Photovoltaic solar frame aluminium alloy section with overlength service-life, production method and structure thereof

A technology for photovoltaic solar energy and aluminum alloy profiles, which is applied in the field of preparation of photovoltaic solar energy frames and ultra-long-life photovoltaic solar energy frame aluminum alloy profiles, and can solve problems such as easy loosening, difficulty in ensuring the fitting gap of profiles, and damage to the end surface anti-corrosion surface treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The ultra-long-life photovoltaic solar frame aluminum alloy profile of the present invention, the raw material of the profile is mainly composed of the following alloy elements by weight percentage: Si 0.3-0.5%, Mg 0.6-1.1%, Cu 0.06-0.12%, Fe≤0.2 %, Ti≤0.1%, Mn≤0.1%, Zn≤0.1%, Cr≤0.1%, the balance is Al and unavoidable impurities, and Si:Mg=1:1.75-1:1.80. The preparation method is as follows: place the Al ingot in a smelting furnace for smelting. When the temperature of the Al liquid in the smelting furnace reaches 700°C to 760°C, first add Cu according to the above ratio, and then add Si and Mg in sequence, and smelt for 5.5-6 hours. Then it is cast into aluminum rods, extruded into aluminum alloy profiles, and finally surface treated to make photovoltaic solar frame aluminum composite profiles.

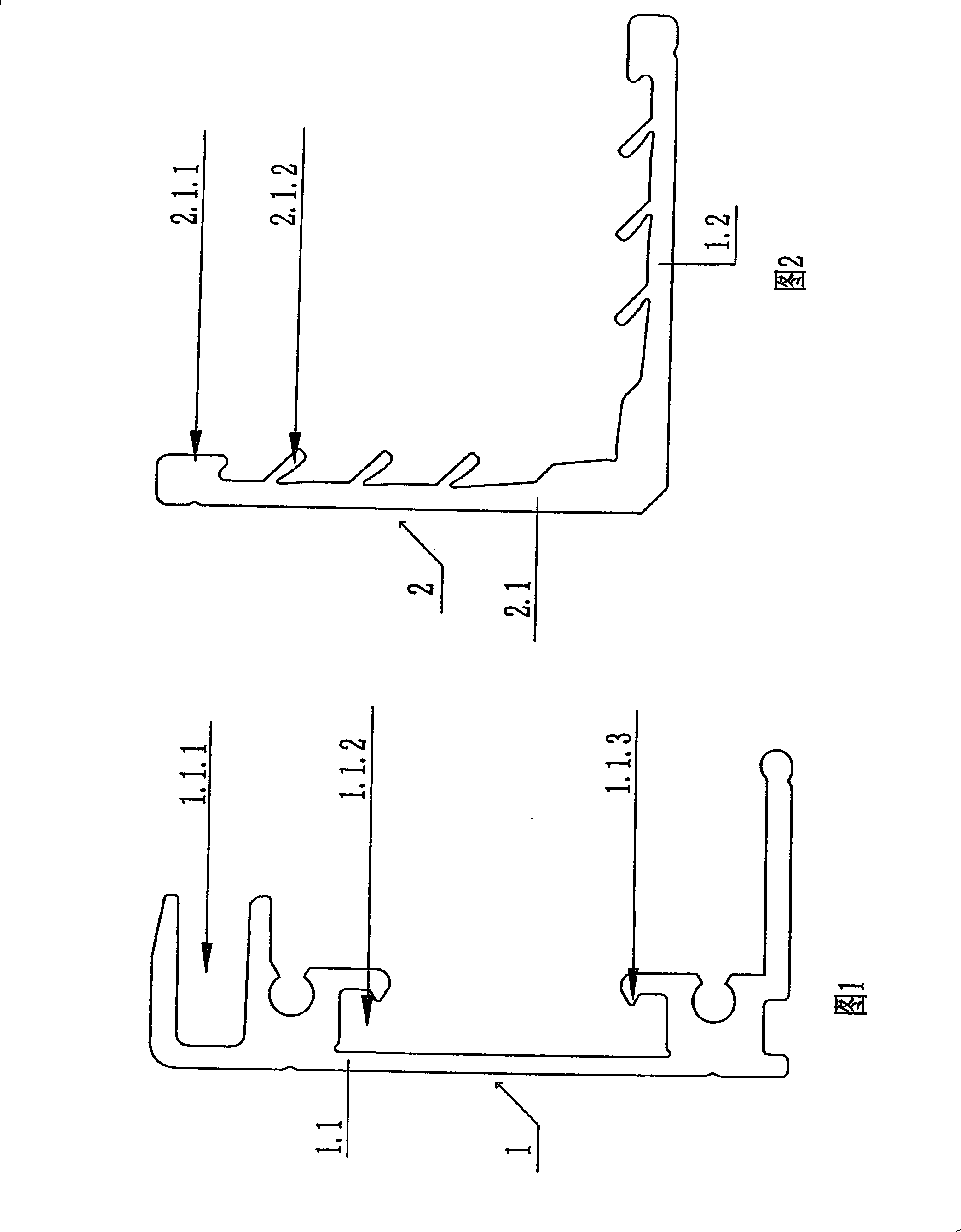

[0016] The ultra-long-life photovoltaic solar frame structure includes a profile 1 and a corner code 2, as shown in Figure 1. The profile 1 is similar to an "L"-shaped structure i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com