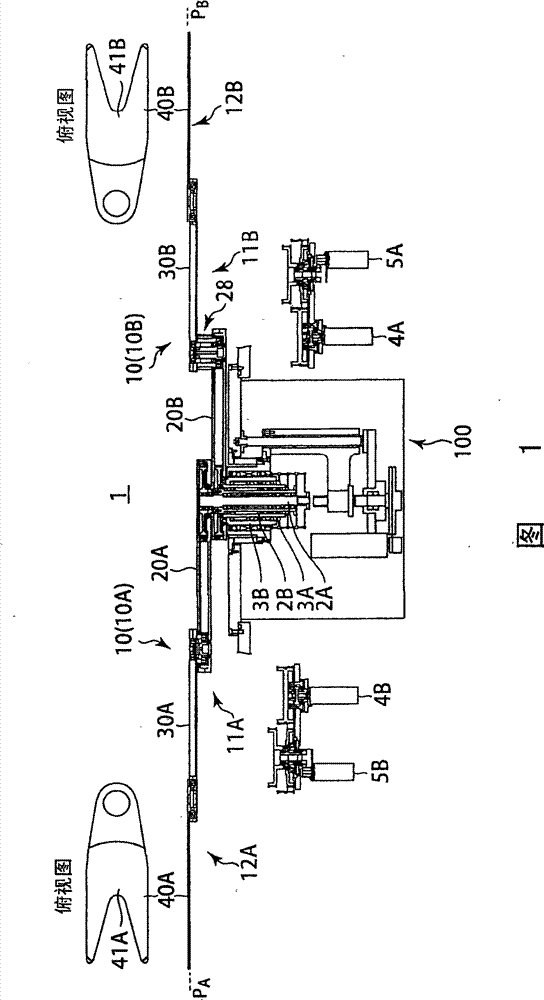

[0081] figure 1 It is a perspective front view showing an example of the industrial robot of the present invention. Such as figure 1 As shown, the industrial robot of the present invention (hereinafter referred to as "robot 1") is an industrial robot having two or more arms 10, and the arms 10 press the arm part 11 and the hand part 12 from the base part 100 side. connected in sequence, the hand 12 moves freely and flexibly while facing a predetermined direction.

[0082] figure 1 The robot 1 having two machine arms 10A, 10B is illustrated in FIG. 4B; arm rotation drive sources 5A, 5B for rotating the arms 10A, 10B around the arm rotation shafts 3A, 3B; connecting members f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com